ASTM D451-91(2002)

(Test Method)Standard Test Method for Sieve Analysis of Granular Mineral Surfacing For Asphalt Roofing Products

Standard Test Method for Sieve Analysis of Granular Mineral Surfacing For Asphalt Roofing Products

SIGNIFICANCE AND USE

This test method is used to determine the grading of materials used as granular mineral surfacing. The results are used to determine compliance of the particle size distribution with applicable specification requirements.

SCOPE

1.1 This test method covers the determination of the particle size distribution of granular mineral surfacing material such as crushed slate, stone, coated granules, etc., used on the weather surface of prepared asphalt roofing and shingles.

1.2 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 451 – 91 (Reapproved 2002)

Standard Test Method for

Sieve Analysis of Granular Mineral Surfacing For Asphalt

Roofing Products

This standard is issued under the fixed designation D 451; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

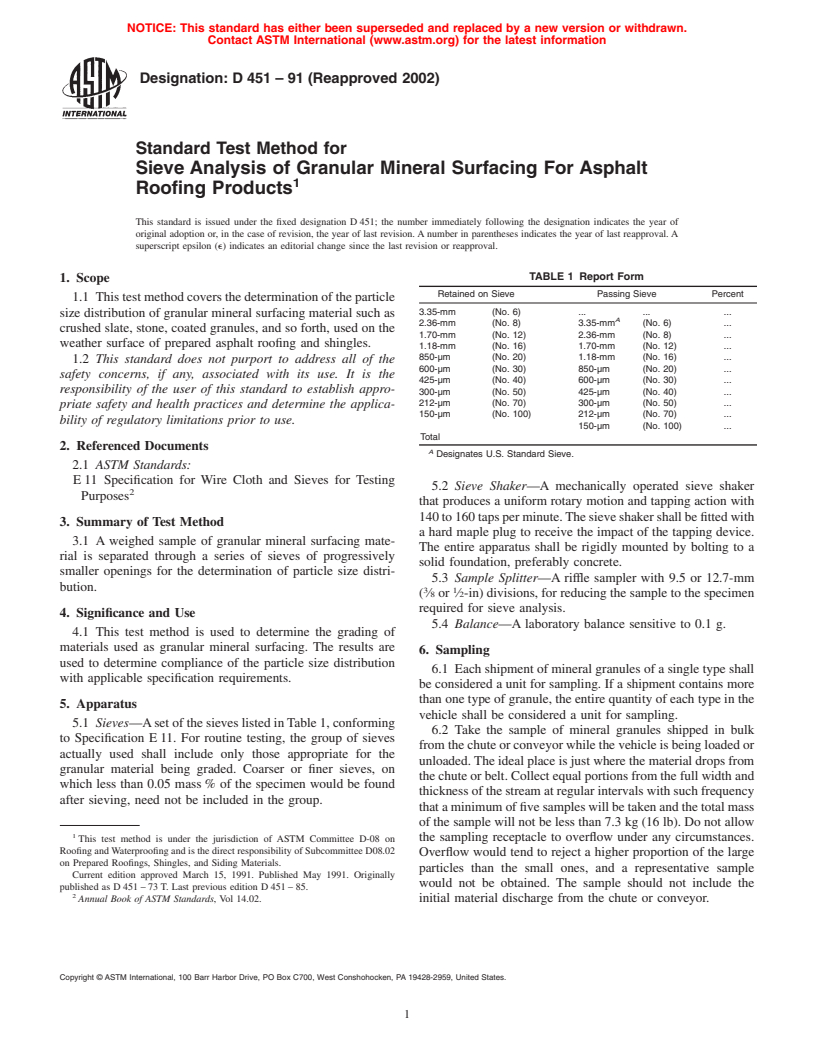

TABLE 1 Report Form

1. Scope

Retained on Sieve Passing Sieve Percent

1.1 This test method covers the determination of the particle

3.35-mm (No. 6) . . .

size distribution of granular mineral surfacing material such as

A

2.36-mm (No. 8) 3.35-mm (No. 6) .

crushed slate, stone, coated granules, and so forth, used on the

1.70-mm (No. 12) 2.36-mm (No. 8) .

weather surface of prepared asphalt roofing and shingles.

1.18-mm (No. 16) 1.70-mm (No. 12) .

850-µm (No. 20) 1.18-mm (No. 16) .

1.2 This standard does not purport to address all of the

600-µm (No. 30) 850-µm (No. 20) .

safety concerns, if any, associated with its use. It is the

425-µm (No. 40) 600-µm (No. 30) .

responsibility of the user of this standard to establish appro-

300-µm (No. 50) 425-µm (No. 40) .

212-µm (No. 70) 300-µm (No. 50) .

priate safety and health practices and determine the applica-

150-µm (No. 100) 212-µm (No. 70) .

bility of regulatory limitations prior to use.

150-µm (No. 100) .

Total

2. Referenced Documents

A

Designates U.S. Standard Sieve.

2.1 ASTM Standards:

E 11 Specification for Wire Cloth and Sieves for Testing

5.2 Sieve Shaker—A mechanically operated sieve shaker

Purposes

that produces a uniform rotary motion and tapping action with

140to160tapsperminute.Thesieveshakershallbefittedwith

3. Summary of Test Method

a hard maple plug to receive the impact of the tapping device.

3.1 A weighed sample of granular mineral surfacing mate-

The entire apparatus shall be rigidly mounted by bolting to a

rial is separated through a series of sieves of progressively

solid foundation, preferably concrete.

smaller openings for the determination of particle size distri-

5.3 Sample Splitter—A riffle sampler with 9.5 or 12.7-mm

bution.

3 1

( ⁄8 or ⁄2-in) divisions, for reducing the sample to the specimen

required for sieve analysis.

4. Significance and Use

5.4 Balance—A laboratory balance sensitive to 0.1 g.

4.1 This test method is used to determine the grading of

materials used as granular mineral surfacing. The results are

6. Sampling

used to determine compliance of the particle size distribution

6.1 Each shipment of mineral granules of a single type shall

with applicable specification requirements.

be considered a unit for sampling. If a shipment contains more

than one type of granule, the entire quantity of each type in the

5. Apparatus

vehicle shall be considered a unit for sampling.

5.1 Sieves—Aset of the sieves listed inTable 1, conforming

6.2 Take the sample of mineral granules shipped in bulk

to Specification E 11. For routine testing, the group of sieves

from the chute or conveyor while the vehicle is being loaded or

actually used shall include only those appropriate for the

unloaded.The ideal place is just where the material drops from

granular material being graded. Coarser or finer sieves, on

the chute or belt. Collect equal portions from the full width and

which less than 0.05 mass % of the specimen would be found

thickness of the stream at regular intervals with such frequency

after sieving, need not be included in the group.

thataminimumoffivesampleswillbetakenandthetotalmass

of the sample will not be less than 7.3 kg (16 lb). Do not allow

the sampling receptacle to overflow under any circumstances.

This test method is under the jurisdiction of ASTM Commi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.