ASTM D5233-92(2004)

(Test Method)Standard Test Method for Single Batch Extraction Method for Wastes

Standard Test Method for Single Batch Extraction Method for Wastes

SCOPE

1.1 This test method is applicable to the extraction of samples of treated or untreated solid wastes or sludges, or solidified waste samples, to provide an indication of the leaching potential.

1.2 This test method is intended to provide an extract for measurement of the concentration of the analytes of concern. The measured values may be compared against set or chosen acceptance levels in some applications.

1.3 If the sole application of the test method is such a pass/fail comparison and a total analysis of the waste demonstrates that individual analytes are not present in the waste, or that the chosen acceptance concentration levels could not possibly be exceeded, the test method need not be run.

1.4 If the sole application of the test method is such a pass/fail comparison and an analysis of any one of the liquid fractions of the extract indicates that the concentration of the target analyte is so high that, even after accounting for dilution from the other fractions of the extract, it would be equal to or above an acceptance concentration level, then the waste fails the test. In such a case it may not be necessary to analyze the remaining fractions of the extract.

1.5 This test method is intended to provide an extract suitable for the measurement of the concentration of analytes that will not volatilize under the conditions of the test method.

1.6 Presence of volatile analytes may be established if an analysis of the extract obtained using this test method detects the target volatile analyte. If its concentration is equal to or exceeds an acceptance level for that analyte, the waste fails the test. However, extract from this test method shall not be used to determine the concentration of volatile organic analytes.

1.7 This test method is intended to describe only the procedure for performing a batch extraction. It does not describe all of the sampling and analytical requirements that may be associated with the application of this test method.

1.8 The values stated in either SI or inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.9 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precautionary statement, see Note 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5233–92 (Reapproved 2004)

Standard Test Method for

Single Batch Extraction Method for Wastes

This standard is issued under the fixed designation D5233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

1.1 This test method is applicable to the extraction of

responsibility of the user of this standard to establish appro-

samples of treated or untreated solid wastes or sludges, or

priate safety and health practices and determine the applica-

solidified waste samples, to provide an indication of the

bility of regulatory limitations prior to use. For a specific

leaching potential.

precautionary statement, see Note 8.

1.2 This test method is intended to provide an extract for

measurement of the concentration of the analytes of concern.

2. Referenced Documents

The measured values may be compared against set or chosen

2.1 ASTM Standards:

acceptance levels in some applications.

D75 Practice for Sampling Aggregates

1.3 If the sole application of the test method is such a

D420 Guide to Site Characterization for Engineering De-

pass/fail comparison and a total analysis of the waste demon-

sign and Construction Purposes

strates that individual analytes are not present in the waste, or

D653 Terminology Relating to Soil, Rock, and Contained

that the chosen acceptance concentration levels could not

Fluids

possibly be exceeded, the test method need not be run.

D1129 Terminology Relating to Water

1.4 If the sole application of the test method is such a

D1193 Specification for Reagent Water

pass/fail comparison and an analysis of any one of the liquid

D2234/D2234M Practice for Collection of a Gross Sample

fractions of the extract indicates that the concentration of the

of Coal

target analyte is so high that, even after accounting for dilution

D3370 Practices for Sampling Water from Closed Conduits

from the other fractions of the extract, it would be equal to or

E122 Practice for Calculating Sample Size to Estimate,

above an acceptance concentration level, then the waste fails

With Specified Precision, the Average for a Characteristic

the test. In such a case it may not be necessary to analyze the

of a Lot or Process

remaining fractions of the extract.

ES 16 Practice for the Generation of Environmental Data

1.5 This test method is intended to provide an extract

Related to Waste Management Activities

suitable for the measurement of the concentration of analytes

that will not volatilize under the conditions of the test method.

3. Terminology

1.6 Presence of volatile analytes may be established if an

3.1 Definitions—For definitions of terms used but not de-

analysis of the extract obtained using this test method detects

fined in this test method, see Terminology D1129.

the target volatile analyte. If its concentration is equal to or

exceeds an acceptance level for that analyte, the waste fails the

4. Summary of Test Method (See Fig. 1)

test. However, extract from this test method shall not be used

4.1 Forwastescontaininglessthan0.5 %drysolidmaterial,

to determine the concentration of volatile organic analytes.

the filtrate of the waste, after filtration through a 0.6 to 0.8-µm

1.7 This test method is intended to describe only the

glass fiber filter, is defined as the method extract. Extraction of

procedure for performing a batch extraction. It does not

,

4 5

the solid is not required for such wastes.

describe all of the sampling and analytical requirements that

4.2 For wastes containing greater than or equal to 0.5 % dry

may be associated with the application of this test method.

solid material, the liquid, if any, is separated from the solid

1.8 The values stated in either SI or inch-pound units are to

be regarded as the standard. The values given in parentheses

are for information only.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This test method is under the jurisdiction of ASTM Committee D34 on Waste Annual Book of ASTM Standards, Vol 11.04 (see 1991 edition).

Disposal and is the direct responsibility of Subcommittee D34.01.06 on Analytical Federal Register, Vol 55, No. 61, March 29, 1990. Toxicity Characteristics

Methods. Revisions, Final Rule.

Current edition approved March 15, 1992. Published May 1992. DOI: 10.1520/ Federal Register, Vol 55, No. 126, June 29, 1990. Toxicity Characteristic

D5233-92R04. Revisions, Final Rule, Corrections.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5233–92 (2004)

FIG. 1 Method Flow Chart

phase and stored for later analysis.The solid phase is extracted 5.2 The extraction conditions of the test method were

with an amount of extraction fluid equal to 20 times the weight chosen to simulate a potential disposal scenario to which the

of the solid phase.The extraction fluid used is a function of the wastes may be exposed.

alkalinity of the solid phase of the waste. Following extraction, 5.3 One intent of this test method is that the amount of acid

the liquid extract is separated from the solid phase by filtration

in the extraction fluids reflect the acid available from the

through a 0.6 to 0.8-µm glass fiber filter. leachate of a specific landfill where municipal and industrial

4.3 If compatible (that is, multiple phases will not form

wastes were co-disposed.

upon combination), the initial liquid phase of the waste is 5.4 One intent of this test method is to not allow the pH of

added to the liquid extract, and these are analyzed together. If

the extraction fluid to be lower than that of the leachate of a

incompatible, the liquids are analyzed separately and the specific landfill where municipal and industrial wastes were

results are combined mathematically to yield a volume-

co-disposed. Therefore, the pH of the extraction fluid was

weighted average concentration. chosen with the following considerations:

(1) Not to be less than 4.93 6 0.05 for the extraction of

5. Significance and Use

wasteswithanacidneutralizationcapacityoflessthantheacid

5.1 This test method is intended to generate an extract with

a concentration of the target analyte(s) representative of the

expected release under the scenario simulated, and which can

Kimmel, T. A., and Friedman, D. A., “Model Assumptions and Rationale

be compared with concentration levels acceptable in waste

BehindtheDevelopmentofEPIII,”ASTMSTP886,J.K.Petros,etal,Eds.,ASTM,

disposal, treatment, or production activities. Philadelphia, PA, 1986, pp. 36–53.

D5233–92 (2004)

available in the total volume of extraction fluid used in the 6.2 Extraction Vessel—Suitable vessels include cylindri-

method (Extraction Fluid No. 1). cally shaped, minimum 2-L size, with capacity sufficient to

(2)At2.88 60.05,asdefinedbythepHoftheacid,forthe holdthesampleandtheextractionfluid.Head-spaceisallowed

extraction of wastes with an acid neutralization capacity of in this vessel. The extraction bottles may be constructed from

more than the acid available in the extraction fluid used in the various plastic materials, depending on the analytes of interest

method (Extraction Fluid No. 2). and the nature of the waste. Plastic bottles, other than polytet-

5.5 The interpretation and use of the results of this test rafluoroethylene, shall not be used if organics are to be

method are limited by the assumptions of a single co-disposal investigated.Thebottlesshouldbesturdy,inordertowithstand

scenario and by the factors affecting the composition of a the impact of the falling sample fragments, and shall have a

landfill leachate and chemical or other differences between a leak-free seal. The use of polytetrafluoroethylene tape is

selected extraction fluid and the real landfill leachate. recommended to ensure a tight seal. Due to their potential for

5.6 This test method may be affected by biological changes breakage, the use of glass bottles is not recommended.

in the waste, and it is not designed to isolate or measure the

NOTE 2—Suitable bottles range from 4.0 to 4.5 in. (102 to 114 mm) in

effect of such processes.

diameter and from 8.5 to 13.0 in. (216 to 330 mm) in height.

5.7 This test method produces extracts that are amenable to

6.3 Filtration Device—It is recommended that all filtrations

the determination of both minor and major constituents. When

be performed in a hood. Wastes should be filtered using

minor constituents are being determined, it is especially

positive-pressure filtration using a pre-purified grade inert gas

important that precautions be taken in sample storage and

such as nitrogen.

handling to avoid possible contamination of the samples.

6.3.1 Filter Holder, capable of supporting a glass fiber filter

5.8 The agitation technique, rate, liquid-to-solid ratio, and

and able to withstand the pressure needed to accomplish

filtrationconditionsspecifiedinthemethodmaynotbesuitable

separation (maximum 50 psi or 345 kPa). These devices shall

for extracting all types of wastes.

have a minimum internal volume of 300 mL and shall be

5.9 This test method is intended to extract the samples in

equipped to accommodate a minimum filter size of 47 mm.

their original physical state as is, without any size reduction.

(Filter holders having an internal capacity of 2.2 L and

However, the sample/extractor interaction is expected to cor-

equipped to accommodate a 142-mm diameter filter are rec-

relate with the environmental conditions to which a waste may

ommended.)

be exposed.

6.3.1.1 Materials of Construction—Filtration devices shall

5.10 The extraction conditions defined by this test method

be made of inert materials that will not leach or adsorb the

are expected to yield steady-state concentrations, determined

analytesofconcern.Glass,polytetrafluoroethylene,ortype316

by the extraction liquid-to-solid ratio and the duration of the

stainless steel equipment may be used when both organic and

extraction, which may or may not agree with the concentration

inorganic analytes are of concern. Devices made of high-

of an equilibrium.

density polyethylene (HDPE), polypropylene (PP), or polyvi-

nylchloride (PVC) may be used when only inorganics are of

6. Apparatus and Materials

concern.

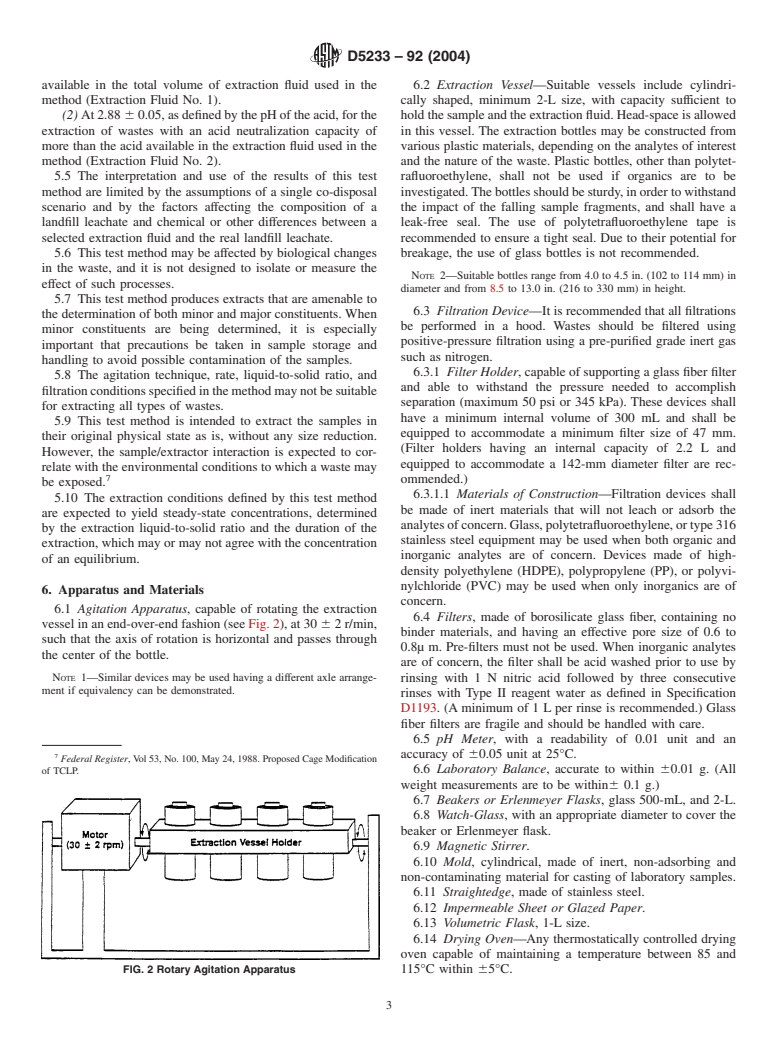

6.1 Agitation Apparatus, capable of rotating the extraction

6.4 Filters, made of borosilicate glass fiber, containing no

vessel in an end-over-end fashion (see Fig. 2), at 30 6 2 r/min,

binder materials, and having an effective pore size of 0.6 to

such that the axis of rotation is horizontal and passes through

0.8µ m. Pre-filters must not be used. When inorganic analytes

the center of the bottle.

are of concern, the filter shall be acid washed prior to use by

NOTE 1—Similar devices may be used having a different axle arrange- rinsing with 1 N nitric acid followed by three consecutive

ment if equivalency can be demonstrated.

rinses with Type II reagent water as defined in Specification

D1193. (A minimum of 1 L per rinse is recommended.) Glass

fiber filters are fragile and should be handled with care.

6.5 pH Meter, with a readability of 0.01 unit and an

7 accuracy of 60.05 unit at 25°C.

Federal Register, Vol 53, No. 100, May 24, 1988. Proposed Cage Modification

6.6 Laboratory Balance, accurate to within 60.01 g. (All

of TCLP.

weight measurements are to be within6 0.1 g.)

6.7 Beakers or Erlenmeyer Flasks, glass 500-mL, and 2-L.

6.8 Watch-Glass, with an appropriate diameter to cover the

beaker or Erlenmeyer flask.

6.9 Magnetic Stirrer.

6.10 Mold, cylindrical, made of inert, non-adsorbing and

non-contaminating material for casting of laboratory samples.

6.11 Straightedge, made of stainless steel.

6.12 Impermeable Sheet or Glazed Paper.

6.13 Volumetric Flask, 1-L size.

6.14 Drying Oven—Any thermostatically controlled drying

oven capable of maintaining a temperature between 85 and

FIG. 2 Rotary Agitation Apparatus 115°C within 65°C.

D5233–92 (2004)

6.15 Graduated Pipet, readable to 0.1 mL. 8.3 Where no specific methods are available, sampling

6.16 Hot Plate, equipped for agitation and temperature methodology for materials of similar physical form shall be

control capable of maintaining a 50 6 3°C temperature. used.

6.17 Graduated Measuring Cylinder, with a precision of 8.4 It is important that the sample of the waste be represen-

63%. tative with respect to surface area, as variations in surface area

would directly affect the extraction characteristics of the

7. Reagents

sample. Waste samples should contain a representative distri-

7.1 Purity of Reagents—Reagent grade chemicals shall be bution of particle sizes.

used in all tests. Unless otherwise indicated, it is intended that

NOTE 3—Information on obtaining representative samples can also be

all reagents shall conform to the specifications of the Commit- 9

found in Pierre Gy’s Sampling Theory and Practice.

tee onAnalytical Reagents of theAmerican Chemical Society,

8.5 Approximately 100 g of solid phase samples are re-

where such specifications are available. Other grades may be

quiredforeachextraction.Preliminaryevaluationalsorequires

used, provided it is first ascertained that the reagent is of

100 g of solid phase sample. A larger sample size may be

sufficiently high purity to permit its use without lessening the

required, depending on the solids content of the waste sample

accuracy of the determination.

(percent solids; see 10.2.9).

7.2 Purity of Water—Reagent water is defined as water in

8.6 Enough extract should be generated such that the

which an interfering analyte is not observed at or above the

volumewillbesufficienttosupportalloftheanalysesrequired.

method detection limit of the analyte(s) of interest. Type II of

If the volume of extract generated by the performance of a

Specification D1193 or equivalent meets the definition of

single extraction will not be sufficient to perform all of the

reagent water.

analyses to be conducted, it is recommended that more than

7.3 HydrochloricAcid (HCl), 1 N, made fromACS reagent

one extraction be performed and that the extracts from each

grade.

extraction be combined and then aliquoted for analysis.

7.4 Nitric Acid (HNO ), 1 N, made from ACS reagent

8.7 For the evaluation of solidified or stabilized wastes, or

grade.

both, samples may be cast in the form of a cylinder that will fit

7.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.