ASTM C28/C28M-00(2005)

(Specification)Standard Specification for Gypsum Plasters

Standard Specification for Gypsum Plasters

ABSTRACT

This specification covers four gypsum plasters; gypsum mill-mixed plaster, gypsum neat plaster, gypsum wood fibered plaster, and gypsum gauging plaster. The plasters shall contain a volume of aggregate not more than requirements prescribed. Compressive strength test and Vicat test shall be performed to meet the requirements.

SCOPE

1.1 This specification covers four gypsum plasters; gypsum mill-mixed plaster, gypsum neat plaster, gypsum wood fibered plaster and gypsum gauging plaster.

Note 1—Specification C 842 contains application procedures for interior gypsum plaster.

1.2 The values stated in either inch-pound or SI (metric) units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system shall be used independently of the other. Values from the two systems shall not be combined. This paragraph does not apply to the appendix.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 The following safety hazards caveat pertains only to the test methods described in the appendix to this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C28/C28M – 00 (Reapproved 2005)

Standard Specification for

Gypsum Plasters

This standard is issued under the fixed designation C28/C28M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C35 Specification for Inorganic Aggregates for Use in

Gypsum Plaster

1.1 This specification covers four gypsum plasters; gypsum

C471M Test Methods for Chemical Analysis of Gypsum

mill-mixed plaster, gypsum neat plaster, gypsum wood fibered

and Gypsum Products (Metric)

plaster and gypsum gauging plaster.

C472 Test Methods for Physical Testing of Gypsum, Gyp-

NOTE 1—Specification C842 contains application procedures for inte-

sum Plasters and Gypsum Concrete

rior gypsum plaster.

C778 Specification for Standard Sand

1.2 The values stated in either inch-pound or SI (metric)

C842 Specification for Application of Interior Gypsum

units are to be regarded separately as the standard. Within the

Plaster

text, the SI units are shown in brackets. The values stated in

E11 SpecificationforWovenWireTestSieveClothandTest

each system shall be used independently of the other. Values

Sieves

from the two systems shall not be combined. This paragraph

3. Terminology

does not apply to the appendix.

1.3 The text of this standard references notes and footnotes

3.1 Definitions—Definitions shall be in accordance with

which provide explanatory material. These notes and footnotes

Terminology C11.

(excluding those in tables and figures) shall not be considered

3.2 Definitions of Terms Specific to This Standard:

as requirements of the standard.

3.2.1 gypsum gauging plaster for finish coat, n—a calcined

1.4 The following safety hazards caveat pertains only to the

gypsum plaster designed to be mixed with lime putty for the

test methods described in the appendix to this specification.

finish coat.

This standard does not purport to address all of the safety

3.2.2 gypsum neat plaster, n—calcined gypsum mixed at

concerns, if any, associated with its use. It is the responsibility

the mill with other ingredients to control working quality and

of the user of this standard to establish appropriate safety and

setting time.

health practices and determine the applicability of regulatory

3.2.2.1 Discussion—Neat plaster is either fibered or unfi-

limitations prior to use.

bered. The addition of aggregate is required on the job.

3.2.3 gypsum mill-mixed plaster, n—calcined gypsum plas-

2. Referenced Documents

ter, mixed at the mill with a mineral aggregate, designed to

2.1 ASTM Standards:

function as a base coat to receive various finish coats.

C11 TerminologyRelatingtoGypsumandRelatedBuilding

3.2.3.1 Discussion—Othermaterialsarenotprohibitedfrom

Materials and Systems

beingaddedtocontrolsettingtimeandotherdesirableworking

C22/C22M Specification for Gypsum

properties.

3.2.4 gypsum wood-fibered plaster, n—A calcined gypsum

plaster in which wood fiber is used as an aggregate.

This specification is under the jurisdiction of ASTM Committee C11 on

Gypsum and Related Building Materials and Systems and is the direct responsibility 4. Materials

of Subcommittee C11.01 on Specifications and Test Methods for Gypsum Products.

4.1 Calcined Gypsum—Calcined gypsum shall be manufac-

Current edition approved Oct. 1, 2005. Published October 2005. Originally

{1

tured from gypsum meeting the requirements of Specification

approved in 1920. Last previous edition approved in 2000 as C28/C28M – 00 .

DOI: 10.1520/C0028_C0028M-00R05.

C22/C22M.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 Vermiculite Aggregate, Specification C35.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.3 Perlite Aggregate, Specification C35.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.4 Sand Aggregate, Specification C35.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C28/C28M – 00 (2005)

4.5 Ottawa Sand, Specification C778 for 20–30 sand. selected at random. Samples shall be taken both from the outer

4.6 Wood Fiber, non staining wood fiber. portion and the center of each package. The materials so

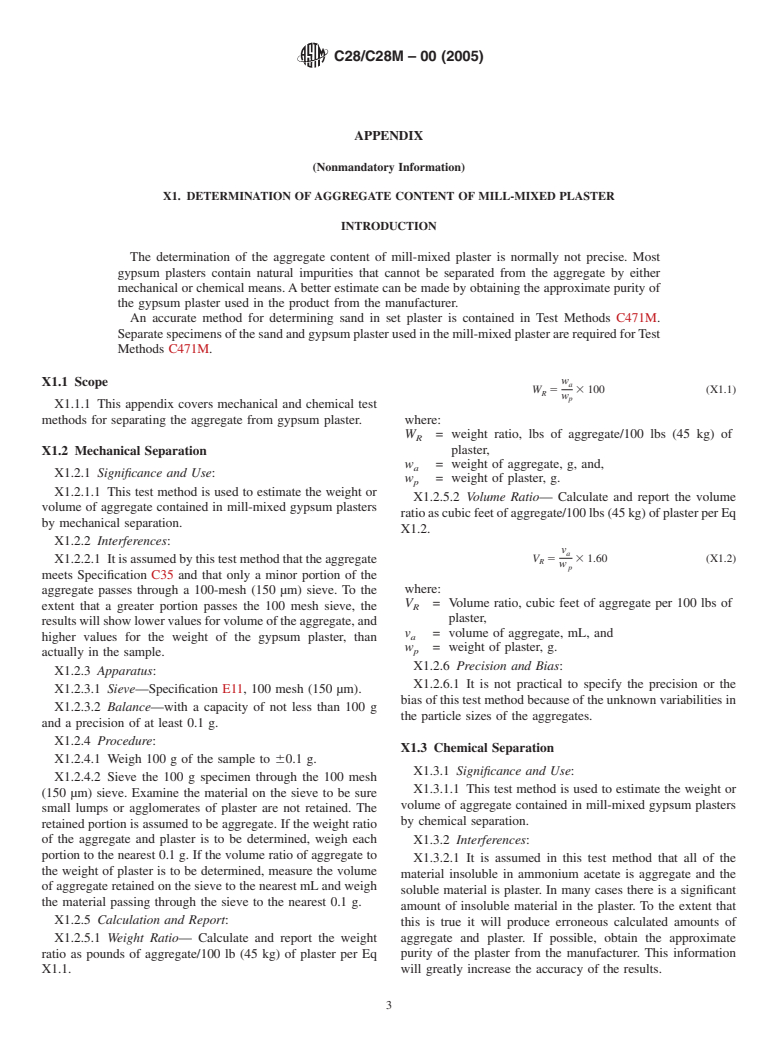

TABLE 1 Composition and Physical Properties

B

Composition, Aggregate per 100 lb Compressive Strength

A

Setting Time

of Plaster, not more than not less than

Product Aggregate Type

3 3

ft m hours psi MPa

Mill-Mixed Plaster over Lath Base Vermiculite 2 0.057 1 ⁄2 to 8 450 3.1

Perlite 2 0.057 1 ⁄2 to 8 600 4.1

Sand 2.5 0.071 1 ⁄2 to 8 700 4.8

Mill-Mixed Plaster over Masonry Vermiculite 3 0.085 1 ⁄2 to 8 325 2.2

Perlite 3 0.085 1 ⁄2 to 8 400 2.8

Sand 3 0.085 1 ⁄2 to 8 400 2.8

C D

Neat Plaster none . . 2 to 16 750 5.2

Wood Fibered Plaster none . . 1 ⁄2 to 8 1200 8.3

E

Gauging Plaster none . . 1200 8.3

A

Setting time shall be not less than the shorter time shown nor more than the longer time shown.

B

Compressive strengths are as tested at the setting times specified in Test Methods C472.

C

When mixed with 3 parts by weight of Ottawa sand.

D

When mixed with 2 parts by weight of Ottawa sand.

E

When not retarded, the setting time shall be not less than 20 nor more than 40 minutes and, when retarded, not less than 40 minutes.

5. Composition obtained shall be thoroughly mixed to provide a composite

sample of not less than 7 lb [ 3.2 kg]. This composite sample

5.1 When tested in accordance with Test Methods C471M,

shall be placed immediately in a clean, dry, airtight container

calcined gypsum shall contain no less than 66.0 weight %

1 for delivery to the laboratory.

CaSO · ⁄2 H O.

5.2 Aggregate—plastersshallcontainavolumeofaggregate

8. Packaging and Package Marking

not more than that shown in Table 1.

8.1 Gypsum plasters shall be dry and free of lumps, and

NOTE 2—An approximation of the aggregate content may be made by

shall be shipped in packages.

using the test methods in the appendix. A more accurate method for

8.2 When shipped for resale, the following information

determining sand in plaster is described in Test Methods C471M. Test

shall be legibly marked on each package or on a tag of suitable

MethodsC471Mrequiresthattheoriginalsandandplastercomponentsbe

size attached to the package:

available separately.

8.2.1 Name of manufacturer or seller,

6. Mechanical Properties

8.2.2 Brand, and

8.2.3 Net weight of the package.

6.1 Compressive Strength—When tested in accordance with

Test Methods C472 the compressive strength shall be as

9. Inspection

specified in Table 1.

6.2 Setting Time—When tested in accordance with Test 9.1 Inspection of the gypsum plaster shall be agreed upon

between the purchaser and the supplier as part of the purchase

MethodsC472usingtheVicatmethod,thesettingtimeshallbe

as specified in Table 1. agreement.

NOTE 3—Setting Time—Attention is directed to conditions affecting job

10. Rejection

set of gypsum plasters that are usually beyond the control of the producer.

10.1 Rejectionofgypsumplasterthatfailstoconformtothe

Materials added at the site of application such as water and aggregates

requirements of this specification shall be reported to the

affect job sets. In addition, the various bases with different absorptive

values may affect job performance.The plaster may be retarded to provide producer or supplier promptly and in writing. The notice of

a setting time of not more than 4 h. Setting times more than 2 h may result

rejection shall contain a statement documenting requirements

in lower compressive strengths.

of this specification.

6.3 Fineness of Gauging Plaster for Finish Coat—When

11. Certification

tested in accordance with Test Method C472 all shall pass a

No. 14 [1.4 mm] sieve and not less than 60 % shall pass a No.

11.1 When specified in the purchase agreement, a manufac-

100 [150 µm] sieve.

turer’s or suppli

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:C28/C28M–00 Designation: C 28/C 28M – 00 (Reapproved 2005)

Standard Specification for

Gypsum Plasters

This standard is issued under the fixed designation C 28/C 28M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Note 1 was editorially added May 2002.

1. Scope

1.1 This specification covers four gypsum plasters; gypsum mill-mixed plaster, gypsum neat plaster, gypsum wood fibered

plaster and gypsum gauging plaster.

NOTE 1—Specification C 842 contains application procedures for interior gypsum plaster.

1.2 The values stated in either inch-pound or SI (metric) units are to be regarded separately as the standard. Within the text, the

SI units are shown in brackets. The values stated in each system shall be used independently of the other. Values from the two

systems shall not be combined. This paragraph does not apply to the appendix.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 The following safety hazards caveat pertains only to the test methods described in the appendix to this specification. This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2.1 ASTM Standards:

C11 Terminology Relating to Gypsum and Related Building Materials and Systems

C22 Specification for Gypsum

C35 Specification for Inorganic Aggregates for Use in Gypsum Plaster

C 471M Test Methods for Chemical Analysis of Gypsum and Gypsum Products

C 472 Test Methods for Physical Testing of Gypsum, Gypsum Plasters, and Gypsum Concrete

C 778 Specification for Standard Sand

C 842 Specification for Application of Interior Gypsum Plaster

E11 Specification for Wire-Cloth and Sieves for Testing Purposes

3. Terminology

3.1 Definitions—Definitions shall be in accordance with Terminology C 11.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 gypsum gauging plaster for finish coat, n—a calcined gypsum plaster designed to be mixed with lime putty for the finish

coat.

3.2.2 gypsum neat plaster, n—calcined gypsum mixed at the mill with other ingredients to control working quality and setting

time.

3.2.2.1 Discussion—Neat plaster is either fibered or unfibered. The addition of aggregate is required on the job.

3.2.3 gypsum mill-mixed plaster, n—calcined gypsum plaster, mixed at the mill with a mineral aggregate, designed to function

as a base coat to receive various finish coats.

This specification is under the jurisdiction of ASTM Committee C11 on Gypsum and Related Building Materials and Systems and is the direct responsibility of

Subcommittee C11.01 on Specifications and Test Methods for Gypsum Products .

Current edition approved May 10, 2000. Published July 2000. Originally published as C28–20T. Last previous edition C28–96

{1

Current edition approved Oct. 1, 2005. Published October 2005. Originally approved in 1920. Last previous edition approved in 2000 as C 28/C 28M – 00 .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 04.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 28/C 28M – 00 (2005)

3.2.3.1 Discussion—Other materials are not prohibited from being added to control setting time and other desirable working

properties.

3.2.4 gypsum wood-fibered plaster, n—A calcined gypsum plaster in which wood fiber is used as an aggregate.

4. Materials

4.1 Calcined Gypsum—Calcined gypsum shall be manufactured from gypsum meeting the requirements of Specification C 22.

4.2 Vermiculite Aggregate, Specification C 35.

4.3 Perlite Aggregate, Specification C 35.

4.4 Sand Aggregate, Specification C 35.

4.5 Ottawa Sand, Specification C 778 for 20–30 sand.

4.6 Wood Fiber, non staining wood fiber.

TABLE 1 Composition and Physical Properties

B

Composition, Aggregate per 100 lb Compressive Strength

A

Setting Time

of Plaster, not more than not less than

Product Aggregate Type

3 3

ft m hours psi MPa

Mill-Mixed Plaster over Lath Base Vermiculite 2 0.057 1 ⁄2 to 8 450 3.1

Perlite 2 0.057 1 ⁄2 to 8 600 4.1

Sand 2.5 0.071 1 ⁄2 to 8 700 4.8

Mill-Mixed Plaster over Masonry Vermiculite 3 0.085 1 ⁄2 to 8 325 2.2

Perlite 3 0.085 1 ⁄2 to 8 400 2.8

Sand 3 0.085 1 ⁄2 to 8 400 2.8

C D

Neat Plaster none . . 2 to 16 750 5.2

Wood Fibered Plaster none . . 1 ⁄2 to 8 1200 8.3

E

Gauging Plaster none . . 1200 8.3

A

Setting time shall be not less than the shorter time shown nor more than the longer time shown.

B

Compressive strengths are as tested at the setting times specified in Test Methods C 472.

C

When mixed with 3 parts by weight of Ottawa sand.

D

When mixed with 2 parts by weight of Ottawa sand.

E

When not retarded, the setting time shall be not less than 20 nor more than 40 minutes and, when retarded, not less than 40 minutes.

5. Composition

5.1 When tested in accordance with Test Methods C 471M, calcined gypsum shall contain no less than 66.0 weight % CaSO

4· ⁄2 H O.

5.2 Aggregate—plasters shall contain a volume of aggregate not more than that shown in Table 1.

NOTE 2—An approximation of the aggregate content may be made by using the test methods in the appendix.Amore accurate method for determining

sandinplasterisdescribedinTestMethodsC 471M.TestMethodsC 471Mrequiresthattheoriginalsandandplastercomponentsbeavailableseparately.

6. Mechanical Properties

6.1 Compressive Strength—When tested in accordance with Test Methods C 472 the compressive strength shall be as specified

in Table 1.

6.2 Setting Time—When tested in accordance with Test Methods C 472 using the Vicat method, the setting time shall be as

specified in Table 1.

NOTE 3—Setting Time—Attention is directed to conditions affecting job set of gypsum plasters that are usually beyond the control of the producer.

Materials added at the site of application such as water and aggregates affect job sets. In addition, the various bases with different absorptive values may

affect job performance. The plaster may be retarded to provide a setting time of not more than 4 h. Setting times more than 2 h may result in lower

compressive strengths.

6.3 Fineness of Gauging Plaster for Finish Coat—When tested in accordance with Test Method C 472 all shall pass a No. 14

[1.4 mm] sieve and not less than 60 % shall pass a No. 100 [150 µm] sieve.

7. Sampling

7.1 At least 1 % of the packages, but not less than 5 packages, shall be sampled. Packages to be sampled shall be selected at

random. Samples shall be taken both from the outer portion and the center of each package. The materials so obtained shall be

thoroughly mixed to provide a composite sample of not less than 7 lb [ 3.2 kg].This composite sample shall be placed immediately

in a clean, dry, airtight container for delivery to the laboratory.

Annual Book of ASTM Standards, Vol 14.02.

Detailed requirements for these sieves are given in Specification E 11.

C 28/C 28M – 00 (2005)

8. Packaging and Package Marking

8.1 Gypsum plasters shall be dry and free of lumps, and shall be shipped in packages.

8.2 When shipped for resale, the following information shall be legibly marked on each package or on a tag of suitable size

attached to the package:

8.2.1 Name of manufacturer or seller,

8.2.2 Brand, and

8.2.3 Net weight of the package.

9. Inspection

9.1 Inspection of the gypsum plaster shall be agreed upo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.