ASTM D7871-13

(Test Method)Standard Test Method for Analysis of Cyclohexane by Gas Chromatography (Effective Carbon Number)

Standard Test Method for Analysis of Cyclohexane by Gas Chromatography (Effective Carbon Number)

SIGNIFICANCE AND USE

5.1 This test method is suitable for setting specifications on the materials referenced in Table 1 and for use as an internal quality control tool where cyclohexane is produced or is used in a manufacturing process. It may also be used in development or research work involving cyclohexane.

5.2 This test method is useful in determining the purity of cyclohexane with normal impurities present. If extremely high boiling or unusual impurities are present in the cyclohexane, this test method would not necessarily detect them and the purity calculation would be erroneous.

SCOPE

1.1 This test method covers the determination of the purity of cyclohexane by gas chromatography.

1.2 This test method has been found applicable to the measurement of impurities such as those found in Table 1, which are impurities that may be found in cyclohexane. The impurities can be analyzed over a range of 1 to 400 mg/kg by this method, but may be applicable to a wider range.

1.3 The limit of detection is 1 mg/kg.

1.4 In determining the conformance of the test results using this test method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7871 − 13

Standard Test Method for

Analysis of Cyclohexane by Gas Chromatography (Effective

Carbon Number)

This standard is issued under the fixed designation D7871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.1 This test method covers the determination of the purity

E355 Practice for Gas Chromatography Terms and Relation-

of cyclohexane by gas chromatography.

ships

1.2 This test method has been found applicable to the

E691 Practice for Conducting an Interlaboratory Study to

measurement of impurities such as those found in Table 1,

Determine the Precision of a Test Method

which are impurities that may be found in cyclohexane. The

E1510 Practice for Installing Fused Silica Open Tubular

impurities can be analyzed over a range of 1 to 400 mg/kg by

Capillary Columns in Gas Chromatographs

this method, but may be applicable to a wider range. 3

2.2 Other Standards:

1.3 The limit of detection is 1 mg/kg. OSHA Regualtions, 29 CFR paragraphs 1910.1000 and

1910.1200

1.4 In determining the conformance of the test results using

this test method to applicable specifications, results shall be

3. Terminology

rounded off in accordance with the rounding-off method of

3.1 See Terminology D4790 for definitions of terms used in

Practice E29.

this test method.

1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Summary of Test Method

standard.

4.1 The specimen to be analyzed is injected into a gas

1.6 This standard does not purport to address all of the

chromatographequippedwithaflameionizationdetector(FID)

safety concerns, if any, associated with its use. It is the

and a capillary column. The peak area of each component is

responsibility of the user of this standard to establish appro-

measured and adjusted using effective carbon number (ECN)

priate safety and health practices and determine the applica-

response factors. The concentration of each component is

bility of regulatory limitations prior to use.Forspecifichazards

calculated based on its relative percentages of total adjusted

statements, see Section 8.

peak area and normalized to 100.0000 %.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 This test method is suitable for setting specifications on

D3437 Practice for Sampling and Handling Liquid Cyclic

the materials referenced in Table 1 and for use as an internal

Products

quality control tool where cyclohexane is produced or is used

D4790 Terminology ofAromatic Hydrocarbons and Related

inamanufacturingprocess.Itmayalsobeusedindevelopment

Chemicals

or research work involving cyclohexane.

D6809 Guide for Quality Control and Quality Assurance

5.2 This test method is useful in determining the purity of

Procedures for Aromatic Hydrocarbons and Related Ma-

cyclohexane with normal impurities present. If extremely high

terials

boiling or unusual impurities are present in the cyclohexane,

this test method would not necessarily detect them and the

This test method is under the jurisdiction of ASTM Committee D16 on

purity calculation would be erroneous.

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

Subcommittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane and Their

Derivatives.

Current edition approved June 1, 2013. Published July 2013. DOI: 10.1520/ AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

D7871-13. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.access.gpo.gov.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Scanlon, J. T. and Willis, D. E., “Calculation of Flame Ionization Detector

Standards volume information, refer to the standard’s Document Summary page on Relative Response Factors Using the Effective Carbon Concept,” Journal of

the ASTM website. Chromatographic Science, Vol. 23, August 1985, ppl. 333-339.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7871 − 13

TABLE 1 Impurities Known or Suggested to be Present in

obtain a minimum peak height response for 1 mg/kg benzene

Commercial Cyclohexane

of twice the height of the signal background noise.

C

6.2 Columns—The choice of column is based on resolution

(1) n-butane

(2) isobutene

requirements. Any column may be used that is capable of

C

resolving all significant impurities from cyclohexane. The

(3) n-pentane

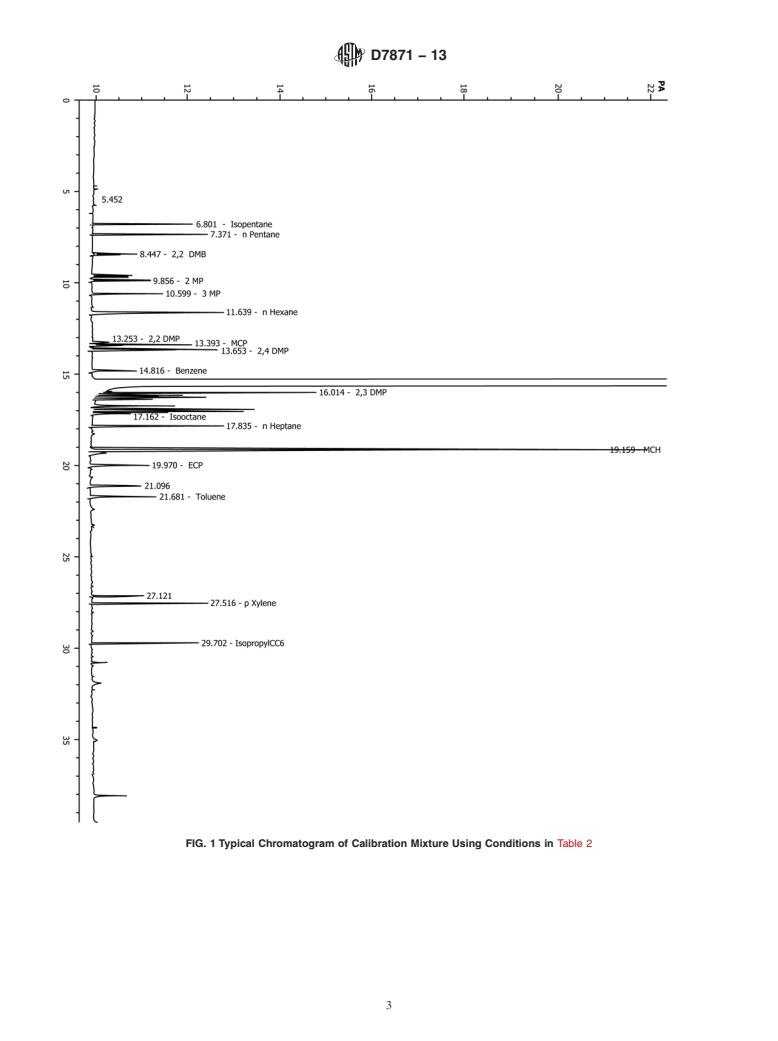

column described in Table 2 has been used successfully.

(4) isopentane

(5) cyclopentane

6.3 Recorder—Electronic integration is required.

C

(6) n-hexane

6.4 Injector—The specimen must be precisely and repeat-

(7) 2-methylpentane

ably injected into the gas chromatograph.An automatic sample

(8) 3-methylpentane

(9) methylcyclopentane

injection device is highly recommended. Manual injection may

(10) benzene

be employed if the precision stated in Tables 4–8 can be

(11) cyclohexene

reliably and consistently satisfied.

(12) 2,2-dimethylbutane

(13) 2,3-dimethylbutane

C

7 7. Reagents and Materials

(14) 3,3-dimethylpentane

(15) 2,2-dimethylpentane

7.1 Purity of Reagents—Reagent grade chemicals shall be

(16) 2,3-dimethylpentane

used in all tests. Unless otherwise indicated, it is intended that

(17) 2,4-dimethylpentane

all reagents shall conform to the specifications of the Commit-

(18) 1,1-dimethylcyclopentane

(19) trans-1,3-dimethylcyclopentane tee onAnalytical Reagents of theAmerican Chemical Society,

(20) trans-1,2-dimethylcyclopentane

where such specifications are available. Other grades may be

(21) cis-1,2-dimethylcyclopentane

used, provided it is first ascertained that the reagent is of

(22) 2,2-dimethylcyclopentane

(23) 2,4-dimethylcyclopentane

sufficiently high purity to permit its use without lessening the

(24) cis-1,3-dimethylcyclopentane

accuracy of the determination.

(25) ethylcyclopentane

(26) methylcyclohexane

(27) 3-ethylpentane 8. Hazards

(28) 3-methylhexane

8.1 Consult current OSHA regulations, suppliers’ Material

(29) 2-methylhexane

(30) n-heptane

SafetyDataSheets,andlocalregulationsforallmaterialslisted

(31) toluene

in this test method.

C

(32) iso-octane

(33) p-xylene 9. Sampling and Handling

C

9.1 Sample the material in accordance with Practice D3437.

(34) isopropylcylohexane

10. Preparation of Apparatus

10.1 Follow manufacturer’s instructions for mounting and

6. Apparatus

conditioning the column into the chromatograph and adjusting

the instrument to the conditions described in Table 2 allowing

6.1 Gas Chromatograph—Any instrument having a flame

ionization detector that can be operated at the conditions given sufficient time for the equipment to reach equilibrium. See

Practices E1510 and E355 for additional information on gas

in Table 2. The system should have sufficient sensitivity to

chromatography practices and terminology.

11. Calibration and Standardization

TABLE 2 Instrumental Parameters

Detector flame ionization

11.1 Prior to implementation of the ECN method, a labora-

Injection Port capillary splitter

tory should demonstrate that acceptable precision and bias can

Column A:

be obtained using a synthetic mixture of known

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.