ASTM D4577-05(2010)

(Test Method)Standard Test Method for Compression Resistance of a Container Under Constant Load

Standard Test Method for Compression Resistance of a Container Under Constant Load

SIGNIFICANCE AND USE

In the distribution system for many products there is a phase wherein the packaged product may be stored for a period of time in a manner such that one or more containers are superimposed one upon the other. The bottom package is thus continually stressed with a constant load.

This test method subjects a container, empty or filled, to a predetermined static load, and to specified atmospheric conditions, if required.

SCOPE

1.1 This test method is designed to determine the resistance of a shipping container to a vertically applied constant load for either a specified time or to failure. The test method may also be used for palletized or unitized load configurations.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4577 − 05 (Reapproved 2010)

Standard Test Method for

Compression Resistance of a Container Under Constant

Load

This standard is issued under the fixed designation D4577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions—General definitions for the packaging and

1.1 This test method is designed to determine the resistance

distribution environments are found in Terminology D996.

of a shipping container to a vertically applied constant load for

either a specified time or to failure. The test method may also

3.2 Definitions of Terms Specific to This Standard:

be used for palletized or unitized load configurations.

3.2.1 load—the force applied to a body, lbf or N.

1.2 This standard does not purport to address all of the 3.2.2 constant load—a load that is invariable or unchanging

safety concerns, if any, associated with its use. It is the

3.2.3 static load—an imposed stationary force, constant in

responsibility of whoever uses this standard to consult and

magnitude, direction, and sense

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

4. Significance and Use

For specific precautionary statements, see Section 6.

4.1 In the distribution system for many products there is a

phasewhereinthepackagedproductmaybestoredforaperiod

2. Referenced Documents

of time in a manner such that one or more containers are

2.1 ASTM Standards: superimposed one upon the other. The bottom package is thus

D642 Test Method for Determining Compressive Resistance continually stressed with a constant load.

of Shipping Containers, Components, and Unit Loads

4.2 This test method subjects a container, empty or filled, to

D644 Test Method for Moisture Content of Paper and

a predetermined static load, and to specified atmospheric

Paperboard by Oven Drying (Withdrawn 2010)

conditions, if required.

D685 Practice for Conditioning Paper and Paper Products

for Testing

5. Apparatus

D996 Terminology of Packaging and Distribution Environ-

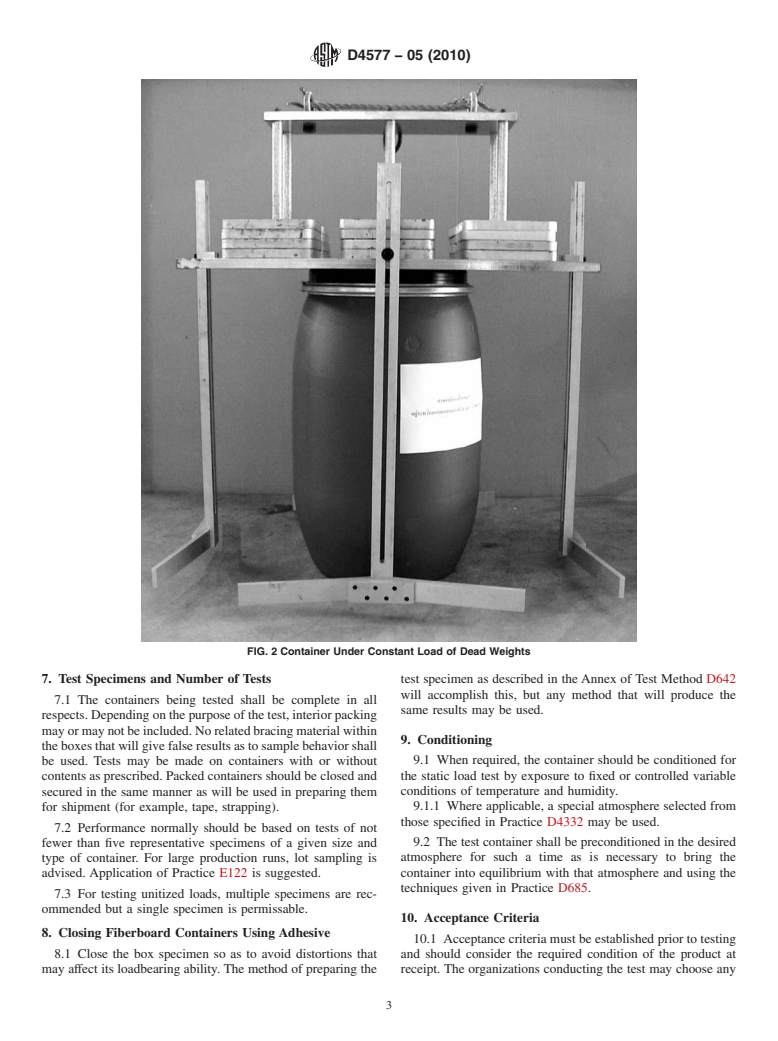

5.1 The testing apparatus shall be capable of imposing a

ments

constant load on the test specimen and may be hydraulically,

D4332 Practice for Conditioning Containers, Packages, or

pneumatically, or mechanically activated. A test apparatus

Packaging Components for Testing

employing dead weights to impose the constant load may be

D4442 Test Methods for Direct Moisture Content Measure-

used, as in Fig. 1 and Fig. 2. Compression machines may also

ment of Wood and Wood-Base Materials

be used, as in Fig. 3 and Fig. 4, and shall contain two platens,

E122 Practice for Calculating Sample Size to Estimate,With

or suitable framework and fixturing, one stationary and one

Specified Precision, the Average for a Characteristic of a

movable in the vertical direction. The movable platen may be

Lot or Process

swiveled (floating) or fixed and should have proper

mechanical, pneumatic, or hydraulic linkages to permit top-to-

bottom loading. If the floor where the test is to be conducted is

This test method is under the jurisdiction of ASTM Committee D10 on

subject to severe vibration, it may be necessary to vibration-

Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping

isolate the test apparatus. The test device should have a timer

Containers and Systems - Application of Performance Test Methods.

for measuring the period of time required to cause container

Current edition approved Aug. 1, 2010. Published October 2010. Originally

approved in 1986. Last previous edition approved in 2005 as D4577 – 05. DOI:

failure and means such as a dial indicator to measure box

10.1520/D4577-05R10.

deformation (inches or millimetres) while under load, or an

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

autographicrecordingdevicethatrecordsloadanddeformation

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on over a period of time.

the ASTM website.

5.2 Closing Equipment for Fiberboard Boxes—Whenempty

The last approved version of this historical standard is referenced on

www.astm.org. boxes are to be tested, suitable closing facilities such as sealing

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4577 − 05 (2010)

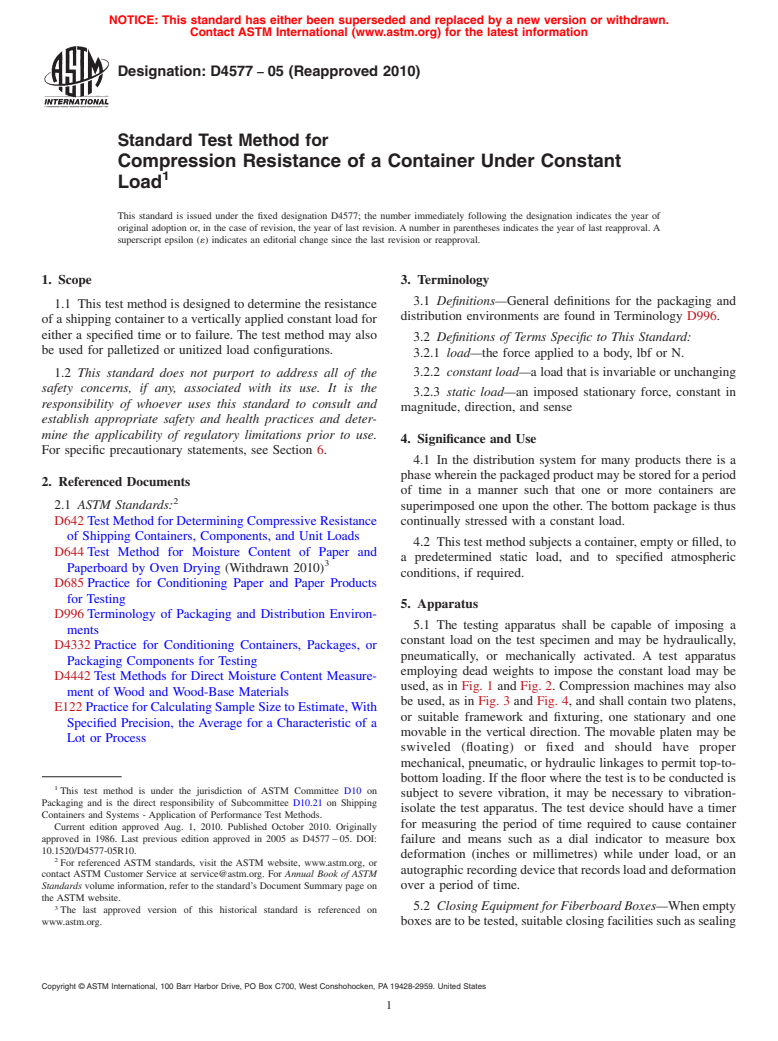

FIG. 1 Containers Under Constant Load of Dead Weights Imposed by Other Containers

boards and proper adhesive for closing the flaps of box 6. Safety Precautions

specimens shall be used. See Test Method D642.

6.1 Performance of a test should never be considered

5.3 Conditioning Apparatus—Adequate facilities shall be without regard to safety. Some apparent precautions against

provided to maintain a conditioned atmosphere of temperature injuries are:

and humidity as required for the purpose of the test.

6.1.1 Careandcautionshouldbeobservedwhileplacingthe

shipping container filled or unfilled on the testing apparatus.

5.4 Miscellaneous Equipment—Drying oven, scales, knife,

6.1.2 The testing apparatus should have load arrestors or

saws, etc., for use in determination of the moisture content or

safety interlocks to prevent complete crushing of the container

for making other supplementary tests of the materials from

after initial failure.

which the containers are made. When testing unit loads, it is

recommended that an empty pallet be placed on top of the unit 6.1.3 When using dead weights, caution should be taken

load test specimen to achieve conditions similar to actual use. when loading and unloading the weights from the apparatus.

D4577 − 05 (2010)

FIG. 2 Container Under Constant Load of Dead Weights

7. Test Specimens and Number of Tests test specimen as described in the Annex of Test Method D642

will accomplish this, but any method that will produce the

7.1 The containers being tested shall be complete in all

same results may be used.

respects.Dependingonthepurposeofthetest,interiorpacking

mayormaynotbeincluded.Norelatedbracingmaterialwithin

9. Conditioning

theboxesthatwillgivefalseresultsastosamplebehaviorshall

9.1 When required, the container should be conditioned for

be used. Tests may be made on containers with or without

contents as prescribed. Packed containers should be closed and the static load test by exposure to fixed or controlled variable

conditions of temperature and humidity.

secured in the same manner as will be used in preparing them

for shipment (for example, tape, strapping). 9.1.1 Where applicable, a special atmosphere selected from

those specified in Practice D4332 may be used.

7.2 Performance normally should be based on tests of not

fewer than five representative specimens of a given size and 9.2 The test container shall be preconditioned in the desired

atmosphere for such a time as is necessary to bring the

type of container. For large production runs, lot sampling is

advised. Application of Practice E122 is suggested. container into equilibrium with that atmosphere and using the

techniques given in Practice D685.

7.3 For testing unitized loads, multiple specimens are rec-

ommended but a single specimen is permissable.

10. Acceptance Criteria

8. Closing Fiberboard Containers Using Adhesive

10.1 Acceptance criteria must be established prior to testing

8.1 Close the box specimen so as to avoid distortions that and should consider the required condition of the product at

may affect its loadbearing ability. The method of preparing the receipt. The organizations conducting the test may choose any

D4577 − 05 (2010)

FIG. 3 Container Under Constant Load in Compression Test Machine With Fixed Platen

should the load exceed 85 % of the test value derived by Method D642

acceptance criteria suitable for their purpose. It is advisable to

testing.

compare test results from proposed containers with the test

results on similar containers whose shipping history is known.

11.2 Whenusingacompressionmachine(Fig.3andFig.4),

center the specimen on the bottom platen of the testing

10.2 Inmanycases,theacceptancecriteriaofapackagethat

apparatus so as not to incur eccentric loading. Induce the test

has been subjected to the test plan can be one of the following:

loadonthespecimen.Theloadshallbeslowlyappliedatanear

Criterion 1—Product is damage-free.

uniform rate until the container supports the entire load. When

Criterion 2—Package is intact.

using dead weights (Fig. 1 and Fig. 2), this is accomplished by

Other acceptance criteria, including provision for accepting

lowering the support jacks and completely freeing the upper

minimal damage to the product or package, may be indicated.

platen.

Acceptance criteria may i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.