ASTM C1810/C1810M-23

(Guide)Standard Guide for Comparing Performance of Concrete-Making Materials Using Mortar Mixtures

Standard Guide for Comparing Performance of Concrete-Making Materials Using Mortar Mixtures

SIGNIFICANCE AND USE

4.1 The results of mortar mixture tests can be suitable for comparing the relative performance of combinations of concrete-making materials such as fine aggregate, chemical admixtures, supplementary cementitious materials (SCMs), water, and hydraulic cement. Furthermore, this guide can be useful to identify unexpected performances due to combination of various materials. The relative trends in performance observed with the mortar method may suggest relative performance in concrete mixtures batched with the same materials and relative mixture proportions.

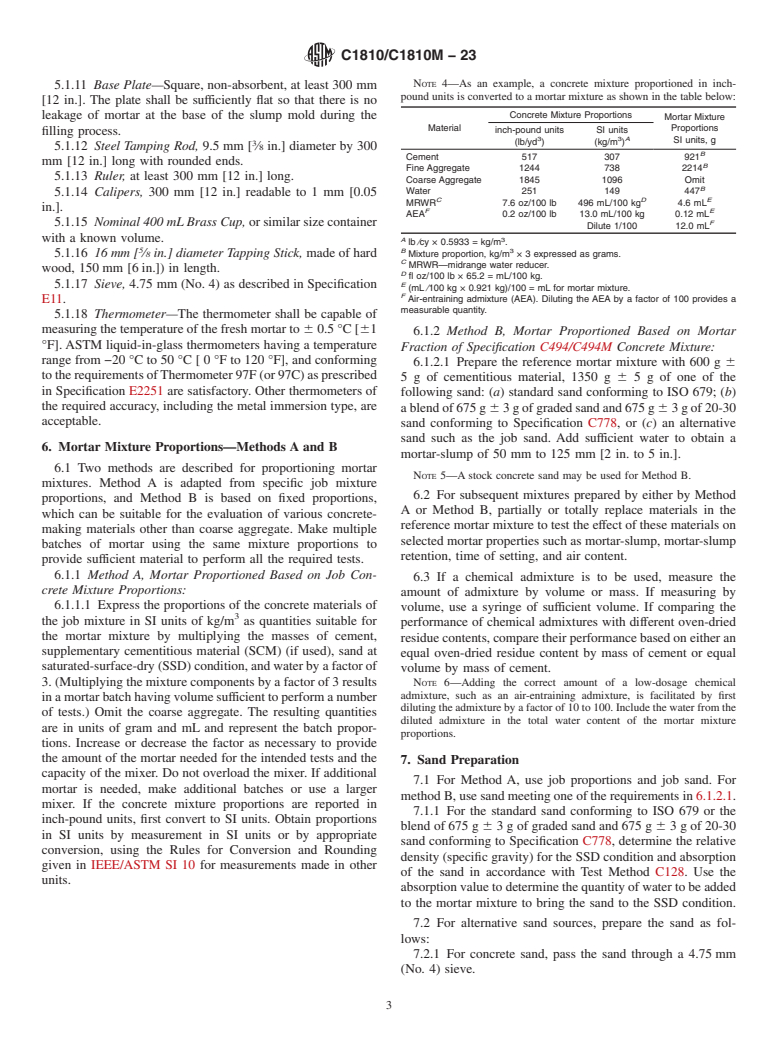

4.2 While there are a number of ways to proportion and mix mortar mixtures, four procedures described in this guide have been used extensively for evaluating the performance of admixtures. Method A enables evaluation of materials using mixture proportions that correspond to specific job conditions. Method B can be used as a general mixture using fixed amounts of a standard sand, cement, and supplementary cementitious materials. Method C is a modified version of Test Method C359 to evaluate the impact of chemical admixtures on the early stiffening of a mortar prepared with specified amounts of job cement, a standard sand, and an amount of water that will produce a mortar with a specified initial penetration measured in accordance with Test Method C359. The measurements of penetration over time can be related to the early stiffening processes associated with false and flash set. Method D is a modified version of Test Method C185 whereby the mortar mixture can be prepared with various combinations of chemical admixtures, supplementary cementitious materials, and job water. Methods A and B would be most applicable for investigating material incompatibility issues associated with ready mixed concrete, while Method C would be applicable for concrete mixed for a short period of time in stationary mixers and transported to the forms in non-agitating equipment. Method D is suitable for all concrete mixing processes and is...

SCOPE

1.1 This guide provides information on how to compare the relative performance and potential incompatibility of combinations of concrete-making materials. Performance tests on fresh and early-age properties of mortar mixtures can be useful indicators of concrete performance using similar materials. The performance tests described in this guide include mortar-slump, mortar spread, mortar-workability retention, early stiffening of mortar, time of setting, air entrainment, and hydration kinetics.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with this guide. Some values only have SI units because the inch-pound equivalents are not used in guide.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Warning—Fresh hydraulic cementitious mixtures are caustic and may cause burns to skin and tissue upon prolonged exposure.2

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1810/C1810M − 23

Standard Guide for

Comparing Performance of Concrete-Making Materials

1

Using Mortar Mixtures

This standard is issued under the fixed designation C1810/C1810M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 This guide provides information on how to compare the

C70 Test Method for Surface Moisture in Fine Aggregate

relative performance and potential incompatibility of combi-

C125 Terminology Relating to Concrete and Concrete Ag-

nations of concrete-making materials. Performance tests on

gregates

fresh and early-age properties of mortar mixtures can be useful

C128 Test Method for Relative Density (Specific Gravity)

indicators of concrete performance using similar materials. The

and Absorption of Fine Aggregate

performance tests described in this guide include mortar-

C185 Test Method for Air Content of Hydraulic Cement

slump, mortar spread, mortar-workability retention, early stiff-

Mortar

ening of mortar, time of setting, air entrainment, and hydration

C219 Terminology Relating to Hydraulic and Other Inor-

kinetics.

ganic Cements

C305 Practice for Mechanical Mixing of Hydraulic Cement

1.2 Units—The values stated in either SI units or inch-

Pastes and Mortars of Plastic Consistency

pound units are to be regarded separately as standard. The

C359 Test Method for Early Stiffening of Hydraulic-Cement

values stated in each system may not be exact equivalents;

(Mortar Method)

therefore, each system shall be used independently of the other.

C403/C403M Test Method for Time of Setting of Concrete

Combining values from the two systems may result in non-

Mixtures by Penetration Resistance

conformance with this guide. Some values only have SI units

C494/C494M Specification for Chemical Admixtures for

because the inch-pound equivalents are not used in guide.

Concrete

1.3 This standard does not purport to address all of the C566 Test Method for Total Evaporable Moisture Content of

Aggregate by Drying

safety concerns, if any, associated with its use. It is the

C670 Practice for Preparing Precision and Bias Statements

responsibility of the user of this standard to establish appro-

for Test Methods for Construction Materials

priate safety, health, and environmental practices and deter-

C778 Specification for Standard Sand

mine the applicability of regulatory limitations prior to use.

C1602/C1602M Specification for Mixing Water Used in the

Warning—Fresh hydraulic cementitious mixtures are caustic

Production of Hydraulic Cement Concrete

and may cause burns to skin and tissue upon prolonged

2

C1679 Practice for Measuring Hydration Kinetics of Hy-

exposure.

draulic Cementitious Mixtures Using Isothermal Calorim-

1.4 This international standard was developed in accor-

etry

dance with internationally recognized principles on standard-

C1777 Test Method for Rapid Determination of the Methyl-

ization established in the Decision on Principles for the

ene Blue Value for Fine Aggregate or Mineral Filler Using

Development of International Standards, Guides and Recom-

a Colorimeter

mendations issued by the World Trade Organization Technical

E11 Specification for Woven Wire Test Sieve Cloth and Test

Barriers to Trade (TBT) Committee.

Sieves

E2251 Specification for Liquid-in-Glass ASTM Thermom-

eters with Low-Hazard Precision Liquids

1

IEEE/ASTM SI 10 American National Standard for Metric

This guide is under the jurisdiction of ASTM Committee C09 on Concrete and

Concrete Aggregates and is the direct responsibility of Subcommittee C09.48 on

Practice

Performance of Cementitious Materials and Admixture Combinations.

Current edition approved Oct. 1, 2023. Published November 2023. Originally

3

approved in 2019. Last previous edition approved in 2022 as C1810/C1810M – 22. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/C1810_C1810M-23. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Standards volume information, refer to the standard’s Document Summary page on

Annual Book of ASTM Standards, Vol. 04.02. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1810

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1810/C1810M − 22 C1810/C1810M − 23

Standard Guide for

Comparing Performance of Concrete-Making Materials

1

Using Mortar Mixtures

This standard is issued under the fixed designation C1810/C1810M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This guide provides information on how to compare the relative performance and potential incompatibility of combinations

of concrete-making materials. Performance tests on fresh and early-age properties of mortar mixtures can be useful indicators of

concrete performance using similar materials. The performance tests described in this guide include mortar-slump, mortar spread,

mortar-workability retention, early stiffening of mortar, time of setting, air entrainment, and hydration kinetics.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from

the two systems may result in non-conformance with this guide. Some values only have SI units because the inch-pound

equivalents are not used in guide.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Warning—Fresh hydraulic cementitious mixtures are caustic and may cause burns to skin and

2

tissue upon prolonged exposure.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

C70 Test Method for Surface Moisture in Fine Aggregate

C125 Terminology Relating to Concrete and Concrete Aggregates

C128 Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate

C185 Test Method for Air Content of Hydraulic Cement Mortar

C219 Terminology Relating to Hydraulic and Other Inorganic Cements

C305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

C359 Test Method for Early Stiffening of Hydraulic-Cement (Mortar Method)

C403/C403M Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance

C494/C494M Specification for Chemical Admixtures for Concrete

1

This guide is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.48 on

Performance of Cementitious Materials and Admixture Combinations.

Current edition approved Dec. 15, 2022Oct. 1, 2023. Published February 2023November 2023. Originally approved in 2019. Last previous edition approved in 20212022

as C1810/C1810M – 21a.C1810/C1810M – 22. DOI: 10.1520/C1810_C1810M-22.10.1520/C1810_C1810M-23.

2

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Annual Book of ASTM Standards, Vol. 04.02.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1810/C1810M − 23

C566 Test Method for Total Evaporable Moisture Content of Aggregate by Drying

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

C778 Specification for Standard Sand

C1602/C1602M Specification for Mixing Water Used in the Production of Hydraulic Cement Concrete

C1679 Practice for Measuring Hydration Kinetics of Hydraulic Cementitious Mixtures Using Isothermal Calorimetry

C1777 Test Method for Rapid Determination of the Methylene Blue Value for Fine Aggregate or Mineral Filler Using a

Colorimeter

E11 Specification for W

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.