ASTM C1277-97

(Specification)Standard Specification for Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings

Standard Specification for Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings

SCOPE

1.1 This specification covers the evaluating of the performance of shielded hubless couplings to join hubless cast iron soil pipe and fittings.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1277 – 97

Standard Specification for

Shielded Couplings Joining Hubless Cast Iron Soil

Pipe and Fittings

This standard is issued under the fixed designation C 1277; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 Descriptions of the following terms used in this

1.1 This specification covers the evaluating of the perfor-

specification are found in Terminology C 717, paragraph 4.2:

mance of shielded hubless couplings to join hubless cast iron

durometer, dynamic.

soil pipe and fittings.

3.2.2 The following descriptions of terms are applicable to

1.2 The values stated in inch-pound units are to be regarded

this specification only:

as the standard. The SI units given in parentheses are for

3.2.2.1 center stop— an integral part of the gasket centered

information only.

on the axial length of the gasket intended to limit the insertion

1.3 The following precautionary caveat pertains only to the

depth of the pipe to be coupled.

test method portion, Section 7, of this specification: This

3.2.2.2 clamp assembly (n)—that portion of the coupling

standard does not purport to address all of the safety concerns,

excluding the gasket.

if any, associated with its use. It is the responsibility of the user

3.2.2.3 coupling (n)— the complete assembly.

of this standard to establish appropriate safety and health

3.2.2.4 fitting (n)— parts of a pipeline other than straight

practices and determine the applicability of regulatory limita-

pipes, valves, or couplings.

tions prior to use.

3.2.2.5 gasket (n)—the elastomeric portion of the coupling.

2. Referenced Documents 3.2.2.6 joint (n)—the point of assembly consisting of the

coupling and the joined pipes or fittings, or both.

2.1 ASTM Standards:

3.2.2.7 shield (n)—an external metallic protective device

A 48 Specification for Gray Iron Castings

designed to protect the sealing gasket from external elements

A 888 Specification for Hubless Cast Iron Soil Pipe and

that could cause failure of the sealing assembly.

Fittings for Sanitary and Storm Drain, Waste, and Vent

Piping Applications

4. Materials and Manufacture

C 564 Specification for Rubber Gaskets for Cast Iron Soil

4.1 Physical properties of gaskets shall comply with Speci-

Pipe and Fittings

fication C 564 using the applicable Durometer hardness re-

C 717 Terminology of Building Seals and Sealants

quirement of the column of Table 1 of that document as

2.2 CISPI Standard:

specified by the manufacturer.

CISPI-301 Specification for Hubless Cast Iron Soil Pipe and

4.2 All cast iron parts shall be made of a minimum class 25

Fittings for Sanitary and Storm Drain, Waste and Vent

4 gray cast iron and shall show compliance to this requirement

Piping Applications

using test methods contained in Specification A 48.

3. Terminology 4.2.1 Clamp assembly screws or bolts shall not have screw-

driver slots.

3.1 Definitions:

3.1.1 Definition of the following term used in this specifi-

5. Elastomeric Gasket Requirements

cation is found in Terminology C 717, paragraph 4.1: elasto-

5.1 The elastomeric gasket shall consist of one piece con-

meric.

forming to the physical requirements.

5.1.1 The elastomeric gasket shall have an inside center stop

This specification is under the jurisdiction of ASTM Committee C-24 on that does not create an enlargement chamber or recess with a

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.75

ledge, shoulder, or reduction of pipe area or offer an obstruc-

on Gaskets and Couplings for Plumbing and Sewer Piping.

tion to flow.

Current edition approved Dec. 10, 1997. Published June 1998. Originally

5.1.2 The elastomeric gasket shall be free of defects that

published as C 1277–94. Last previous edition C 1277–94.

Annual Book of ASTM Standards, Vol 01.02.

affect the use and serviceability.

Annual Book of ASTM Standards, Vol 04.07.

Available from Cast Iron Soil Pipe Institute, 5959 Shallowford Rd., Suite 419,

Chattanooga, TN 37421.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1277

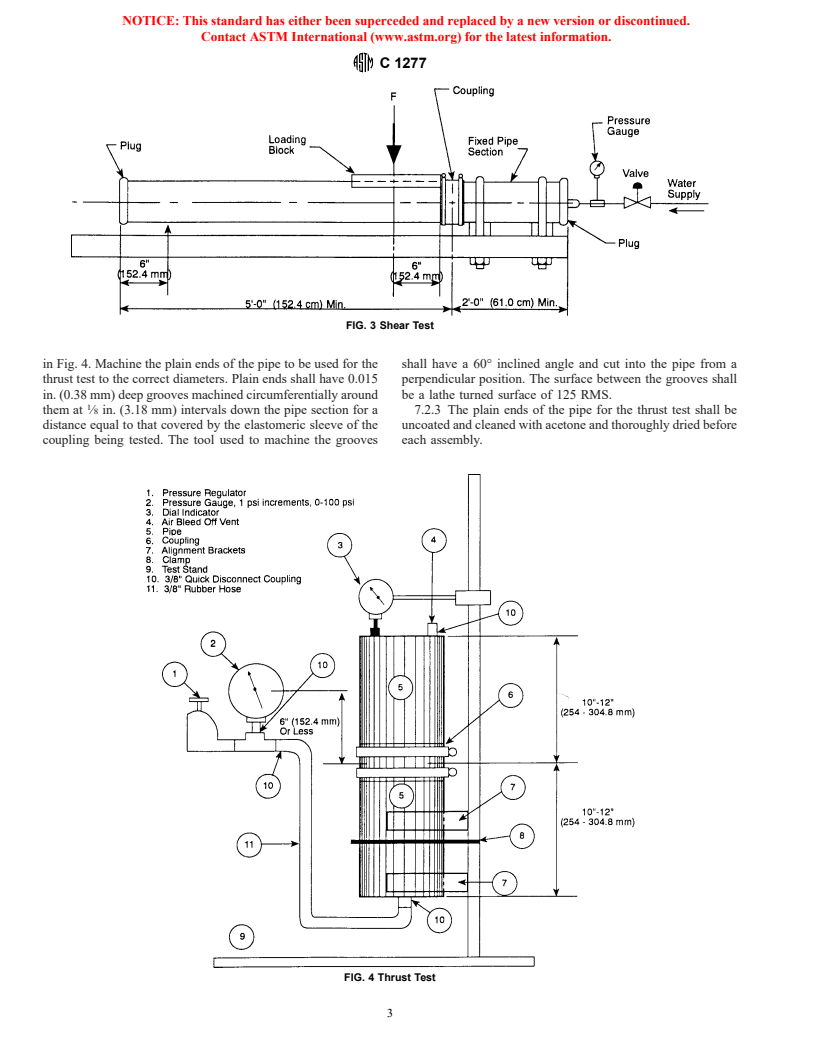

TABLE 1 Dimensions and Tolerances for Hubless Pipe and

7.1.1.2 Fill the assemblies with water, expel all air and

Fittings

apply a hydrostatic pressure in increments of 1 psi (6.9 kPa) at

Size, in. (mm) Outside Diameter, in. (mm)

approximately 30 s intervals until a pressure of 13 psi (89.6

1 ⁄2 (38) 1.906 0.06 (48.26 6 1.52)

kPa) is reached and maintain 30 min. Any leakage shall mean

2 (51) 2.35 6 0.09 (59.69 6 2.29)

failure.

3 (76.2) 3.35 6 0.09 (85.09 6 2.29)

7.1.2 Deflection Test:

4 (102) 4.38 + 0.09/−.05 (111.25 + 2.29/−1.27)

5 (127) 5.30 + 0.09/−.05 (134.62 + 2.29/−1.27)

7.1.2.1 A test apparatus such as the one shown in Fig. 2 is

6 (152) 6.30 + 0.09/−.05 (160.02 + 2.29/−1.27)

suggested. Other testing apparati that provide restraint to the

8 (203) 8.38 + 0.13/−.09 (212.85 + 3.30/−2.29)

10 (254) 10.56 6 0.09 (268.22 6 2.29) assembly shall also be permitted. Close the outboard ends of

the pipe with test plugs.

7.1.2.2 Fill the assembly with water, expel all air, and

hydrostatically pressurize to 4.3 psi (29.6 kPa) for the duration

of the test. One pipe shall be rigidly supported and while the

assembly is under pressure, raise the opposite end of the other

pipe ⁄2 in. (12.7 mm) per lineal foot of pipe. Maintain the

pressure for 5 min. Any leakage shall mean failure.

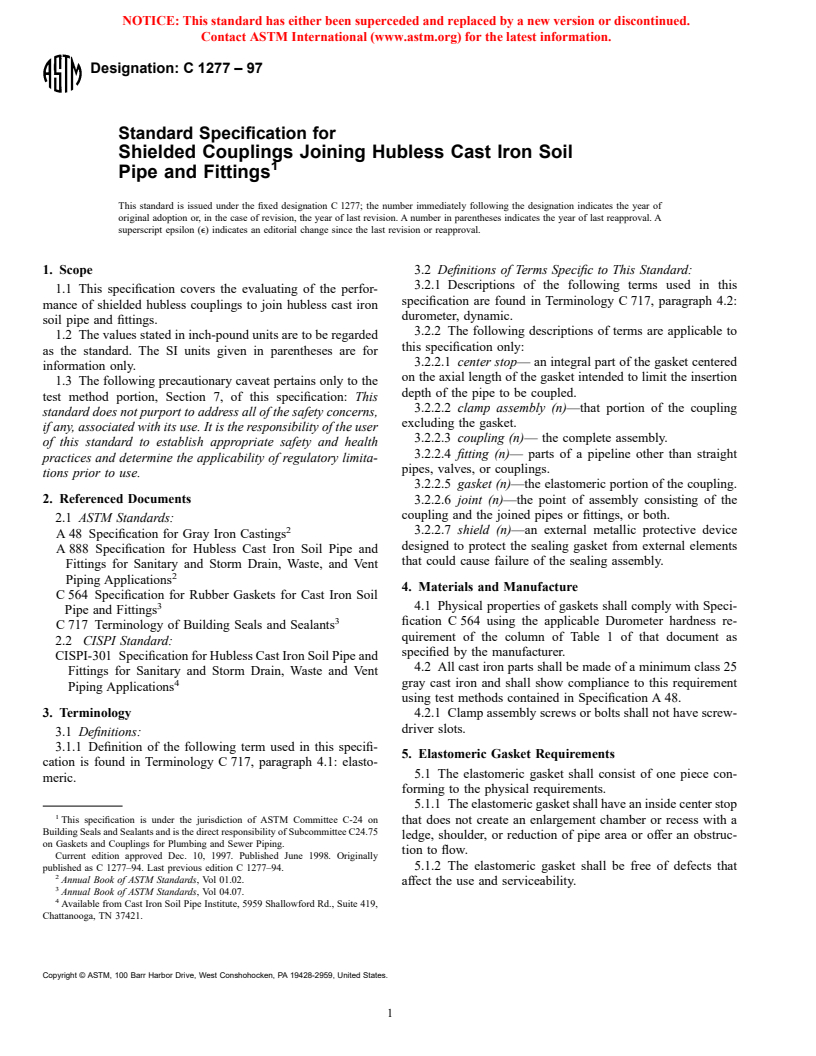

7.1.3 Shear Test:

7.1.3.1 Support two joined lengths of randomly selected

hubless cast iron soil pipe on blocks, a minimum of 1 ⁄2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.