ASTM F1668-08

(Guide)Standard Guide for Construction Procedures for Buried Plastic Pipe

Standard Guide for Construction Procedures for Buried Plastic Pipe

SIGNIFICANCE AND USE

This guide may be used as a reference of acceptable open-cut construction practices for the proper installation of buried fiberglass and thermoplastic pipe. This guide may be used as follows:

4.1.1 Installation contractors have an awareness of the level of workmanship required and use this information for bidding purposes and during construction.

4.1.2 Construction inspectors have a reference of acceptable installation practices.

4.1.3 Specification writers may use this guide as a reference in contract documents.

4.1.4 Designers may review this information during planning and design for factors to consider in the preparation of plans and specifications.

4.1.5 The owner of the pipeline may use this guide as a reference for restoration of proper pipe support and embedment when original construction is disturbed due to repairs, modifications, or construction of adjacent or crossing pipelines or cables.

This guide should not be used to replace project specification requirements, manufacturer’recommendations, plumbing codes, building codes, or ASTM installation standards, but may be used to supplement that information.

SCOPE

1.1 This guide describes installation techniques and considerations for open-cut construction of buried pipe. Although this guide was developed for plastic pipe, the concepts of providing the appropriate soil support, care in handling, correct joining techniques, proper soil compaction methods, and prevention of installation damage may apply to any pipe.

1.1.1 Plastic pipe refers to thermoplastic and fiberglass pipe.

1.1.2 Thermoplastic pipe refers to pipe fabricated from polyvinyl chloride (PVC), polyethylene (PE), acrylonitrile-butadiene styrene (ABS), polybutylene (PB), or polypropylene (PP). A list of ASTM specifications for these products is given in .

1.1.3 Fiberglass pipe refers to a glass-fiber-reinforced thermosetting-resin pipe. A list of ASTM specifications for these products is given in . Note 1 cannot be considered inclusive because there may be unlisted, recently adopted ASTM specifications for new products that may be installed using this guide.Note 2

Only a few of the ASTM specifications listed in include the associated fittings. While this guide applies to the installation of pipe, couplings, and fittings, no attempt was made to list all the possible fitting specifications that may be used in conjunction with the pipe specifications. Consult each specification or manufacturer for appropriate fitting standards.

1.1.4For simplification, the term pipe will be used in this document to mean pipe sections, fittings, and couplings.

1.2 This guide contains general construction information applicable for plastic pipe and supplements the installation standards for the various types of pipe as described in Practices D 2321, D 2774, D 3839, F 690, F 1176, and Guide F 645.

1.3 Flexible pipe, such as thermoplastic and fiberglass, are typically designed to rely on the stiffness of the soil surrounding the pipe for support. The contract documents should describe the requirements of an appropriate soil support system. The construction practices described in this guide can be instrumental in attaining the required soil stiffness.

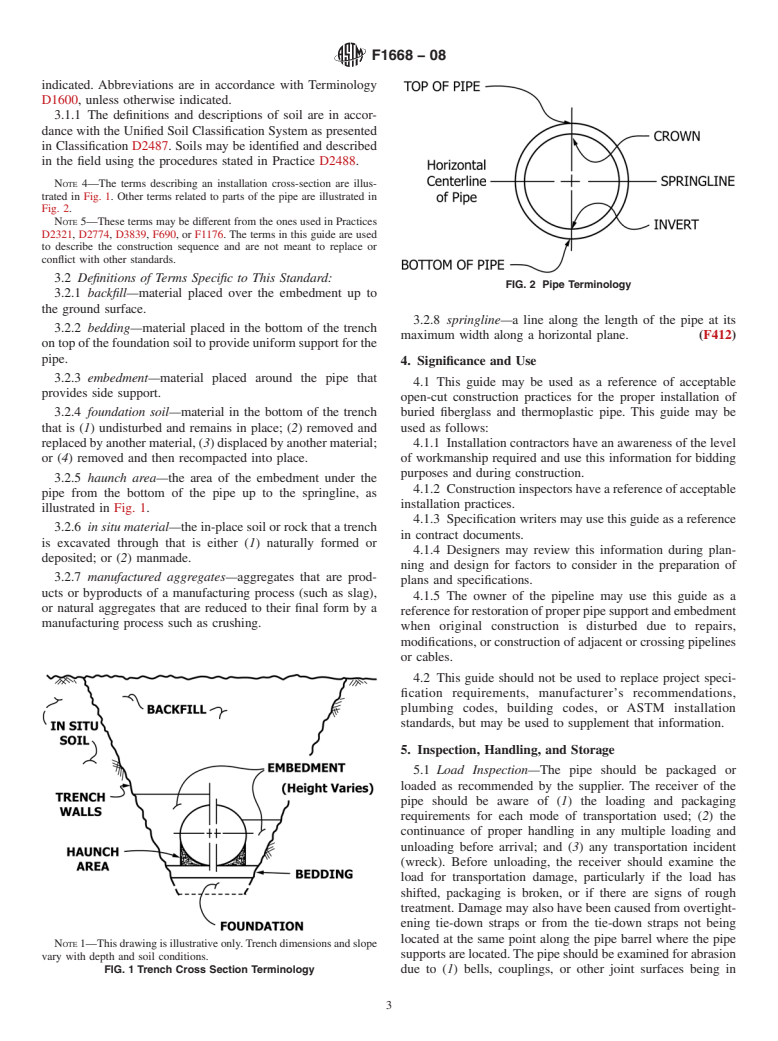

1.3.1 A discussion of the interaction between a buried pipe and the surrounding soil and the importance of attaining proper soil support is in .

1.3.2 Following these guidelines will be helpful in preventing local deformations in the pipe.

1.4 This guide does not cover underwater installation, pipe that needs to be supported on piling, perforated pipe used for drainage, or gas pipelines.

1.5 Pipelines through areas described as "expansive soils," "collapsing soils," landfills or water-logged land (such as swamps) should be constructed using site-specific installation procedures and are not discussed in this guide.

1.6 This guide is not intended to cover all situations. Specific pipe characteristics, fluid transpo...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1668 − 08 AnAmerican National Standard

Standard Guide for

1

Construction Procedures for Buried Plastic Pipe

This standard is issued under the fixed designation F1668; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* system. The construction practices described in this guide can

be instrumental in attaining the required soil stiffness.

1.1 This guide describes installation techniques and consid-

1.3.1 A discussion of the interaction between a buried pipe

erationsforopen-cutconstructionofburiedpipe.Althoughthis

andthesurroundingsoilandtheimportanceofattainingproper

guidewasdevelopedforplasticpipe,theconceptsofproviding

soil support is in Appendix X1.

the appropriate soil support, care in handling, correct joining

1.3.2 Following these guidelines will be helpful in prevent-

techniques, proper soil compaction methods, and prevention of

ing local deformations in the pipe.

installation damage may apply to any pipe.

1.1.1 Plasticpipereferstothermoplasticandfiberglasspipe. 1.4 This guide does not cover underwater installation, pipe

that needs to be supported on piling, perforated pipe used for

1.1.2 Thermoplastic pipe refers to pipe fabricated from

polyvinyl chloride (PVC), polyethylene (PE), acrylonitrile- drainage, or gas pipelines.

butadiene styrene (ABS), polybutylene (PB), or polypropylene

1.5 Pipelines through areas described as “expansive soils,”

(PP).Alist ofASTM specifications for these products is given

“collapsing soils,” landfills or water-logged land (such as

in Appendix X2.

swamps) should be constructed using site-specific installation

1.1.3 Fiberglass pipe refers to a glass-fiber-reinforced

procedures and are not discussed in this guide.

thermosetting-resin pipe. A list of ASTM specifications for

1.6 This guide is not intended to cover all situations.

these products is given in Appendix X2.

Specific pipe characteristics, fluid transported, local site

NOTE 1—Appendix X2 cannot be considered inclusive because there

conditions, environmental concerns, or manufacturer’s recom-

may be unlisted, recently adopted ASTM specifications for new products

mendations may require different guidelines.

that may be installed using this guide.

NOTE 2—Only a few of theASTM specifications listed in Appendix X2 1.7 The construction practices presented in this guide may

include the associated fittings. While this guide applies to the installation

be affected by the installation requirements of owners, speci-

ofpipe,couplings,andfittings,noattemptwasmadetolistallthepossible

fying organizations, or regulatory agencies for pipelines cross-

fitting specifications that may be used in conjunction with the pipe

ing roads and highways, other pipelines or cables, or water-

specifications. Consult each specification or manufacturer for appropriate

ways such as streams, drainage channels, or floodways.

fitting standards.

1.8 Culverts or pipe that are used as passages through water

1.1.4 For simplification, the term pipe will be used in this

document to mean pipe sections, fittings, and couplings. retaining embankments (for example, earth dams) may be

constructed using the principles of this guide, if appropriate

1.2 This guide contains general construction information

provisions are made to prevent water movement along the

applicable for plastic pipe and supplements the installation

outside of the pipe (using impervious soils, cutoff collars, head

standardsforthevarioustypesofpipeasdescribedinPractices

walls, etc.).

D2321, D2774, D3839, F690, F1176, and Guide F645.

1.9 The values stated in SI units are to be regarded as the

1.3 Flexible pipe, such as thermoplastic and fiberglass, are

standard. The inch-pound units in parentheses are given for

typically designed to rely on the stiffness of the soil surround-

information only.

ing the pipe for support. The contract documents should

NOTE 3—There is no similar or equivalent ISO standard covering the

describe the requirements of an appropriate soil support

primary subject matter of this guide.

1.10 This standard does not purport to address all of the

1

This guide is under the jurisdiction ofASTM Committee F17 on Plastic Piping

safety concerns, if any, associated with its use. It is the

Systems and is the direct responsibility of Subcommittee F17.61 on Water.

responsibility of the user of this standard to establish appro-

Current edition approved March 1, 2008. Published April 2008. Originally

priate safety and health practices and determine the applica-

approved in 1995. Last previous edition approved in 2002 as F1668 – 96(2002).

DOI: 10.1520/F1668-08.

bility of regulatory lim

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F 1668–96 (Reapproved 2002) Designation:F 1668–08

Standard Guide for

1

Construction Procedures for Buried Plastic Pipe

This standard is issued under the fixed designation F 1668; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 Thisguidedescribesinstallationtechniquesandconsiderationsforopen-cutconstructionofburiedpipe.Althoughthisguide

was developed for plastic pipe, the concepts of providing the appropriate soil support, care in handling, correct joining techniques,

proper soil compaction methods, and prevention of installation damage may apply to any pipe.

1.1.1 Plastic pipe refers to thermoplastic and fiberglass pipe.

1.1.2 Thermoplastic pipe refers to pipe fabricated from polyvinyl chloride (PVC), polyethylene (PE), acrylonitrile-butadiene

styrene (ABS), polybutylene (PB), or polypropylene (PP). A list of ASTM specifications for these products is given in Appendix

X2.

1.1.3 Fiberglass pipe refers to a glass-fiber-reinforced thermosetting-resin pipe.Alist ofASTM specifications for these products

is given in Appendix X2.

NOTE 1—AppendixX2cannotbeconsideredinclusivebecausetheremaybeunlisted,recentlyadoptedASTMspecificationsfornewproductsthatmay

be installed using this guide.

NOTE 2—Only a few of the ASTM specifications listed in Appendix X2 include the associated fittings. While this guide applies to the installation of

pipe, couplings, and fittings, no attempt was made to list all the possible fitting specifications that may be used in conjunction with the pipe specifications.

Consult each specification or manufacturer for appropriate fitting standards.

1.1.4 For simplification, the term pipe will be used in this document to mean pipe sections, fittings, and couplings.

1.2 This guide contains general construction information applicable for plastic pipe and supplements the installation standards

for the various types of pipe as described in Practices D 2321, D 2774, D 3839, F 690, F 1176, and Guide F 645.

1.3 Flexible pipe, such as thermoplastic and fiberglass, are typically designed to rely on the stiffness of the soil surrounding the

pipe for support.The contract documents should describe the requirements of an appropriate soil support system.The construction

practices described in this guide can be instrumental in attaining the required soil stiffness.

1.3.1 Adiscussion of the interaction between a buried pipe and the surrounding soil and the importance of attaining proper soil

support is in Appendix X1.

1.3.2 Following these guidelines will be helpful in preventing local deformations in the pipe.

1.4 This guide does not cover underwater installation, pipe that needs to be supported on piling, perforated pipe used for

drainage, or gas pipelines.

1.5 Pipelines through areas described as “expansive soils,” “collapsing soils,” landfills or water-logged land (such as swamps)

should be constructed using site-specific installation procedures and are not discussed in this guide.

1.6 This guide is not intended to cover all situations. Specific pipe characteristics, fluid transported, local site conditions,

environmental concerns, or manufacturer’s recommendations may require different guidelines.

1.7 The construction practices presented in this guide may be affected by the installation requirements of owners, specifying

organizations, or regulatory agencies for pipelines crossing roads and highways, other pipelines or cables, or waterways such as

streams, drainage channels, or floodways.

1.8 Culverts or pipe that are used as passages through water retaining embankments (for example, earth dams) may be

constructed using the principles of this guide, if appropriate provisions are made to prevent water movement along the outside of

the pipe (using impervious soils, cutoff collars, head walls, etc.).

1.9 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are given for

information only.

NOTE 3—There is no similar or equivalent ISO standard covering the primary subject matter of this guide.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

1

Thi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.