ASTM B229-95

(Specification)Standard Specification for Concentric-Lay-Stranded Copper and Copper-Clad Steel Composite Conductors

Standard Specification for Concentric-Lay-Stranded Copper and Copper-Clad Steel Composite Conductors

SCOPE

1.1 This specification covers concentric-lay-stranded conductors made from uncoated hard-drawn round copper wires in combination with hard-drawn round copper-clad steel wires, for general use as overhead electrical conductors.

1.2 For the purpose of this specification, conductors are classified under the following type designations (see Fig 1): Type AType GType CType JType DType KType EType NType EKType PType FType V

1.3 The SI values for density are regarded as the standard. For all other properties the inch-pound values are to be regarded as standard and the SI units may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 229 – 95

Standard Specification for

Concentric-Lay-Stranded Copper and Copper-Clad Steel

Composite Conductors

This standard is issued under the fixed designation B 229; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers concentric-lay-stranded con-

ductors made from uncoated hard-drawn round copper wires in

combination with hard-drawn round copper-clad steel wires,

for general use as overhead electrical conductors.

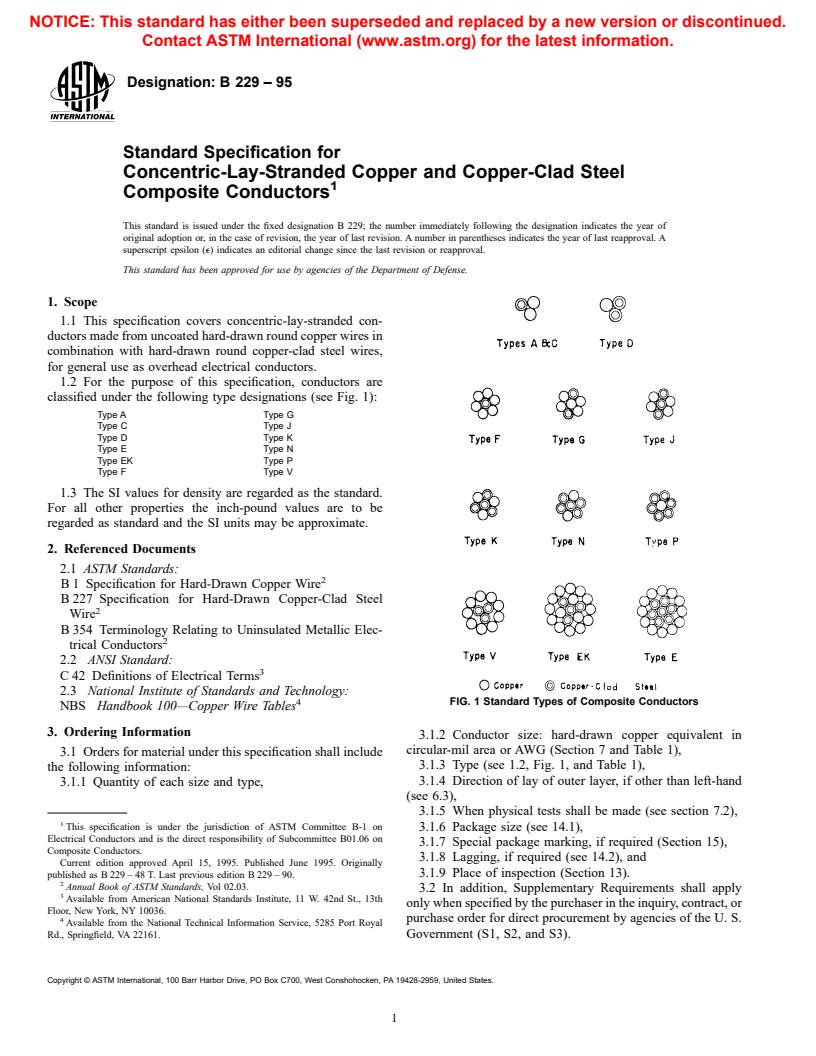

1.2 For the purpose of this specification, conductors are

classified under the following type designations (see Fig. 1):

Type A Type G

Type C Type J

Type D Type K

Type E Type N

Type EK Type P

Type F Type V

1.3 The SI values for density are regarded as the standard.

For all other properties the inch-pound values are to be

regarded as standard and the SI units may be approximate.

2. Referenced Documents

2.1 ASTM Standards:

B 1 Specification for Hard-Drawn Copper Wire

B 227 Specification for Hard-Drawn Copper-Clad Steel

Wire

B 354 Terminology Relating to Uninsulated Metallic Elec-

trical Conductors

2.2 ANSI Standard:

C 42 Definitions of Electrical Terms

2.3 National Institute of Standards and Technology:

4 FIG. 1 Standard Types of Composite Conductors

NBS Handbook 100—Copper Wire Tables

3. Ordering Information

3.1.2 Conductor size: hard-drawn copper equivalent in

circular-mil area or AWG (Section 7 and Table 1),

3.1 Orders for material under this specification shall include

3.1.3 Type (see 1.2, Fig. 1, and Table 1),

the following information:

3.1.4 Direction of lay of outer layer, if other than left-hand

3.1.1 Quantity of each size and type,

(see 6.3),

3.1.5 When physical tests shall be made (see section 7.2),

This specification is under the jurisdiction of ASTM Committee B-1 on 3.1.6 Package size (see 14.1),

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on

3.1.7 Special package marking, if required (Section 15),

Composite Conductors.

3.1.8 Lagging, if required (see 14.2), and

Current edition approved April 15, 1995. Published June 1995. Originally

3.1.9 Place of inspection (Section 13).

published as B 229 – 48 T. Last previous edition B 229 – 90.

Annual Book of ASTM Standards, Vol 02.03.

3.2 In addition, Supplementary Requirements shall apply

Available from American National Standards Institute, 11 W. 42nd St., 13th

only when specified by the purchaser in the inquiry, contract, or

Floor, New York, NY 10036.

4 purchase order for direct procurement by agencies of the U. S.

Available from the National Technical Information Service, 5285 Port Royal

Rd., Springfield, VA 22161. Government (S1, S2, and S3).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 229

TABLE 1 Construction Requirements and Breaking Strength of Concentric-Lay-Stranded Copper and Copper-Clad Steel Composite

Conductors

NOTE 1—Metric Equivalents—For conductor size, 1 cmil = 0.0005067 mm (round to 4 significant figures); for diameter 1 mil = 0.02540 mm (round

to 4 significant figures); for breaking strength, 1 lb = 0.45359 kg (round to 4 significant figures).

Conductor Size, Hard-Drawn Copper Hard-Drawn Copper

Grade 30 EHS Copper-Clad Steel Wires

A

Rated Breaking

Equivalent Wires

Type Strength, min,

Number of Diameter of Number of Diameter of

lb

cmil AWG

Wires Wires, mils Wires Wires, mils

350 000 . E 7 157.6 12 157.6 32 420

350 000 . EK 4 147.0 15 147.0 23 850

350 000 . V 3 175.1 9 189.3 23 480

300 000 . E 7 145.9 12 145.9 27 770

300 000 . EK 4 136.1 15 136.1 20 960

300 000 . V 3 162.1 9 175.2 20 730

250 000 . E 7 133.2 12 133.2 23 920

250 000 . EK 4 124.2 15 124.2 17 840

250 000 . V 3 148.0 9 160.0 17 420

211 600 0000 E 7 122.5 12 122.5 20 730

211 600 0000 G 2 194.4 5 194.4 15 640

211 600 0000 EK 4 114.3 15 114.3 15 370

211 600 0000 V 3 136.1 9 147.2 15 000

211 600 0000 F 1 183.3 6 183.3 12 290

167 800 000 E 7 109.1 12 109.1 16 800

167 800 000 J 3 185.1 4 185.1 16 170

167 800 000 G 2 173.1 5 173.1 12 860

167 800 000 EK 4 101.8 15 101.8 12 370

167 800 000 V 3 121.2 9 131.1 12 200

167 800 000 F 1 163.2 6 163.2 9 980

133 100 00 K 4 178.0 3 178.0 17 600

133 100 00 J 3 164.8 4 164.8 13 430

133 100 00 G 2 154.2 5 154.2 10 510

133 100 00 V 3 108.0 9 116.7 9 846

133 100 00 F 1 145.4 6 145.4 8 094

105 600 0 K 4 158.5 3 158.5 14 490

105 600 0 J 3 146.7 4 146.7 10 970

105 600 0 G 2 137.3 5 137.3 8 563

105 600 0 F 1 129.4 6 129.4 6 536

83 690 1 N 5 154.6 2 154.6 15 410

83 690 1 K 4 141.2 3 141.2 11 900

83 690 1 J 3 130.7 4 130.7 9 000

83 690 1 G 2 122.2 5 122.2 6 956

83 690 1 F 1 115.3 6 115.3 5 266

66 360 2 P 6 154.0 1 154.0 16 870

66 360 2 N 5 137.7 2 137.7 12 680

66 360 2 K 4 125.7 3 125.7 9 730

66 360 2 J 3 116.4 4 116.4 7 322

66 360 2 A 1 169.9 2 169.9 5 876

66 360 2 G 2 108.9 5 108.9 5 626

66 360 2 F 1 102.6 6 102.6 4 233

52 620 3 P 6 137.1 1 137.1 13 910

52 620 3 N 5 122.6 2 122.6 10 390

52 620 3 K 4 112.0 3 112.0 7 910

52 620 3 J 3 103.6 4 103.6 5 955

52 620 3 A 1 151.3 2 151.3 4 810

41 740 4 P 6 122.1 1 122.1 11 420

41 740 4 N 5 109.2 2 109.2 8 460

41 740 4 D 2 161.5 1 161.5 7 340

41 740 4 A 1 134.7 2 134.7 3 938

33 090 5 P 6 108.7 1 108.7 9 311

33 090 5 D 2 143.8 1 143.8 6 035

33 090 5 A 1 120.0 2 120.0 3 193

26 240 6 D 2 128.1 1 128.1 4 942

26 240 6 A 1 106.8 2 106.8 2 585

B

26 240 6 C 1 104.6 2 104.6 2 143

B 229

TABLE 1 Continued

Conductor Size, Hard-Drawn Copper Hard-Drawn Copper

Grade 30 EHS Copper-Clad Steel Wires

A

Rated Breaking

Equivalent Wires

Type Strength, min,

Number of Diameter of Number of Diameter of

lb

cmil AWG

Wires Wires, mils Wires Wires, mils

20 820 7 D 2 114.1 1 114.1 4 022

20 820 7 A 1 126.6 2 89.5 2 754

16 510 8 D 2 101.6 1 101.6 3 256

16 510 8 A 1 112.7 2 79.7 2 233

B

16 510 8 C 1 80.8 2 83.4 1 362

B

11 750 9 ⁄2 D 2 80.8 1 80.8 1 743

A

See Explanatory Note 7.

B

Grade 40 HS.

4. Material for Wires 7. Construction

4.1 The purchaser shall designate the size and type of 7.1 The numbers and diameters of wires in the various types

conductor to be furnished. The position of the hard-drawn of concentric-lay-stranded composite conductors shall conform

copper wires and the copper-clad steel wires in the conductor to the requirements prescribed in Table 1 (Explanatory Note 2).

cross section shall be as shown in Fig. 1.

8. Physical and Electrical Tests

4.2 Before stranding, the wire used shall meet the require-

ments of Specifications B 1 and B 227 that are applicable to its 8.1 Tests for the physical and electrical properties of wires

composing concentric-lay-stranded composite conductors shall

type.

be made before but not after stranding.

5. Joints

8.2 At the option of the purchaser or his representative,

5.1 Copper—Welds and brazes may be made in copper rods

tension and elongation tests on wires before stranding may be

or in copper wires prior to final drawing. Joints may not be

waived, and the completed conductor may be tested as a unit.

made in the finished copper wires composing concentric-lay-

The breaking strength of the conductors so tested shall be not

stranded composite conductors containing a total of seven

less than the rated strength values shown in Table 2. The free

wires or less. In other conductors, welds and brazes may be

length between grips of the test specimen shall be not less than

made in the finished individual copper wires composing the

24 in. (0.61 m), and care shall be taken to ensure that the wires

conductor, but shall be not closer than 50 ft (15 m) to any other

in the conductor are evenly gripped during the test (Explana-

joint in the same layer in the conductor.

tory Note 3).

5.2 Copper-Clad Steel—Joints or splices may be made in

9. Density

the finished individual copper-clad steel wires composing

concentric-lay-stranded conductors, provided that such joints

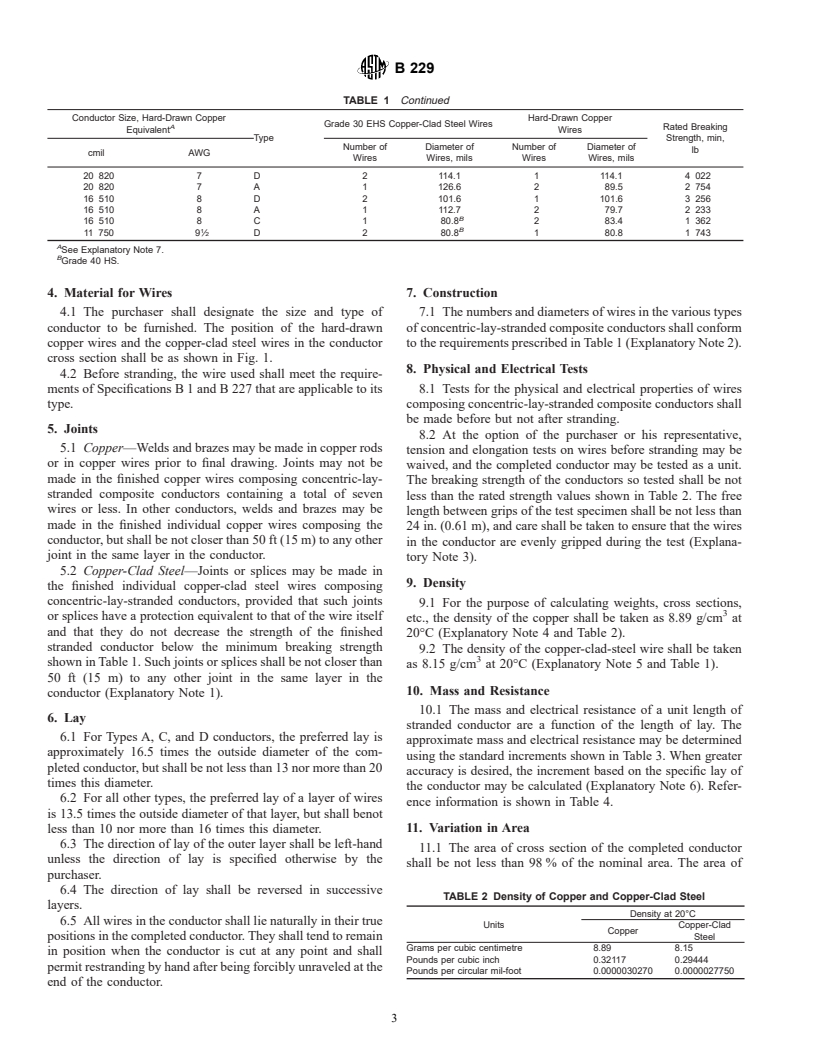

9.1 For the purpose of calculating weights, cross sections,

or splices have a protection equivalent to that of the wire itself

etc., the density of the copper shall be taken as 8.89 g/cm at

and that they do not decrease the strength of the finished

20°C (Explanatory Note 4 and Table 2).

stranded conductor below the minimum breaking strength

9.2 The density of the copper-clad-steel wire shall be taken

shown in Table 1. Such joints or splices shall be not closer than

as 8.15 g/cm at 20°C (Explanatory Note 5 and Table 1).

50 ft (15 m) to any other joint in the same layer in the

10. Mass and Resistance

conductor (Explanatory Note 1).

10.1 The mass and electrical resistance of a unit length of

6. Lay

stranded conductor are a function of the length of lay. The

6.1 For Types A, C, and D conductors, the preferred lay is

approximate mass and electrical resistance may be determined

approximately 16.5 times the outside diameter of the com-

using the standard increments shown in Table 3. When greater

pleted conductor, but shall be not less than 13 nor more than 20

accuracy is desired, the increment based on the specific lay of

times this diameter.

the conductor may be calculated (Explanatory Note 6). Refer-

6.2 For all other types, the preferred lay of a layer of wires

ence information is shown in Table 4.

is 13.5 times the outside diameter of that layer, but shall benot

less than 10 nor more than 16 times this diameter. 11. Variation in Area

6.3 The direction of lay of the outer layer shall be left-hand

11.1 The area of cross section of the completed conductor

unless the direction of lay is specified otherwise by the

shall be not less than 98 % of the nominal area. The area of

purchaser.

6.4 The direction of lay shall be reversed in successive

TABLE 2 Density of Copper and Copper-Clad Steel

layers.

Density at 20°C

6.5 All wires in the conductor shall lie naturally in their true

Units Copper-Clad

Copper

positions in the completed conductor. They shall tend to remain Steel

Grams per cubic centimetre 8.89 8.15

in position when the conductor is cut at any point and shall

Pounds per cubic inch 0.32117 0.29444

permit restranding by hand after being forcibly unraveled at the

Pounds per circular mil-foot 0.0000030270 0.0000027750

end of the conductor.

B 229

TABLE 3 Standard Increments Due to Stranding

accordance with this specification.

Increment (Increase) of

Type of Conductor

Resistance and Weight, %

14. Packaging and Shipping

A, C and D 0.8

14.1 Package sizes for conductors shall be agreed upon by

F, G, J, K, N and P 1.0

the manufacturer and the purchaser in the placing of individual

V 1.2

E and EK 1.4 orders (Explanatory Note 9).

14.2 The conductors shall be protected against damage in

ordinary handling and shipping. If heavy wood lagging is

cross section of a conductor shall be considered to be the sum

required, it shall be specified by the purchaser at the time of

of the cross-sectional areas of its component wires at any point

purchase.

when measured perpendicularly to their axes (Explanatory

Note 8).

15. Marking

12. Finish

15.1 The net mass, length (or lengths, and number of

lengths, if more than one length is included in the package),

12.1 The conductor shall be free of all imperfections not

size, type of conductor, purchase order number, and any other

consistent with the best commercial practice.

marks required by the purchase order shall be marked on a tag

13. Inspection

attached to the end of the conductor inside of the package. The

same information, together with the manufacturer’s serial

13.1 Unless otherwise specified in the contract or purchase

number (if any) and all shipping marks required by the

order, the manufacturer shall be responsible for the perfor-

purchaser, shall appear on the outside of each package.

mance of all inspection and test requirements specified.

13.2 All inspections and tests shall be made at the place of

16. Keywords

manufacture unless otherwise especially agreed to between the

manufacturer and the purchaser at the time of the purchase. 16.1 composite conductors; concentric-lay-stranded copper

13.3 The manufacturer shall afford the inspector represent- conductor; copper-clad steel conductor; copper electrical con-

ing the purchaser all reasonable manufacturer’s facilities nec- ductor; electrical conductor; electrical conductor—copper;

essary to ensure that the material is being furnished in stranded copper conductor

EXPLANATORY NOTES

NOTE 1—Joints or splices in individual copper-clad steel wires in their specimen. Various means are available, such as a long tube or socket into

finished size are made by electrical butt welding. Two types of joints are which the conductor may be soldered, or in which, after insertion, the

used and are described as follows: conductors may be swaged or pressed without serious distortion. Ordinary

(a) Weld-Annealed Joints—After butt welding, the wire is annealed for jaws or clamping devices usually are not suitable. The conductor testing

a distance of approximately 5 in. (127 mm) on each side of the weld. The facilities of many commercial laboratories are limited to a breaking

weld then is protected from corrosion with a snug fitting seamless copper strength of 30 000 lb (13.6 Mg) or less. Consequently, it may not be

sleeve which extends at least ⁄8 in. (9.5 mm) on each side of the weld and feasible to test the very large-sized conductors as a unit. Where such is

which is thoroughly sealed to the wire with solder. The wall thickness of imperative, special arrangements for the testing shall be agreed upon

the sleeve is at least 10 % of the radius of the wire. between the manufacturer and the purchaser.

This joint has a tensile strength of approximately 60 000 psi (415 MPa).

NOTE 4—The value of density of copper is in accordance with the

This is less than the strength of the individual wires, but an allowance is

International Annealed Copper Standard. As pointed out in the discussion

made for this in the rated strength of the conductor as a whole. The

of this subject in NBS Handbook 100 of the National Institute of Standards

completed conductor when containing such joints is required to have the

and Technology, there is no appreciable difference in values of density of

full rated strength.

hard-drawn and annealed copper wire. Equivalent expressions of density

This type of joint is only slightly larger than the wire itself and is

at 20°C are given in Table 3.

applicable for 7-wire composite conductors (except Types F and G) and

NOTE 5—The value of density of coppe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.