ASTM A1064/A1064M-12

(Specification)Standard Specification for Carbon-Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete

Standard Specification for Carbon-Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete

SCOPE

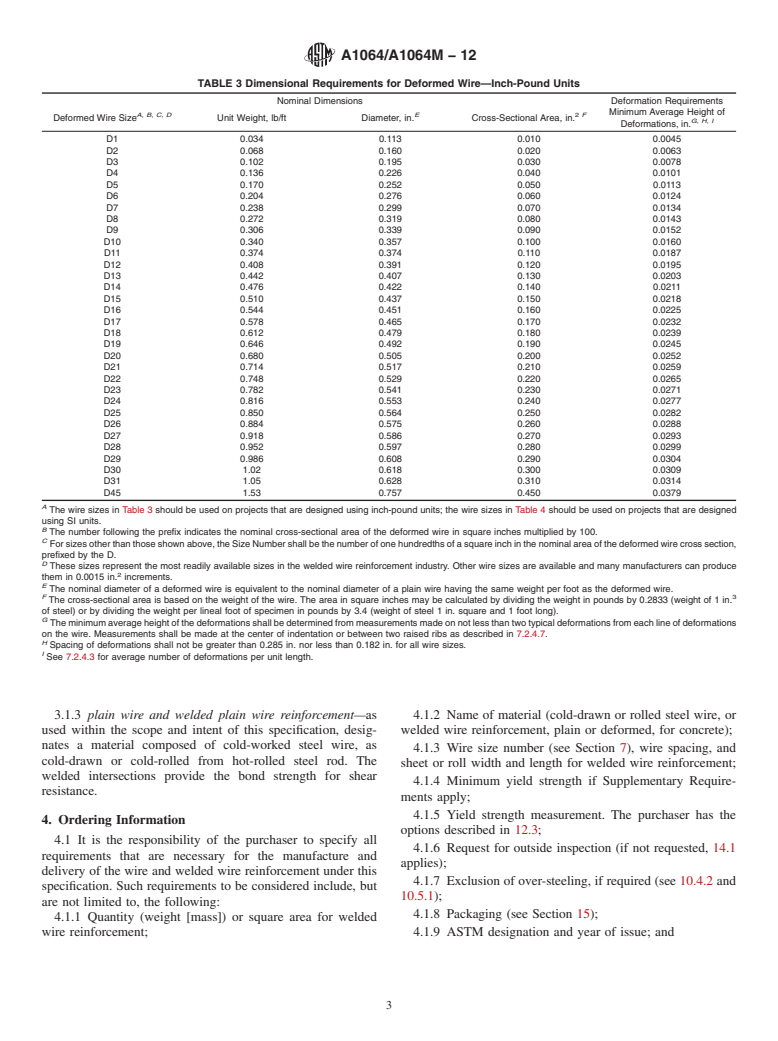

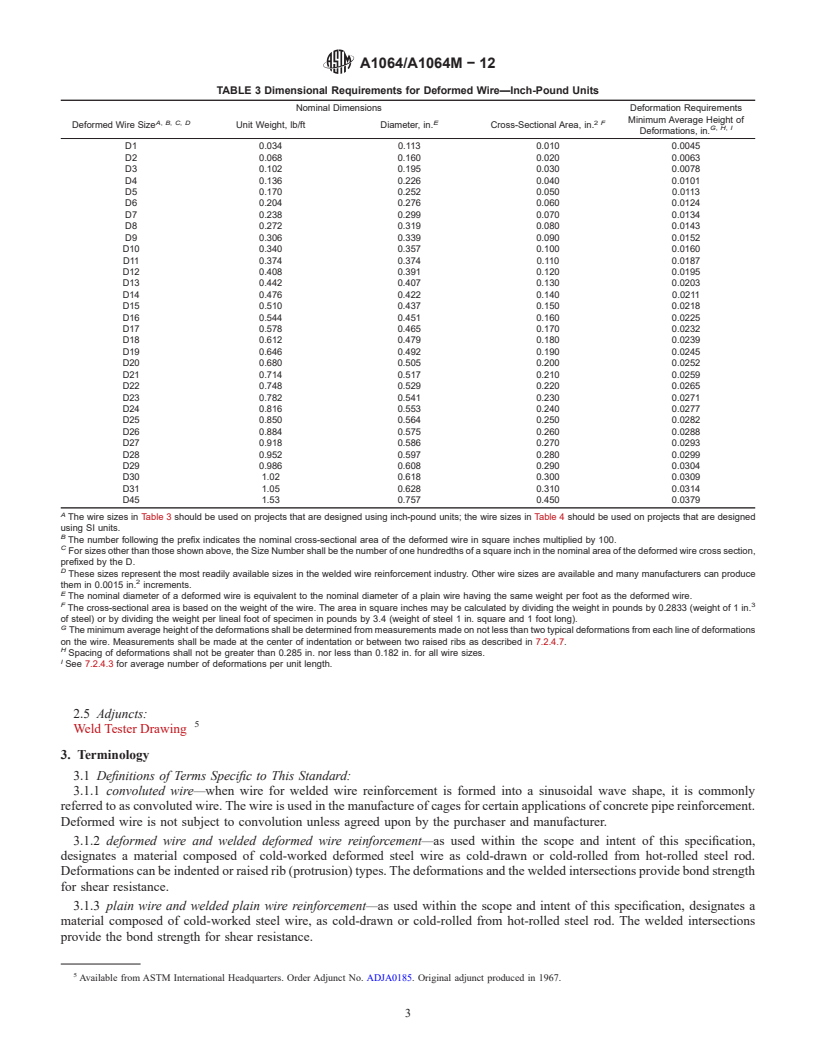

1.1 This specification covers carbon-steel wire and welded wire reinforcement produced from hot-rolled rod to be used for the reinforcement of concrete. The steel wire is cold-worked, drawn or rolled, plain (non-deformed, as-drawn or galvanized), or deformed. Welded wire reinforcement is made from plain or deformed wire, or a combination of plain and deformed wire. Common wire sizes and dimensions are given in Table 1, Table 2, Table 3, and Table 4. Actual wire sizes are not restricted to those shown in the tables.TABLE 1 Dimensional Requirements for Plain Wire—Inch-Pound UnitsA

Size NumberB , C, D

Nominal Diameter

in. [mm]E

Nominal Area

in.2 [mm 2]

W 0.5

0.080 [2.03]

0.005 [3.23]

W 1.2

0.124 [3.14]

0.012 [7.74]

W 1.4

0.134 [3.39]

0.014 [9.03]

W 2

0.160 [4.05]

0.020 [12.9]

W 2.5

0.178 [4.53]

0.025 [16.1]

W 2.9

0.192 [4.88]

0.029 [18.7]

W 3.5

0.211 [5.36]

0.035 [22.6]

W 4

0.226 [5.73]

0.040 [25.8]

W 4.5

0.239 [6.08]

0.045 [29.0]

W 5

0.252 [6.41]

0.050 [32.3]

W 5.5

0.265 [6.72]

0.055 [35.5]

W 6

0.276 [7.02]

0.060 [38.7]

W 8

0.319 [8.11]

0.080 [51.6]

W 10

0.357 [9.06]

0.100 [64.5]

W 11

0.374 [9.50]

0.110 [71.0]

W 12

0.391 [9.93]

0.120 [77.4]

W 14

0.422 [10.7]

0.140 [90.3]

W 16

0.451 [11.5]

0.160 [103]

W 18

0.479 [12.2]

0.180 [116]

W 20

0.505 [12.8]

0.200 [129]

W 22

0.529 [13.4]

0.220 [142]

W 24

0.553 [14.0]

0.240 [155]

W 26

0.575 [14.6]

0.260 [168]

W 28

0.597 [15.2]

0.280 [181]

W 30

0.618 [15.7]

0.300 [194]

W 31

0.628 [16.0]

0.310 [200]

W 45

0.757 [19.2]

0.450 [290] A Table 1 should be used on projects that are designed using inch-pound units; Table 2 should be used on projects that are designed using SI units.B The number following the prefix indicates the nominal cross-sectional area of the wire in square inches multiplied by 100.C For sizes other than those shown above, the Size Number shall be the number of one hundredth of a square inch in the nominal area of the wire cross section, prefixed by the W.D These sizes represent the most readily available sizes in the welding wire reinforcement industry. Other wire sizes are available and many manufactures can produce them in 0.0015 in.2 increments.E The nominal diameter is based on the nominal area of the wire.TABLE 2 Dimensional Requirements for Plain Wire—SI UnitsA

Size NumberB , C, D

Nominal Diameter

mm [in.]E

Nominal Area

mm2 [in. 2]

MW 5

2.52 [0.099]

5 [0.008]

MW 10

3.57 [0.140]

10 [0.016]

MW 15

4.37 [0.172]

15 [0.023]

MW 20

5.05 [0.199]

20 [0.031]

MW 25

5.64 [0.222]

25 [0.039]

MW 30

6.18 [0.243]

30 [0.047]

MW 35

6.68 [0.263]

35 [0.054]

MW 40

7.14 [0.281]

40 [0.062]

MW 45

7.57 [0.298]

45 [0.070]

MW 50

7.98 [0.314]

50 [0.078]

MW 55

8.37 [0.329]

55 [0.085]

MW 60

8.74 [0.344]

60 [0.093]

MW 65

9.10 [0.358]

65 [0.101]

MW 70

9.44 [0.372]

70 [0.109]

MW 80

10.1 [0.397]

80 [0.124]

MW 90

10.7 [0.421]

90 [0.140]

MW 100

11.3 [0.444]

100 [0.155]

MW 120

12.4 [0.487]

120 [0.186]

MW 130

12.9 [0.507]

130 [0.202]

MW 200

16.0 [0.628]

200 [0.310]

MW 290

19.2 [0.757]

290 [0.450] A The wire sizes in Table 1 should be used on projects that are designed using inch-pound units; the wire sizes in Table 2 should be used on projects that are designed using SI units.B The number following the prefix indicates the nominal cross-sectional area of the wire in square milimetres.C For sizes other than those shown above, the Size Number shall be the number of square millimetres in the nominal area of the wire cross section, prefixed by the MW.D These sizes represent the most readily availabl...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1064/A1064M −12

StandardSpecification for

Carbon-Steel Wire and Welded Wire Reinforcement, Plain

1

and Deformed, for Concrete

This standard is issued under the fixed designation A1064/A1064M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers carbon-steel wire and welded

A370 Test Methods and Definitions for Mechanical Testing

wirereinforcementproducedfromhot-rolledrodtobeusedfor

of Steel Products

the reinforcement of concrete. The steel wire is cold-worked,

A641/A641M Specification for Zinc–Coated (Galvanized)

drawnorrolled,plain(non-deformed,as-drawnorgalvanized),

Carbon Steel Wire

or deformed.Welded wire reinforcement is made from plain or

A700 Practices for Packaging, Marking, and Loading Meth-

deformed wire, or a combination of plain and deformed wire.

ods for Steel Products for Shipment

CommonwiresizesanddimensionsaregiveninTable1,Table

E83 Practice for Verification and Classification of Exten-

2, Table 3, and Table 4. Actual wire sizes are not restricted to

someter Systems

those shown in the tables.

3

2.2 U.S. Military Standard:

NOTE 1—Welded wire for concrete reinforcement has historically been

MIL-STD-129 Marking for Shipment and Storage

described by various terms: welded wire fabric, WWF, fabric, and mesh.

3

2.3 U.S. Military Standard:

The wire reinforcement industry has adopted the term welded wire

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

reinforcement (WWR) as being more representative of the applications of

4

the products being manufactured. Therefore, the term welded wire fabric

2.4 American Concrete Institute (ACI) Standard:

has been replaced with the term welded wire reinforcement in this

ACI 318 Building Code Requirements for Structural Con-

specification and in related specifications.

crete

1.2 Supplementary Requirements describe high-strength

2.5 Adjuncts:

5

wire, which manufacturers furnish when specifically ordered.

Weld Tester Drawing

Manufacturers furnish high-strength wire in place of regular

wire if mutually agreed to by the purchaser and the manufac-

3. Terminology

turer.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 convoluted wire—when wire for welded wire rein-

1.3 The values stated in either inch-pound or SI units are to

forcement is formed into a sinusoidal wave shape, it is

be regarded separately as standard. Within the text the SI units

commonly referred to as convoluted wire. The wire is used in

are shown in brackets (except in Table 2 and Table 4). The

the manufacture of cages for certain applications of concrete

values stated in each system are not exact equivalents;

pipe reinforcement. Deformed wire is not subject to convolu-

therefore,eachsystemmustbeusedindependentlyoftheother.

tion unless agreed upon by the purchaser and manufacturer.

Combining values may result in nonconformance with the

specification.

3.1.2 deformed wire and welded deformed wire

reinforcement—as used within the scope and intent of this

1.4 This standard does not purport to address all of the

specification, designates a material composed of cold-worked

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

bility of regulatory limitations prior to use.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee www.dodssp.daps.mil.

4

A01.05 on Steel Reinforcement. Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

Current edition approved Nov. 15, 2012. Published December 2012. Originally Hills, MI 48333-9094, http://www.concrete.org.

5

approved in 2009. Last previous edition approved in 2010 as A1064/A1064M-10. Available from ASTM International Headquarters. Order Adjunct No.

DOI: 10.1520/A1064_A1064M-12. ADJA0185. Original adjunct produced in 1967.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A1064/A1064M − 10 A1064/A1064M − 12

Standard Specification for

SteelCarbon-Steel Wire and Welded Wire Reinforcement,

1

Plain and Deformed, for Concrete

This standard is issued under the fixed designation A1064/A1064M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon («) indicates an editorial change since the last revision or reapproval.

1

εNOTE—Editorial corrections were made to Section 2 and the Summary of Changes in October 2012.

1. Scope*

1.1 This specification covers steelcarbon-steel wire and welded wire reinforcement produced from hot-rolled rod to be used for

the reinforcement of concrete. The steel wire is cold-worked, drawn or rolled, plain (non-deformed, as-drawn or galvanized), or

deformed. Welded wire reinforcement is made from plain or deformed wire, or a combination of plain and deformed wire.

Common wire sizes and dimensions are given in Table 1, Table 2, Table 3, and Table 4. Actual wire sizes are not restricted to those

shown in the tables.

NOTE 1—Welded wire for concrete reinforcement has historically been described by various terms: welded wire fabric, WWF, fabric, and mesh. The

wire reinforcement industry has adopted the term welded wire reinforcement (WWR) as being more representative of the applications of the products

being manufactured. Therefore, the term welded wire fabric has been replaced with the term welded wire reinforcement in this specification and in related

specifications.

1.2 Supplement S1 describesSupplementary Requirements describe high-strength wire, which manufacturers furnish when

specifically ordered. Manufacturers furnish high-strength wire in place of regular wire if mutually agreed to by the purchaser and

the manufacturer.

1.3 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text the SI units are

shown in brackets (except in Table 2 and Table 4). The values stated in each system are not exact equivalents; therefore, each

system must be used independently of the other. Combining values may result in nonconformance with the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A496/A496M Specification for Steel Wire, Deformed, for Concrete Reinforcement

A641/A641M Specification for Zinc–Coated (Galvanized) Carbon Steel Wire

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

E83 Practice for Verification and Classification of Extensometer Systems

3

2.2 U.S. Military Standard:

MIL-STD-129 Marking for Shipment and Storage

3

2.3 U.S. Military Standard:

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

4

2.4 American Concrete Institute (ACI) Standard:

ACI 318 Building Code Requirements for Structural Concrete

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.05

on Steel Reinforcement.

Current edition approved Oct. 1, 2010Nov. 15, 2012. Published November 2010December 2012. Originally approved in 2009. Last previous edition approved in 20092010

as A1064/A1064M-09.-10. DOI: 10.1520/A1064_A1064M-10.10.1520/A1064_A1064M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

4

Available from American Concrete Institute (ACI), P.O. Box 9094, Farmington Hills, MI 48333-9094, http://www.concrete.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1064/A1064M − 12

A

TABLE 1 Dimensional Requirements for Plain Wire—Inch-Pound Units

Nominal Diameter No

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.