ASTM B42-02e1

(Specification)Standard Specification for Seamless Copper Pipe, Standard Sizes

Standard Specification for Seamless Copper Pipe, Standard Sizes

ABSTRACT

This specification covers seamless copper pipe in all nominal standard pipe sizes, both regular and extra-strong, suitable for use in plumbing, boiler feed lines, and for similar purposes. The material shall conform to the specified chemical requirements. The pipe shall be produced from one of C10200, C10300, C10800, C12000, and C12200 copper UNS numbers. All pipes shall normally be furnished in the prescribed annealed, light drawn, or hard drawn temper. The pipe shall be made from copper that is free of cuprous oxide, as determined by microscopical examination. The pipe shall be subjected to expansion or flattening, Eddy-current, and hydrostatic tests. Samples for chemical analysis shall be taken in accordance with Practice E255. However, the manufacturer shall have the option of determining conformance by analyzing samples taken at the time the castings are poured or from the semifinished product, subject to the conditions set in the specification.

SCOPE

1.1 This specification covers seamless copper pipe in all nominal or standard pipe sizes, both regular and extra-strong, suitable for use in plumbing, boiler feed lines, and for similar purposes.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: B42 – 02

Standard Specification for

1

Seamless Copper Pipe, Standard Sizes

This standard is issued under the fixed designation B42; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Referenced Documents were editorially corrected in November 2003.

1. Scope* E62 Test Methods for Chemical Analysis of Copper and

2 Copper Alloys (Photometric Methods)

1.1 This specification covers seamless copper pipe in all

E243 Practice for Electromagnetic (Eddy-Current) Exami-

nominal or standard pipe sizes, both regular and extra-strong,

nation of Copper and Copper-Alloy Tubes

suitable for use in plumbing, boiler feed lines, and for similar

3

E255 Practice for Sampling Copper and Copper Alloys for

purposes.

the Determination of Chemical Composition

1.2 The values stated in inch-pound units are to be regarded

E478 TestMethodsforChemicalAnalysisofCopperAlloys

as the standard. The values given in parentheses are provided

E527 Practice for Numbering Metals and Alloys in the

for information purposes only.

Unified Numbering System (UNS)

2. Referenced Documents

3. Terminology

2.1 The following documents of the issue in effect on date

3.1 Definitions:

of material purchase form a part of this specification to the

3.1.1 lengths—straight pieces of the product.

extent referenced herein:

4

3.1.1.1 standard—uniform lengths recommended in a Sim-

2.2 ASTM Standards:

plified Practice Recommendation or established as a Commer-

B153 Test Method for Expansion (Pin Test) of Copper and

cial Standard.

Copper-Alloy Pipe and Tubing

3.1.2 tube, seamless—a tube produced with a continuous

B170 Specification for Oxygen-Free Electrolytic Copper—

periphery in all stages of the operations.

Refinery Shapes

3.1.2.1 pipe—a seamless tube conforming to the particular

B601 Classification for Temper Designations for Copper

dimensions commercially known as Nominal or Standard Pipe

and Copper Alloys—Wrought and Cast

Sizes.

E8 Test Methods for Tension Testing of Metallic Materials

3.2 Definitions of Terms Specific to This Standard:

E29 Practice for Using Significant Digits in Test Data to

3.2.1 capable of—as used in this specification, the test need

Determine Conformance with Specifications

not be performed by the producer of the material. However,

E53 Test Method for Determination of Copper in Unalloyed

should subsequent testing by the purchaser establish that the

Copper by Gravimetry

material does not meet these requirements the material shall be

subject to rejection.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4. Ordering Information

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

4.1 Orders for material under this specification shall include

Current edition approved Nov. 10, 2003. Published June 2002. Originally

the following information:

published as B42 – 22 T. Last previous edition B42 – 98. DOI: 10.1520/B0042-

4.1.1 Type of copper, if required,

02E01.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- 4.1.2 Temper (see 6.1),

cation SB-42 in Section II of that Code.

4.1.3 Pipe size, regular or extra-strong, (see 10.2),

3

The UNS system for copper and copper alloys (see Practice E527) is a simple

4.1.4 Length (see 10.3),

expansion of the former standard designation system accomplished by the addition

4.1.5 Total length of each size,

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate

composition variations of the base alloy.

4.1.6 If material is required to meet ASME Boiler and

4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Pressure Vessel Code,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.7 Certification, if required (see 18.1),

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.1.8 Mill test report, if required (see 20.1),

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

B42–02

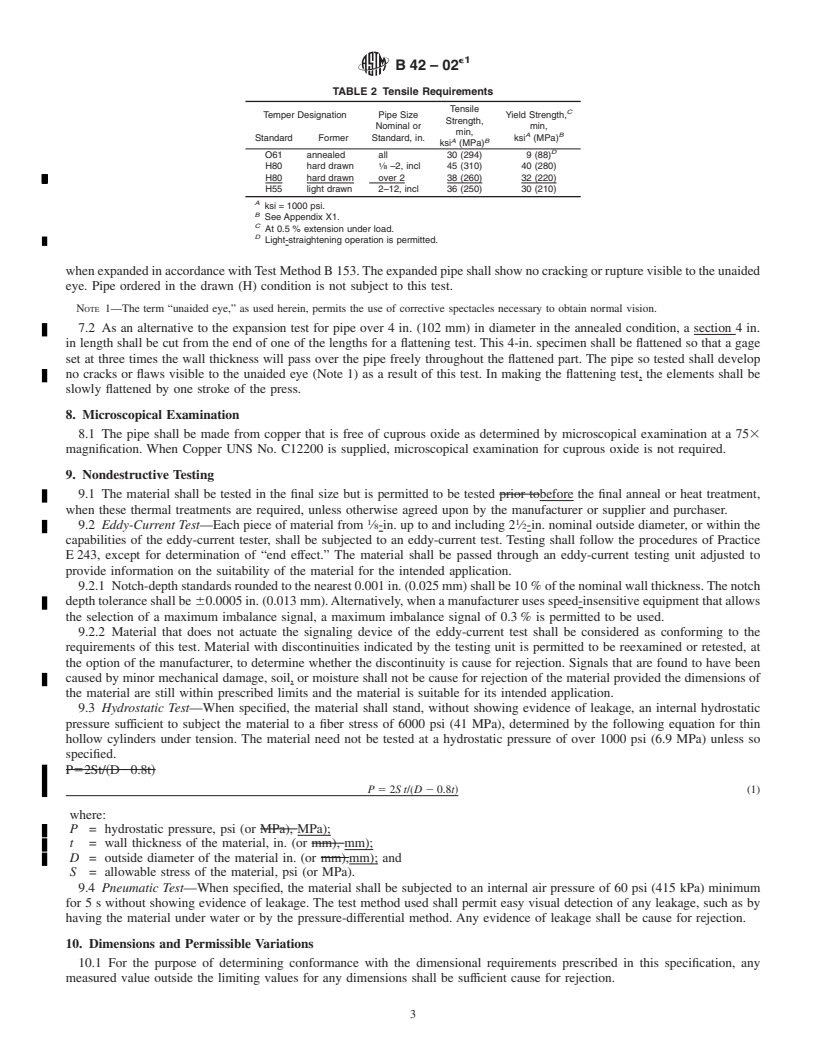

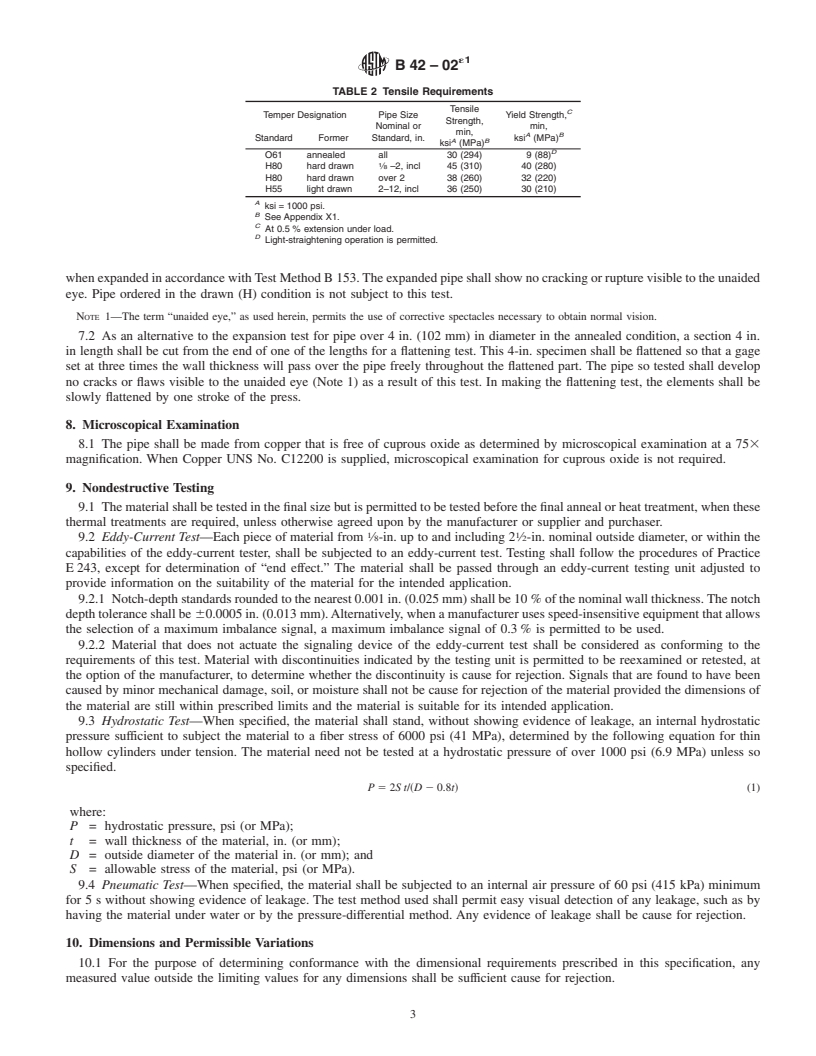

TABLE 2 Tensile Requirements

4.1.9 Hydrostatic test, if required, and

4.1.10 Pneumatic test, if required. Tensile

C

Temper Designation Pipe Size Yield Strength,

Strength,

4.2 In addition, when material is purchased for agencies of

Nominal or min,

min,

A B

Standard Former Standard, in. ksi (MPa)

the U.S. Government, it shall conform to the Supplementary A B

ksi (MPa)

D

Requirements

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:B42–96 Designation: B 42 – 02

Standard Specification for

1

Seamless Copper Pipe, Standard Sizes

ThisstandardisissuedunderthefixeddesignationB 42;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Referenced Documents were editorially corrected in November 2003.

1. Scope*

2

1.1 This specification covers seamless copper pipe in all nominal or standard pipe sizes, both regular and extra-strong, suitable

3

for use in plumbing, boiler feed lines, and for similar purposes.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for

information purposes only.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

4

B 153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

4

B 170 Specification for Oxygen-Free Electrolytic Copper—Refinery Shapes

4

B 601 Practice for Temper Designations for Copper and Copper Alloys—Wrought and Cast

5

E 8 Test Methods for Tension Testing of Metallic Materials

6

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53Test Methods for Chemical Analysis of Copper

7

E 53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

7

E55Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition

7

E62Test Methods for ChemicalAnalysis of Copper and CopperAlloys (Photometric Methods) 62 Test Methods for Chemical

7

Analysis of Copper and Copper Alloys (Photometric Method)

8

E 243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

7

E478Test Methods for Chemical Analysis of Copper Alloys

7

E 255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

7

E 478 Test Methods for Chemical Analysis of Copper Alloys

9

E 527 Practice for Numbering Metals and Alloys (UNS)

3. Terminology

3.1 Definitions:

3.1.1 lengths—straight pieces of the product.

3.1.1.1 standard—uniform lengths recommended in a Simplified Practice Recommendation or established as a Commercial

Standard.

3.1.2 tube, seamless— a tube produced with a continuous periphery in all stages of the operations.

1

This specification is under the jurisdiction ofASTM Committee B-5B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

Current edition approved AprilApr. 10, 1996.2002. Published June 1996.2002. Originally published as B 42 – 22 T. Last previous edition B 42 – 938.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SB-42 in Section II of that Code.

3

The UNS system for copper and copper alloys (see Practice E 527) is a simple expansion of the former standard designation system accomplished by the addition of

a prefix “C” and a suffix “00.” The suffix can be used to accommodate composition variations of the base alloy.

4

Annual Book of ASTM Standards, Vol 02.01.

5

Annual Book of ASTM Standards, Vol 03.01.

6

Annual Book of ASTM Standards, Vol 14.02.

7

Annual Book of ASTM Standards, Vol 03.05.

8

Annual Book of ASTM Standards, Vol 03.03.

9

Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

B42–02

3.1.2.1 pipe—aseamlesstubeconformingtotheparticulardimensionscommerciallyknownasNominalorStandardPipeSizes.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 capable of—as used in this specification, the test need not be performed by the producer of the material. However, should

subsequent testing by the purchaser establish that the material does not meet these requirements the material shall be subject to

rejection.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Type of copper, if required,

4.1.2 Temper (see 6.1),

4.1.3 Pipe size, regular or extra-strong, (see 10.2),

4.1.4 Length (see 10.3),

4.1.5

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:B42–02 Designation: B 42 – 02

Standard Specification for

1

Seamless Copper Pipe, Standard Sizes

ThisstandardisissuedunderthefixeddesignationB 42;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Referenced Documents were editorially corrected in November 2003.

1. Scope*

2

1.1 This specification covers seamless copper pipe in all nominal or standard pipe sizes, both regular and extra-strong, suitable

3

for use in plumbing, boiler feed lines, and for similar purposes.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for

information purposes only.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

4

B 153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

4

B 170 Specification for Oxygen-Free Electrolytic Copper—Refinery Shapes

4

B 601 Practice for Temper Designations for Copper and Copper Alloys—Wrought and Cast

5

E8 Test Methods for Tension Testing of Metallic Materials

6

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

7

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry E55Practice for Sampling Wrought

Nonferrous Metals andAlloys for De-

termination of Chemical Composi-

7

tion

7

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Method)

8

E 243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

7

E 255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

7

E 478 Test Methods for Chemical Analysis of Copper Alloys

9

E 527 Practice for Numbering Metals and Alloys (UNS)

3. Terminology

3.1 Definitions:

3.1.1 lengths—straight pieces of the product.

3.1.1.1 standard—uniform lengths recommended in a Simplified Practice Recommendation or established as a Commercial

Standard.

3.1.2 tube, seamless— a tube produced with a continuous periphery in all stages of the operations.

3.1.2.1 pipe—aseamlesstubeconformingtotheparticulardimensionscommerciallyknownasNominalorStandardPipeSizes.

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Apr. 10, 2002. Published June 2002. Originally published as B 42 – 22 T. Last previous edition B 42 – 98.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SB-42 in Section II of that Code.

3

The UNS system for copper and copper alloys (see Practice E 527) is a simple expansion of the former standard designation system accomplished by the addition of

a prefix “C” and a suffix “00.” The suffix can be used to accommodate composition variations of the base alloy.

4

Annual Book of ASTM Standards, Vol 02.01.

5

Annual Book of ASTM Standards, Vol 03.01.

6

Annual Book of ASTM Standards, Vol 14.02.

7

Annual Book of ASTM Standards, Vol 03.05.

8

Annual Book of ASTM Standards, Vol 03.03.

9

Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

B42–02

3.2 Definitions of Terms Specific to This Standard:

3.2.1 capable of—as used in this specification, the test need not be performed by the producer of the material. However, should

subsequent testing by the purchaser establish that the material does not meet these requirements the material shall be subject to

rejection.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Type of copper, if required,

4.1.2 Temper (see 6.1),

4.1.3 Pipe size, regular or extra-strong, (see 10.2),

4.1.4 Length (see 10.3),

4.1.5 Total length of each size,

4.1.6 If material is required to meet ASME Boiler and Pressure Vessel Code,

4.1.7 Certification, if required (see 18.1),

4.1.8 Mill test report, if required (see 20.1),

4.1.9 Hydrostati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.