ASTM B447-00

(Specification)Standard Specification for Welded Copper Tube

Standard Specification for Welded Copper Tube

SCOPE

1.1 This specification establishes the requirements for welded copper tube with a longitudinal seam free of filler metal produced from sheet or strip of the following coppers:Copper UNS Nos.Type of CopperC10100Oxygen-free electronicC10200Oxygen-freeC10300Oxygen-free, extra low phosphorusC10800Oxygen-free, low phosphorusC11000Electrolytic tough pitchC12000Phosphorus deoxidized, low residual phosphorusC12200Phosphorus deoxidized, high residual phosphorusC14200Phosphorus deoxidized, arsenical

1.2 Unless otherwise specified in the contract or purchase order, product furnished of any listed copper, with the exception of copper C11000, shall be considered acceptable.

1.2.1 Copper C11000 welded tube shall not be used in applications in which heating may cause hydrogen embrittlement.

1.3 Values stated in inch-pound units are the standard except for grain size which is given in SI units. Values given in parentheses are for information only.

1.4 The following hazard caveat pertains only to Section of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: B 447 – 00

Standard Specification for

Welded Copper Tube

This standard is issued under the fixed designation B447; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * B193 Test Method for Resistivity of Electrical Conductor

Materials

1.1 This specification establishes the requirements for

B577 Test Methods for Detection of Cuprous Oxide (Hy-

weldedcoppertubewithalongitudinalseamfreeoffillermetal

drogen Embrittlement Susceptibility) in Copper

produced from sheet or strip of the following coppers:

B601 Practice for Temper Designations for Copper and

Copper UNS Nos. Type of Copper

Copper Alloys—Wrought and Cast

C10100 Oxygen-free electronic

B846 Terminology for Copper and Copper Alloys

C10200 Oxygen-free

E3 Practice for Preparation of Metallographic Specimens

C10300 Oxygen-free, extra low phosphorus

E8 TestMethodsforTensionTestingofMetallicMaterials

C10800 Oxygen-free, low phosphorus

C11000 Electrolytic tough pitch

E29 Practice for Using Significant Digits in Test Data to

C12000 Phosphorus deoxidized, low residual phosphorus

Determine Conformance with Specifications

C12200 Phosphorus deoxidized, high residual phosphorus

E53 Methods for Chemical Analysis of Copper

C14200 Phosphorus deoxidized, arsenical

E62 Test Methods for Chemical Analysis of Copper and

1.2 Unless otherwise specified in the contract or purchase

Copper Alloys (Photometric Methods)

order, product furnished of any listed copper, with the excep-

E112 Test Methods for Determining the Average Grain

tion of copper C11000, shall be considered acceptable.

Size

1.2.1 Copper C11000 welded tube shall not be used in

E193 Specification for Laboratory Glass Micropipets

applications in which heating may cause hydrogen embrittle-

E243 Practice for Electromagnic (Eddy-Current) Examina-

ment.

tion of Copper and Copper-Alloy Tubes

1.3 Valuesstatedininch-poundunitsarethestandardexcept

E255 Practice for Sampling Copper and CopperAlloys for

for grain size which is given in SI units. Values given in

Determination of Chemical Composition

parentheses are for information only.

1.4 The following hazard caveat pertains only to Section 15

3. Terminology

of this specification: This standard does not purport to address

3.1 Definitions:

all of the safety concerns, if any, associated with its use. It is

3.1.1 For definitions of terms related to copper and copper

the responsibility of the user of this standard to establish

alloys refer to Terminology B846.

appropriate safety and health practices and determine the

3.2 Definitions of Terms Specific to This Standard:

applicability of regulatory limitations prior to use.

3.2.1 capable of—the test need not be performed by the

manufacturer or the producer; however, should subsequent

2. Referenced Documents

testing by the purchaser establish that the product does not

2.1 ASTM Standards:

meet these requirements, the product shall be subject to

2.1.1 The following documents in the current issue of the

rejection.

Annual Book of ASTM Standards form a part of this specifi-

3.2.2 flash—themetalthatprotrudesattheweld,bothinside

cation to the extent referenced herein:

andoutsideofthetube,asaresultofthepressureappliedwhen

B153 Test Method for Expansion (Pin Test) of Copper and

a forge-type seam is produced. The two types of flash are

Copper-Alloy Pipe and Tubing

internal flash and external flash.

B170 SpecificationforOxygen-FreeElectrolyticCopper—

3.2.3 lengths, mill—straight lengths, including ends, that

Refinery Shapes

can be conveniently manufactured in the mills.

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe Annual Book of ASTM Standards, Vol 02.03.

and Tube. Annual Book of ASTM Standards, Vol 03.01.

Current edition approved Sept. 10, 2000. Published November 2000. Originally Annual Book of ASTM Standards, Vol 14.02.

e1 6

published as B447–67. Last previous edition B447–97 . Annual Book of ASTM Standards, Vol 03.05.

2 7

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 03.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 447

3.2.3.1 Discussion—Full-length pieces are usually 10, 12, 5.2.3 Hydrogen embrittlement susceptibility test (Section

or 20 ft and subject to established length tolerances. 13),

3.2.4 lengths, multiple—straight lengths of integral mul- 5.2.4 Hydrostatic test (see 15.3),

tiples of a base length, with a suitable allowance for cutting, if 5.2.5 Pneumatic test (see 15.4),

and when specified. 5.2.6 Certification (Section 25), and

3.2.5 lengths, stock—straight lengths that are mill cut and 5.2.7 Mill test report (Section 26).

stored in advance of orders.

6. Material and Manufacture

3.2.5.1 Discussion—Stocklengthsareusually6to20ftand

subject to established tolerances.

6.1 Material:

3.2.6 scarfing—the removal of flash by a cutting operation.

6.1.1 The material shall be sheet or strip of the copper

3.2.7 tube—a hollow product of round or any other cross specified in the ordering information and shall be of such

section, having a continuous periphery.

soundness as to be suitable for the production of the products

described herein.

4. Classification

6.1.2 In the event heat identification or traceability is

required, the purchaser shall specify the details desired.

4.1 The following types of welded tube are manufactured

under this specification:

NOTE 1—Because of the discontinuous nature of the processing of

4.1.1 As-Welded—Aconditioncreatedasaresultofforming

castings into wrought products, it is not always practical to identify a

specific casting analysis with a specific quantity of finished material.

sheet or plate into tubular form and welding without subse-

quent heat treatment or cold work.

6.2 Manufacture:

4.1.2 Welded and Annealed—Welded tube annealed to pro-

6.2.1 The welded tube shall be manufactured from either

duce a uniform grain size appropriate to the specified annealed

cold-rolledorannealedsheetorstrip.Thesheetorstripshallbe

temper.

formed into a tubular shape on a suitable forming mill.

4.1.3 Welded and Cold Drawn—Welded tube with internal

6.2.2 Welding shall be accomplished by any process that

and external flash removed by scarfing or the internal flash

produces forge or fusion welds leaving no crevice in the weld

displaced and subsequently cold drawn to conform to a

seam visible to the unaided eye.

specified temper.

6.2.2.1 Forge-Welded Tube—The edges of the strip shall be

4.1.4 Fully Finished:

heated to the required welding temperature, usually by a

4.1.4.1 Welded tube with internal and external flash re-

high-frequency electric current and be pressed firmly together

moved by scarfing and subsequently cold drawn over a

causing a forged-type joint to be formed with internal and

mandrel and annealed as necessary to conform to the specified

external flash.

temper.

6.2.2.2 Fusion-Welded Tube—Theedgesofthestripshallbe

4.1.4.2 Welded tube that has been mechanically worked

brought together and welded, usually by a GTAW welding

smooth without the need for internal or external scarfing or

process, without the addition of filler metal, causing a fusion-

other metal removal and subsequently cold drawn over a

type joint to be formed with no internal or external flash.

mandrel and annealed as necessary to conform to the specified

6.2.3 Flash Removal—The external flash of forge welded

size and temper.

tubeshallberemovedbyscarfingandtheinternalflashshallbe

treated by one of the following techniques:

5. Ordering Information

6.2.3.1 IFI—Internal flash to remain in the as-welded con-

dition.

5.1 Contract or purchase orders for product under this

6.2.3.2 IFR—Internal flash to be removed by scarfing.

specification shall include the following information:

6.2.3.3 IFD—Internalflashdisplacedbyrollingordrawing.

5.1.1 Specification designation and year of issue,

6.2.4 Unless otherwise specified in the contract or purchase

5.1.2 Copper designation (for example, C10300),

order,theweldedtubeshallbefurnishedwiththeinternalflash

5.1.3 Tube type (Section 4),

in the IFI condition.

5.1.4 Internal flash treatment (see 6.2.4),

5.1.5 Temper (Section 8),

7. Chemical Composition

5.1.6 Dimensions; diameter, wall thickness, length, and so

7.1 Thematerialshallconformtothecompositionalrequire-

forth (Section 16),

ments listed in Table 1 for the copper specified.

5.1.7 How furnished; straight length or coil,

7.1.1 The composition limits do not preclude the presence

5.1.8 Quantity; total weight or number of pieces or coils

of other elements. When limits for unnamed elements are

each copper, tube type, size, and temper, and

required, they shall be established and analysis required by

5.1.9 When product is purchased for electrical conductor

agreement between the manufacturer and the purchaser.

application (Section 10).

5.2 The following are options available under this specifi-

8. Temper

cation and shall be specified in the contract or purchase order

when required:

8.1 Tempers, as defined in Practice B601, of the various

5.2.1 Heat identification or traceability details (see 6.1.2), tube types are as follows:

5.2.2 Microscopical examination microphotographs (see 8.1.1 As-Welded:

12.1.1), 8.1.1.1 As-welded from annealed strip WM50,

B 447

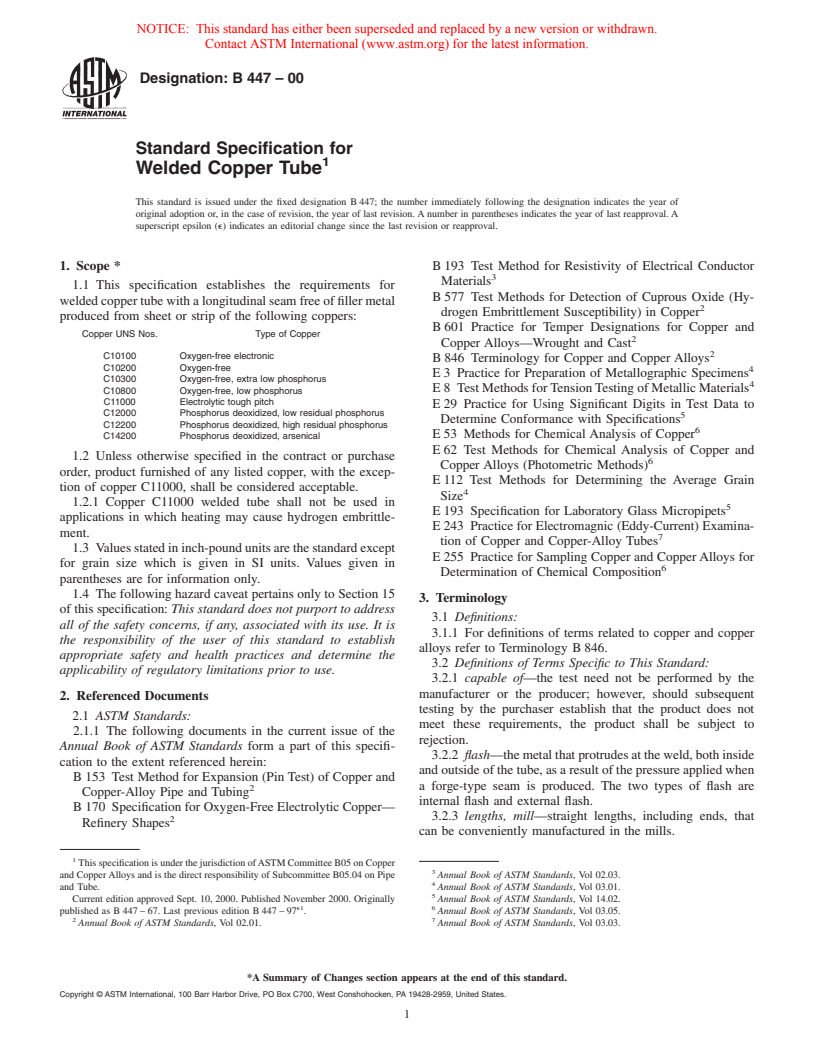

TABLE 1 Chemical Requirements

10.1.1 When specified in the contract or purchase order,

Composition, % product purchased for electrical conductor applications shall

Copper

conform to the requirements of Table 3 for the copper and

Phosphorus Arsenic

UNS No. A

Copper, min

temper specified in the ordering information when tested in

Min Max Min Max

accordance with Specification E193.

B,C

C10100 99.99 . . . .

D

C10200 99.95 . . . .

E NOTE 2—The International Annealed Copper Standard electrical con-

C10300 99.95 0.001 0.005 . .

E

ductivity equivalents are given in Appendix X2.

C10800 99.95 0.005 0.012 . .

C11000 99.90 . . . .

C12000 99.90 0.004 0.012 . .

11. Mechanical Property Requirements

C12200 99.9 0.015 0.040 . .

C14200 99.4 0.015 0.040 0.15 0.50

11.1 Tensile Strength:

A

Copper (including silver).

11.1.1 As welded, welded and cold drawn, and fully fin-

B

This value is exclusive of silver and shall be determined by difference of

ished tube in drawn tempers shall conform with the tensile

“impurity total” from 100 %. “Impurity total” is defined as the sum of sulfur, silver,

lead, tin, bismuth, arsenic, antimony, iron, nickel, zinc, phosphorus, selenium,

strength requirements prescribed in Table 4 when tested in

tellurium, manganese, cadmium, and oxygen present in the sample.

accordance with Test Methods E8.

C

Impurity maximums for C10100 shall be: antimony 4, arsenic 5, bismuth 1,

cadmium 1, iron 10, lead 5, manganese 0.5, nickel 10, oxygen 5, phosphorus 3,

11.1.1.1 Tensile test results shall be the criteria for rejection

selenium 3, silver 25, sulfur 15, tellurium 2, tin 2, and zinc 1.

based upon mechanical properties.

D

Oxygen in C10200 shall be 10 ppm max.

E

Copper + silver + phosphorus. 11.2 Rockwell Hardness:

11.2.1 Rockwell hardness values given inTable 2 andTable

4areforgeneralinformationandassistanceintestingandshall

8.1.1.2 As-welded from half hard strip WM02, and

not be used as a basis for product rejection.

8.1.1.3 As-welded from hard strip WM04.

8.1.2 Welded and Annealed:

NOTE 3—The Rockwell hardness test offers a quick and convenient

8.1.2.1 Welded and soft annealed W060, and method for checking general conformity to the specification requirements

for temper, grain size, and tensile strength.

8.1.2.2 Welded and light annealed W050.

8.1.3 Welded and Cold Drawn:

12. Microscopical Examination

8.1.3.1 Welded and drawn eighth hard WH00,

8.1.3.2 Welded and drawn half hard WH02, and

12.1 Tubes produced of coppers C10100, C10200, C10300,

8.1.3.3 Welded and hard drawn WH04.

and C12000 shall be significantly free of cuprous oxide when

8.1.4 Fully Finished:

tested in accordance with Test Method A of Test Methods

8.1.4.1 Fully finished, soft annealed O60,

B577.

8.1.4.2 Fully finished, light annealed O50,

12.1.1 When specified in the ordering information, micro-

8.1.4.3 Fully finished, light drawn H55,

photographs of the manufacture’s test specimens shall be

8.1.4.4 Fully finished, drawn general purpose H58, and

provided (see 5.2.1).

8.1.4.5 Fully finished, hard drawn H80.

13. Hydrogen Embrittlement Susceptibility

9. Property Requirements of Annealed Welded Tube and

13.1 When specified in the ordering information, tube

Annealed Fully Finished Welded Tube

produced of coppers C10100, C10200, C10300, C10800,

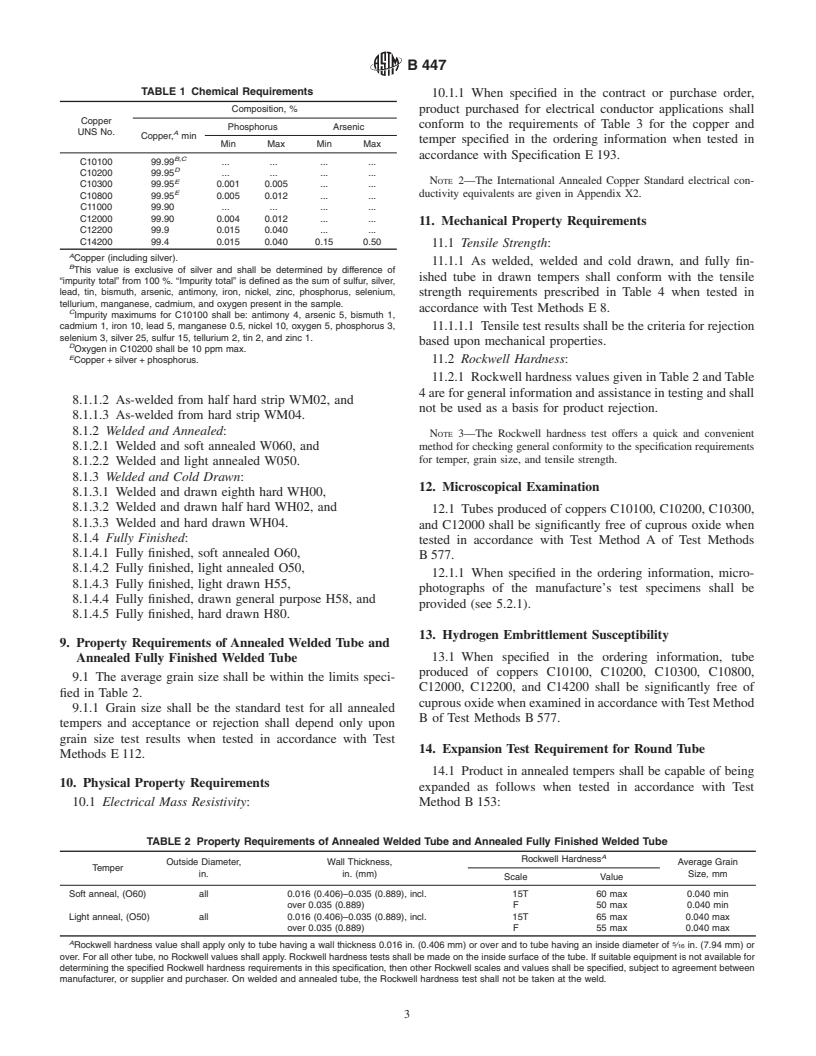

9.1 The average grain size shall be within the limits speci-

C12000, C12200, and C14200 shall be significantly free of

fied in Table 2.

cuprousoxidewhenexaminedinaccordancewithTestMethod

9.1.1 Grain size shall be the standard test for all annealed

B of Test Methods B577.

tempers and acceptance or rejection shall depend only upon

grain size test results when tested in accordance with Test

14. Expansion Test Requirement for Round Tube

Methods E112.

14.1 Product in annealed tempers shall be capable of being

10. Physical Property Requirements

expanded as follows when tested in accordance with Test

10.1 Electrical Mass Resistivity: Method B153:

TABLE 2 Property Requirements of Annealed Welded Tube and Annealed Fully Finished Welded Tube

A

Rockwell Hardness

Outside Diameter, Wall Thickness, Average Grain

Temper

in. in. (mm) Size, mm

Scale Value

Soft anneal, (O60) all 0.016 (0.406)–0.035 (0.889), incl. 15T 60 max 0.040 min

over 0.035 (0.889) F 50 max 0.040 min

Light anneal, (O50) all 0.016 (0.406)–0.035 (0.889), incl. 15T 65 max 0.040 max

over 0.035 (0.889) F 55 max 0.040 max

A

Rockwell hardness value shall apply only to tube having a wall thickness 0.016 in. (0.406 mm) or over and to tube having an inside diameter of ⁄16 in. (7.94 mm) or

over. For all other tube, no Rockwell values shall apply. Rockwell hardness tests shall be made on the inside surface of the tube. If suitable equipment is not available for

determining the specified Rockwell hardness requirements in this specification, then other Rockwell scales and values shall be specified, subject to agreement between

manufacturer, or supplier and purchaser. On welded and annealed tube, the Rockwell hardness test shall not be taken at the weld.

B 447

TABLE 3 Electrical Resistivity material is not generally available or that no tolerances have been

2 established.

Electrical Resistivity, max, V·g/m

Copper Alloy UNS Nos.

16.4 Wall Thickness Tolerances—Wallthicknessofthetube

Tempers

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.