ASTM D5705-03(2008)

(Test Method)Standard Test Method for Measurement of Hydrogen Sulfide in the Vapor Phase Above Residual Fuel Oils

Standard Test Method for Measurement of Hydrogen Sulfide in the Vapor Phase Above Residual Fuel Oils

SIGNIFICANCE AND USE

Excessive levels of hydrogen sulfide in the vapor phase above residual fuel oils in storage tanks may result in a health hazard, OSHA limits violation, and public complaints about odors. Control measures to maintain safe levels of H2S in the tank atmosphere for those working in the vicinity require a consistent method for the assessment of potentially hazardous levels of H2S in fuel oils (Warning—H2S is a highly toxic substance. Use extreme care in the sampling and handling of samples that are suspected of containing high levels of H2S.).

This test method has been developed to provide refineries, fuel terminals, and independent testing laboratories, which do not have access to analytical instruments such as a gas chromatograph, with a simple and consistent field test method for the rapid determination of H2S in the vapor phase of residual fuel oils.

This test method does not necessarily simulate the vapor phase H2S concentration of a fuel storage tank. It does, however, provide a level of consistency so that the test result is only a function of the residual fuel oil sample and not the test method, operator, or location. No general correlation can be established between this field test and actual vapor phase concentrations of H2S in residual fuel oil storage or transports. However, a facility that produces fuel oil from the same crude source under essentially constant conditions might be able to develop a correlation for its individual case.

SCOPE

1.1 This test method covers the field determination of hydrogen sulfide (H2S) in the vapor phase (equilibrium headspace) of a residual fuel oil sample.

1.2 The test method is applicable to liquids with a viscosity range of 5.5 mm2/s at 40°C to 50 mm2/s at 100°C. The test method is applicable to fuels conforming to Specification D 396 Grade Nos. 4, 5 (Heavy), and 6.

1.3 The applicable range is from 5 to 4000 parts per million by volume (ppm v/v) (micro mole/mole).

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5705 – 03 (Reapproved 2008)

Standard Test Method for

Measurement of Hydrogen Sulfide in the Vapor Phase

Above Residual Fuel Oils

This standard is issued under the fixed designation D5705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope refining process and lighter distillates blended to a fuel oil

viscosity specification.

1.1 This test method covers the field determination of

3.1.2.1 Discussion—Under the conditions of this test (1:1

hydrogen sulfide (H S) in the vapor phase (equilibrium head-

liquid/vapor ratio, temperature, and agitation) the HSinthe

space) of a residual fuel oil sample. 2

vapor phase (sample’s headspace) will be in equilibrium with

1.2 The test method is applicable to liquids with a viscosity

2 2

the H S in the liquid phase.

range of 5.5 mm /s at 40°C to 50 mm /s at 100°C. The test 2

methodisapplicabletofuelsconformingtoSpecificationD396

4. Summary of Test Method

Grade Nos. 4, 5 (Heavy), and 6.

4.1 A1-LH S-inert test container (glass test bottle) is filled

1.3 The applicable range is from 5 to 4000 parts per million

to 50 volume % with fuel oil from a filled H S-inert container

by volume (ppm v/v) (micro mole/mole).

(glass sample bottle) just prior to testing. In the test container,

1.4 The values stated in SI units are to be regarded as

the vapor space above the fuel oil sample is purged with

standard. No other units of measurement are included in this

nitrogen to displace air. The test container with sample is

standard.

heated in an oven to 60°C, and agitated on an orbital shaker at

1.5 This standard does not purport to address all of the

220 rpm for 3 min.

safety concerns, if any, associated with its use. It is the

4.2 Alength-of-stain detector tube and hand-operated pump

responsibility of the user of this standard to establish appro-

are used to measure the H S concentration in the vapor phase

priate safety and health practices and determine the applica-

of the test container. The length-of-stain detector tube should

bility of regulatory limitations prior to use.

be close to but not in contact with the liquid surface.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 Excessive levels of hydrogen sulfide in the vapor phase

D396 Specification for Fuel Oils

above residual fuel oils in storage tanks may result in a health

D4057 Practice for Manual Sampling of Petroleum and

hazard, OSHA limits violation, and public complaints about

Petroleum Products

odors. Control measures to maintain safe levels of HSinthe

3. Terminology tank atmosphere for those working in the vicinity require a

consistent method for the assessment of potentially hazardous

3.1 Definitions:

levels of H S in fuel oils (Warning—H S is a highly toxic

2 2

3.1.1 equilibrium headspace, n—the vapor space above the

substance. Use extreme care in the sampling and handling of

liquid in which all vapor components are in equilibrium with

samples that are suspected of containing high levels of H S.).

the liquid components.

5.2 This test method has been developed to provide refin-

3.1.2 residual fuel oil, n—a fuel oil comprising a blend of

eries, fuel terminals, and independent testing laboratories,

viscous long, short, or cracked residue from a petroleum

which do not have access to analytical instruments such as a

gas chromatograph, with a simple and consistent field test

This test method is under the jurisdiction of ASTM Committee D02 on method for the rapid determination of H S in the vapor phase

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

of residual fuel oils.

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

5.3 Thistestmethoddoesnotnecessarilysimulatethevapor

Current edition approved Dec. 1, 2008. Published February 2009. Originally

phase H S concentration of a fuel storage tank. It does,

approved in 1995. Last previous edition approved in 2003 as D5705–03. DOI:

10.1520/D5705-03R08.

however, provide a level of consistency so that the test result is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

only a function of the residual fuel oil sample and not the test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

method, operator, or location. No general correlation can be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. established between this field test and actual vapor phase

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5705 – 03 (2008)

concentrations of H S in residual fuel oil storage or transports.

However, a facility that produces fuel oil from the same crude

source under essentially constant conditions might be able to

develop a correlation for its individual case.

6. Interferences

6.1 Typically, sulfur dioxide and mercaptans may cause

positive interferences. In some cases, nitrogen dioxide can

cause a negative interference. Most detector tubes will have a

precleanse layer designed to remove certain interferences up to

some maximum interferant level. Consult the manufacturer’s

instructions for specific interference information.

7. Apparatus

7.1 Shaker, a bench-top orbital shaker and platform

equipped with a four-prong clamp to hold 1-L Boston round-

bottom glass bottles and capable of operation at 220 rpm.

7.2 Timer, capable of measuring from1sto30min at

second intervals.

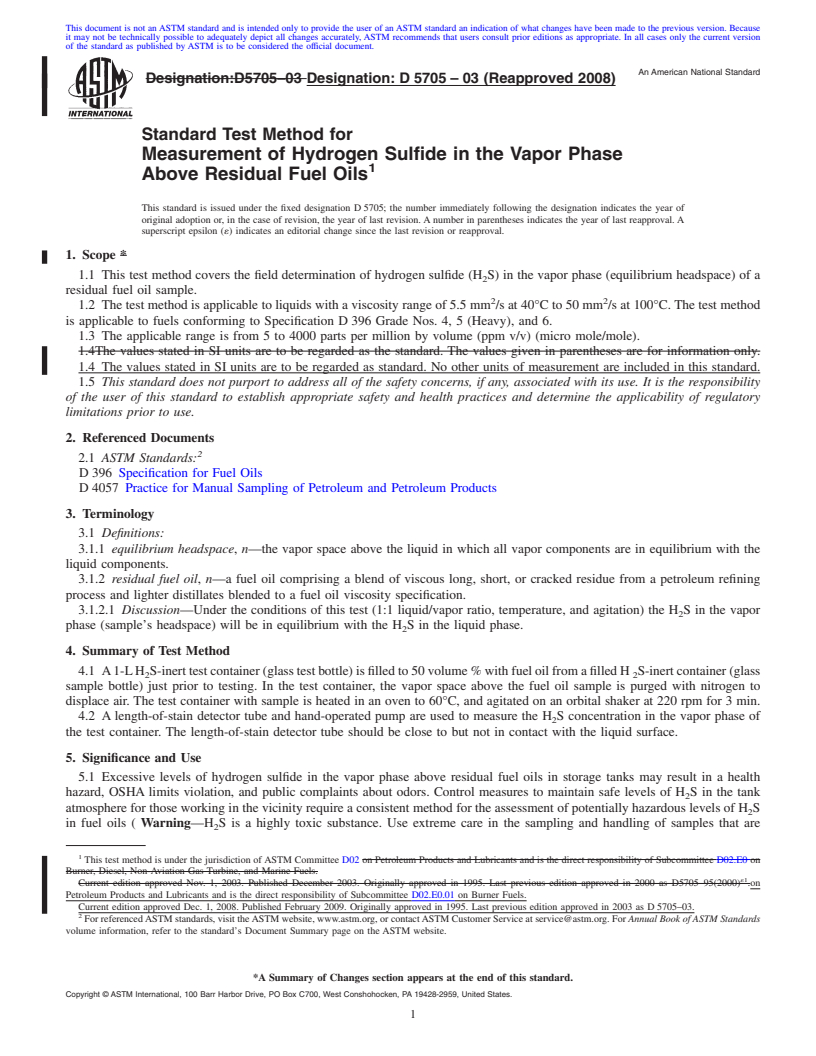

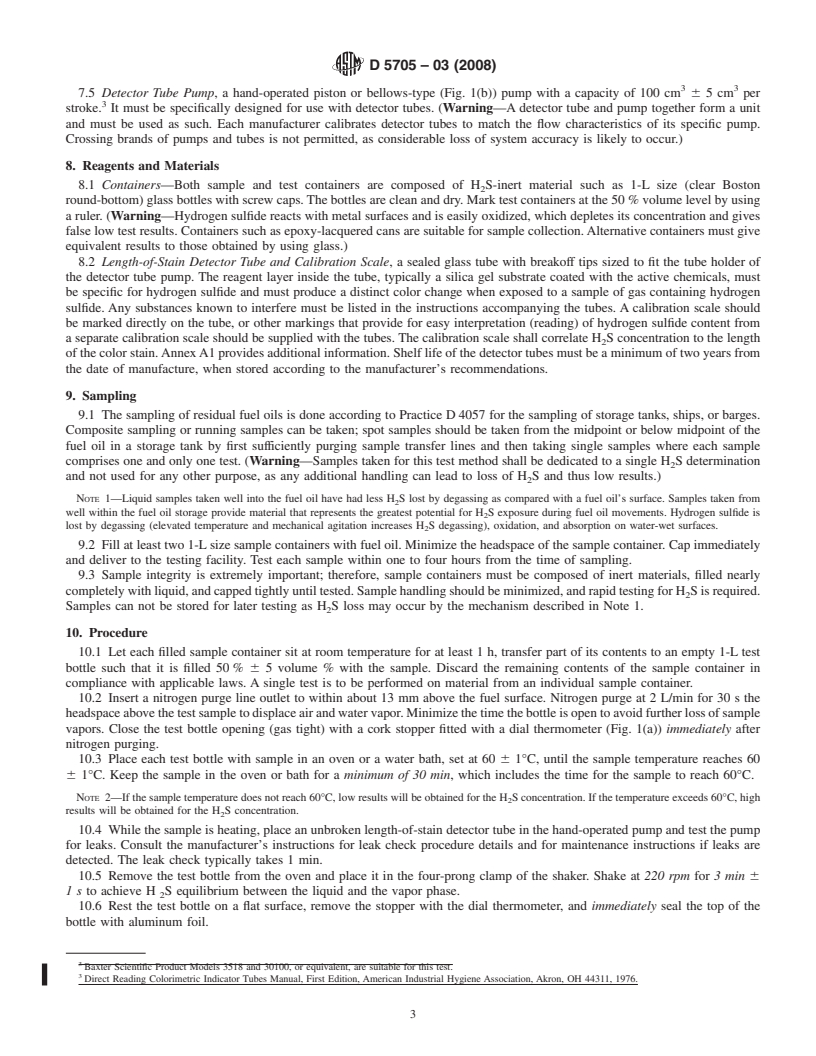

7.3 Stopper with Temperature Measuring Device, a No. 2

cork stopper with a temperature measuring devices inserted

through it that is capable of accurately measuring the tempera-

tureofthesampleat60 61°Casrequiredintheprocedureand

extending at least 25 mm into the residual fuel but no closer

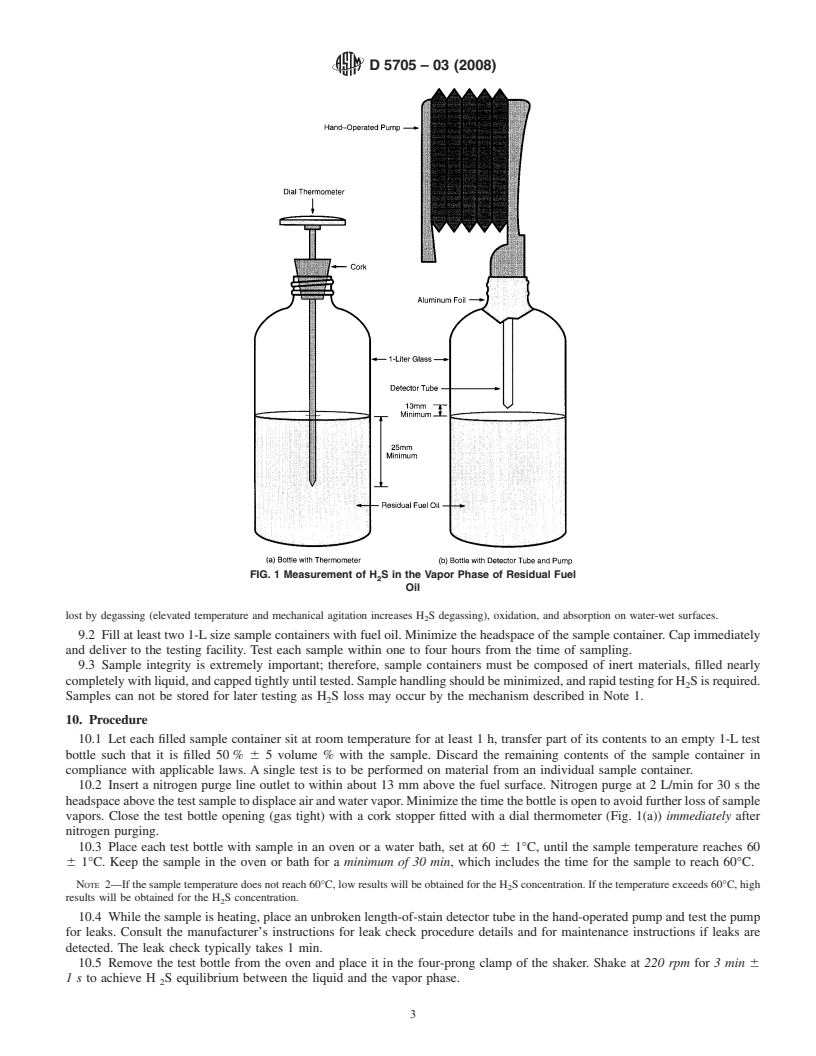

than 25 mm from the bottom of a test bottle (see Fig. 1(a)). A

dialthermometerhavingarangeof–18to82°Canda200–mm

stem has been found suitable to use.

7.4 Oven or Water Bath, capable of heating the fuel oil

samples to 60 6 1°C.

7.5 Detector Tube Pump,ahand-operatedpistonorbellows-

3 3

type (Fig. 1(b)) pump with a capacity of 100 cm 65cm per

stroke. It must be specifically designed for use with detector

FIG. 1 Measurement of H S in the Vapor Phase of Residual Fuel

tubes. (Warning—A detector tube and pump together form a

Oil

unit and must be used as such. Each manufacturer calibrates

detector tubes to match the flow characteristics of its specific

containing hydrogen sulfide. Any substances known to inter-

pump. Crossing brands of pumps and tubes is not permitted, as

fere must be listed in the instructions accompanying the tubes.

considerable loss of system accuracy is likely to occur.)

A calibration scale should be marked directly on the tube, or

other markings that provide for easy interpretation (reading) of

8. Reagents and Materials

hydrogen sulfide content from a separate calibration scale

8.1 Containers—Both sample and test containers are com-

should be supplied with the tubes. The calibration scale shall

posed of H S-inert material such as 1-L size (clear Boston

correlate H S concentration to the length of the color stain.

round-bottom) glass bottles with screw caps. The bottles are

Annex A1 provides additional information. Shelf life of the

cleananddry.Marktestcontainersatthe50 %volumelevelby

detector tubes must be a minimum of two years from the date

using a ruler. (Warning—Hydrogen sulfide reacts with metal

of manufacture, when stored according to the manufacturer’s

surfaces and is easily oxidized, which depletes its concentra-

recommendations.

tion and gives false low test results. Containers such as

epoxy-lacquered cans are suitable for sample collection.Alter-

9. Sampling

nativecontainersmustgiveequivalentresultstothoseobtained

9.1 The sampling of residual fuel oils is done according to

by using glass.)

Practice D4057 for the sampling of storage tanks, ships, or

8.2 Length-of-Stain Detector Tube and Calibration Scale,a

barges. Composite sampling or running samples can be taken;

sealed glass tube with breakoff tips sized to fit the tube holder

spot samples should be taken from the midpoint or below

of the detector tube pump. The reagent layer inside the tube,

midpoint of the fuel oil in a storage tank by first sufficiently

typicallyasilicagelsubstratecoatedwiththeactivechemicals,

purging sample transfer lines and then taking single samples

must be specific for hydrogen sulfide and must produce a

where each sample comprises one and only one test.

distinct color change when exposed to a sample of gas

(Warning—Samples taken for this test method shall be dedi-

cated to a single H S determination and not used for any other

purpose, as any additional handling can lead to loss of H S and

Direct Reading Colorimetric Indicator Tubes Manual, First Edition, American 2

Industrial Hygiene Association, Akron, OH 44311, 1976. thus low results.)

D5705 – 03 (2008)

NOTE 1—Liquid samples taken well into the fuel oil have had less H S

only contacting the sample’s vapor phase. Do not allow the

lost by degassing as compared with a fuel oil’s surface. Samples taken

detector tube to contact the liquid, see Fig. 1(b). Use one full

from well within the fuel oil storage provide material that represents the

compression stroke.

greatest potential for H S exposure during fuel oil movements. Hydrogen

10.9 Remove the detector tube after complete decompres-

sulfideislostbydegassing(elevatedtemperatureandmechanicalagitation

sion of the pump and immediately read the H S concentration

increases H S degassing), o

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:D5705–95 (Reapproved 2000) Designation: D 5705 – 03 (Reapproved

2008)

Standard Test Method for

Measurement of Hydrogen Sulfide in the Vapor Phase

Above Residual Fuel Oils

This standard is issued under the fixed designation D5705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Warning notes were placed in the text in April 2000.

1. Scope

1.1 This test method covers the field determination of hydrogen sulfide (H S) in the vapor phase (equilibrium headspace) of a

residual fuel oil sample.

2 2

1.2 Thetestmethodisapplicabletoliquidswithaviscosityrangeof5.5mm /sat40°Cto50mm /sat100°C.Thetestmethod

is applicable to fuels conforming to Specification D396 Grade Nos. 4, 5 (Heavy), and 6.

1.3 The applicable range is from 5 to 4000 parts per million by volume (ppm v/v) (micro mole/mole).

1.4The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D396 Specification for Fuel Oils

D4057 Standard Practice for Manual Sampling of Petroleum and Petroleum Products

3. Terminology

3.1 Definitions:

3.1.1 equilibrium headspace, n—the vapor space above the liquid in which all vapor components are in equilibrium with the

liquid components.

3.1.2 residual fuel oil, n—a fuel oil comprising a blend of viscous long, short, or cracked residue from a petroleum refining

process and lighter distillates blended to a fuel oil viscosity specification.

3.1.2.1 Discussion—Under the conditions of this test (1:1 liquid/vapor ratio, temperature, and agitation) the H S in the vapor

phase (sample’s headspace) will be in equilibrium with the H S in the liquid phase.

4. Summary of Test Method

4.1 A1-LH S-inerttestcontainer(glasstestbottle)isfilledto50volume%withfueloilfromafilledH S-inertcontainer(glass

2 2

sample bottle) just prior to testing. In the test container, the vapor space above the fuel oil sample is purged with nitrogen to

displace air. The test container with sample is heated in an oven to 60°C, and agitated on an orbital shaker at 220 rpm for 3 min.

4.2 Alength-of-stain detector tube and hand-operated pump are used to measure the H S concentration in the vapor phase of

the test container. The length-of-stain detector tube should be close to but not in contact with the liquid surface.

5. Significance and Use

5.1 Excessive levels of hydrogen sulfide in the vapor phase above residual fuel oils in storage tanks may result in a health

hazard, OSHA limits violation, and public complaints about odors. Control measures to maintain safe levels of H S in the tank

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0.01

on Burner Fuels.

Current edition approved May 15, 1995. Published July 1995.

Current edition approved Dec. 1, 2008. Published February 2009. Originally approved in 1995. Last previous edition approved in 2003 as D5705–03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 05.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5705 – 03 (2008)

atmosphereforthoseworkinginthevicinityrequireaconsistentmethodfortheassessmentofpotentiallyhazardouslevelsofH S

in fuel oils ( Warning—H S is a highly toxic substance. Use extreme care in the sampling and handling of samples that are

suspected of containing high levels of H S.).

5.2 This test method has been developed to provide refineries, fuel terminals, and independent testing laboratories, which do

nothaveaccesstoanalyticalinstrumentssuchasagaschromatograph,withasimpleandconsistentfieldtestmethodfortherapid

determination of H S in the vapor phase of residual fuel oils.

5.3 This test method does not necessarily simulate the vapor phase H S concentration of a fuel storage tank. It does, however,

provide a level of consistency so that the test result is only a function of the residual fuel oil sample and not the test method,

operator,orlocation.NogeneralcorrelationcanbeestablishedbetweenthisfieldtestandactualvaporphaseconcentrationsofH S

in residual fuel oil storage or transports. However, a facility that produces fuel oil from the same crude source under essentially

constant conditions might be able to develop a correlation for its individual case.

6. Interferences

6.1 Typically, sulfur dioxide and mercaptans may cause positive interferences. In some cases, nitrogen dioxide can cause a

negative interference. Most detector tubes will have a precleanse layer designed to remove certain interferences up to some

maximum interferant level. Consult the manufacturer’s instructions for specific interference information.

7. Apparatus

7.1 Shaker, a bench-top orbital shaker and platform equipped with a four-prong clamp to hold 1-LBoston round-bottom glass

bottles and capable of operation at 220 rpm.

7.2 Timer, capable of measuring from1sto30minat second intervals.

7.3 Stopper with Thermometer,aNo.2corkstopperwithadialthermometerhavingarangeof−18to82°Canda200-mmstem.

The thermometer is inserted through the stopper such that the stem will extend at least 25 mm into the fuel but be no closer than

25 mm from the bottom of a test bottle (Stopper with Temperature Measuring Device, a No. 2 cork stopper with a temperature

measuringdevicesinsertedthroughitthatiscapableofaccuratelymeasuringthetemperatureofthesampleat60 61°Casrequired

in the procedure and extending at least 25 mm into the residual fuel but no closer than 25 mm from the bottom of a test bottle

(see Fig. 1(a)). (a)). A dial thermometer having a range of –18 to 82°C and a 200–mm stem has been found suitable to use.

7.4 Oven or Water Bath, capable of heating the fuel oil samples to 60 6 1°C.

3 3

7.5 Detector Tube Pump, a hand-operated piston or bellows-type (Fig. 1(b)) pump with a capacity of 100 cm 65cm per

stroke. It must be specifically designed for use with detector tubes. (Warning—Adetector tube and pump together form a unit

and must be used as such. Each manufacturer calibrates detector tubes to match the flow characteristics of its specific pump.

Crossing brands of pumps and tubes is not permitted, as considerable loss of system accuracy is likely to occur.). occur.)

8. Reagents and Materials

8.1 Containers—Both sample and test containers are composed of H S-inert material such as 1-L size (clear Boston

round-bottom)glassbottleswithscrewcaps.Thebottlesarecleananddry.Marktestcontainersatthe50%volumelevelbyusing

a ruler. (Warning—Hydrogen sulfide reacts with metal surfaces and is easily oxidized, which depletes its concentration and gives

falselowtestresults.Containerssuchasepoxy-lacqueredcansaresuitableforsamplecollection.Alternativecontainersmustgive

equivalent results to those obtained by using glass.). glass.)

8.2 Length-of-Stain Detector Tube and Calibration Scale, a sealed glass tube with breakoff tips sized to fit the tube holder of

the detector tube pump. The reagent layer inside the tube, typically a silica gel substrate coated with the active chemicals, must

be specific for hydrogen sulfide and must produce a distinct color change when exposed to a sample of gas containing hydrogen

sulfide. Any substances known to interfere must be listed in the instructions accompanying the tubes. A calibration scale should

be marked directly on the tube, or other markings that provide for easy interpretation (reading) of hydrogen sulfide content from

a separate calibration scale should be supplied with the tubes.The calibration scale shall correlate H S concentration to the length

ofthecolorstain.AnnexA1providesadditionalinformation.Shelflifeofthedetectortubesmustbeaminimumoftwoyearsfrom

the date of manufacture, when stored according to the manufacturer’s recommendations.

9. Sampling

9.1 The sampling of residual fuel oils is done according to Practice D4057 for the sampling of storage tanks, ships, or barges.

Composite sampling or running samples can be taken; spot samples should be taken from the midpoint or below midpoint of the

fuel oil in a storage tank by first sufficiently purging sample transfer lines and then taking single samples where each sample

comprises one and only one test. (Warning—Samples taken for this test method shall be dedicated to a single H S determination

and not used for any other purpose, as any additional handling can lead to loss of H S and thus low results.).

NOTE 1—Liquid samples taken well into the fuel oil have had less H S lost by degassing as compared with a fuel oil’s surface. Samples taken from

well within the fuel oil storage provide material that represents the greatest potential for H S exposure during fuel oil movements. Hydrogen sulfide is

Annual Book of ASTM Standards, Vol 05.02.

Direct Reading Colorimetric Indicator Tubes Manual, First Edition, American Industrial Hygiene Association, Akron, OH 44311, 1976.

D 5705 – 03 (2008)

FIG. 1 Measurement of H

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D5705–03 Designation: D 5705 – 03 (Reapproved 2008)

Standard Test Method for

Measurement of Hydrogen Sulfide in the Vapor Phase

Above Residual Fuel Oils

This standard is issued under the fixed designation D 5705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope *

1.1 This test method covers the field determination of hydrogen sulfide (H S) in the vapor phase (equilibrium headspace) of a

residual fuel oil sample.

2 2

1.2 The test method is applicable to liquids with a viscosity range of 5.5 mm /s at 40°C to 50 mm /s at 100°C. The test method

is applicable to fuels conforming to Specification D 396 Grade Nos. 4, 5 (Heavy), and 6.

1.3 The applicable range is from 5 to 4000 parts per million by volume (ppm v/v) (micro mole/mole).

1.4The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 396 Specification for Fuel Oils

D 4057 Practice for Manual Sampling of Petroleum and Petroleum Products

3. Terminology

3.1 Definitions:

3.1.1 equilibrium headspace, n—the vapor space above the liquid in which all vapor components are in equilibrium with the

liquid components.

3.1.2 residual fuel oil, n—a fuel oil comprising a blend of viscous long, short, or cracked residue from a petroleum refining

process and lighter distillates blended to a fuel oil viscosity specification.

3.1.2.1 Discussion—Under the conditions of this test (1:1 liquid/vapor ratio, temperature, and agitation) the H S in the vapor

phase (sample’s headspace) will be in equilibrium with the H S in the liquid phase.

4. Summary of Test Method

4.1 A1-LH S-inerttestcontainer(glasstestbottle)isfilledto50volume %withfueloilfromafilledH S-inertcontainer(glass

2 2

sample bottle) just prior to testing. In the test container, the vapor space above the fuel oil sample is purged with nitrogen to

displace air. The test container with sample is heated in an oven to 60°C, and agitated on an orbital shaker at 220 rpm for 3 min.

4.2 A length-of-stain detector tube and hand-operated pump are used to measure the H S concentration in the vapor phase of

the test container. The length-of-stain detector tube should be close to but not in contact with the liquid surface.

5. Significance and Use

5.1 Excessive levels of hydrogen sulfide in the vapor phase above residual fuel oils in storage tanks may result in a health

hazard, OSHA limits violation, and public complaints about odors. Control measures to maintain safe levels of H S in the tank

atmosphere for those working in the vicinity require a consistent method for the assessment of potentially hazardous levels of H S

in fuel oils ( Warning—H S is a highly toxic substance. Use extreme care in the sampling and handling of samples that are

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0 on

Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

´1

Current edition approved Nov. 1, 2003. Published December 2003. Originally approved in 1995. Last previous edition approved in 2000 as D5705–95(2000) .on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0.01 on Burner Fuels.

Current edition approved Dec. 1, 2008. Published February 2009. Originally approved in 1995. Last previous edition approved in 2003 as D 5705–03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5705 – 03 (2008)

suspected of containing high levels of H S.).

5.2 This test method has been developed to provide refineries, fuel terminals, and independent testing laboratories, which do

not have access to analytical instruments such as a gas chromatograph, with a simple and consistent field test method for the rapid

determination of H S in the vapor phase of residual fuel oils.

5.3 This test method does not necessarily simulate the vapor phase H S concentration of a fuel storage tank. It does, however,

provide a level of consistency so that the test result is only a function of the residual fuel oil sample and not the test method,

operator,orlocation.NogeneralcorrelationcanbeestablishedbetweenthisfieldtestandactualvaporphaseconcentrationsofH S

in residual fuel oil storage or transports. However, a facility that produces fuel oil from the same crude source under essentially

constant conditions might be able to develop a correlation for its individual case.

6. Interferences

6.1 Typically, sulfur dioxide and mercaptans may cause positive interferences. In some cases, nitrogen dioxide can cause a

negative interference. Most detector tubes will have a precleanse layer designed to remove certain interferences up to some

maximum interferant level. Consult the manufacturer’s instructions for specific interference information.

7. Apparatus

7.1 Shaker, a bench-top orbital shaker and platform equipped with a four-prong clamp to hold 1-L Boston round-bottom glass

bottles and capable of operation at 220 rpm.

7.2 Timer, capable of measuring from1sto30minat second intervals.

7.3 Stopper with Temperature Measuring Device, a No. 2 cork stopper with a temperature measuring devices inserted through

it that is capable of accurately measuring the temperature of the sample at 60 6 1°C as required in the procedure and extending

at least 25 mm into the residual fuel but no closer than 25 mm from the bottom of a test bottle (see Fig. 1(a)).Adial thermometer

having a range of –18 to 82°C and a 200–mm stem has been found suitable to use.

7.4 Oven or Water Bath, capable of heating the fuel oil samples to 60 6 1°C.

FIG. 1 Measurement of H S in the Vapor Phase of Residual Fuel

Oil

D 5705 – 03 (2008)

3 3

7.5 Detector Tube Pump, a hand-operated piston or bellows-type (Fig. 1(b)) pump with a capacity of 100 cm 65cm per

stroke. It must be specifically designed for use with detector tubes. (Warning—A detector tube and pump together form a unit

and must be used as such. Each manufacturer calibrates detector tubes to match the flow characteristics of its specific pump.

Crossing brands of pumps and tubes is not permitted, as considerable loss of system accuracy is likely to occur.)

8. Reagents and Materials

8.1 Containers—Both sample and test containers are composed of H S-inert material such as 1-L size (clear Boston

round-bottom) glass bottles with screw caps.The bottles are clean and dry. Mark test containers at the 50 % volume level by using

a ruler. (Warning—Hydrogen sulfide reacts with metal surfaces and is easily oxidized, which depletes its concentration and gives

false low test results. Containers such as epoxy-lacquered cans are suitable for sample collection.Alternative containers must give

equivalent results to those obtained by using glass.)

8.2 Length-of-Stain Detector Tube and Calibration Scale, a sealed glass tube with breakoff tips sized to fit the tube holder of

the detector tube pump. The reagent layer inside the tube, typically a silica gel substrate coated with the active chemicals, must

be specific for hydrogen sulfide and must produce a distinct color change when exposed to a sample of gas containing hydrogen

sulfide. Any substances known to interfere must be listed in the instructions accompanying the tubes. A calibration scale should

be marked directly on the tube, or other markings that provide for easy interpretation (reading) of hydrogen sulfide content from

a separate calibration scale should be supplied with the tubes. The calibration scale shall correlate H S concentration to the length

of the color stain.AnnexA1 provides additional information. Shelf life of the detector tubes must be a minimum of two years from

the date of manufacture, when stored according to the manufacturer’s recommendations.

9. Sampling

9.1 The sampling of residual fuel oils is done according to Practice D 4057 for the sampling of storage tanks, ships, or barges.

Composite sampling or running samples can be taken; spot samples should be taken from the midpoint or below midpoint of the

fuel oil in a storage tank by first sufficiently purging sample transfer lines and then taking single samples where each sample

comprises one and only one test. (Warning—Samples taken for this test method shall be dedicated to a single H S determination

and not used for any other purpose, as any additional handling can lead to loss of H S and thus low results.)

NOTE 1—Liquid samples taken well into the fuel oil have had less H S lost by degassing as compared with a fuel oil’s surface. Samples taken from

well within the fuel oil storage provide material that represents the greatest potential for H S exposure during fuel oil movements. Hydrogen sulfide is

lost by degassing (elevated temperature and mechanical agitation increases H S degassing), oxidation, and absorption on water-wet surfaces.

9.2 Fill at least two 1-Lsize sample containers with fuel oil. Minimize the headspace of the sample container. Cap immediately

and deliver to the testing facility. Test each sample within one to four hours from the time of sampling.

9.3 Sample integrity is extremely important; therefore, sampl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.