ASTM D4543-08

(Practice)Standard Practices for Preparing Rock Core as Cylindrical Test Specimens and Verifying Conformance to Dimensional and Shape Tolerances

Standard Practices for Preparing Rock Core as Cylindrical Test Specimens and Verifying Conformance to Dimensional and Shape Tolerances

SIGNIFICANCE AND USE

p>The dimensional, shape, and surface tolerances of rock core specimens are important for determining rock properties of intact specimens. This is especially true for strong rocks, greater than 7250 psi (50 MPa). Dimensional and surface tolerance checks are required in the test methods listed in Section 2.1. To simplify test procedures in laboratories, the parts of those procedures that are common to the test methods in Section 2.1 are given in this standard.

This procedure is applicable to all the standards listed in Section 2.1. However, specimens for Test Method D 2936 do not need to be machined or to meet the specified tolerances for flatness and parallelism.

The moisture condition of the specimen at the time of the sample preparation can have a significant effect upon the strength and deformation characteristics of the rock. Good practice generally dictates that laboratory tests be made upon specimens representative of field conditions. Thus, it follows that the field moisture condition of the specimen should be preserved until the time of the test. In some instances, however, there may be reasons for testing specimens at other moisture contents, from saturation to dry. In any case, the moisture content of the test specimen should be tailored to the problem at hand. Excess moisture will affect the adhesion of resistance strain gages, if used, and the accuracy of their performance. Adhesives used to bond the rock to steel end pieces in the direct tension test will also be affected adversely by excess moisture.

Note 2—The quality of the result produced by these practices is dependent upon the competence of the personnel performing it and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing and sampling. Users of these practices are cautioned that compliance with Practice D 3740 does not in itself assure reliable results. Reliable results ...

SCOPE

1.1 These practices specify procedures for laboratory rock core test specimen preparation of rock core from drill core and block samples for strength and deformation testing and for determining the conformance of the test specimen dimensions with tolerances established by this practice. Cubical, rectangular, or other shapes are not covered by this practice. However, some of the information contained with in this practice and in standard Test Method C 170 may still be of use to preparing other test specimen shapes.

1.2 Rock is a complex engineering material that can vary greatly as a function of lithology, stress history, weathering, moisture content and chemistry, and other natural geologic processes. As such, it is not always possible to obtain or prepare rock core specimens that satisfy the desirable tolerances given in this practice. Most commonly, this situation presents itself with weaker, more porous, and poorly cemented rock types and rock types containing significant or weak (or both) structural features. For these and other rock types which are difficult to prepare, all reasonable efforts shall be made to prepare a specimen in accordance with this practice and for the intended test procedure. However, when it has been determined by trial that this is not possible, prepare the rock specimen to the closest tolerances practicable and consider this to be the best effort (Note 1) and report it as such and if allowable or necessary for the intended test, capping the ends of the specimen as discussed in this practice is permitted.

Note 1—Best effort in surface preparation refers to the use of a well-maintained surface grinder, lathe or lapping machine by an experienced operator in which a reasonable number of attempts has been made to meet the tolerances required in this procedure.

1.3 This practices covers some, but not all of the curatorial issues that should be implemented. For curatorial issues that should b...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4543 − 08

Standard Practices for

Preparing Rock Core as Cylindrical Test Specimens and

Verifying Conformance to Dimensional and Shape

1

Tolerances

This standard is issued under the fixed designation D4543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* refer to Practices D5079 and to the specific test standards in

section 2.1 for which the specimens are being prepared.

1.1 These practices specify procedures for laboratory rock

core test specimen preparation of rock core from drill core and

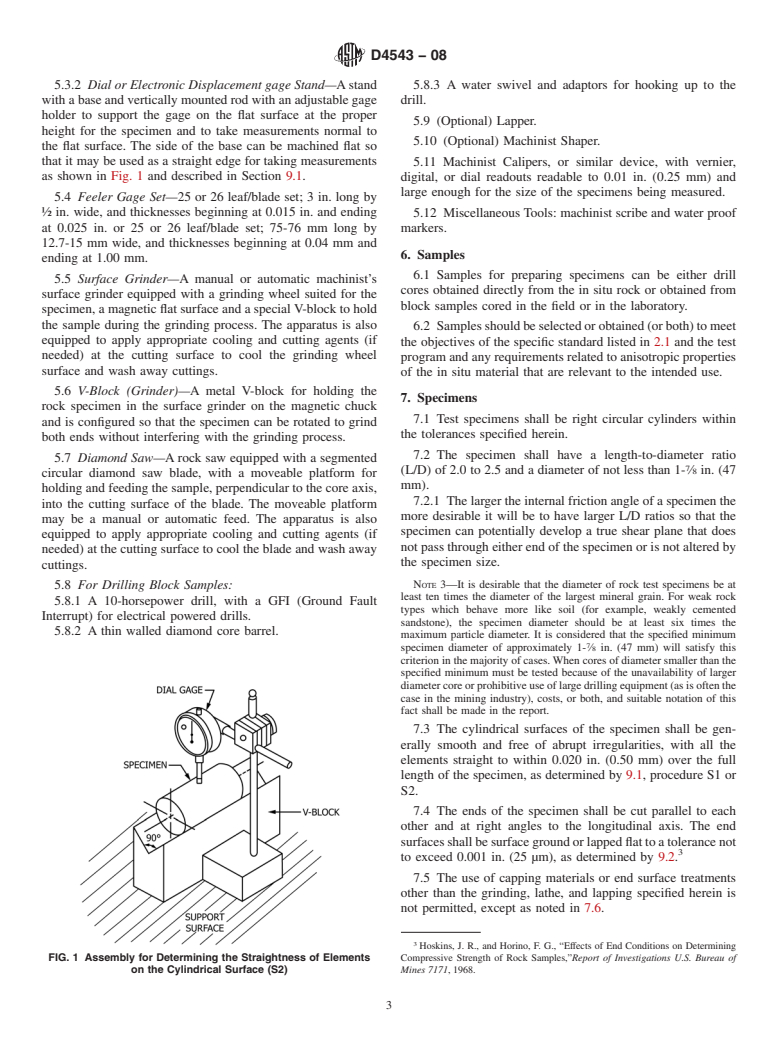

1.4 This practice also prescribes tolerance checks on the

block samples for strength and deformation testing and for

length-to-diameter ratio, straightness of the elements on the

determining the conformance of the test specimen dimensions

cylindricalsurface,theflatnessoftheendbearingsurfaces,and

with tolerances established by this practice. Cubical,

the perpendicularity of the end surfaces with the axis of the

rectangular, or other shapes are not covered by this practice.

core.

However, some of the information contained with in this

1.5 The requirement for specifying the moisture condition

practice and in standard Test Method C170 may still be of use

of the test specimen is also stated. However, the requirements

to preparing other test specimen shapes.

in the specific test standards in section 2.1 should be followed

1.2 Rock is a complex engineering material that can vary

too.

greatly as a function of lithology, stress history, weathering,

1.6 All observed and calculated values shall conform to the

moisture content and chemistry, and other natural geologic

guidelines for significant digits and rounding established in

processes. As such, it is not always possible to obtain or

Practice D6026, unless superseded by this standard.

prepare rock core specimens that satisfy the desirable toler-

1.6.1 The practices/procedures used to specify how data are

ances given in this practice. Most commonly, this situation

collected/recorded and calculated in this standard are regarded

presents itself with weaker, more porous, and poorly cemented

as the industry standard. In addition, they are representative of

rock types and rock types containing significant or weak (or

the significant digits that generally should be retained. The

both) structural features. For these and other rock types which

proceduresuseddonotconsidermaterialvariation,purposefor

are difficult to prepare, all reasonable efforts shall be made to

obtaining the data, special purpose studies, or any consider-

prepareaspecimeninaccordancewiththispracticeandforthe

ations for the user’s objectives; and it is common practice to

intendedtestprocedure.However,whenithasbeendetermined

increase or reduce significant digits of reported data to be

by trial that this is not possible, prepare the rock specimen to

commensuratewiththeseconsiderations.Itisbeyondthescope

the closest tolerances practicable and consider this to be the

of this standard to consider significant digits used in analysis

best effort (Note 1) and report it as such and if allowable or

methods for engineering design.

necessary for the intended test, capping the ends of the

specimen as discussed in this practice is permitted.

1.7 Units—The dimensional values stated in either inch-

pound units or SI units are to be regarded as standard, such as

NOTE 1—Best effort in surface preparation refers to the use of a

4 to 12 in. or 100 to 300 mm.The values stated in each system

well-maintained surface grinder, lathe or lapping machine by an experi-

enced operator in which a reasonable number of attempts has been made

may not be exact equivalents; therefore, each system shall be

to meet the tolerances required in this procedure.

used independently of the other. Combining values from the

1.3 This practices covers some, but not all of the curatorial two systems may result in non-conformance with the standard.

issues that should be implemented. For curatorial issues that (Note, when mass measurements are added to determine

should be followed before and during specimen preparation densities or unit weights, add the following.)

1.7.1 Only the SI units are used for mass determinations,

calculations and reported results. However, the use of balances

or scales recording pounds of mass (lbm) shall not be regarded

1

ThesepracticesareunderthejurisdictionofASTMCommitteeD18onSoiland

RockandarethedirectresponsibilityofSubcommitteeD18.12onRockMechanics. as nonconformance with this standard.

Current edition approved Jan. 1, 2008. Published February 2008. Originally

1.8 This standard does not purport to address all of the

ap

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4543–07 Designation: D 4543 – 08

Standard Practices for

Preparing Rock Core as Cylindrical Test Specimens and

Verifying Conformance to Dimensional and Shape

1

Tolerances

This standard is issued under the fixed designation D4543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1Thispracticespecifies1.1 Thesepracticesspecifyproceduresforlaboratoryrockcoretestspecimenpreparationofrockcore

from drill core and block samples for strength and deformation testing and for determining the conformance of the test specimen

dimensions with tolerances established by this practice. Cubical, rectangular, or other shapes are not covered by this practice.

However, some of the information contained with in this practice and in standard Test Method C170 may still be of use to

preparing other test specimen shapes.

1.2Rock1.2 Rock is a complex engineering material that can vary greatly as a function of lithology, stress history, weathering,

moisture content and chemistry, and other natural geologic processes.As such, it is not always possible to obtain or prepare rock

core specimens that satisfy the desirable tolerances given in this practice. Most commonly, this situation presents itself with

weaker, more porous, and poorly cemented rock types and rock types containing significant and/oror weak (or both) structural

features. For these and other rock types which are difficult to prepare, all reasonable efforts shall be made to prepare a specimen

in accordance with this practice and for the intended test procedure. However, when it has been determined by trial that this is not

possible, prepare the rock specimen to the closest tolerances practicable and consider this to be the best effort (Note 1) and report

it as such and if allowable or necessary for the intended test, capping the ends of the specimen as discussed in this practice is

permitted.

NOTE 1—Best effort in surface preparation refers to the use of a well-maintained surface grinder, lathe or lapping machine by an experienced operator

in which a reasonable number of attempts has been made to meet the tolerances required in this procedure.

1.3This1.3 This practices covers some, but not all of the curatorial issues that should be implemented. For curatorial issues that

should be followed before and during specimen preparation refer to Practices D5079 and to the specific test standards in section

2.1 for which the specimens are being prepared.

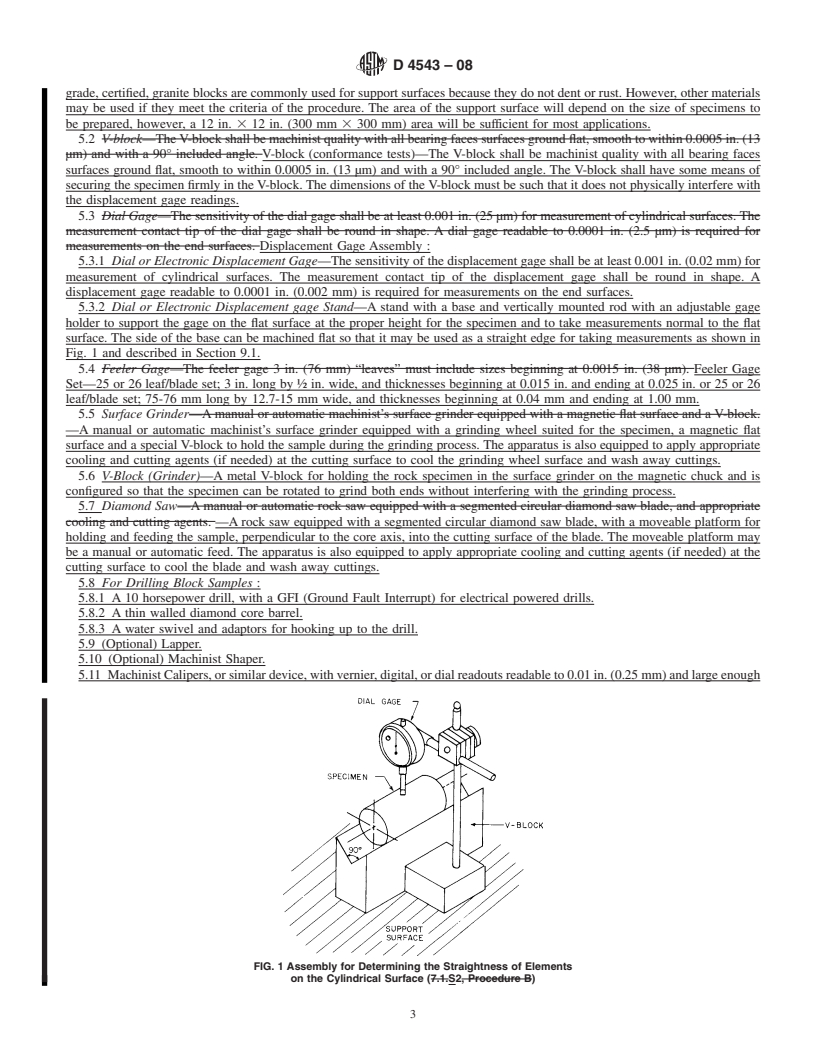

1.4This1.4 This practice also prescribes tolerance checks on the length-to-diameter ratio, straightness of the elements on the

cylindrical surface, the flatness of the end bearing surfaces, and the perpendicularity of the end surfaces with the axis of the core.

1.5 The requirement for specifying the moisture condition of the test specimen is also stated. However, the requirements in the

specific test standards in section 2.1 should be followed too.

1.6All1.6 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in

Practice D6026, unless superseded by this standard.

1.6.1 The practices/procedures used to specify how data are collected/recorded and calculated in this standard are regarded as

theindustrystandard.Inaddition,theyarerepresentativeofthesignificantdigitsthatgenerallyshouldberetained.Theprocedures

useddonotconsidermaterialvariation,purposeforobtainingthedata,specialpurposestudies,oranyconsiderationsfortheuser’s

objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these

considerations.Itisbeyondthescopeofthisstandardtoconsidersignificantdigitsusedinanalysismethodsforengineeringdesign.

1.7 Units—The dimensional values stated in either inch-pound units or SI units are to be regarded as standard, such as 4 to 12

in. or 100 to 300 mm. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.(Note,when

mass measurements are added to determine densities or unit weights, add the following.)

1.7.1Only1.7.1 Only the SI units are used for mass determinations, calculations and reported results. However, the use of

balances or scales recording pounds of mass (lbm) shall not be regar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.