ASTM D4855-97(2002)

(Practice)Standard Practice for Comparing Test Methods (Withdrawn 2008)

Standard Practice for Comparing Test Methods (Withdrawn 2008)

SIGNIFICANCE AND USE

Task groups developing a test method frequently find themselves with two or more alternative procedures that must be compared. Three common situations are:

4.1.1 Two or more new test methods may have been proposed to measure a property for which there is no existing method.

4.1.2 A new test method may have been suggested to replace an existing test method.

4.1.3 Two or more existing test methods may overlap in their scopes so that one should be chosen over the other.

The selection of one test method in preference to another is not simply a statistical choice. There are many other aspects of two test methods that should be considered, which may have an influence (on the engineering judgment of the task group) equal to or greater than the statistical evidence. Some of these characteristics are discussed in Section 6.

SCOPE

1.1 This practice provides a procedure for evaluating and comparing test methods under controlled conditions using the same materials tested during the same time span. The practice describes how to obtain and compare estimates on precision, sensitivity, and bias.

1.2 This practice covers the following topics:Topic TitleSection numberScope1Referenced Documents2Terminology3Significance and Use4Requirements for Materials5Evaluating Test Methods6Sensitivity Criterion7Basic Statistical Design8Experimental Procedure9Procedure for Comparing Precision10Evaluating the Bias Between Test Methods11Procedure for Comparing Sensitivities12Report13

WITHDRAWN RATIONALE

This practice provides a procedure for evaluating and comparing test methods under controlled conditions using the same materials tested during the same time span. The practice describes how to obtain and compare estimates on precision, sensitivity, and bias.

This practice is being withdrawn with no replacement because D13 no longer has the expertise to maintain and statistical standards are being maintained by committee E11.

Formerly under the jurisdiction of Committee D13 on Textiles, this practice was withdrawn in July 2008.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4855–97 (Reapproved 2002)

Standard Practice for

Comparing Test Methods

This standard is issued under the fixed designation D4855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

statements on the relative merits of the two test methods are part of the

1. Scope

output.

1.1 This practice provides a procedure for evaluating and

comparing test methods under controlled conditions using the

3. Terminology

same materials tested during the same time span. The practice

3.1 Definitions:

describes how to obtain and compare estimates on precision,

3.1.1 accuracy, n—of a test method, the degree of agree-

sensitivity, and bias.

ment between the true value of the property being tested (or an

1.2 This practice covers the following topics:

acceptedstandardvalue)andtheaverageofmanyobservations

Topic Title Section

made according to the test method, preferably by many

number

observers. (See also bias and precision.)

Scope 1

3.1.1.1 Discussion—Increased accuracy is associated with

Referenced Documents 2

decreased bias relative to the true value; two methods with

Terminology 3

equal bias relative to the true value have equal accuracy even

Significance and Use 4

Requirements for Materials 5

if one method is more precise than the other. The true value is

Evaluating Test Methods 6

the exact value of the property being tested for the statistical

Sensitivity Criterion 7

universe being sampled. When the true value is not known or

Basic Statistical Design 8

Experimental Procedure 9

cannot be determined, and an acceptable standard value is not

Procedure for Comparing Precision 10

available, accuracy cannot be established. No valid inferences

Evaluating the Bias Between Test Methods 11

on the accuracy of a method can be drawn from an individual

Procedure for Comparing Sensitivities 12

Report 13

observation.

3.1.2 bias, n—in statistics, a constant or systematic error in

2. Referenced Documents

test results.

2.1 ASTM Standards:

3.1.2.1 Discussion—Bias can exist between the accepted

D123 Terminology Relating to Textiles

reference value and a test result obtained from one method,

D2905 Practice for Statements on Number of Specimens

between test results obtained from two methods, or between

for Textiles

two test results obtained from a single method, for example,

D2906 Practice for Statements on Precision and Bias for

between operators or between laboratories.

Textiles

3.1.3 confidence interval, n—the interval estimate of a

E456 Terminology Relating to Quality and Statistics

population parameter computed so that the statement “the

2.2 ASTM Adjuncts:

population parameter lies in this interval” will be true, on the

TEX-PAC

average, in a stated proportion of the times such statements are

made.

NOTE 1—Tex-Pac is a group of PC programs on floppy disks, available

throughASTM Headquarters, 100 Barr Harbor Drive, Conshohocken, PA

3.1.4 confidence level, n—the stated proportion of times the

19428,USA.Thecalculationsforcomparingtheprecision,sensitivityand

confidence interval is expected to include the population

bias of two test methods can be done using one of these programs and

parameter.

3.1.4.1 Discussion—Statisticians generally accept that, in

the absence of special consideration, 0.95 or 95% is a realistic

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

confidence level. If the consequences of incorrectly estimating

is the direct responsibility of Subcommittee D13.93 on Statistics.

the confidence interval would be grave, then a higher confi-

Current edition approved September 10, 1997. Published August 1998. Origi-

nally published as D4855–88. Last previous edition D4855–91.

dence level might be considered. If the consequences of

Annual Book of ASTM Standards, Vol 07.01.

incorrectly estimating the confidence interval are of less than

Annual Book of ASTM Standards, Vol 14.02.

1 usual concern, then a lower confidence interval might be

PC programs on floppy disks are available throughASTM. For a 3 ⁄2 inch disk

request PCN:12-429040-18, for a 5 ⁄4 inch disk request PCN:12-429041-18. considered.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4855–97 (2002)

3.1.5 confidence limits, n—the two statistics that define the 3.1.17 statistic, n—a quantity that is calculated from obser-

ends of a confidence interval. vations on a sample and that estimates a parameter of a sample

and that estimates a parameter of a population.

3.1.6 degrees of freedom, n—for a set,thenumberofvalues

that can be assigned arbitrarily and still get the same value for 3.1.18 t-test, n—atestofstatisticalsignificancebasedonthe

each of one or more statistics calculated from the set of data. useofStudent’s t-distributionandusedtocomparetwosample

averages or a sample average and a hypothetical value.

3.1.6.1 Discussion—For example, if only an average is

specifiedforasetoffiveobservations,therearefourdegreesof 3.1.19 Type I error—See error of the first kind.

freedom since the same average can be obtained with any

3.1.20 Type II error—See error of the second kind.

values substituted for four of the five observations as long as

3.1.21 For definitions of textile terms used in this standard,

thefifthvalueissettogivethecorrecttotal.Ifboththeaverage

refer to Terminology D123. For definitions of other statistical

and the standard deviation have been specified, there are only

terms used in this standard, refer to Terminology D4392 or

three degrees of freedom left.

Terminology E456.

3.1.7 error of the first kind, a, n—in a statistical test, the

rejection of a statistical hypothesis when it is true. (Syn. Type

4. Significance and Use

I error.)

4.1 Task groups developing a test method frequently find

3.1.8 error of the second kind, b, n—in a statistical test, the

themselves with two or more alternative procedures that must

acceptance of a statistical hypothesis when it is false. (Syn.

be compared. Three common situations are:

Type II error.)

4.1.1 Two or more new test methods may have been

3.1.9 F-test, n—atestofstatisticalsignificancebasedonthe

proposed to measure a property for which there is no existing

use of George W. Snedecor’s F-distribution and used to

method.

compare two sample variances or a sample variance and a

4.1.2 A new test method may have been suggested to

hypothetical value.

replace an existing test method.

3.1.10 interference, n—in testing, an effect due to the

4.1.3 Two or more existing test methods may overlap in

presence of a constituent or characteristic that influences the

their scopes so that one should be chosen over the other.

measurement of another constituent or characteristic.

4.2 The selection of one test method in preference to

3.1.11 least difference of practical importance, d, n—the

another is not simply a statistical choice.There are many other

smallest difference based on engineering judgment deemed to

aspects of two test methods that should be considered, which

be of practical importance when considering whether a signifi-

mayhaveaninfluence(ontheengineeringjudgmentofthetask

cant difference exists between two statistics or between a

group)equaltoorgreaterthanthestatisticalevidence.Someof

statistic and a hypothetical value.

these characteristics are discussed in Section 6.

3.1.12 parameter, n—in statistics, a variable that describes

a characteristic of a population or mathematical model.

5. Requirements for Materials

3.1.13 precision, n—thedegreeofagreementwithinasetof

5.1 The number and type of materials to be included in a

observations or test results obtained as directed in a method.

comparison study will depend on the following:

3.1.13.1 Discussion—The term “precision,” delimited in

5.1.1 The range of the values of the property being mea-

various ways, is used to describe different aspects of precision.

sured on a given material and how the precision varies over

This usage was chosen in preference to the use of “repeatabil-

that range,

ity” and “reproducibility,” which have been assigned conflict-

ing meanings by various authors and standardizing bodies.

5.1.2 The number of different materials to which the test

method is applied.

3.1.14 ruggedness test, n—anexperimentinwhichenviron-

mental or test conditions are deliberately varied in order to 5.1.3 The difficulty and expense involved in obtaining,

evaluate the effects of such variations.

processing, and distributing samples,

3.1.15 sensitivity, n—for a single test method, the result of

5.1.4 The difficulty of, length of time required for, and

dividing (1) the derivative of measurements at different levels

expense of performing the tests, and

of a property of interest to known values of the property by (2)

5.1.5 The uncertainty of prior information on any of these

the standard deviation of such measurements. (Syn. absolute

points. For example, if it is already known that the precision is

sensitivity.)

relativelyconstantorproportionaltotheaverageleveloverthe

3.1.15.1 Discussion—Thesensitivityofasingletestmethod

range of values of interest, a smaller number of materials will

may be determined only with materials for which the values of

be needed than if it is known that the precision changes

the property of interest is known.

erratically at different levels. A preliminary pilot or screening

3.1.16 sensitivity ratio, SR, n—in comparing two test meth- program may help to settle some of these questions, and may

ods, the ratio of the sensitivities of the test methods with the often result in the saving of considerable time and expense in

the full comparison study.

larger sensitivity in the numerator. (Syn. relative sensitivity.)

3.1.16.1 Discussion—When the same materials are used for 5.2 In general, a minimum of three materials should be

eachtestmethod,thesensitivityratiomaybedeterminedusing considered acceptable, and for development of broadly appli-

materials for which the value of the property of interest is not cable precision statements, six or more materials should be

known. included in the study.

D4855–97 (2002)

5.3 Whenever feasible, the material representing any given improved sensitivity, a shorter elapsed time to get test results,

levelinacomparisonstudyshouldbemadeashomogeneousas or a reduced cost without unduly disturbing any other charac-

possible prior to its subdivision into portions or specimens that teristics of the test method.

are allocated to the different methods.

7. Sensitivity Criterion

5.4 For each level of material, an adequate quantity

7.1 Sometimes a test method that is more precise than

(sample) of reasonably homogeneous material should be avail-

able for subdivision for each test method. This supply of another test method has less discriminating power from the

standpoint of detecting changes in the level in the property of

material should include a reserve of 50% beyond the require-

ments of the protocol for the comparison study for possible interest. The sensitivity criterion is a quantitative measure of

the relative merit of two test methods which:

lateruseincheckingresultsorretestingthetestmethodsinone

or more laboratories. 7.1.1 Combines the precision of each method with the

abilityofthetestmethodtomeasuredifferencesintheproperty

6. Evaluating Test Methods

of interest.

6.1 Each Proposed New Test Method—When evaluating 7.1.2 Permits the comparison of test methods for which test

one or more test methods, take into account the following

results are reported in different units of measure. For this

features that are desirable in a proposed test method: reason, comparisons of the sensitivity of two methods may be

6.1.1 The relationship between the test results and the

more meaningful than comparisons of their precisions.

property of interest is clearly understood. 7.2 When comparing test methods on the basis of data

6.1.2 Thereisasmallornon-existentbiasoverawiderange

collected,itisimportantthatthetaskgrouphasformulatedand

of test results. evaluated a plan for analysis of the data so as to arrive at a

6.1.3 The test method is precise enough to satisfy the

correctdecision,beforeconductinganytests.Statisticaltestsof

requirements of the application. significance are recommended as a means of helping make the

6.1.4 The test method has acceptable ruggedness and sen- decisions for these reasons: they are objective, they require a

sitivity. clearstatementoftheproblem,theymakemoreefficientuseof

6.1.5 Any potential interferences are known and small the observed data than subjective techniques, and they allow

enough to tolerate. control of the probability of concluding two test methods are

6.1.6 There is a low cost for making an observation with different when they are really alike, as well as the probability

short times for learning to run the test, getting ready to run the of concluding two test methods are alike when they are really

test and cleaning up after running the test. different.

6.1.7 The test method may have other special attributes that

8. Basic Statistical Design

encourage its selection as a preferred method.

6.1.8 Data are available from the advocates of the test 8.1 Decide whether the precision, the sensitivity, the accu-

method to support the above claims. racy, or the bias of the two test methods is to be compared.

6.2 Two or More New Test Methods—When two or more 8.2 Specify the values of probability of Type I error, a,

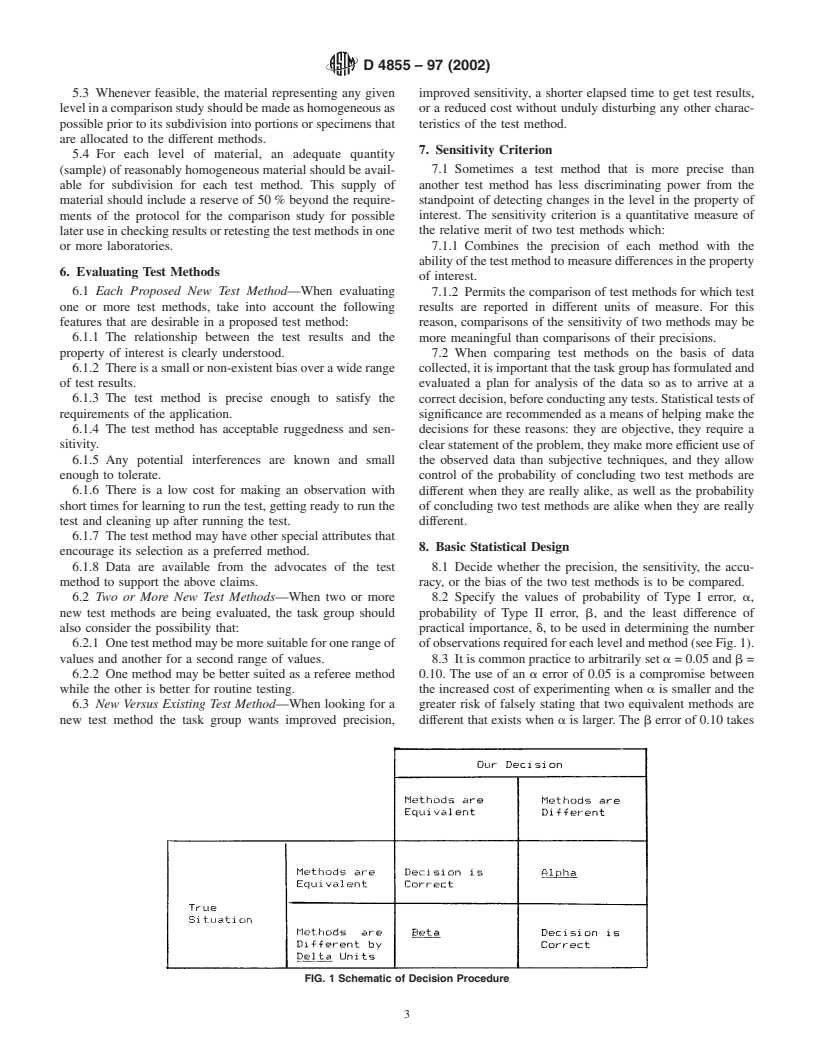

new test methods are being evaluated, the task group should probability of Type II error, b, and the least difference of

also consider the possibility that: practical importance, d, to be used in determining the number

6.2.1 Onetestmethodmaybemoresuitableforonerangeof ofobservationsrequiredforeachlevelandmethod(seeFig.1).

values and another for a second range of values. 8.3 It is common practice to arbitrarily set a = 0.05 and b =

6.2.2 One method may be better suited as a referee method 0.10. The use of an a error of 0.05 is a compromise between

while the other is better for routine testing. the increased cost of experimenting when a is smaller and the

6.3 New Versus Existing Test Method—When looking for a greater risk of falsely stating that two equivalent methods are

new test method the task group wants improved precision, different that exists when a is larger. The b error of 0.10 takes

FIG. 1 Schematic of Decision Procedure

D4855–97 (2002)

into account the fact that the risk of failing to detect a true 8.7 Analyze the data and calculate the test statistic in 8.4.

differencebetweentwomethods

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.