ASTM F21-20

(Test Method)Standard Test Method for Hydrophobic Surface Films by the Atomizer Test

Standard Test Method for Hydrophobic Surface Films by the Atomizer Test

SIGNIFICANCE AND USE

5.1 The atomizer test as described in this test method is rapid, nondestructive, and may be used for control and evaluation of processes for the removal of hydrophobic contaminants. The test may also be used for the detection and control of hydrophobic contaminants in processing environments. For this application, a surface free of hydrophobic films is exposed to the environment and subsequently tested.4

5.2 This test method is related to Test Method F22. This test method may be suitable as an alternative to the water-break test when the surface of interest should not or cannot be immersed or doused with water, or when such immersion or dousing is impractical.

Note 1: This test method is not appropriate where line of sight evaluation is not feasible; or for assembled hardware where there is a risk for entrapment of water in faying surfaces or complex structures where it may not be effectively removed.

5.3 This test method is not quantitative and is typically restricted to applications where a pass/fail evaluation of cleanliness will suffice.

5.4 For quantitative measurement of surface wetting, test methods that measure contact angle of a sessile drop of water or other test liquid may be used in some applications. Measurement methods based on contact angle are shown in Test Methods C813, D5946, and D7490; and Practice D7334.

5.4.1 Devices for in situ measurement of contact angle are available. These devices are limited to a small measurement surface area and may not reflect the cleanliness condition of a larger surface. For larger surface areas, localized contact angle measurement, or other quantitative inspection, combined with water break testing may be useful.

5.5 This test method is only for use on test surfaces composed of materials, such as metal surfaces, that are hydrophilic (“wettable”) when clean. Some materials such as gold and many plastics are poorly wetted by water, making contamination difficult to detect by this method.

SCOPE

1.1 This test method covers the detection of the presence of hydrophobic (nonwetting) films on surfaces and the presence of hydrophobic organic materials in processing environments. When properly conducted, the test will enable detection of fractional molecular layers of hydrophobic organic contaminants. On very rough or porous surfaces, the sensitivity of the test may be significantly decreased.

1.2 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F21 − 20

Standard Test Method for

1

Hydrophobic Surface Films by the Atomizer Test

ThisstandardisissuedunderthefixeddesignationF21;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope strates and Pigments by Advancing Contact Angle Mea-

surement

1.1 This test method covers the detection of the presence of

D7490TestMethodforMeasurementoftheSurfaceTension

hydrophobic (nonwetting) films on surfaces and the presence

of Solid Coatings, Substrates and Pigments using Contact

of hydrophobic organic materials in processing environments.

Angle Measurements

When properly conducted, the test will enable detection of

F22Test Method for Hydrophobic Surface Films by the

fractional molecular layers of hydrophobic organic contami-

Water-Break Test

nants. On very rough or porous surfaces, the sensitivity of the

test may be significantly decreased.

3. Terminology

1.2 Units—The values stated in SI units are to be regarded

3.1 Definitions:

as standard. The values given in parentheses after SI units are

3.1.1 contact angle, n—the interior angle that a drop makes

providedforinformationonlyandarenotconsideredstandard.

between the substrate and a tangent drawn at the intersection

1.3 This standard does not purport to address all of the

between the drop and the substrate as shown in Fig. 1; this is

safety concerns, if any, associated with its use. It is the

theangleformedbyaliquidatthethreephaseboundarywhere

responsibility of the user of this standard to establish appro-

a liquid, gas (air), and solid intersect.

priate safety, health, and environmental practices and deter-

3.1.2 hydrophilic, adj—having a strong affinity for water;

mine the applicability of regulatory limitations prior to use.

wettable.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 3.1.2.1 Discussion—Hydrophilic surfaces exhibit zero con-

tact angle with water. A sessile drop of water applied to the

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- surface will immediately spread out to form a film.

3.1.3 hydrophobic, adj—having little affinity for water;

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. nonwettable.

3.1.3.1 Discussion—Hydrophobic surfaces exhibit contact

2. Referenced Documents

angles between a sessile drop of water and the surface

2

2.1 ASTM Standards:

appeciably greater than zero.

C813TestMethodforHydrophobicContaminationonGlass

3.1.4 sessile drop, n—a drop of liquid sitting on the upper

by Contact Angle Measurement

side of a horizontal surface.

D351Classification for Natural Muscovite Block Mica and

3.1.5 water-break, n—a break in the continuity of a film of

Thins Based on Visual Quality

water on a surface on removal from an aqueous bath or on

D1193Specification for Reagent Water

removal of a flowing water source from the surface.

D5946Test Method for Corona-Treated Polymer Films Us-

ing Water Contact Angle Measurements

4. Summary of Test Method

D7334Practice for Surface Wettability of Coatings, Sub-

3

4.1 The atomizer test is performed by subjecting the dry

surface to be tested to a fine water spray. The interpretation of

the test is based upon the pattern of wetting. In the absence of

1

This test method is under the jurisdiction of ASTM Committee E21 on Space

hydrophobic films, the impinging water droplets will wet the

Simulation andApplications of SpaceTechnology and is the direct responsibility of

Subcommittee E21.05 on Contamination. surface and spread immediately to form a continuous water

Current edition approved April 1, 2020. Published May 2020. Originally

film. Contaminated areas having a surface tension lower than

approved in 1962. Last previous edition approved in 2014 as F21–14. DOI:

water will cause the water to bead up at that location. Most

10.1520/F0021-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Linford, H. B., and Saubestre, E. B., “ANew Degreasing EvaluationTest:The

the ASTM website. Atomizer Test,” ASTM Bulletin, May 1953, p. 47.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F21−20

gold and many

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F21 − 14 F21 − 20

Standard Test Method for

1

Hydrophobic Surface Films by the Atomizer Test

This standard is issued under the fixed designation F21; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the detection of the presence of hydrophobic (nonwetting) films on surfaces and the presence of

hydrophobic organic materials in processing environments. When properly conducted, the test will enable detection of fractional

molecular layers of hydrophobic organic contaminants. On very rough or porous surfaces, the sensitivity of the test may be

significantly decreased.

1.2 Units—The values stated in SI units are to be regarded as the standard. The inch-pound values given in parentheses are for

information only.after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C813 Test Method for Hydrophobic Contamination on Glass by Contact Angle Measurement

D351 Classification for Natural Muscovite Block Mica and Thins Based on Visual Quality

D1193 Specification for Reagent Water

D2578 Test Method for Wetting Tension of Polyethylene and Polypropylene Films

D5946 Test Method for Corona-Treated Polymer Films Using Water Contact Angle Measurements

D7334 Practice for Surface Wettability of Coatings, Substrates and Pigments by Advancing Contact Angle Measurement

D7490 Test Method for Measurement of the Surface Tension of Solid Coatings, Substrates and Pigments using Contact Angle

Measurements

F22 Test Method for Hydrophobic Surface Films by the Water-Break Test

3. Terminology

3.1 Definitions:

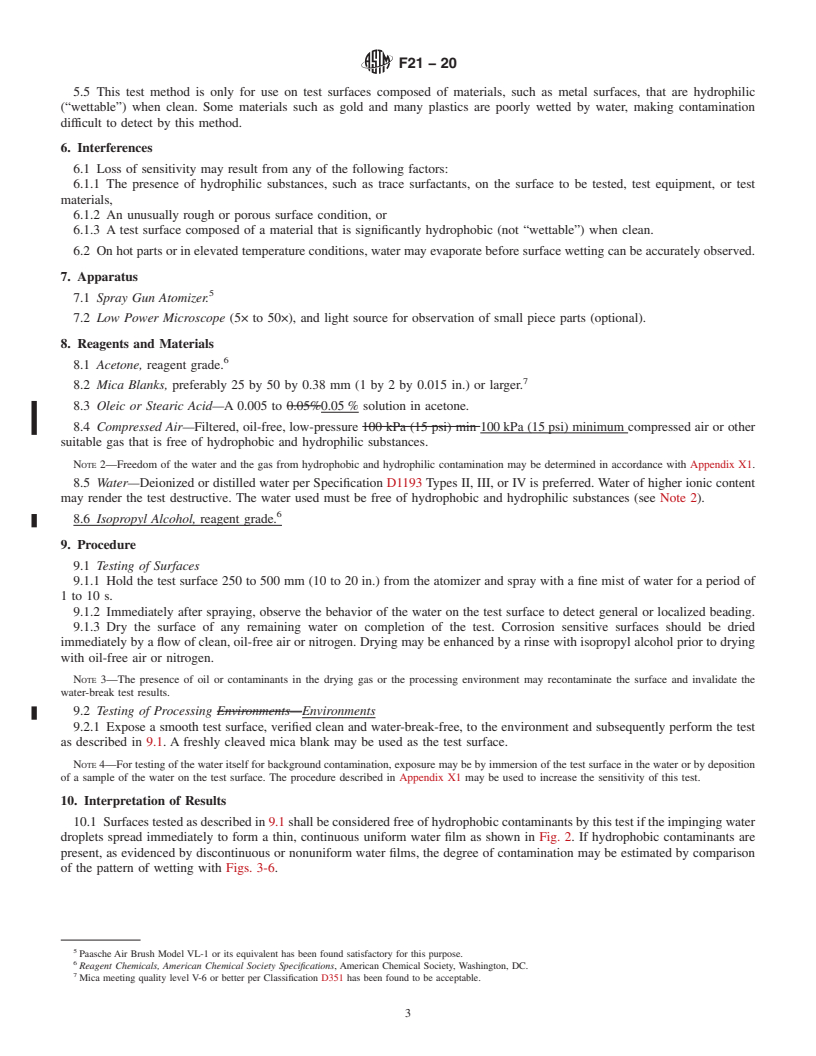

3.1.1 contact angle, n—the interior angle that a drop makes between the substrate and a tangent drawn at the intersection

between the drop and the substrate as shown in Fig. 1; this is the angle formed by a liquid at the three phase boundary where a

liquid, gas (air), and solid intersect.

3.1.2 hydrophilic, adj—having a strong affinity for water; wettable.

3.1.2.1 Discussion—

Hydrophilic surfaces exhibit zero contact angle with water. A sessile drop of water applied to the surface will immediately spread

out to form a film.

1

This test method is under the jurisdiction of ASTM Committee E21 on Space Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.05 on Contamination.

Current edition approved Nov. 1, 2014April 1, 2020. Published November 2014May 2020. Originally approved in 1962. Last previous edition approved in 20072014 as

F21 – 65F21 – 14.(2007). DOI: 10.1520/F0021-14.10.1520/F0021-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F21 − 20

FIG. 1 Contact Angle

3.1.3 hydrophobic, adj—having little affinity for water; nonwettable.

3.1.3.1 Discussion—

Hydrophobic surfaces exhibit contact angles between a sessile drop of water and the surface appeciably greater than zero.

3.1.4 sessile drop, n—a drop of liquid sitting on the upper side of a horizontal surface.

3.1.5 water-break, n—a break in the continuity of a film of water on a surface on removal from an aqueous bath or on removal

of a flowing water source from the surface.

3.1.5 contact angle, n—the interior angle that a drop makes between the substrate and a tangent drawn at the intersection

between the drop and the substrate as shown in Fig. 1; th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.