ASTM D6497-02(2010)

(Guide)Standard Guide for Mechanical Attachment of Geomembrane to Penetrations or Structures

Standard Guide for Mechanical Attachment of Geomembrane to Penetrations or Structures

SIGNIFICANCE AND USE

This guide attempts to detail specific areas of concern regarding the attachment of geomembranes to structures. Components of the geomembrane attachment are addressed as to the type and use of each component.

Although this guide does not address all aspects of geomembrane attachments, the user of this guide may note important objectives and design issues of each component of the geomembrane. All these objectives and design issues may or may not be required to obtain an appropriate geomembrane attachment. By describing these areas of concern, it is hoped that the user of this guide will be able to design geomembrane attachments, develop specifications or construct geomembrane attachments, or both, which fulfill the requirements of its design intent.

SCOPE

1.1 This guide covers procedures that can be employed to mechanically attach fabricated geomembranes to structures, pipes, etc.

1.2 This guide does not address all problems or situations a geomembrane installer or design engineer may face in the attachment of geomembranes to structures, pipes, etc. The sole purpose of this standard guide is to point out typical problems with geomembrane attachments and clearly state objectives of each component of the geomembrane attachment(s).

1.3 This guide has been generated for geomembrane application(s); however, a geomembrane installer or design engineer, or both, may find portions of this guide applicable to other geosynthetics.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6497 − 02(Reapproved 2010)

Standard Guide for

Mechanical Attachment of Geomembrane to Penetrations or

Structures

This standard is issued under the fixed designation D6497; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 banding strap, n—a flexible narrow strip of metal,

plastic or other material, which compresses the geomembrane

1.1 This guide covers procedures that can be employed to

around a penetration by acting as a clamp around the penetra-

mechanically attach fabricated geomembranes to structures,

tion.

pipes, etc.

3.1.2 batten, n—a rigid narrow strip of metal, wood, plastic

1.2 This guide does not address all problems or situations a

or other material which distributes the forces to compress the

geomembrane installer or design engineer may face in the

geomembrane against a penetration or structure.

attachment of geomembranes to structures, pipes, etc. The sole

purpose of this standard guide is to point out typical problems

3.1.3 boot, n—a factory or field fabricated geomembrane

with geomembrane attachments and clearly state objectives of

wrap used to seal around a pipe penetration prior to attachment

each component of the geomembrane attachment(s).

(see Fig. 1).

1.3 This guide has been generated for geomembrane appli-

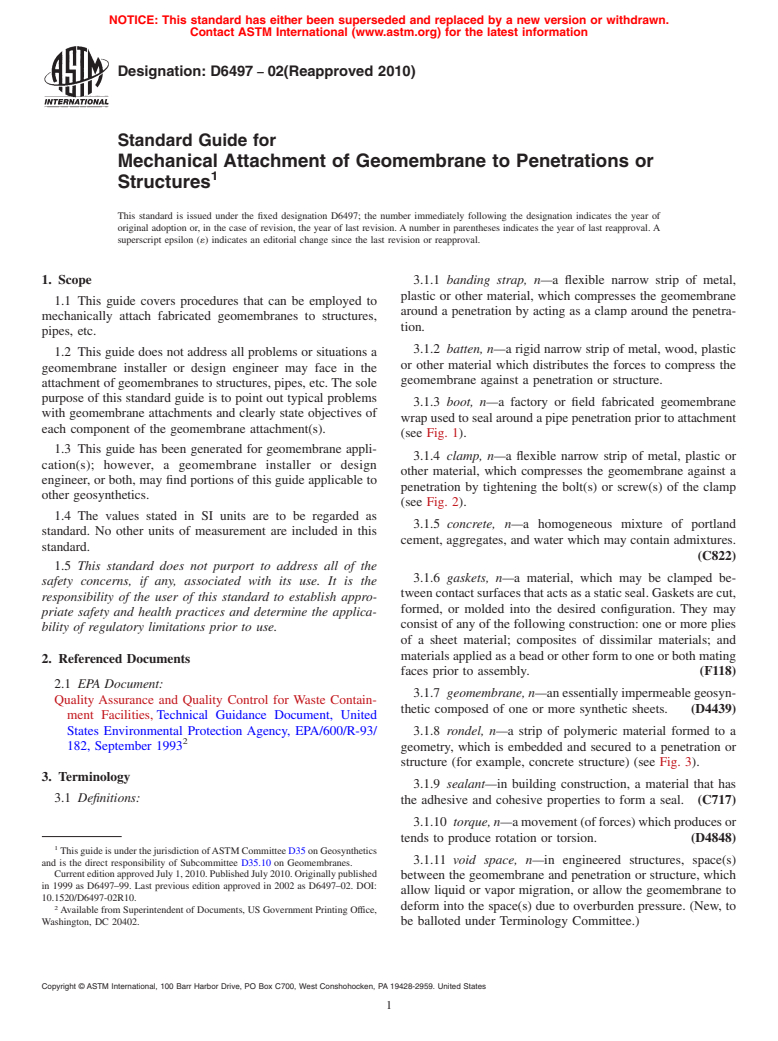

3.1.4 clamp, n—a flexible narrow strip of metal, plastic or

cation(s); however, a geomembrane installer or design

other material, which compresses the geomembrane against a

engineer, or both, may find portions of this guide applicable to

penetration by tightening the bolt(s) or screw(s) of the clamp

other geosynthetics.

(see Fig. 2).

1.4 The values stated in SI units are to be regarded as

3.1.5 concrete, n—a homogeneous mixture of portland

standard. No other units of measurement are included in this

cement, aggregates, and water which may contain admixtures.

standard.

(C822)

1.5 This standard does not purport to address all of the

3.1.6 gaskets, n—a material, which may be clamped be-

safety concerns, if any, associated with its use. It is the

tweencontactsurfacesthatactsasastaticseal.Gasketsarecut,

responsibility of the user of this standard to establish appro-

formed, or molded into the desired configuration. They may

priate safety and health practices and determine the applica-

consist of any of the following construction: one or more plies

bility of regulatory limitations prior to use.

of a sheet material; composites of dissimilar materials; and

materials applied as a bead or other form to one or both mating

2. Referenced Documents

faces prior to assembly. (F118)

2.1 EPA Document:

3.1.7 geomembrane, n—anessentiallyimpermeablegeosyn-

Quality Assurance and Quality Control for Waste Contain-

thetic composed of one or more synthetic sheets. (D4439)

ment Facilities, Technical Guidance Document, United

States Environmental Protection Agency, EPA/600/R-93/ 3.1.8 rondel, n—a strip of polymeric material formed to a

182, September 1993

geometry, which is embedded and secured to a penetration or

structure (for example, concrete structure) (see Fig. 3).

3. Terminology

3.1.9 sealant—in building construction, a material that has

3.1 Definitions:

the adhesive and cohesive properties to form a seal. (C717)

3.1.10 torque,n—amovement(offorces)whichproducesor

tends to produce rotation or torsion. (D4848)

This guide is under the jurisdiction ofASTM Committee D35 on Geosynthetics

3.1.11 void space, n—in engineered structures, space(s)

and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

CurrenteditionapprovedJuly1,2010.PublishedJuly2010.Originallypublished

between the geomembrane and penetration or structure, which

in 1999 as D6497–99. Last previous edition approved in 2002 as D6497–02. DOI:

allow liquid or vapor migration, or allow the geomembrane to

10.1520/D6497-02R10.

deform into the space(s) due to overburden pressure. (New, to

Available from Superintendent of Documents, US Government Printing Office,

Washington, DC 20402. be balloted under Terminology Committee.)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6497 − 02 (2010)

FIG. 1 Pipe Penetration—Perpendicular Face

4. Significance and Use sufficient torque to compress the geomembrane against the

penetration or structure. The geomembrane is held in place by

4.1 This guide attempts to detail specific areas of concern

the friction generated by the compression effect of the batten

regarding the attachment of geomembranes to structures.

(see Fig. 4).

Components of the geomembrane attachment are addressed as

to the type and use of each component. 5.1.1 A compression sealant or gasket can be used between

the geomembrane and the penetration or structure or batten, or

4.2 Although this guide does not address all aspects of

both. The compression sealant or gasket will limit the migra-

geomembrane attachments, the user of this guide may note

tion of liquid or vapor through the batten connection.

important objectives and design issues of each component of

the geomembrane. All these objectives and design issues may

5.2 Clamp(s) or Banding Strap(s)—Clamps or banding

or may not be required to obtain an appropriate geomembrane

straps are commonly used to attach a geomembrane to a

attachment. By describing these areas of concern, it is hoped

smooth,roundpenetrationorstructure(forexample,pipe).The

that the user of this guide will be able to design geomembrane

geomembrane is placed around the penetration or structure and

attachments, develop specifications or construct geomembrane

welded as close as possible to the circumference of the

attachments, or both, which fulfill the requirements of its

penetration or structure.Agasket is placed around the penetra-

design intent.

tion or structure at the location of the clamp placement to form

a seal between the geomembrane and penetration or structure.

5. Types of Connection

Thegeomembraneisthenputin-placeandoverthegasket.The

5.1 Batten(s)—Battens are commonly used to attach a

clamp or banding strap is commonly tightened by applying a

geomembrane to a smooth, flat surface. Anchor bolts are

torque to a bolt or bolts, a screw or screws, or other mechanical

embedded into the penetration or structure at set locations. A

device, which applies a pulling force that decreases the length

gasket is placed in-line with the bolts to form a seal between

of the clamp, or banding strap, thereby compressing the

the geomembrane and structure. Geomembrane is pushed or

geomembrane and gasket to the penetration or structure. The

forcedovertheboltstoinsureatightfitandthenplacedagainst

geomembrane is held in place by the friction generated by

the penetration or structure. The batten, which has holes in it

that are in alignment with the bolts, is placed over the tightening the clamp or banding strap and compressing the

geomembrane. Nuts are placed on the bolts and tightened with geomembrane against the penetration or structure.

D6497 − 02 (2010)

FIG. 2 Clamp Detail

5.2.1 A compression sealant or gasket can be used between weldingprocess.Thegeomembraneandrondelorpipemustbe

the geomembrane and the penetration or structure or clamp, or clean or prepared, or both, according to the prescribed

both. The compression sealant or gasket will limit the migra- geomembrane manufacturer’s procedure before welding.

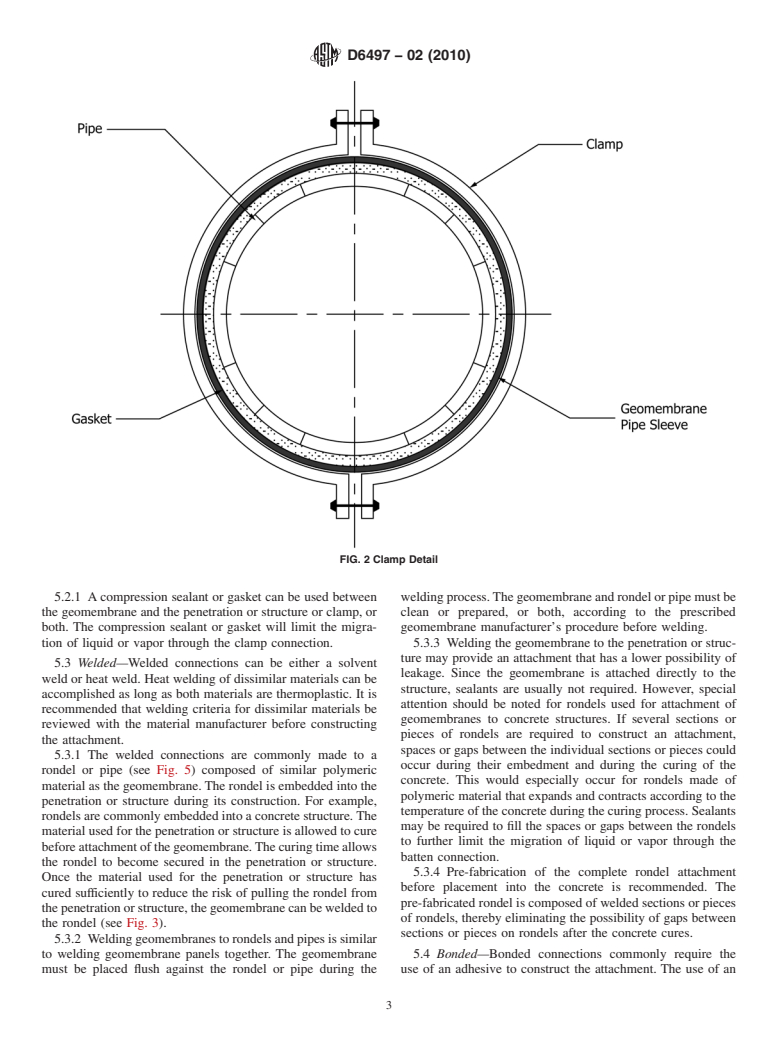

tion of liquid or vapor through the clamp connection. 5.3.3 Welding the geomembrane to the penetration or struc-

ture may provide an attachment that has a lower possibility of

5.3 Welded—Welded connections can be either a solvent

leakage. Since the geomembrane is attached directly to the

weld or heat weld. Heat welding of dissimilar materials can be

structure, sealants are usually not required. However, special

accomplished as long as both materials are thermoplastic. It is

attention should be noted for rondels used for attachment of

recommended that welding criteria for dissimilar materials be

geomembranes to concrete structures. If several sections or

reviewed with the material manufacturer before constructing

pieces of rondels are required to construct an attachment,

the attachment.

spaces or gaps between the individual sections or pieces could

5.3.1 The welded connections are commonly made to a

occur during their embedment and during the curing of the

rondel or pipe (see Fig. 5) composed of similar polymeric

concrete. This would especially occur for rondels made of

material as the geomembrane. The rondel is embedded into the

polymeric material that expands and contracts according to the

penetration or structure during its construction. For example,

temperature of the concrete during the curing process. Sealants

rondels are commonly embedded into a concrete structure.The

may be required to fill the spaces or gaps between the rondels

material used for the penetration or structure is allowed to cure

to further limit the migration of liquid or vapor through the

beforeattachmentofthegeomembrane.Thecuringtimeallows

batten connection.

the rondel to become secured in the penetration or structure.

5.3.4 Pre-fabrication of the complete rondel attachment

Once the material used for the penetration or structure has

before placement into the concrete is recommended. The

cured sufficiently to reduce the risk of pulling the rondel from

pre-fabricated rondel is composed of welded sections or pieces

thepenetrationorstructure,thegeomembranecanbeweldedto

of rondels, thereby eliminating the possibility of gaps between

the rondel (see Fig. 3).

sections or pieces on rondels after the concrete cures.

5.3.2 Weldinggeomembranestorondelsandpipesissimilar

to welding geomembrane panels together. The geomembrane 5.4 Bonded—Bonded connections commonly require the

must be placed flush against the rondel or pipe during the use of an adhesive to construct the attachment. The use of an

D6497 − 02 (2010)

FIG. 3 Rondel Connection

FIG. 4 Anchor Bolt Geomembrane Connection

adhesive allows the geomembrane to be attached to dis-similar structure. The application and curing of the adhesive should

material. The adhesive used must be compatible with both the not significantly deteriorate the strength of the geomembrane

geomembrane and the surface material of the penetration or

D6497 − 02 (2010)

FIG. 5 Pipe Boot

or the material surface of the penetration or structure beyond 7. Critical Areas for the Protection of the Geomembrane

the design requirements of the attachment.

7.1 Surface Characteristics—The surface of the structure

5.4.1 The geomembrane and the surface of the penetration

for which the geomembrane is to be attached should be

or structure should be clean and prepared according the

constructed or formed to limit damage to the geomembrane.

adhesive manufacturer’s and geomembrane manufacturer’s

This is particularly important in cases where the geomembrane

recommendation.

will be pressed against the structure. Irregularities in the

5.4.2 Bonding the geomembrane to the penetration or struc-

structuresurfacecouldcausestresspointsinthegeomembrane,

ture may provide an attachment, which has a lower possibility

thereby, allowing portion(s) of the geomembrane to yield at a

of leakage. Since the geomembrane is attached directly to the

lower load than its design application. If a structure cannot be

structure, sealants are usually not required.

constructed or formed without irregularities, then a protective

layer should be placed between the structure and the geomem-

6. Types of Structures

brane (see Fig. 4).

6.1 Concrete—Concrete structures that require attachment

7.2 Edges of Structures—Edges or corners of structures

of geomembranes include, but are not limited to, pads, floors,

should be rounded to limit possible damage to the geomem-

walls, tanks, manholes, and pylons. The use of battens, clamps

brane.Aprotective layer can be constructed or placed over the

or banding strips, or bonding can attach a geomembrane to

edge or corner to protect the geomembrane.

concrete structures. When attaching a geomembrane to any

concrete structure, consider each critical concern detailed in

7.3 Large Voids Under Geomembrane —Large voids under

Section 7.

the geomembrane can cause deformation and stress in the

geomembrane and geomembrane seams if, under pressure or

6.2 Metal—Metal structures that require attachment of

load, the geomembrane is forced into the void(s). Large voids

geomembranes include, but are not limited to, pads, floors,

should be filled or bridged to stop the geomembrane and

walls, pipes, and tanks. The use of battens, clamps or banding

geomembrane seams from becoming overly stressed (see Figs.

strips, can attach a geomembrane to metal structures. When

6 and 7).

attaching a geomembrane to any metal structure, consider each

critical concern detailed in Section 7.

7.4 Settlement Around Structures —If a geomembrane is to

6.3 Pipe—Pipe structures can be composed of concrete, be connected to a structure and placed over an area which may

metalorpolymer.Clamps,bandingstrips,solventweld,orheat settle at a greater or lesser rate than the structure, the design

weld can attach a geomembrane to pipe structures. The engineer or geomembrane installer should take precautions to

attachment of a geomembrane to any pipe structure should limit settlement around the structure. If settlement around the

consider critical concerns detailed in 7.1, 7.3, 7.4, 7.5, and 7.6. structure cannot be avoided, then the design engineer should

D6497 − 02 (2010)

FIG. 6 Liner Penetration Detail

FIG. 7 Tank Corner Detail

design a flexible connection to the structure that considers 7.5 In-Plane Attachment—The geomembrane should be

settlement and alleviates the stresses, which could occur due to placedinparallelor“in-plane”withthestructureorpenetration

settlement. to be attached. The geomembrane should lie flat against the

D6497 − 02 (2010)

surface of the structure or penetration for a sufficient distance of the attachment should be the clean geomembrane, structure,

prior to the geomembrane being placed “out of plane” of the and type of connection used to perform the attachment.

structure or penetration. This is to avoid bridging within

8.2 Type of Attachment:

attachment, pulling away from the structure, or stresses within

8.2.1 Battens:

the geomembrane during the pl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.