ASTM A980-97(2003)

(Specification)Standard Specification for Steel, Sheet, Carbon, Ultra High Strength Cold Rolled

Standard Specification for Steel, Sheet, Carbon, Ultra High Strength Cold Rolled

ABSTRACT

This specification covers the standard for cold rolled ultra high strength carbon steel sheet in coils or cut lengths. The sheet shall be produced from aluminum killed steel and shall undergo continuous annealing to austenitic temperatures and then be water quenched. Cast or heat analysis shall conform to the prescribed chemical composition requirements in carbon, manganese, phosphorus, sulfur, and aluminum. Tension test shall be done on the point immediately adjacent to the material to be tested and properties shall conform to the specified tensile strength. The sheet shall have a matte surface finish texture and shall have cut edges. Unless otherwise specified, the sheet shall undergo oiling.

SCOPE

1.1 This specification covers a cold rolled ultra high strength carbon steel sheet in coils or cut lengths. The product is available in four strength levels. the steel's strength is obtained by water quenching from an austenitic temperature resulting in a martensitic microstructure. This product is intended for miscellaneous applications where ultra high strength, weight saving, and good weldability are important.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A980 – 97 (Reapproved 2003)

Standard Specification for

Steel, Sheet, Carbon, Ultra High Strength Cold Rolled

This standard is issued under the fixed designation A980; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

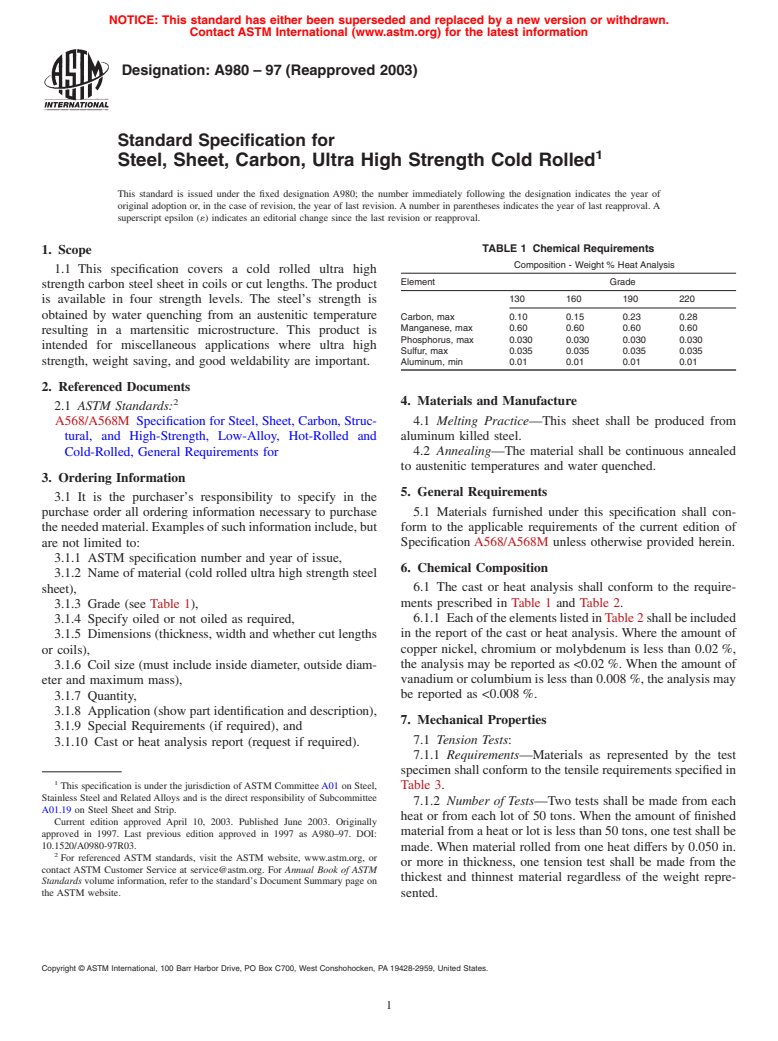

TABLE 1 Chemical Requirements

1. Scope

Composition - Weight % Heat Analysis

1.1 This specification covers a cold rolled ultra high

Element Grade

strength carbon steel sheet in coils or cut lengths. The product

is available in four strength levels. The steel’s strength is 130 160 190 220

obtained by water quenching from an austenitic temperature

Carbon, max 0.10 0.15 0.23 0.28

Manganese, max 0.60 0.60 0.60 0.60

resulting in a martensitic microstructure. This product is

Phosphorus, max 0.030 0.030 0.030 0.030

intended for miscellaneous applications where ultra high

Sulfur, max 0.035 0.035 0.035 0.035

strength, weight saving, and good weldability are important.

Aluminum, min 0.01 0.01 0.01 0.01

2. Referenced Documents

2 4. Materials and Manufacture

2.1 ASTM Standards:

4.1 Melting Practice—This sheet shall be produced from

A568/A568M Specification for Steel, Sheet, Carbon, Struc-

tural, and High-Strength, Low-Alloy, Hot-Rolled and aluminum killed steel.

4.2 Annealing—The material shall be continuous annealed

Cold-Rolled, General Requirements for

to austenitic temperatures and water quenched.

3. Ordering Information

5. General Requirements

3.1 It is the purchaser’s responsibility to specify in the

purchase order all ordering information necessary to purchase 5.1 Materials furnished under this specification shall con-

form to the applicable requirements of the current edition of

theneededmaterial.Examplesofsuchinformationinclude,but

are not limited to: Specification A568/A568M unless otherwise provided herein.

3.1.1 ASTM specification number and year of issue,

6. Chemical Composition

3.1.2 Name of material (cold rolled ultra high strength steel

6.1 The cast or heat analysis shall conform to the require-

sheet),

ments prescribed in Table 1 and Table 2.

3.1.3 Grade (see Table 1),

3.1.4 Specify oiled or not oiled as required, 6.1.1 EachoftheelementslistedinTable2shallbeincluded

in the report of the cast or heat analysis. Where the amount of

3.1.5 Dimensions (thickness, width and whether cut lengths

copper nickel, chromium or molybdenum is less than 0.02 %,

or coils),

the analysis may be reported as <0.02 %. When the amount of

3.1.6 Coil size (must include inside diameter, outside diam-

vanadium or columbium is less than 0.008 %, the analysis may

eter and maximum mass),

be reported as <0.008 %.

3.1.7 Quantity,

3.1.8 Application (show part identification and description),

7. Mechanical Properties

3.1.9 Special Requirements (if required), and

7.1 Tension Tests:

3.1.10 Cast or heat analysis report (request if required).

7.1.1 Requirements—Materials as represented by the test

specimen shall conform to the tensile requirements specified in

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Table 3.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

7.1.2 Number of Tests—Two tests shall be made from each

A01.19 on Steel Sheet and Strip.

heat or from each lot of 50 tons. When the amount of finished

Current edition approved April 10, 2003. Published June 2003. Originally

material from a heat or lot is less than 50 tons, one test shall be

approved in 1997. Last previous edition approved in 1997 as A980–97. DOI:

10.1520/A0980-97R03.

made. When material rolled from one heat di

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.