ASTM C1698-09(2014)

(Test Method)Standard Test Method for Autogenous Strain of Cement Paste and Mortar

Standard Test Method for Autogenous Strain of Cement Paste and Mortar

SIGNIFICANCE AND USE

5.1 Autogenous strain is the self-created bulk strain of cement paste, mortar, or concrete during hardening at constant temperature. In conventional concrete, autogenous shrinkage strain is generally negligible, but in concrete with low water-cementitious materials ratio (w/cm) or with silica fume it may be considerable (1).5 Restraint of the autogenous strain by aggregates or adjoining structural members may result in formation of micro and macro cracks that impair strength, durability and aesthetics. Cracks may also be a problem with regard to hygienic cleaning of surfaces.

5.2 An accurate measurement of the autogenous strain of cementitious mixtures with low w/cm is important for evaluating the risk of early-age cracking of concrete structures. Measurements of autogenous strain have been carried out using either volumetric or linear methods. Both methods may show evidence of significant artifacts (1); therefore, results of the two methods may disagree considerably if not carried out properly.

5.3 A sealed, flexible corrugated mold system (2) combines the advantages of linear and volumetric measurement of autogenous strain, while avoiding most of their disadvantages. The mold effectively prevents moisture loss and minimizes restraint to volume change during hardening. Moreover, results obtained with the corrugated mold system agree with those from the volumetric method, once some artifacts, in particular water absorption through the membrane used to contain the test specimen, have been eliminated in the latter (3,4). The corrugated mold system is easier to use and shows better repeatability than the volumetric technique (3,4). Measurements with the corrugated mold system are in good agreement with unrestrained length change measurements obtained using Test Method C157/C157M with sealed specimens (5); however, Test Method C157/C157M does not allow measurement of the shrinkage occurring before 24 h (5).

5.4 This test method can be used to evaluate the effec...

SCOPE

1.1 This test method measures the bulk strain of a sealed cement paste or mortar specimen, including those containing admixtures, various supplementary cementitious materials (SCM), and other fine materials, at constant temperature and not subjected to external forces, from the time of final setting until a specified age. This strain is known as autogenous strain. Autogenous strain is most significant in concrete with low water-cementitious materials ratio (w/cm) (See Note 1).

Note 1: A low water-cementitious materials ratio (w/cm) can be considered to be a water to cement ratio of 0.40 or lower for this test.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.2)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1698 − 09 (Reapproved 2014)

Standard Test Method for

Autogenous Strain of Cement Paste and Mortar

This standard is issued under the fixed designation C1698; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C219 Terminology Relating to Hydraulic Cement

C305 Practice for Mechanical Mixing of Hydraulic Cement

1.1 This test method measures the bulk strain of a sealed

Pastes and Mortars of Plastic Consistency

cement paste or mortar specimen, including those containing

C403/C403M Test Method for Time of Setting of Concrete

admixtures, various supplementary cementitious materials

Mixtures by Penetration Resistance

(SCM), and other fine materials, at constant temperature and

C1005 Specification for Reference Masses and Devices for

not subjected to external forces, from the time of final setting

Determining Mass and Volume for Use in the Physical

untilaspecifiedage.Thisstrainisknownas autogenous strain.

Testing of Hydraulic Cements

Autogenous strain is most significant in concrete with low

2.2 API Specification

water-cementitious materials ratio (w/cm) (See Note 1).

RP 10B-2/ISO 10426-2 Recommended Practice for Testing

NOTE 1—A low water-cementitious materials ratio (w/cm) can be

considered to be a water to cement ratio of 0.40 or lower for this test. Well Cements

1.2 The values stated in SI units are to be regarded as

3. Terminology

standard. No other units of measurement are included in this

3.1 Definitions:

standard.

3.1.1 For definitions of terms used in this test method, refer

1.3 This standard does not purport to address all of the

to Terminologies C125 and C219.

safety concerns, if any, associated with its use. It is the

3.2 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

3.2.1 autogenous strain, n—the bulk strain of a sealed

priate safety and health practices and determine the applica-

specimen of a cementitious mixture, not subjected to external

bility of regulatory limitations prior to use. (Warning—Fresh

forcesandunderconstanttemperature,measuredfromthetime

hydraulic cementitious mixtures are caustic and may cause

offinalsettinguntilaspecifiedage;negativestraincorresponds

chemical burns to skin and tissue upon prolonged exposure. )

to shrinkage and positive strain corresponds to expansion.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

4.1 Aspecimen of freshly mixed paste or mortar is prepared

C125 Terminology Relating to Concrete and Concrete Ag-

using a corrugated mold that offers little resistance to length

gregates

changeofthespecimen.Themoldissealedtopreventmoisture

C157/C157M Test Method for Length Change of Hardened

loss and the specimen is stored at constant temperature.

Hydraulic-Cement Mortar and Concrete

Starting at the time of final setting, the length of the specimen

C191 TestMethodsforTimeofSettingofHydraulicCement

is measured using a dilatometer. The change in length is

by Vicat Needle

recorded at regular time intervals until the designated age. The

C192/C192M Practice for Making and Curing Concrete Test

change in length and original length of the specimen are used

Specimens in the Laboratory

to compute the autogenous strain.

1 5. Significance and Use

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

5.1 Autogenous strain is the self-created bulk strain of

C09.68 on Volume Change.

cement paste, mortar, or concrete during hardening at constant

Current edition approved Oct. 1, 2014. Published November 2014. Originally

approved in 2009. Last previous edition approved in 2009 as C1698-09. DOI:

temperature. In conventional concrete, autogenous shrinkage

10.1520/C1698-09R14.

strain is generally negligible, but in concrete with low water-

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

cementitious materials ratio (w/cm) or with silica fume it may

Annual Book of ASTM Standards, Vol. 04.02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Petroleum Institute (API), 1220 L. St., NW,

the ASTM website. Washington, DC 20005-4070, http://www.api.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1698 − 09 (2014)

be considerable (1). Restraint of the autogenous strain by 5.5 The autogenous shrinkage strain of mortar specimens

aggregates or adjoining structural members may result in will be less than that of paste specimens for the same w/cm.

formation of micro and macro cracks that impair strength, The autogenous shrinkage strain of concrete will be less than

durability and aesthetics. Cracks may also be a problem with that of mortar for the same w/cm. The nominal maximum

regard to hygienic cleaning of surfaces. aggregate size for mortar used in this test method is 4.75 mm.

5.2 An accurate measurement of the autogenous strain of

6. Apparatus

cementitious mixtures with low w/cm is important for evalu-

6.1 The apparatus to measure autogenous strain is com-

ating the risk of early-age cracking of concrete structures.

posed of a corrugated mold with two end plugs, a dilatometer

Measurementsofautogenousstrainhavebeencarriedoutusing

bench, a length measuring gauge, and a reference bar (see Fig.

either volumetric or linear methods. Both methods may show

1).

evidence of significant artifacts (1); therefore, results of the

two methods may disagree considerably if not carried out

6.2 Molds—The molds consist of corrugated plastic tubes,

properly.

having a length of 420 6 5 mm and an outer diameter of 29 6

0.5 mm (see Note 2). The plastic tubes are made of 0.5 6

5.3 Asealed, flexible corrugated mold system (2) combines

0.2-mm thick low-density polyethylene (PE) and have

the advantages of linear and volumetric measurement of

triangular-shaped corrugations in order to minimize restraint in

autogenous strain, while avoiding most of their disadvantages.

the longitudinal direction (see Fig. 2). The distance between

The mold effectively prevents moisture loss and minimizes

corrugations is 5.8 6 0.2 mm. The mold is tightly closed with

restraint to volume change during hardening. Moreover, results

two tapered end plugs having a length of 19 6 0.5 mm. The

obtained with the corrugated mold system agree with those

diameter of the plastic end plugs tapers from 21 6 0.1 mm to

from the volumetric method, once some artifacts, in particular

22.4 6 0.1 mm (see Fig. 3).

waterabsorptionthroughthemembraneusedtocontainthetest

NOTE 2—The small diameter of the molds limits the temperature

specimen, have been eliminated in the latter (3,4). The corru-

differences that may arise during hydration of the cementitious materials.

gated mold system is easier to use and shows better repeatabil-

Typical maximum temperature increase in the center of the test specimen,

ity than the volumetric technique (3,4). Measurements with the

due to heat of hydration of cement paste or mortar has been determined to

corrugated mold system are in good agreement with unre-

be 2 °C. The maximum longitudinal restraint stress exerted by the molds

has been determined to be 0.001 MPa (6).

strained length change measurements obtained using Test

Method C157/C157M with sealed specimens (5); however,

6.3 Dilatometer Bench—The dilatometer bench consists of

Test Method C157/C157M does not allow measurement of the

three stainless steel rods with a diameter of 20 6 1.0 mm and

shrinkage occurring before 24 h (5).

two stainless steel end plates. Technical drawings of a suitable

dilatometer bench are shown in Fig. 4. During measurement,

5.4 This test method can be used to evaluate the effects of

the test specimen is positioned horizontally and is supported

cementitious materials, admixtures, and mixture proportions

longitudinally by the two upper rods.

on autogenous shrinkage strain of paste or mortar specimens.

6.4 Length Measuring Gauge—A gauge measures length

changes at one end of the specimen. The measuring range of

The boldface numbers in parentheses refer to a list of references at the end of

the gauge shall be at least 10 mm and the resolution shall be at

this standard.

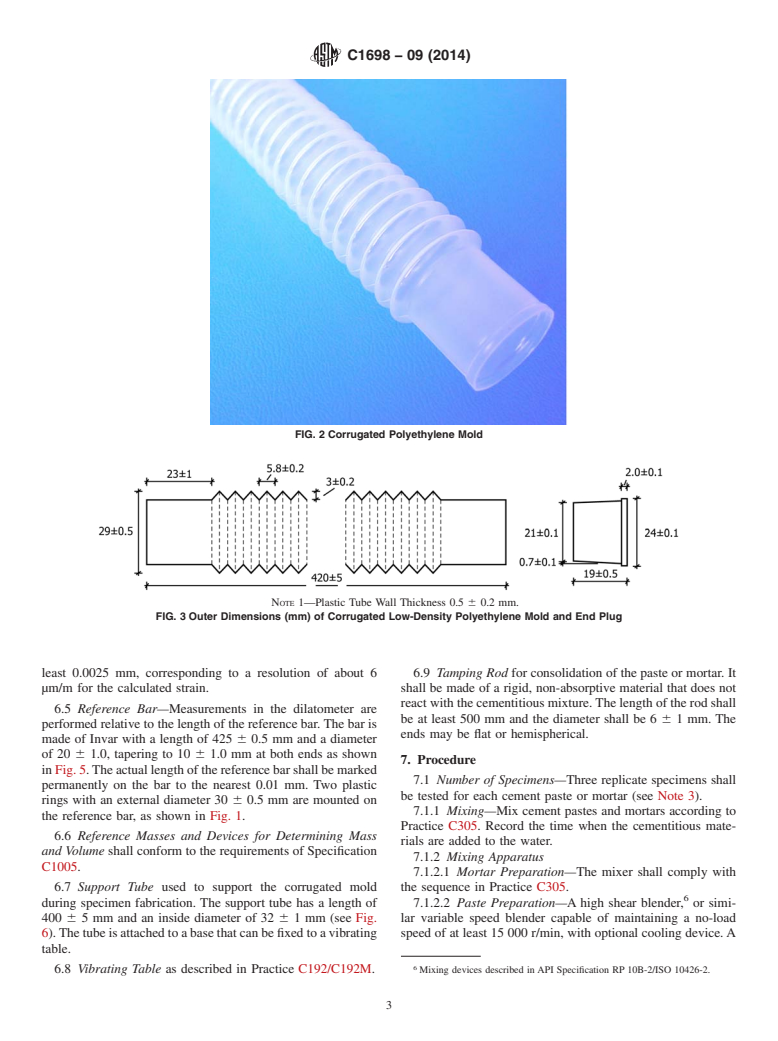

NOTE 1—In the foreground a corrugated PE-mold with two specially shaped end plugs and a 425 mm reference bar. In the background the dilatometer

bench with a test specimen placed for length measurement. To the right a digital length gauge with remote control.

FIG. 1 A Suitable Dilatometer Bench with Accessories

C1698 − 09 (2014)

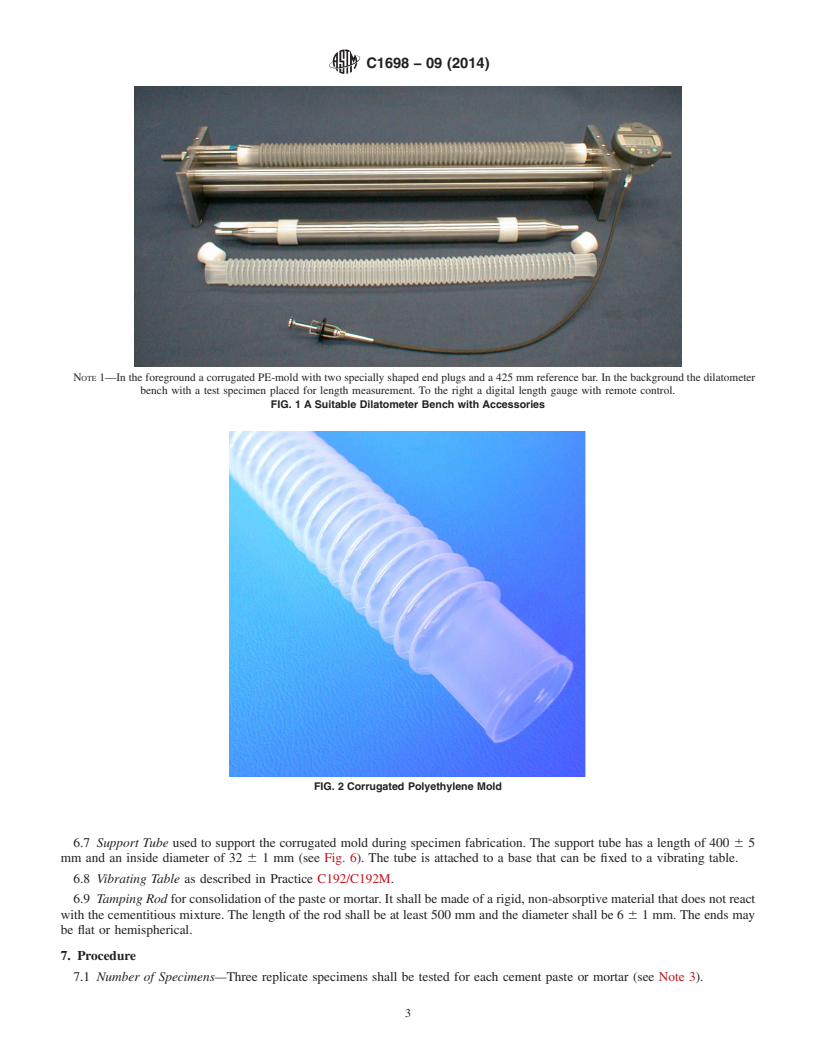

FIG. 2 Corrugated Polyethylene Mold

NOTE 1—Plastic Tube Wall Thickness 0.5 6 0.2 mm.

FIG. 3 Outer Dimensions (mm) of Corrugated Low-Density Polyethylene Mold and End Plug

least 0.0025 mm, corresponding to a resolution of about 6 6.9 Tamping Rod for consolidation of the paste or mortar. It

µm/m for the calculated strain. shall be made of a rigid, non-absorptive material that does not

react with the cementitious mixture.The length of the rod shall

6.5 Reference Bar—Measurements in the dilatometer are

be at least 500 mm and the diameter shall be 6 6 1 mm. The

performed relative to the length of the reference bar.The bar is

ends may be flat or hemispherical.

made of Invar with a length of 425 6 0.5 mm and a diameter

of 20 6 1.0, tapering to 10 6 1.0 mm at both ends as shown

7. Procedure

inFig.5.Theactuallengthofthereferencebarshallbemarked

7.1 Number of Specimens—Three replicate specimens shall

permanently on the bar to the nearest 0.01 mm. Two plastic

be tested for each cement paste or mortar (see Note 3).

rings with an external diameter 30 6 0.5 mm are mounted on

7.1.1 Mixing—Mix cement pastes and mortars according to

the reference bar, as shown in Fig. 1.

Practice C305. Record the time when the cementitious mate-

6.6 Reference Masses and Devices for Determining Mass

rials are added to the water.

and Volume shall conform to the requirements of Specification

7.1.2 Mixing Apparatus

C1005.

7.1.2.1 Mortar Preparation—The mixer shall comply with

6.7 Support Tube used to support the corrugated mold the sequence in Practice C305.

during specimen fabrication. The support tube has a length of 7.1.2.2 Paste Preparation—A high shear blender, or simi-

400 6 5 mm and an inside diameter of 32 6 1 mm (see Fig. lar variable speed blender capable of maintaining a no-load

6).Thetubeisattachedtoabasethatcanbefixedtoavibrating speed of at least 15 000 r/min, with optional cooling device.A

table.

6.8 Vibrating Table as described in Practice C192/C192M. Mixing devices described in API Specification RP 10B-2/ISO 10426-2.

C1698 − 09 (2014)

NOTE 1—All dimensions are in mm (tolerance 6 0.5 %).

FIG. 4 Technical Drawing of the Dilatometer Bench Shown in Fig. 1

Top: Plan View. Bottom: Elevation View of End Plate

NOTE 1—All dimensions are in mm and tolerances given in the text.

FIG. 5 Technical Drawing of the Reference Bar Shown in Fig. 1

hand-held household mixer capable of mixing paste at not less cementitiousmixture,dropthemintothemold,andconsolidate

than 400 r/min or other mixers for paste or mortar preparation with the tamping rod. To ensure that the cast specimens have

are also permitted.

approximately the same length, do not stretch or compress the

NOTE 3—About 185 mL of cement paste or mortar are needed to fill

corrugated mold during filling. For fluid mixtures, the corru-

each corrugated mold. For a paste with a water-cement ratio of 0.4, this

gated mold shall be held only by the support tube during

corresponds to approximately 360 g of paste.

casting. For semi-fluid and stiff mixtures, manually maintain

7.2 Filling and Closing of Molds—Clamp the mounting

the initial length of the mold during compaction. Fill the mold

base of the support tube to a vibrating table. Measure the

to approximately 15 mm below the top end of the mold to

lengths of the plugs to be used for each specimen. Place a plug

allow room for the top end plug. Before mounting the top end

intooneendofthemold,andpositionthemold,withtheclosed

plug, gently compress the corrugated mold to bring the cement

end down, inside the support tube. If the cementitious mixture

paste or mortar in contact with the end plug. Mount the end

is pourable, slowly pour the mixture into the corrugated mold

plug during relief of the compression of the corrugated mold.

with the vibrating table turned on (see Fig. 7). For a semi-fluid

Use a screwing motion of the end plug to ease the mounting

mixture, fill the mold in four equal layers and compact each

operation.Immediatelyaftercasting,carefullywipethesurface

layer 5 times with the tamping rod before each subsequent

of the corrugated mold with a dry cloth to remove any cement

layer is cast. The rod shall just penetrate the underlying layer.

paste, mortar, or water.

For a stiff mixture, hand prepare rolled sections of the

C1698 − 09 (2014)

NOTE 1—All dimensions are in mm. The base of the support tube allows clamping to a vibration table.

FIG. 6 Suitable Dimensions of the Support Tube That is Used During Filling of the Corrugated Molds

7.3 Measuring Room—To minimize the influence of tem-

perature variations, both the specimens and the dilatometer

shallbekeptinathermostaticallycontrolledroomorcabinetat

all times during the test. Maintain the surrounding air tempera-

ture at 23.0 6 1.0 °C, unless otherwise specified (see Note 4).

Do not store specimens in a water bath due to possible water

transport through the corrugated molds.

NOTE 4—The measurement can be performed at any temperature

specified by the user, provided that the temperature in the measuring room

or cabinet is maintained constant during the test with a tolerance of 6 1.0

°C.

7.4 Specimen Storage—After filling and sealing the molds,

store the specimens horizontally on a smooth surface, to avoid

any restraint to length change. Support specimens along their

entire length to avoid damage and to ensure they remain

straight (see Note 5). Maintain a separation of at least 30 mm

between specimens during the first day of measurement to

allow dispersion of their heats of hydration.

NOTE 5—Corrugated plastic sheets as shown in Fig. 8 or other suitable

materials can be used to support the molded specimens.

NOTE 1—An empty corrugated mold, clos

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1698 − 09 C1698 − 09 (Reapproved 2014)

Standard Test Method for

Autogenous Strain of Cement Paste and Mortar

This standard is issued under the fixed designation C1698; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method measures the bulk strain of a sealed cement paste or mortar specimen, including those containing

admixtures, various supplementary cementitious materials (SCM), and other fine materials, at constant temperature and not

subjected to external forces, from the time of final setting until a specified age. This strain is known as autogenous strain.

Autogenous strain is most significant in concrete with low water-cementitious materials ratio (w/cm) (See Note 1).

NOTE 1—A low water-cementitious materials ratio (w/cm) can be considered to be a water to cement ratio of 0.40 or lower for this test.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and

tissue upon prolonged exposure.Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to

skin and tissue upon prolonged exposure. )

2. Referenced Documents

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C157/C157M Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete

C191 Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle

C192/C192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C219 Terminology Relating to Hydraulic Cement

C305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

C403/C403M Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance

C1005 Specification for Reference Masses and Devices for Determining Mass and Volume for Use in the Physical Testing of

Hydraulic Cements

2.2 API Specification

RP 10B-2/ISO 10426-2 Recommended Practice for Testing Well Cements

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminologies C125 and C219.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 autogenous strain, n—the bulk strain of a sealed specimen of a cementitious mixture, not subjected to external forces and

under constant temperature, measured from the time of final setting until a specified age; negative strain corresponds to shrinkage

and positive strain corresponds to expansion.

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.68 on

Volume Change.

Current edition approved Oct. 1, 2009Oct. 1, 2014. Published November 2009November 2014. Originally approved in 2009. Last previous edition approved in 2009 as

C1698-09. DOI: 10.1520/C1698-09.10.1520/C1698-09R14.

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Annual Book of ASTM Standards, VolVol. 04.02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Petroleum Institute (API), 1220 L. St., NW, Washington, DC 20005-4070, http://www.api.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1698 − 09 (2014)

4. Summary of Test Method

4.1 A specimen of freshly mixed paste or mortar is prepared using a corrugated mold that offers little resistance to length change

of the specimen. The mold is sealed to prevent moisture loss and the specimen is stored at constant temperature. Starting at the

time of final setting, the length of the specimen is measured using a dilatometer. The change in length is recorded at regular time

intervals until the designated age. The change in length and original length of the specimen are used to compute the autogenous

strain.

5. Significance and Use

5.1 Autogenous strain is the self-created bulk strain of cement paste, mortar, or concrete during hardening at constant

temperature. In conventional concrete, autogenous shrinkage strain is generally negligible, but in concrete with low water-

cementitious materials ratio (w/cm) or with silica fume it may be considerable (1). Restraint of the autogenous strain by aggregates

or adjoining structural members may result in formation of micro and macro cracks that impair strength, durability and aesthetics.

Cracks may also be a problem with regard to hygienic cleaning of surfaces.

5.2 An accurate measurement of the autogenous strain of cementitious mixtures with low w/cm is important for evaluating the

risk of early-age cracking of concrete structures. Measurements of autogenous strain have been carried out using either volumetric

or linear methods. Both methods may show evidence of significant artifacts (1); therefore, results of the two methods may disagree

considerably if not carried out properly.

5.3 A sealed, flexible corrugated mold system (2) combines the advantages of linear and volumetric measurement of autogenous

strain, while avoiding most of their disadvantages. The mold effectively prevents moisture loss and minimizes restraint to volume

change during hardening. Moreover, results obtained with the corrugated mold system agree with those from the volumetric

method, once some artifacts, in particular water absorption through the membrane used to contain the test specimen, have been

eliminated in the latter (3,4). The corrugated mold system is easier to use and shows better repeatability than the volumetric

technique (3,4). Measurements with the corrugated mold system are in good agreement with unrestrained length change

measurements obtained using Test Method C157/C157M with sealed specimens (5); however, Test Method C157/C157M does not

allow measurement of the shrinkage occurring before 24 h (5).

5.4 This test method can be used to evaluate the effects of cementitious materials, admixtures, and mixture proportions on

autogenous shrinkage strain of paste or mortar specimens.

5.5 The autogenous shrinkage strain of mortar specimens will be less than that of paste specimens for the same w/cm. The

autogenous shrinkage strain of concrete will be less than that of mortar for the same w/cm. The nominal maximum aggregate size

for mortar used in this test method is 4.75 mm.

6. Apparatus

6.1 The apparatus to measure autogenous strain is composed of a corrugated mold with two end plugs, a dilatometer bench, a

length measuring gauge, and a reference bar (see Fig. 1).

6.2 Molds—The molds consist of corrugated plastic tubes, having a length of 420 6 5 mm and an outer diameter of 29 6 0.5

mm (see Note 2). The plastic tubes are made of 0.5 6 0.2-mm thick low-density polyethylene (PE) and have triangular-shaped

corrugations in order to minimize restraint in the longitudinal direction (see Fig. 2). The distance between corrugations is 5.8 6

0.2 mm. The mold is tightly closed with two tapered end plugs having a length of 19 6 0.5 mm. The diameter of the plastic end

plugs tapers from 21 6 0.1 mm to 22.4 6 0.1 mm (see Fig. 3).

NOTE 2—The small diameter of the molds limits the temperature differences that may arise during hydration of the cementitious materials. Typical

maximum temperature increase in the center of the test specimen, due to heat of hydration of cement paste or mortar has been determined to be 2 °C.

The maximum longitudinal restraint stress exerted by the molds has been determined to be 0.001 MPa (6).

6.3 Dilatometer Bench—The dilatometer bench consists of three stainless steel rods with a diameter of 20 6 1.0 mm and two

stainless steel end plates. Technical drawings of a suitable dilatometer bench are shown in Fig. 4. During measurement, the test

specimen is positioned horizontally and is supported longitudinally by the two upper rods.

6.4 Length Measuring Gauge—A gauge measures length changes at one end of the specimen. The measuring range of the gauge

shall be at least 10 mm and the resolution shall be at least 0.0025 mm, corresponding to a resolution of about 6 μm/m for the

calculated strain.

6.5 Reference Bar—Measurements in the dilatometer are performed relative to the length of the reference bar. The bar is made

of Invar with a length of 425 6 0.5 mm and a diameter of 20 6 1.0, tapering to 10 6 1.0 mm at both ends as shown in Fig. 5.

The actual length of the reference bar shall be marked permanently on the bar to the nearest 0.01 mm. Two plastic rings with an

external diameter 30 6 0.5 mm are mounted on the reference bar, as shown in Fig. 1.

6.6 Reference Masses and Devices for Determining Mass and Volume shall conform to the requirements of Specification C1005.

The boldface numbers in parentheses refer to a list of references at the end of this standard.

C1698 − 09 (2014)

NOTE 1—In the foreground a corrugated PE-mold with two specially shaped end plugs and a 425 mm reference bar. In the background the dilatometer

bench with a test specimen placed for length measurement. To the right a digital length gauge with remote control.

FIG. 1 A Suitable Dilatometer Bench with Accessories

FIG. 2 Corrugated Polyethylene Mold

6.7 Support Tube used to support the corrugated mold during specimen fabrication. The support tube has a length of 400 6 5

mm and an inside diameter of 32 6 1 mm (see Fig. 6). The tube is attached to a base that can be fixed to a vibrating table.

6.8 Vibrating Table as described in Practice C192/C192M.

6.9 Tamping Rod for consolidation of the paste or mortar. It shall be made of a rigid, non-absorptive material that does not react

with the cementitious mixture. The length of the rod shall be at least 500 mm and the diameter shall be 6 6 1 mm. The ends may

be flat or hemispherical.

7. Procedure

7.1 Number of Specimens—Three replicate specimens shall be tested for each cement paste or mortar (see Note 3).

C1698 − 09 (2014)

NOTE 1—Plastic Tube Wall Thickness 0.5 6 0.2 mm.

FIG. 3 Outer Dimensions (mm) of Corrugated Low-Density Polyethylene Mold and End Plug

NOTE 1—All dimensions are in mm (tolerance 6 0.5 %).

FIG. 4 Technical Drawing of the Dilatometer Bench Shown in Fig. 1

Top: Plan View. Bottom: Elevation View of End Plate

NOTE 1—All dimensions are in mm and tolerances given in the text.

FIG. 5 Technical Drawing of the Reference Bar Shown in Fig. 1

7.1.1 Mixing—Mix cement pastes and mortars according to Practice C305. Record the time when the cementitious materials are

added to the water.

7.1.2 Mixing Apparatus

7.1.2.1 Mortar Preparation—The mixer shall comply with the sequence in Practice C305.

C1698 − 09 (2014)

NOTE 1—All dimensions are in mm. The base of the support tube allows clamping to a vibration table.

FIG. 6 Suitable Dimensions of the Support Tube That is Used During Filling of the Corrugated Molds

7.1.2.2 Paste Preparation—A high shear blender, or similar variable speed blender capable of maintaining a no-load speed of

at least 15 000 r/min, with optional cooling device. A hand-held household mixer capable of mixing paste at not less than 400 r/min

or other mixers for paste or mortar preparation are also permitted.

NOTE 3—About 185 mL of cement paste or mortar are needed to fill each corrugated mold. For a paste with a water-cement ratio of 0.4, this corresponds

to approximately 360 g of paste.

7.2 Filling and Closing of Molds—Clamp the mounting base of the support tube to a vibrating table. Measure the lengths of

the plugs to be used for each specimen. Place a plug into one end of the mold, and position the mold, with the closed end down,

inside the support tube. If the cementitious mixture is pourable, slowly pour the mixture into the corrugated mold with the vibrating

table turned on (see Fig. 7). For a semi-fluid mixture, fill the mold in four equal layers and compact each layer 5 times with the

tamping rod before each subsequent layer is cast. The rod shall just penetrate the underlying layer. For a stiff mixture, hand prepare

rolled sections of the cementitious mixture, drop them into the mold, and consolidate with the tamping rod. To ensure that the cast

specimens have approximately the same length, do not stretch or compress the corrugated mold during filling. For fluid mixtures,

the corrugated mold shall be held only by the support tube during casting. For semi-fluid and stiff mixtures, manually maintain

the initial length of the mold during compaction. Fill the mold to approximately 15 mm below the top end of the mold to allow

room for the top end plug. Before mounting the top end plug, gently compress the corrugated mold to bring the cement paste or

mortar in contact with the end plug. Mount the end plug during relief of the compression of the corrugated mold. Use a screwing

motion of the end plug to ease the mounting operation. Immediately after casting, carefully wipe the surface of the corrugated mold

with a dry cloth to remove any cement paste, mortar, or water.

7.3 Measuring Room—To minimize the influence of temperature variations, both the specimens and the dilatometer shall be

kept in a thermostatically controlled room or cabinet at all times during the test. Maintain the surrounding air temperature at 23.0

6 1.0 °C, unless otherwise specified (see Note 4). Do not store specimens in a water bath due to possible water transport through

the corrugated molds.

Mixing devices described in API Specification RP 10B-2/ISO 10426-2.

C1698 − 09 (2014)

NOTE 1—An empty corrugated mold, closed at one end with an end plug, is inserted into the support tube and positioned vertically on

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.