ASTM D1720-96(2000)

(Test Method)Standard Test Method for Dilution Ratio of Active Solvents in Cellulose Nitrate Solutions

Standard Test Method for Dilution Ratio of Active Solvents in Cellulose Nitrate Solutions

SCOPE

1.1 This test method covers the determination of the volume ratio of hydrocarbon diluent to active solvent required to cause persistent heterogeneity (precipitation) in a solution of cellulose nitrate.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 6.

1.3 For hazard information and guidance, see the supplier's Material Safety Data Sheet.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1720 – 96 (Reapproved 2000)

Standard Test Method for

Dilution Ratio of Active Solvents in Cellulose Nitrate

Solutions

This standard is issued under the fixed designation D 1720; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the volume 4.1 By use of standard or reference grade materials for any

ratio of hydrocarbon diluent to active solvent required to cause two of the three components, namely, oxygenated solvent,

persistent heterogeneity (precipitation) in a solution of cellu- diluent, or cellulose nitrate, the effect of different batches or

lose nitrate. different types of the third component can be determined.

1.2 This standard does not purport to address all of the 4.2 This test method is applicable for the determination of

safety concerns, if any, associated with its use. It is the the following:

responsibility of the user of this standard to establish appro- 4.2.1 The dilution ratio of toluene as the standard diluent to

priate safety and health practices and determine the applica- an oxygenated solvent under test, using as the solute standard

bility of regulatory limitations prior to use. For specific hazard cellulose nitrate as defined in 5.2.

statements, see Section 6. 4.2.2 The dilution ratio of a hydrocarbon diluent under test

1.3 For hazard information and guidance, see the supplier’s to n-butyl acetate as the standard solvent, using as a solute

Material Safety Data Sheet. standard cellulose nitrate as defined in 5.2.

4.2.3 The dilution ratio of toluene, as the standard diluent, to

2. Referenced Documents

n-butyl acetate as the standard solvent, using as the solute

2.1 ASTM Standards: cellulose nitrate of varying solubility characteristics.

D 301 Test Methods for Soluble Cellulose Nitrate

5. Materials

D 841 Specification for Nitration Grade Toluene

D 4615 Specification for n-Butyl Acetate (All Grades) 5.1 n-Butyl Acetate (90 to 92 %), conforming to Specifi-

cation D 4615.

3. Terminology

NOTE 2—This grade of n-butyl acetate contains 8 to 10 % n-butyl

3.1 Definitions of Terms Specific to This Standard:

alcohol.

3.1.1 dilution ratio—the maximum number of unit volumes

5.2 Cellulose Nitrate, conforming to the Sampling section

of a diluent that can be added to a unit volume of solvent to

(Appearance, Ash, and Stability requirements) of Test Methods

cause the first persistent heterogeneity (precipitation) in the

D 301 and of such quality that, when used in determining the

solution at a concentration of 8 g cellulose nitrate per 100 mL

toluene dilution ratios of n-butyl acetate and methyl n-propyl

of combined solvent plus diluent and at a temperature of 25 6

ketone, it will give results between the following limits:

3°C.

Toluene Dilution Ratio

NOTE 1—The dilution ratio decreases as the cellulose nitrate concen-

n-butyl acetate 2.73 to 2.83

tration at the end point increases. It is, therefore, necessary to set an

methyl n-propyl ketone 3.80 to 3.90

arbitrary concentration of cellulose nitrate as part of the dilution ratio

term. For this purpose 8.0 g of cellulose nitrate per 100 mL of solvent plus

5.3 Toluene (Toluol), conforming to Specification D 841.

diluent has been adopted.

6. Hazards

6.1 Soluble cellulose nitrate is a flammable material, the

This test method is under the jurisdiction of ASTM Committee D01 on Paint

degree of flammability varying with the extent and nature of

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

the wetting medium. Cellulose nitrate is always wet with water

Current edition approved Nov. 10, 1996. Published January 1997. Originally

or alcohol in commercial handling, shipping, and storage, in

published as D 1720 – 60 T. Last previous edition D 1720 – 93.

2 which condition it presents no unusual hazard. Dry cellulose

Annual Book of ASTM Standards, Vol 06.03.

Annual Book of ASTM Standards, Vol 06.04. nitrate, if ignited by fire, spark, or static electricity, burns very

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 1720

TABLE 1 Volume of Solvent Required to Dissolve Cellulose

rapidly. Do not store samples of dry cellulose nitrate at any

Nitrate

time. Dry only that portion required for immediate test. Wear a

Probable Dilution Ratio, volume of mL of Solvent per5gof Cellulose

face shield when the oven is opened after samples have been

diluent:volume of solvent Nitrate at 25°C

heated. Wet excess material and the samples left after testing

1 25.0

with water and dispose of properly.

2 16.7

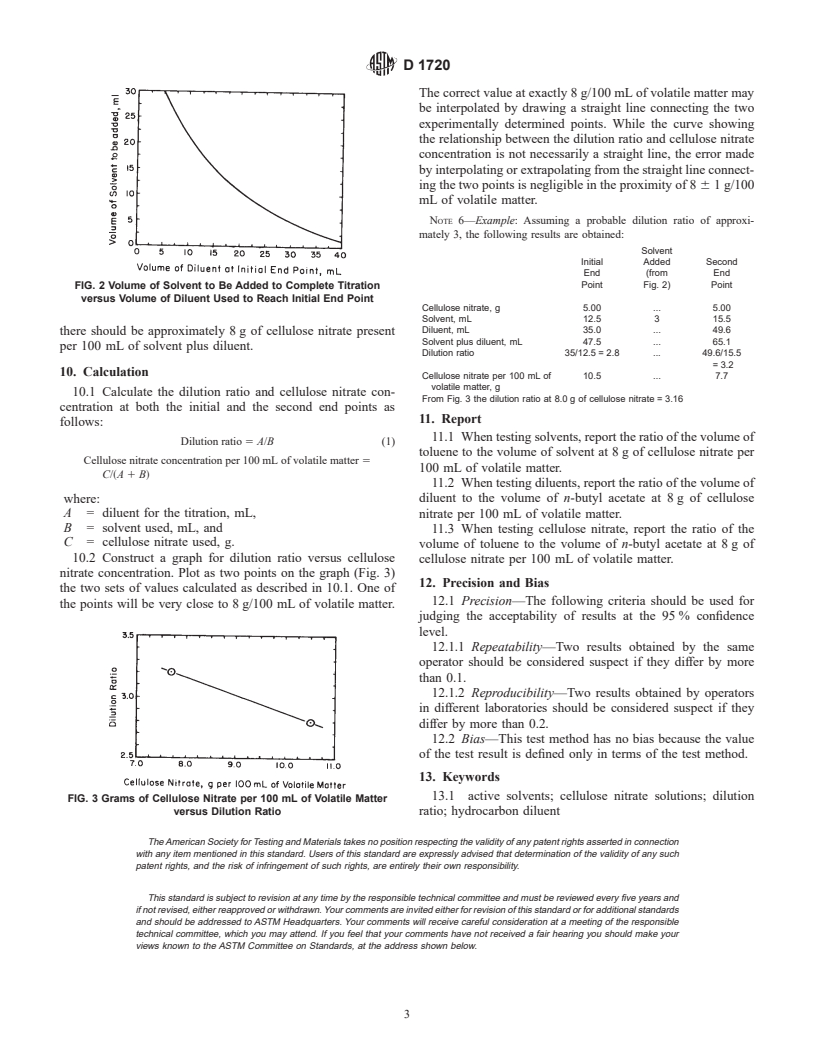

3 12.5

7. Drying Cellulose Nitrate

4 10.0

5 8.3

7.1 Dry not more than 20 g of cellulose nitrate at a time by

spreading in a thin layer on a tray at room temperature for 12

to 16 h, or on top of a 100°C oven where the temperature is 35

to 40°C for about 8 h (Warning, see 6.1). Alternatively, use a

8.2 On an analytical balance, weigh 5 6 0.01 g of the

steam or hot water-heated oven maintained at 45 to 50°C to dry

cellulose nitrate into a 125-mL cork-stoppered, preweighed

specimens in about 8 h. For safety reasons, the oven should

Erlenmeyer flask, or other suitable container. From a buret add

have the latch removed.

the volume of solvent indicated in Table 1. Swirl the flask until

7.2 Another simple way to dry small quantities of cellulose

the cellulose nitrate is completely dissolved. When a high

nitrate is to use a drier assembled from common laboratory

concentration of cellulose nitrate in solvent is required, disper-

apparatus. The assembled drier is shown in Fig. 1. Hot air from

sion may be more quickly accomplished by adding a measured

a laboratory electric oven is drawn through wet cellulose

portion of the diluent to the flask. This reduces the solids

nitrate contained in a brass tube hooked up through a thistle

concentration and thus lowers the viscosity of the solution,

tube, or small funnel, and suction flask to a water aspirator or

making it easier to dissolve the cellulose nitrate.

other vacuum source. The brass pipe should be about 40 mm in

diameter and 200 mm long, these relative dimensions having

9. Procedure

been found to give efficient results. Such a tube will hold about

9.1 Add the diluent, maintained at 25 6 3.0°C, to the flask

25 g, dry weight, of wet cellulose nitrate. The pipe is insulated

from a buret in small additions. Five-millilitre increments may

to conserve heat. The suction flask end of the brass tube is fitted

be added at first, bu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.