ASTM F3090-20

(Test Method)Standard Test Method for Fatigue Testing of Acetabular Devices for Total Hip Replacement

Standard Test Method for Fatigue Testing of Acetabular Devices for Total Hip Replacement

SIGNIFICANCE AND USE

5.1 This in-vitro test method includes the use of cyclic forces to evaluate the fatigue strength of acetabular shells or monoblock acetabular devices used in THR.

5.2 Fracture or cracking of acetabular shells or monoblock acetabular devices in THR, although rare, does occur.

SCOPE

1.1 This test method is intended to evaluate the fatigue strength of metallic acetabular shells with hemispheric outer surfaces.

1.2 This test method, as described, is not intended to evaluate the following: the strength of components that may be mated with the acetabular shells (for example, augments, acetabular liners); attributes of the shells not related to strength (for example, fixation, coating adhesion); the strength of acetabular shell features away from, or loaded differently than, the primary load bearing region of the shell (for example, screws, spikes, flanges); non-hemispherical shells (for example, patient-matched geometries); or corrosion between modular components.

1.3 Modifications to this test method (for example, different support medium, different size/position of unsupported region, different testing environment) may result in a method appropriate to evaluate the characteristics listed in 1.2. Such modification must have adequate justification.

1.4 Although the methodology described does not replicate all physiological force conditions, it is a means of in vitro comparison of acetabular device designs under repeated forces.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3090 − 20

Standard Test Method for

Fatigue Testing of Acetabular Devices for Total Hip

1

Replacement

This standard is issued under the fixed designation F3090; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method is intended to evaluate the fatigue

strength of metallic acetabular shells with hemispheric outer

2. Referenced Documents

surfaces.

2

2.1 ASTM Standards:

1.2 This test method, as described, is not intended to

E4Practices for Force Verification of Testing Machines

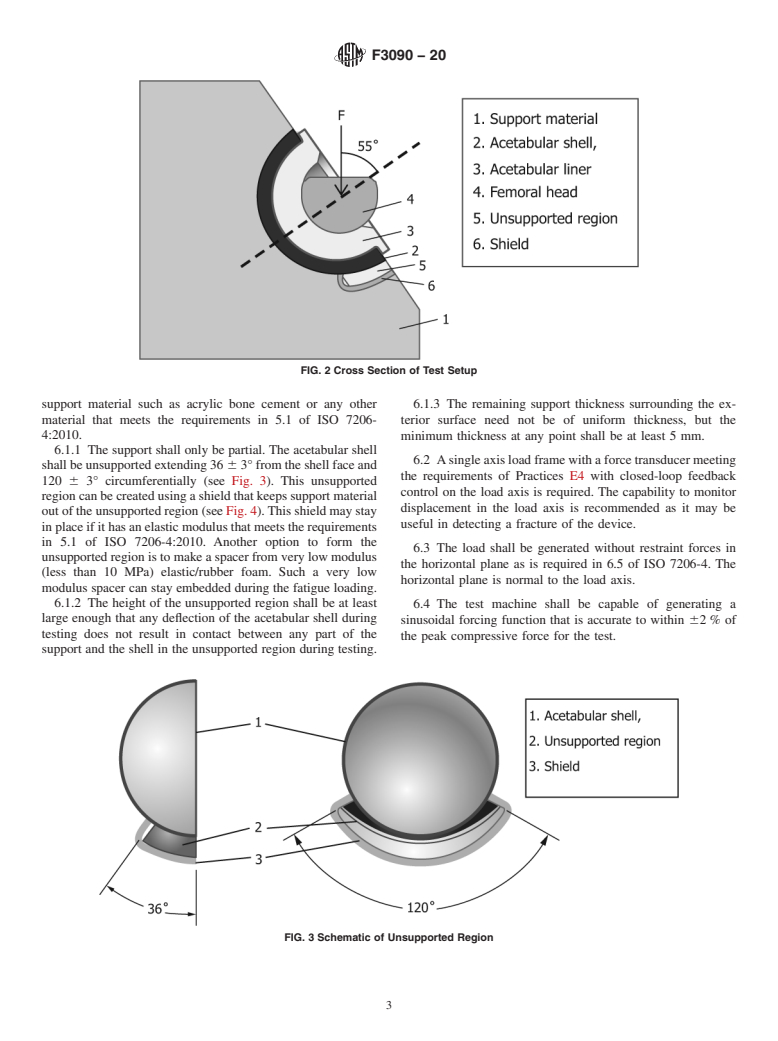

evaluatethefollowing:thestrengthofcomponentsthatmaybe

F1820Test Method for Determining the Forces for Disas-

mated with the acetabular shells (for example, augments,

sembly of Modular Acetabular Devices

acetabularliners);attributesoftheshellsnotrelatedtostrength

F2345Test Methods for Determination of Static and Cyclic

(for example, fixation, coating adhesion); the strength of

Fatigue Strength of Ceramic Modular Femoral Heads

3

acetabular shell features away from, or loaded differently than,

2.2 ISO Standards:

the primary load bearing region of the shell (for example,

ISO 4287 Geometrical Product Specifications (GPS)—

screws, spikes, flanges); non-hemispherical shells (for

Surface texture: Profile method—Terms, definitions and

example, patient-matched geometries); or corrosion between

surface texture parameters

modular components.

ISO 4288 Geometrical Product Specifications (GPS—

Surface texture: Profile method—Rules and procedures

1.3 Modificationstothistestmethod(forexample,different

for the assessment of surface texture

support medium, different size/position of unsupported region,

ISO 7206-4Implants for surgery—Partial and total hip joint

different testing environment) may result in a method appro-

prostheses—Part 4: Determination of endurance proper-

priate to evaluate the characteristics listed in 1.2. Such modi-

ties and performance of stemmed femoral components

fication must have adequate justification.

1.4 Although the methodology described does not replicate

3. Terminology

all physiological force conditions, it is a means of in vitro

3.1 Definitions of Terms Specific to This Standard:

comparisonofacetabulardevicedesignsunderrepeatedforces.

3.1.1 acetabular liner, n—portion of a modular acetabular

1.5 The values stated in SI units are to be regarded as

device with a concave spherical shape intended to articulate

standard. No other units of measurement are included in this

withtheheadofafemoralprosthesis;theexternalgeometryof

standard.

this component interfaces directly with the acetabular shell

through a locking mechanism which may be integral to the

1.6 This standard does not purport to address all of the

design of the liner and shell or may rely upon additional

safety concerns, if any, associated with its use. It is the

components or fixation methods (for example a metal ring or

responsibility of the user of this standard to establish appro-

bone cement).

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.1.2 acetabular shell, n—the metallic external, concave

1.7 This international standard was developed in accor-

structurethatmechanicallysupportstheacetabularliner,whose

dance with internationally recognized principles on standard-

external features interface with the bones of the pelvic socket

ization established in the Decision on Principles for the

(forexample,throughbonecement,intimatepress-fit,coatings

Development of International Standards, Guides and Recom-

forattachmenttobonecementortissue,integralscrewthreads,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF04onMedical contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

andSurgicalMaterialsandDevicesandisthedirectresponsibilityofSubcommittee Standards volume information, refer to the standard’s Document Summary page on

F04.22 on Arthroplasty. the ASTM website.

3

Current edition approved Oct. 1, 2020. Published November 2020. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/F3090-20. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.