ASTM F791-96(2013)

(Test Method)Standard Test Method for Stress Crazing of Transparent Plastics

Standard Test Method for Stress Crazing of Transparent Plastics

SIGNIFICANCE AND USE

4.1 This test method provides a guide for evaluating a specific solvent, chemical, or compound that may be detrimental to a transparent plastic as a result of a manufacturing process, a fabrication operation, or the operational environment. All transparent plastics are susceptible to crazing, though in widely varying degree and from a variety of causes. This test method is intended to allow establishment of the crazing stress when the simultaneous action of both load and a material that would cause crazing is applied producing non-reversible damage that might limit the usage of that transparent plastic in a specific application.

SCOPE

1.1 This test method covers the determination of the critical crazing stress for a transparent plastic material when exposed to a specific solvent, chemical, or compound at a specific temperature.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F791 − 96 (Reapproved 2013)

Standard Test Method for

1

Stress Crazing of Transparent Plastics

ThisstandardisissuedunderthefixeddesignationF791;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope and scattered with varied lengths and depths but usually are

oriented perpendicular to a tensile stress. Crazing may be

1.1 This test method covers the determination of the critical

difficult to detect. It becomes more pronounced when viewed

crazing stress for a transparent plastic material when exposed

with a light source that is at an oblique angle.

to a specific solvent, chemical, or compound at a specific

temperature.

4. Significance and Use

1.2 This standard does not purport to address all of the

4.1 This test method provides a guide for evaluating a

safety concerns, if any, associated with its use. It is the

specific solvent, chemical, or compound that may be detrimen-

responsibility of the user of this standard to establish appro-

tal to a transparent plastic as a result of a manufacturing

priate safety and health practices and determine the applica-

process, a fabrication operation, or the operational environ-

bility of regulatory limitations prior to use.

ment.Alltransparentplasticsaresusceptibletocrazing,though

inwidelyvaryingdegreeandfromavarietyofcauses.Thistest

2. Referenced Documents

method is intended to allow establishment of the crazing stress

2

2.1 ASTM Standards:

when the simultaneous action of both load and a material that

D618 Practice for Conditioning Plastics for Testing

would cause crazing is applied producing non-reversible dam-

E691 Practice for Conducting an Interlaboratory Study to

age that might limit the usage of that transparent plastic in a

Determine the Precision of a Test Method

specific application.

2.2 Other Method:

5. Apparatus

ARTC (Aircraft Research and Testing Committee of the

Aircraft Industries Association of America, Inc.) Condi-

5.1 Test Fixture, with fluorescent light source illustrated and

3

tioning Method

constructed as shown in Figs. 1 and 2.

5.2 Drill Fixture constructed as shown in Fig. 3.

3. Terminology

5.3 Marking Fixture, constructed as shown in Fig. 3.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 crazing—a group of surface fissures that appear to be

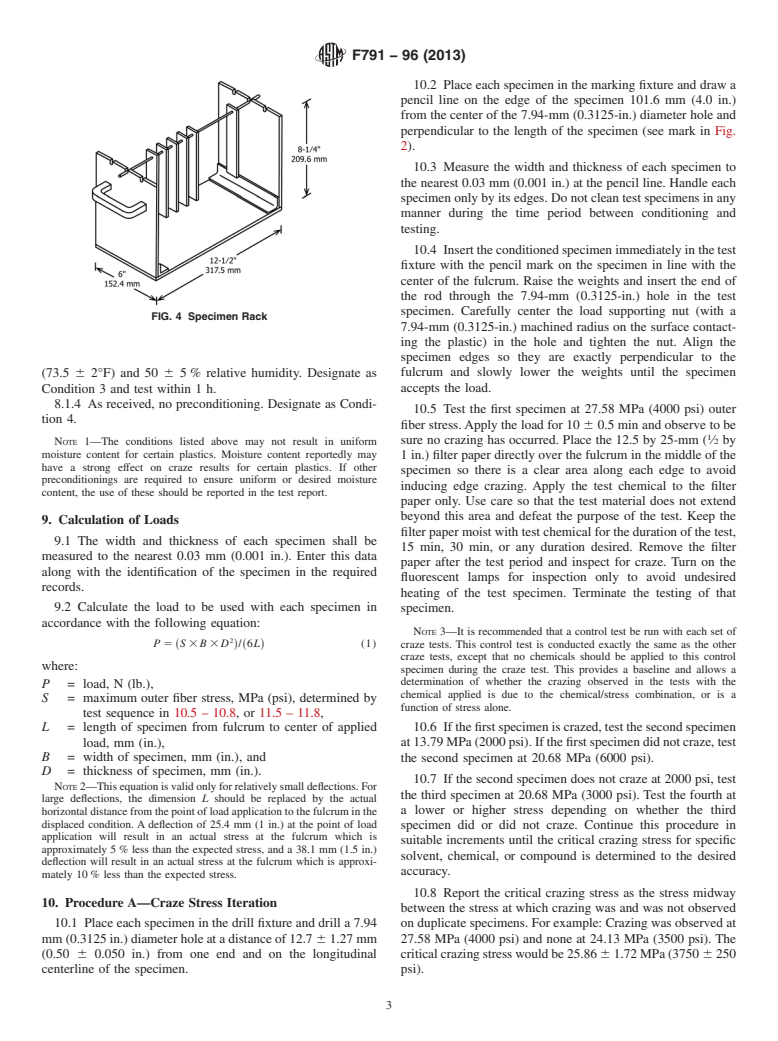

5.4 Portable Specimen Rack, constructed in the manner as

small cracks in the material, although they are not.

shown in Fig. 4 for handling and conditioning test specimens.

3.1.1.1 Discussion—Crazing is a form of yielding in poly-

5.5 Weights—A container and shot for the application of

mers characterized by a spongy void filled fibrillar structure.

weight on the rack as shown in Fig. 1.

The density in the craze changes resulting in a change in the

5.6 Filter Paper, quantity of 0.50 by 1.0-in. (12.7 by

index of refraction, which causes light to be reflected off of the

25.4-mm) pieces of filter, medium-retention filter paper.

crazes. This light reflection causes the crazes to sparkle when

viewed from certain angles. The crazes are sometimes random

6. Test Specimens

6.1 The test specimen shall be machined from the transpar-

1

This test method is under the jurisdiction of ASTM Committee F07 on

ent plastic material to be evaluated. A minimum of six

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

specimens for each solvent, chemical, or compound is re-

Transparent Enclosures and Materials.

quired. It is preferred that the transparent plastic sheet material

Current edition approved Dec. 1, 2013. Published December 2013. Originally

approvedin1982.Lastpreviouseditionapprovedin2008asF791 – 96(2008).DOI:

thickness be 6.35 6 0.64 mm (0.250 6 0.025 in.), but any

10.1520/F0791-96R13.

thickness material may be used. Orientation of each test

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

specimen within the test sheet or part should be recorded.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6.2 Thetestspecimensshallbe25.4 60.8mm(1.00 60.03

the ASTM website.

3

in.) wide by 177.8 6 1.27 mm (7.00 6 0.05 in.) long by

Available from Aircraft Industries Association, 1725 DeSales St. NW,

Washington, DC 20034. thickness.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F791 − 96 (2013)

FIG. 1 Accelerated Crazing Test Fixture

FIG. 3 Fixtures for Specimen Pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.