ASTM B687-99(2023)

(Specification)Standard Specification for Brass, Copper, and Chromium-Plated Pipe Nipples

Standard Specification for Brass, Copper, and Chromium-Plated Pipe Nipples

ABSTRACT

This specification establishes the requirements for brass and copper pipe nipples within a specified size range. Chromium-plated pipe nipples covered by this specification are intended for use in the interior of decorative appliances. Both brass and copper pipe nipples should be produced from regular or extra strong pipes while chromium-plated pipe nipples are produced from regular weight brass pipes. All pipe nipples should be threaded in both ends with NPT Taper Pipe Threads except for close nipples with lengths shorter than the specified value. Threads should be right hand on both ends except when otherwise specified. Chromium plated nipples use short plumbing (hospital) threads. Pipe nipple ends shall be cut reasonable square to the central axis and chamfered on the outside with all outside burrs removed.

SCOPE

1.1 This specification establishes the requirements for brass and copper pipe nipples in standard pipe sizes from 1/8 to 8 in., inclusive, in standard lengths, and chromium-plated pipe nipples in standard pipe sizes from 1/8 to 2 in., inclusive, in standard lengths.

1.1.1 Chromium-plated pipe nipples ordered under this specification are intended for interior use in decorative applications.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B687 − 99 (Reapproved 2023)

Standard Specification for

Brass, Copper, and Chromium-Plated Pipe Nipples

This standard is issued under the fixed designation B687; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope B846 Terminology for Copper and Copper Alloys

E29 Practice for Using Significant Digits in Test Data to

1.1 This specification establishes the requirements for brass

Determine Conformance with Specifications

and copper pipe nipples in standard pipe sizes from ⁄8 to 8 in.,

inclusive, in standard lengths, and chromium-plated pipe 2.2 ANSI/ASME Standard:

nipples in standard pipe sizes from ⁄8 to 2 in., inclusive, in B1.20.1 Pipe Threads, General Purpose (Inch)

standard lengths.

2.3 Military Standard:

1.1.1 Chromium-plated pipe nipples ordered under this

MIL-STD-105 Sampling Procedures and Tables for Inspec-

specification are intended for interior use in decorative appli- 4

tion by Attributes

cations.

1.2 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

3.1 Definitions:

conversions to SI units that are provided for information only

3.1.1 For definitions of terms relating to copper and copper

and are not considered standard.

alloys, refer to Terminology B846.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Ordering Information

responsibility of the user of this standard to establish appro-

4.1 Contracts and purchase orders for product under this

priate safety, health, and environmental practices and deter-

specification are to contain the following information:

mine the applicability of regulatory limitations prior to use.

4.1.1 ASTM specification designation and year of issue,

1.4 This international standard was developed in accor-

4.1.2 Type of material (Section 5),

dance with internationally recognized principles on standard-

4.1.3 Weight of material; regular or extra strong,

ization established in the Decision on Principles for the

4.1.4 Diameter; nominal or actual outside diameter,

Development of International Standards, Guides and Recom-

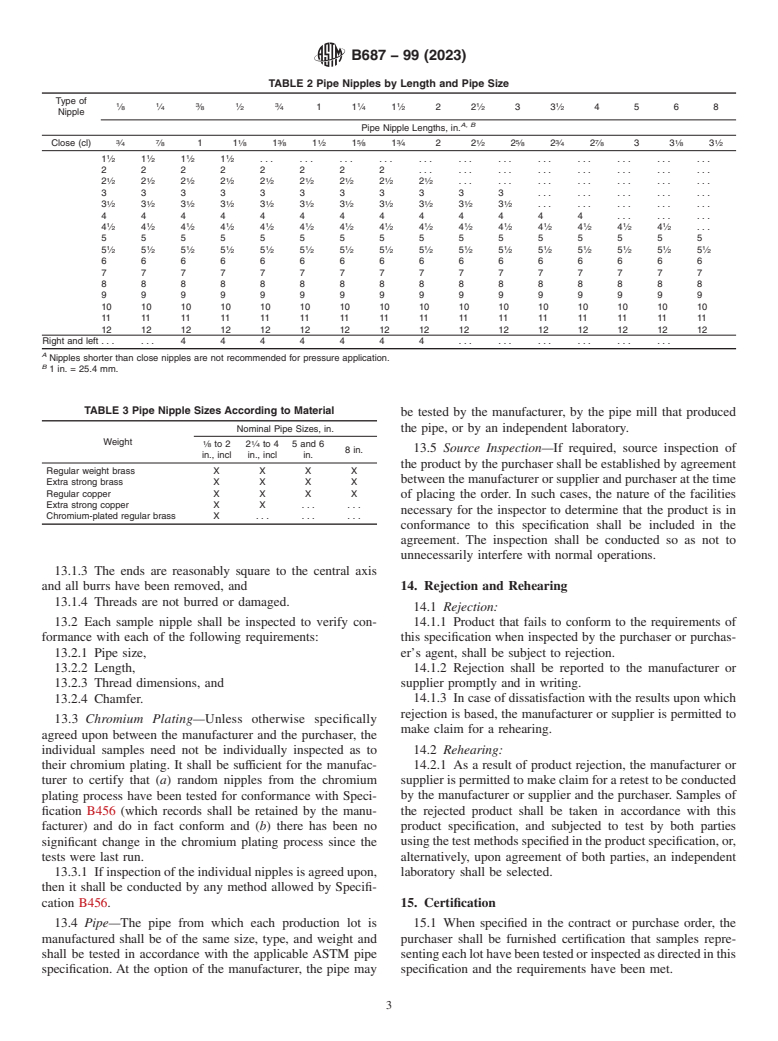

4.1.5 Length; standard or special (8.2 and Table 2), and

mendations issued by the World Trade Organization Technical

4.1.6 Quantity; number of pieces or total weight of each

Barriers to Trade (TBT) Committee.

material and size.

2. Referenced Documents

4.2 The following options are available under this specifi-

cation and are to be specified in the contract or purchase order

2.1 ASTM Standards:

when required:

B42 Specification for Seamless Copper Pipe, Standard Sizes

4.2.1 Chromium plated finish,

B43 Specification for Seamless Red Brass Pipe, Standard

4.2.2 Short Plumbing (hospital) threads,

Sizes

4.2.3 Certification (Section 16), and

B456 Specification for Electrodeposited Coatings of Copper

4.2.4 Test and Inspection Reports, if required (Section 17).

Plus Nickel Plus Chromium and Nickel Plus Chromium

4.3 In addition, when material is purchased for agencies of

the U.S. government, it shall conform to the supplementary

This specification is under the jurisdiction of ASTM Committee B05 on Copper

requirements as defined herein when specified in the contract

and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe

or purchase order.

and Tube.

Current edition approved April 15, 2023. Published April 2023. Originally

approved in 1981. Last previous edition approved in 2016 as B687 – 99 (2016).

DOI: 10.1520/B0687-99R23.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B687 − 99 (2023)

A, B

TABLE 1 Short Plumbing (Hospital) Threads

threads. All other dimensions, tolerances, and gaging practices

remain the same as ANSI B1.20.1, and the Annex.

NOTE 1—Short plumbing (hospital) threads are normally used only on

chromium-plated nipples. The purpose of such threads is that a minimum 8.2.1.1 Threads shall be right hand on both ends, except

of thread shall remain exposed after the nipple is screwed into a fitting.

when otherwise specified.

Overall External

Nominal Outside Threads 8.2.2 Threads, Chromium-Plated Nipples—Threads on

Thread Length, L

Pipe Size, Diameter per in., 4

chromium-plated nipples shall be gaged after plating. Threads

NPS of Pipe, D N

Inches Threads

on ⁄8 in. to 1 in. standard pipe size nipples shall be NPT Taper

⁄8 0.405 27 0.26 7

Pipe Threads, in accordance with 8.2.1. Threads on 1 ⁄4 in. to

⁄4 0.540 18 0.33 6

3 2 in. standard pipe size nipples shall be short plumbing

⁄8 0.675 18 0.33 6

⁄2 0.840 14 0.43 6

(hospital) threads, in accordance with Table 1. On ⁄8 in. to 1 in.

⁄4 1.050 14 0.43 6

standard pipe size nipples, short plumbing (hospital) threads, if

1 1.315 11 ⁄2 0.52 6

1 1

specified, shall be in accordance with Table 1.

1 ⁄4 1.660 11 ⁄2 0.52 6

1 1

1 ⁄2 1.900 11 ⁄2 0.52 6

2 2.375 11 ⁄2 0.52 6

9. Workmanship, Finish, and Appearance

A

All dimensions, except threads per inch, in inches.

B

9.1 End Finish—The ends of the pipe nipples shall be

This table represents a modification of Table 2 of ANSI B1.20.1; L is modified as

shown. E , L , and V are modified accordingly. The threads shall meet the gaging

2 2 chamfered on the outside at an angle of 35° 6 10° to the

requirements of Sections 6 and 11 of this specification.

central axis. (It is standard practice that the ⁄8 in. nominal size

nipples need not be chamfered.) Ends shall be cut reasonably

square to the central axis. All burrs on the outside shall be

5. Materials and Manufacture

removed.

5.1 Copper pipe nipples shall be produced from regular or

9.2 Chromium Plating—Chromium plate on brass nipples

extra strong pipe conforming to the requirements of Specifi-

shall meet the requirements of service condition SC I of

cation B42.

Specification B456, except the equivalent nickel thickness

shall be 0.003 mm.

5.2 Brass pipe nipples shall be produced from regular or

extra strong pipe conforming to the requirements of Specifi-

10. Sampling

cation B43.

10.1 A random sample of pipe nipples shall be selected from

5.3 Chromium-plated pipe nipples shall be produced from

one production lot in accordance with MIL-STD-105 at In-

regular weight brass pipe conforming to the requirements of

spection Level II. In terms of defects per 100 units, the

Specification B43.

Acceptable Quality Level (AQL) shall be 1.5.

10.1.1 Production Lot—A production lot shall be as deter-

6. Chemical Composition

mined by the manufacturer, provided that all of the pipe used

6.1 The chemical composition shall conform to the require-

in a single production lot shall comply with the provisions of

ments of the specification under which the pipe was ordered.

Section 5 and all of the nipples shall be of the same size,

length, type, weight, finish, and thread form.

7. Temper

7.1 The product temper and its properties and characteristics

11. Number of Tests and Retests

shall conform to the requirements of the specification under

11.1 Allowances for resampling and retesting shall be in

which the pipe was ordered.

accordance with the Inspection Level and Acceptable Quality

8. Dimensions, Mass and Permissible Variations

Levels detailed in 10.1.

8.1 Lengths:

12. Significance of Numerical Limits

8.1.1 The standard lengths and sizes of nipples generally

available are shown in Table 2. The availability of such nipples

12.1 For the purpose of determining compliance with the

indicated by pipe size are shown in Table 3.

specified limits for the requirements listed in the following

8.1.2 Special lengths and sizes of nipples are permitted to be

table, an observed value shall be rounded as indicated in

specified when required. Standard and special lengths shall accordance with the rounding method of Practice E29:

conform to the tolerance requirements of 8.1.3.

Rounded Unit for

Property Observed or Calculated Value

8.1.3 Tolerances—Nipples with lengths up through 12 in.

(305 mm) long shall have a length tolerance of 6 ⁄16 in.

Linear Dimensions nearest unit in the last right-hand significant

(1.6 mm). Nipples over 12 in. long shall have a tolerance of

Tolerances digit used in expressing the limiting value

6 ⁄8 in. (3.2 mm).

13. Inspection

8.2 Threads:

8.2.1 Pipe nipples shall be threaded on both ends with NPT 13.1 Each sample nipple shall be examined visually to

Taper Pipe Threads conforming to the requirements of ANSI verify conformance with each of the following requirements:

B1.20.1, except for close nipples where L4 and V are shorter, 13.1.1 The material is the type and weight of material

due to fewer imperfect threads. It is standard manufacturing specified,

practice on all other nipple lengths to vary the L4 6 two 13.1.2 The finish is as specified, if chromium-plated,

B687 − 99 (2023)

TABLE 2 Pipe Nipples by Length and Pipe Size

Type of

1 1 3 1 3 1 1 1 1

⁄8 ⁄4 ⁄8 ⁄2 ⁄4 1 1 ⁄4 1 ⁄2 2 2 ⁄2 3 3 ⁄2 4 5 6 8

Nipple

A, B

Pipe Nipple Lengths, in.

3 7 1 3 1 5 3 1 5 3 7 1 1

Close (cl) ⁄4 ⁄8 1 1 ⁄8 1 ⁄8 1 ⁄2 1 ⁄8 1 ⁄4 2 2 ⁄2 2 ⁄8 2 ⁄4 2 ⁄8 3 3 ⁄8 3 ⁄2

1 1 1 1

1 ⁄2 1 ⁄2 1 ⁄2 1 ⁄2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 2 2 2 2 2 2 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.