ASTM D4863-00

(Test Method)Standard Test Method for Determination of Lubricity of Two-Stroke-Cycle Gasoline Engine Lubricants

Standard Test Method for Determination of Lubricity of Two-Stroke-Cycle Gasoline Engine Lubricants

SCOPE

1.1 This test method evaluates the ability of lubricants to minimize piston and bore scuffing in two-stroke-cycle spark-ignition gasoline engines.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in SI units are the standard. Values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4863 – 00 An American National Standard

Standard Test Method for

Determination of Lubricity of Two-Stroke-Cycle Gasoline

Engine Lubricants

This standard is issued under the fixed designation D 4863; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 2896 Test Method for Base Number of Petroleum Prod-

ucts by Potentiometric Perchloric Acid Titration

1.1 This test method evaluates the ability of lubricants to

D 4857 Test Method for Determination of the Ability of

minimize piston and bore scuffing in two-stroke-cycle spark-

Lubricants to Minimize Ring Sticking and Piston Deposits

ignition gasoline engines.

in Two-Stroke-Cycle Gasoline Engines Other Than Out-

1.2 This standard does not purport to address all of the

boards

safety concerns, if any, associated with its use. It is the

D 4858 Test Method for Determination of the Tendency of

responsibility of the user of this standard to establish appro-

Lubricants to Promote Preignition in Two-Stroke-Cycle

priate safety and health practices and determine the applica-

Gasoline Engines

bility of regulatory limitations prior to use.

E 178 Practice for Dealing with Outlying Observations

1.3 The values stated in SI units are the standard. The values

2.2 Coordinating European Council (CEC) Standard

in parentheses are provided for information only.

CEC L-19-T-77 The Evaluation of the Lubricity of Two-

2. Referenced Documents

Stroke Engine Oils

2.1 ASTM Standards:

B 152 Specification for Copper Sheet, Strip, Plate, and

3. Terminology

Rolled Bar

4 3.1 Definitions:

D 439 Specification for Automotive Gasoline

3.1.1 combustion chamber—in reciprocating internal com-

D 445 Test Method for Kinematic Viscosity of Transparent

bustion engines, the volume bounded by the piston crown and

and Opaque Liquids (and the Calculation of Dynamic

any portion of the cylinder walls extending above the piston

Viscosity)

crown when in the top dead center position, and the inner

D 664 Test Method for Acid Number of Petroleum Products

surface of the cylinder head including any spark plugs and

by Potentiometric Titration

other inserted components. D 4858

D 874 Test Method for Sulfated Ash from Lubricating Oils

3.1.2 lubricity—a qualitative term describing the ability of a

and Additives

lubricant to minimize friction between and damage to surfaces

D 2270 Practice for Calculating Viscosity Index from Kine-

in relative motion under load.

matic Viscosity at 40° and 100°C

3.1.3 preignition—in a spark-ignition engine, ignition of

D 2700 Test Method for Knock Characteristics of Motor

6 the mixture of fuel and air in the combustion chamber before

Octane Number of Spark-Ignition Engine Fuel

the passage of the spark. D 4858

D 2885 Test Method for Research and Motor Octane Rat-

6 3.1.4 scuff, scuffıng—in lubrication, damage caused by

ings Using On-Line Analyzers

instantaneous localized welding between surfaces in relative

motion which does not result in immobilization of the parts.

3.1.5 spark plug fouling—deposition of essentially noncon-

This standard is under the jurisdiction of ASTM Committee D02 on Petroleum

Products and Lubricants and is the direct responsibility of Subcommittee D02.B on ducting material onto the electrodes of a spark plug that may,

Automotive Lubricants.

but will not necessarily, prevent the plug from operating.

Current edition approved Nov. 10, 2000. Published November 2000. Originally

D 4857

published as D 4863 – 88. Last previous edition D 4863 – 95.

Until the next revision of this test method, the ASTM Test Monitoring Center 3.1.6 spark plug whiskering, or spark plug bridging—a

will update changes in this test method by means of Information Letters. These can

deposit of conductive material on the spark plug electrodes

be obtained from the ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA

15206–4489. ATT: Administrator. This edition incorporates revisions in all Infor-

mation Letters through No. 00–2.

3 7

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 05.02.

4 8

Discontinued; see 1990 Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 14.02.

5 9

Annual Book of ASTM Standards, Vol 05.01. Order from the Coordinating European Council, 61 New Cavendish Street,

Annual Book of ASTM Standards, Vol 05.05. London W1M 8AR, England.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4863

of available models with the manufacturer.

which tends to form a bridge between them, thus shorting out

the plug. D 4857

6.1.2 Adjustment of Piston Clearance— For the purposes of

3.2 Definitions of Terms Specific to This Standard:

this test method, the cylinder bore shall be honed to give a 0.10

to 0.13 mm (0.004 to 0.005 in.) piston skirt diametral clearance

3.2.1 benchmark reference oil—a reference oil that repre-

sents an acceptable level of performance with regard to the with a 0.45 to 0.7 μm (18 to 28 μin.) arithmetic mean roughness

finish, as specified in A3.4. It is recommended that a number of

property evaluated in an engine test and whose performance in

the test is equaled, within the tolerance allowed, or exceeded cylinders be honed out as it is normally necessary to use a new

piston for each test and a new cylinder after every three tests.

by that of the non-reference oil.

The modified cylinders shall be clearly marked as such.

4. Summary of Test Method (1) The power and specific fuel consumption curves at 500

r/min intervals over the range from 3000 to 6000 r/min.

4.1 The test has been developed to replace the CEC L-19-

(2) The spark plug gasket temperatures for each point of the

T-77 Lubricity Test, for which test engines are no longer

3 power curve.

available. It is run in a 49 cm single-cylinder air-cooled

(3) Modified piston clearance, with measurements of the

two-stroke-cycle engine operated at 4000 r/min wide open

piston and cylinder bore dimensions. Additional modified

throttle (WOT) using a 150:1 mixture of gasoline and oil by

piston and cylinder assemblies can also be supplied.

volume. After conditions have stabilized, the cooling air is cut

(4) Measurements of the piston rings, ring grooves, ring

off. The output torque is measured when the spark plug gasket

clearances, and ring gaps.

temperature reaches 200°C (392°F) and again when it reaches

6.2 Test Stand—The dynamometer shall be able to absorb

350°C (662°F), at which point the cooling air is restored. The

2.5 kW (3.3 hp) at 4000 r/min with an inherent torque

smaller the reduction in torque output during this period, the

measurement accuracy of 60.5 % or better, and be capable of

better the ability of the oil to lubricate the piston. This test is

maintaining 4000 6 30 r/min with varying power input. A

not normally damaging to the engine. Sets of five such

direct shaft drive or a belt drive from the engine crankshaft

tightenings are normally run, using alternately a benchmark

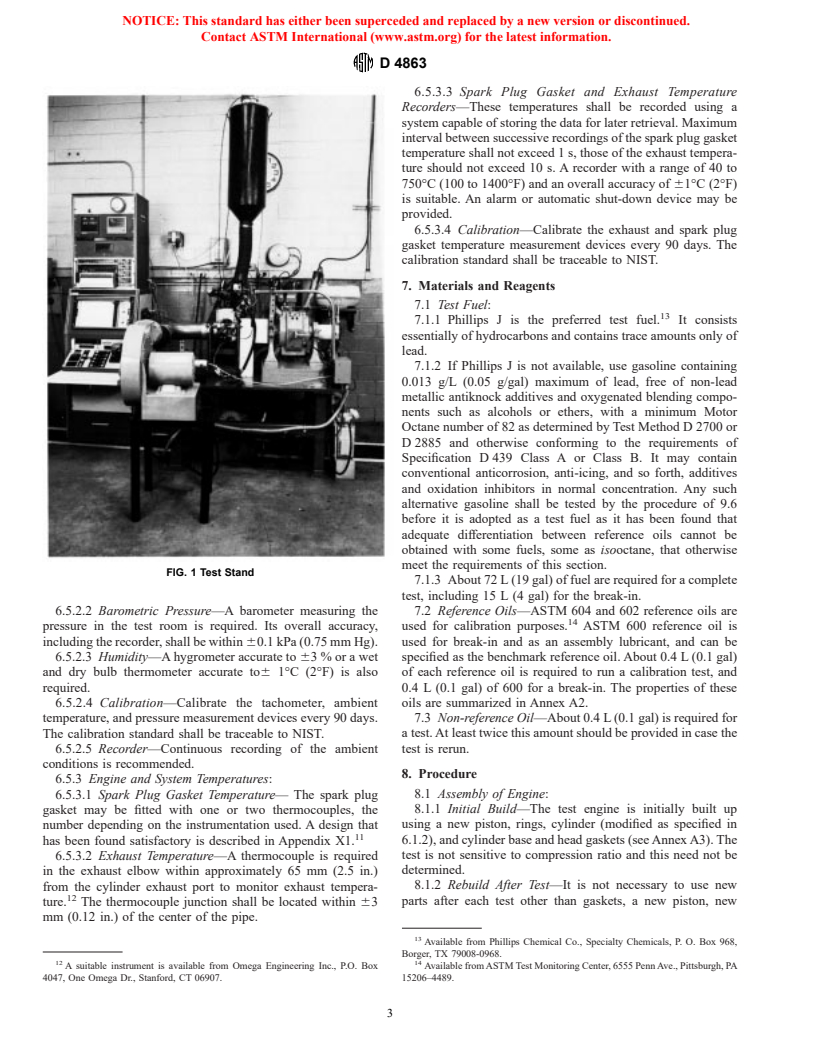

may be used. A complete test stand assembly, as shown in Fig.

reference oil and the non-reference oil for each set.

1, is available.

NOTE 1—Pass-fail Criterion—The mean torque drop obtained with a

6.3 Cooling Blower—The original internal engine fan shall

candidate oil shall be the same or less than that with the reference oil as

be removed or have its blades machined off. A variable

calculated by the procedures of Annex A4. 3

delivery blower with a free flow capacity of about 34 m /min

(1200 ft /min) of air is recommended. The flow from the

5. Significance and Use

blower shall be directed toward the intake side of the engine, as

5.1 The oil in a two-stroke-cycle gasoline engine is either

may be seen in Fig. 1.

mixed with the fuel prior to use or is metered into the fuel

6.4 Fuel System—Quick disconnects or other means to

supply at, or at some point prior to, its passage into the engine

facilitate rapid interchange of fuel supply shall be provided as

crankcase. The possibility of the amount of oil actually present

near to the carburetor as practicable. When local regulations

in the engine being less than optimum always exists. Also, with

permit their use, outboard portable fuel tanks of about 20 to 25

some oil metering systems short periods of operation with less

L (5 to 6 gal) capacity and flexible fuel hoses are suitable. In

oil than desirable can occur when the power is increased

any case three fuel sources will be needed for a test, one for the

suddenly. It has also been found that the incidence of piston

non-reference oil fuel mix, one for the reference oil fuel mix,

scuff early in the life of the engine may be related to the

and one supplying test gasoline only with no oil. The tempera-

lubricity of the oil used as defined by test procedures of this

ture of the fuel entering the carburetor shall not exceed 25°C

type.

(77°F), and this may require cooling in hot climates.

6.5 Instrumentation:

6. Apparatus

6.5.1 Tachometer—An electronic or vibration tachometer

accurate to 625 r/min.

6.1 Test Engine and Stand:

6.5.2 Measurement of Ambient Conditions— It is assumed

6.1.1 Test Engine Configuration—A Yamaha CE-50 49 cm

in this section that the engine draws ambient air from the test

loop-scavenged air-cooled two-stroke-cycle engine is used.

room. If it is supplied with air from a controlled source,

This has 40 mm (1.57 in.) bore, 39.2 mm (1.54 in.) stroke, with

references to ambient temperature, pressure and humidity

an aluminum piston operating in a cast iron cylinder bore. The

apply to the air from the controlled source.

cylinder head is removable, with a hemispherical combustion

6.5.2.1 Temperature—A thermocouple or thermometer shall

chamber. Further details are given in Annex A1. For the

be provided to read air temperature in the range 10 to 50°C (50

purposes of this test the standard piston-to-bore clearance is

to 120°F). The overall accuracy of temperature measurement,

increased as specified in 6.1.2. The engine is no longer

including that of recorders, shall be within 61°C (2°F).

produced. Small quantities of parts can be obtained through

Yamaha dealers. Special arrangements must be made through

Yamaha for the production of large quantities of test parts.

Obtainable from Engineering and Service Dept., Yamaha International Corp.,

P.O. Box 6555, Cypress, CA 90630. Parts, but not complete engines, are obtainable

NOTE 2—The engine designation normally includes a final letter

from Yamaha motorcycle dealers.

indicating the model, such as CE-50S, the model on which this test was

A thermocouple gasket that has been found satisfactory may be obtained from

developed. If this model is not available check the suitability for this test Lewis Engineering, 238-T Water St., Naugatuck, CT 06770.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4863

6.5.3.3 Spark Plug Gasket and Exhaust Temperature

Recorders—These temperatures shall be recorded using a

system capable of storing the data for later retrieval. Maximum

interval between successive recordings of the spark plug gasket

temperature shall not exceed 1 s, those of the exhaust tempera-

ture should not exceed 10 s. A recorder with a range of 40 to

750°C (100 to 1400°F) and an overall accuracy of 61°C (2°F)

is suitable. An alarm or automatic shut-down device may be

provided.

6.5.3.4 Calibration—Calibrate the exhaust and spark plug

gasket temperature measurement devices every 90 days. The

calibration standard shall be traceable to NIST.

7. Materials and Reagents

7.1 Test Fuel:

7.1.1 Phillips J is the preferred test fuel. It consists

essentially of hydrocarbons and contains trace amounts only of

lead.

7.1.2 If Phillips J is not available, use gasoline containing

0.013 g/L (0.05 g/gal) maximum of lead, free of non-lead

metallic antiknock additives and oxygenated blending compo-

nents such as alcohols or ethers, with a minimum Motor

Octane number of 82 as determined by Test Method D 2700 or

D 2885 and otherwise conforming to the requirements of

Specification D 439 Class A or Class B. It may contain

conventional anticorrosion, anti-icing, and so forth, additives

and oxidation inhibitors in normal concentration. Any such

alternative gasoline shall be tested by the procedure of 9.6

before it is adopted as a test fuel as it has been found that

adequate differentiation between reference oils cannot be

obtained with some fuels, some as isooctane, that otherwise

meet the requirements of this section.

FIG. 1 Test Stand

7.1.3 About 72 L (19 gal) of fuel are required for a complete

test, including 15 L (4 gal) for the break-in.

6.5.2.2 Barometric Pressure—A barometer measuring the 7.2 Reference Oils—ASTM 604 and 602 reference oils are

pressure in the test room is required. Its overall accuracy, used for calibration purposes. ASTM 600 reference oil is

including the recorder, shall be within 60.1 kPa (0.75 mm Hg). used for break-in and as an assembly lubricant, and can be

6.5.2.3 Humidity—A hygrometer accurate to 63 % or a wet specified as the benchmark reference oil. About 0.4 L (0.1 gal)

and dry bulb thermometer accurate to6 1°C (2°F) is also of each reference oil is required to run a calibration test, and

required. 0.4 L (0.1 gal) of 600 for a break-in. The properties of these

6.5.2.4 Calibration—Calibrate the tachometer, ambient oils are summarized in Annex A2.

temperature, and pressure measurement devices every 90 days. 7.3 Non-reference Oil—About 0.4 L (0.1 gal) is required for

The calibration standard shall be traceable to NIST. a test. At least twice this amount should be provided in case the

6.5.2.5 Recorder—Continuous recording of the ambient test is rerun.

conditions is recommended.

8. Procedure

6.5.3 Engine and System Temperatures:

8.1 Assembly of Engine:

6.5.3.1 Spark Plug Gasket Temperature— The spark plug

8.1.1 Initial Build—The test engine is initially built up

gasket may be fitted with one or two thermocouples, the

number depending on the instrumentation used. A design that using a new piston, rings, cylinder (modified as specified in

6.1.2), and cylinder base and head gaskets (see Annex A3). The

has been found satisfactory is described in Appendix X1.

6.5.3.2 Exhaust Temperature

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.