ASTM D6464-03a(2009)e1

(Specification)Standard Specification for Expandable Foam Adhesives for Fastening Gypsum Wallboard to Wood Framing

Standard Specification for Expandable Foam Adhesives for Fastening Gypsum Wallboard to Wood Framing

ABSTRACT

This specification establishes minimum performance requirements for determining strength, aging, and working properties of expandable foam adhesives intended for bonding back surfaces of gypsum wallboards of all thicknesses to wood framing. Minimum physical and performance requirements are specified for all measured properties of adhesives and adhesive bonds. Shear strength, tensile strength, adhesive open assembly time determination, substrate wet-out by adhesive, accelerated adhesive aging, freeze-thaw stability, suitability of a laminating adhesive for vinyl-covered wallboard, suitability for stain resistance for vinyl-covered wallboard, and gap filling tests shall be performed to conform to the specified requirements.

SCOPE

1.1 This specification establishes minimum performance requirements for determining strength, aging, and working properties of expandable foam adhesives intended for bonding back surfaces of gypsum wallboards of all thicknesses to wood framing. Minimum physical and performance requirements are specified for all measured properties of adhesives and adhesive bonds.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D6464 −03a (Reapproved 2009)

Standard Specification for

Expandable Foam Adhesives for Fastening Gypsum

Wallboard to Wood Framing

This standard is issued under the fixed designation D6464; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in November 2009.

1. Scope* 3.2 Definitions of Terms Specific to This Standard:

3.2.1 expandable foam adhesive, n—any polymer that ex-

1.1 This specification establishes minimum performance

pands during delivery or cure to fill the space between

requirements for determining strength, aging, and working

substrates.

properties of expandable foam adhesives intended for bonding

backsurfacesofgypsumwallboardsofallthicknessestowood

4. Significance and Use

framing.Minimumphysicalandperformancerequirementsare

specifiedforallmeasuredpropertiesofadhesivesandadhesive

4.1 This specification applies to expandable foam adhesives

bonds.

used to bond the back surface of gypsum wallboard to

1.2 The values stated in inch-pound units are to be regarded

Douglas-fir dimensional lumber or other lumber species of

as standard. The values given in parentheses are mathematical

equivalent bonding qualities capable of meeting the test

conversions to SI units that are provided for information only

requirements.

and are not considered standard.

4.2 The specification establishes the minimum strength

1.3 This standard does not purport to address all of the

requirements of the bond for the selected assembly materials.

safety concerns, if any, associated with its use. It is the

4.3 Theadhesiveisnotconsideredasubstituteformechani-

responsibility of the user of this standard to establish appro-

calfasteners.Fastenerswillberequiredtorestrictexpansionof

priate safety and health practices and determine the applica-

the foam adhesive while it cures. The recommended fastening

bility of regulatory limitations prior to use.

schedulemustappearinthemanufacturer’sapplicationinstruc-

2. Referenced Documents

tions.

2.1 ASTM Standards:

4.4 The tests are suitable for product performance certifica-

C1396/C1396MSpecification for Gypsum Board

tion and quality control programs, and can be useful to the

D905Test Method for Strength Properties of Adhesive

generalpublic,adhesivemanufacturers,distributors,specifiers,

Bonds in Shear by Compression Loading

architects,contractors,testinglaboratoriesandotherbusinesses

D907Terminology of Adhesives

and professionals.

E4Practices for Force Verification of Testing Machines

E177Practice for Use of the Terms Precision and Bias in 4.5 Theresultsdonotincludeallpossibleconditions,which

ASTM Test Methods

may occur during final assembly, but indicate a set of perfor-

mance characteristics for laboratory controlled bonding vari-

3. Terminology

ables.

3.1 Definitions—Many terms in this specification are de-

fined in Terminology D907.

5. Adhesive Physical Property Requirements

5.1 Open Assembly Time—These adhesives have a distinct

This specification is under the jurisdiction of ASTM Committee D14 on

open assembly time and this time must be agreed upon by the

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

user and the manufacturer.

Adhesives.

Current edition approved Nov. 1, 2009. Published December 2009. Originally

ε1

5.2 Storage Life—The adhesive shall remain serviceable

approved in 1999. Last previous edition approved in 2003 as D6464-03a . DOI:

10.1520/D6464-03A09E01.

and meet all the requirements of this specification for not less

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

than six months after delivery, when stored in original un-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

opened containers at temperatures ranging from 40 to 85°F (4

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. to 30°C).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6464−03a (2009)

6. Adhesive Properties and Performance

6.1 The adhesives shall conform to the requirements sum-

marized in Table 1.

7. Materials and Apparatus for Conducting Tests

7.1 Adhesives—The adhesive shall be an expandable foam

adhesive.

7.2 Gypsum Wallboard— ⁄2 in. (12.7 mm) thick, complying

with Specification C1396/C1396M; the dimensions are speci-

fied in each test.

3 23

7.3 Plywood— ⁄4 or ⁄32 in. (19 or 18.3 mm)-thick U.S.

Product Standard PS-1-95 grade marked stamped, commercial

plywood, Exterior, Group 1 Species, A-A or A-B grade face

and back veneers. The test specimen dimensions are specified

in each test.

1 1 1

7.4 Douglas-Fir Lumber—1 ⁄2 by 1 ⁄2 by 3 ⁄2 in. (38 by 38

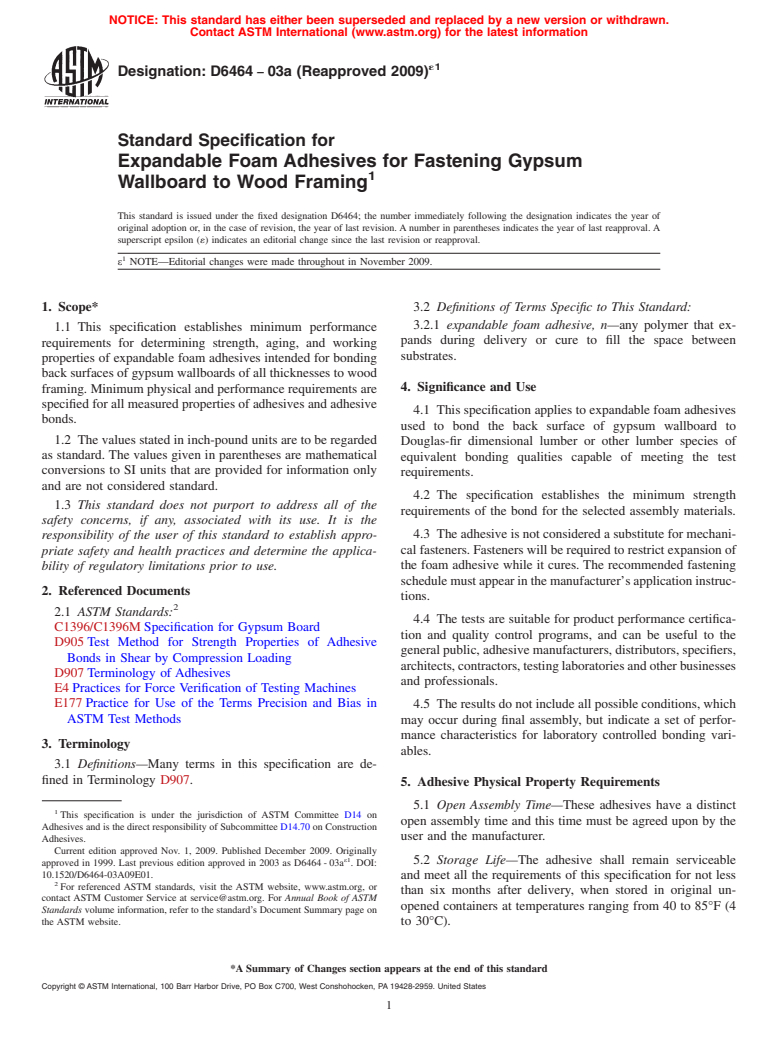

FIG. 1Tensile Strength Test Specimen Assembly

by 89 mm), clear, dry lumber, (moisture content of 8 to 10%),

with the bonding surface free of bark, knots, splits, and pitch.

7.10 1-Pt and 1-Gal Non-Reactive Metal Can.

NOTE 1—The tensile test will use one of the ends of the block as a

7.11 Food Wrap Polyethylene Film—0.8 mil thickness

bonding surface and should be an edge grain face.

sheet.

7.5 Tensile Test Fixture—An assembly of one, 5 by 5 in.

(127 by 127 mm) by ⁄2 in. (6.35 mm) thick steel plate and two 7.12 Steel Mandrel—1 in. (25.4 mm) diameter steel rod or

1 1 1

6 in. long sections of 1 ⁄2 by 1 ⁄2 (38.1 by 38.1 mm) by ⁄4 in. pipe section with smooth and uniform surface.

(6.4 mm) thick steel angles (Fig. 1).

7.13 Tension Rod—Asteelrodforconnectingthetensiletest

7.6 Garnet Paper—No. 120 grit, 3/0. specimen assembly to the test machine.

7.7 Plywood Shim—4by3 ⁄2in.or4by4in.(101.6by88.9 7.14 Testing Machine—Any suitable testing machine that is

3 23

mm or 101.6 by 101.6 mm) piece of ⁄4-in. (19-mm) or ⁄32-in. capable of operation at a constant rate of motion of the

(18.3-mm) thick U.S. Product Standard PS-1-95 grade marked moveable head and has an accuracy of 61% when calibrated

stamped,commercialplywood,Exterior,Group1Species,A-A in accordance with Practices E4 requirements.

or A-B grade face and back veneers.

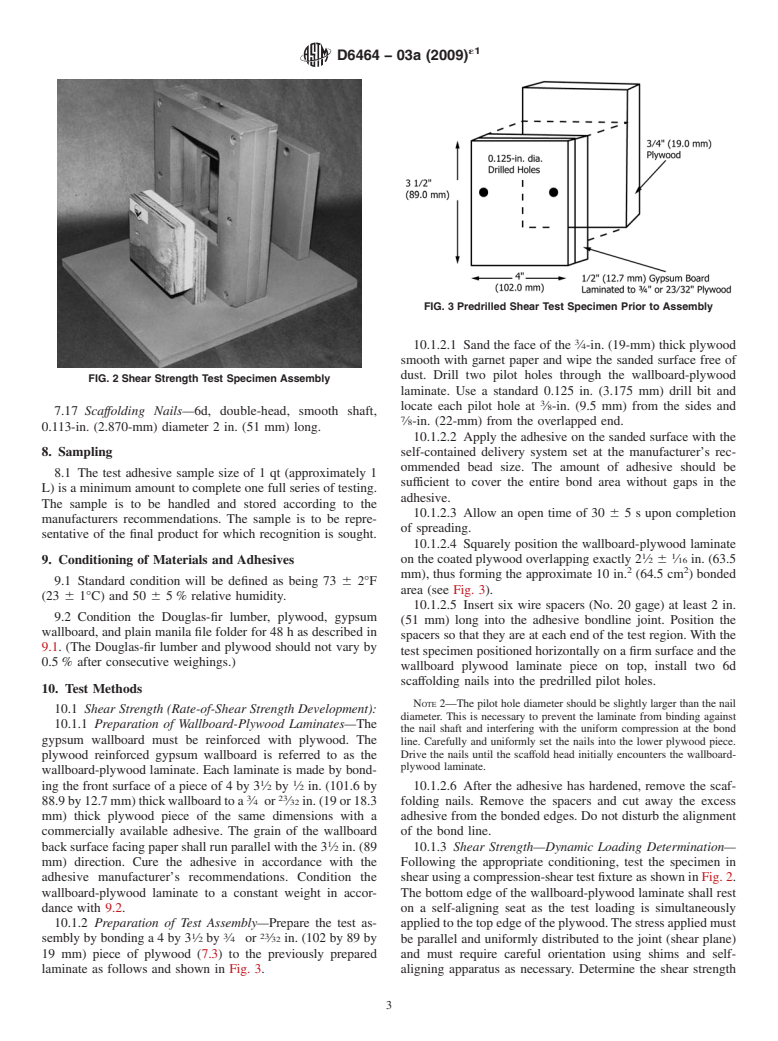

7.15 CompressionShearTestFixture—Acompression-shear

7.8 Manila Folder—Plain manila paper, 11 point weight, apparatusthatissimilarto,butofalargerscalethanthefixture

(.011-in. (0.28-mm) thick). recommendedinTestMethodD905.Asimilarfixtureisshown

in Fig. 2.

7.9 Vinyl-Covered Wallboard—A manufactured product

consistingofgypsumwallboardwith2milminimumthickness 7.16 Wood Screw with Eyelet—#6 by 1 ⁄2 in. (38.1 mm)

vinyl overlay bonded to the wallboard front face. long, ⁄8 in. (19.5 mm) inside diameter eyelet.

TABLE 1 Adhesive Properties and Performance Requirements

Test Method Section Property Condition Requirements

Rate of shear strength 10.1.4 shear strength 24 h at STD. COND. 10 psi (69 kPa) min

10.1.5 shear strength 14 days at STD. COND. 40 psi (276 kPa) min

10.1.6 shear strength 14 days at STD. COND., + cyclic 32 psi (220 kPa) min

lab exposure, + 2 days at STD. COND.

10.1.7 resistance to static load in shear (a) 40 lb (178 N) for 24 h at STD. COND. no bond separation

(b) 20 lb (89 N) for 24 h at 100°F (38°C) no bond separation

Rate of strength development 10.2.2 tensile strength 24 h at STD. COND. 15 psi (103 kPa) min

10.2.2 tensile strength 14 days at STD. COND. 25 psi (172 kPa) min

Adhesive open-time determination 10.3 open time 24 h at STD. COND. 75 % paper transfer, min

Substrate wet-out by adhesive

1. Plywood 10.4.1 wet out spatula applied good wetting property

2. Wallboard 10.4.2 wet out spatula applied good wetting property

Adhesive aging 10.5 accelerated aging 500 h at 158°F (70°C) no cracking or chipping

Freeze thaw stability † 10.6 low temperature storage 3 cycles of 24 h at 0°F + 24 h at no change in workability; 10 psi

STD. COND. (69 kPa) shear strength, min

Suitability of a laminating adhesive 10.7 compatibility 24 h at 100°F (38°C) no blistering, vinyl-film

for vinyl-covered wallboard discoloration, or bond failure

Suitability for Stain Resistance for 10.8 staining 1 h at STD. COND. no swelling or discoloration

Vinyl-covered wallboard

Bridging 10.9 gap-filling 48 h at STD. COND. intact adhesive bond line, report

length and paper failure %

† Corrected editorially.

´1

D6464−03a (2009)

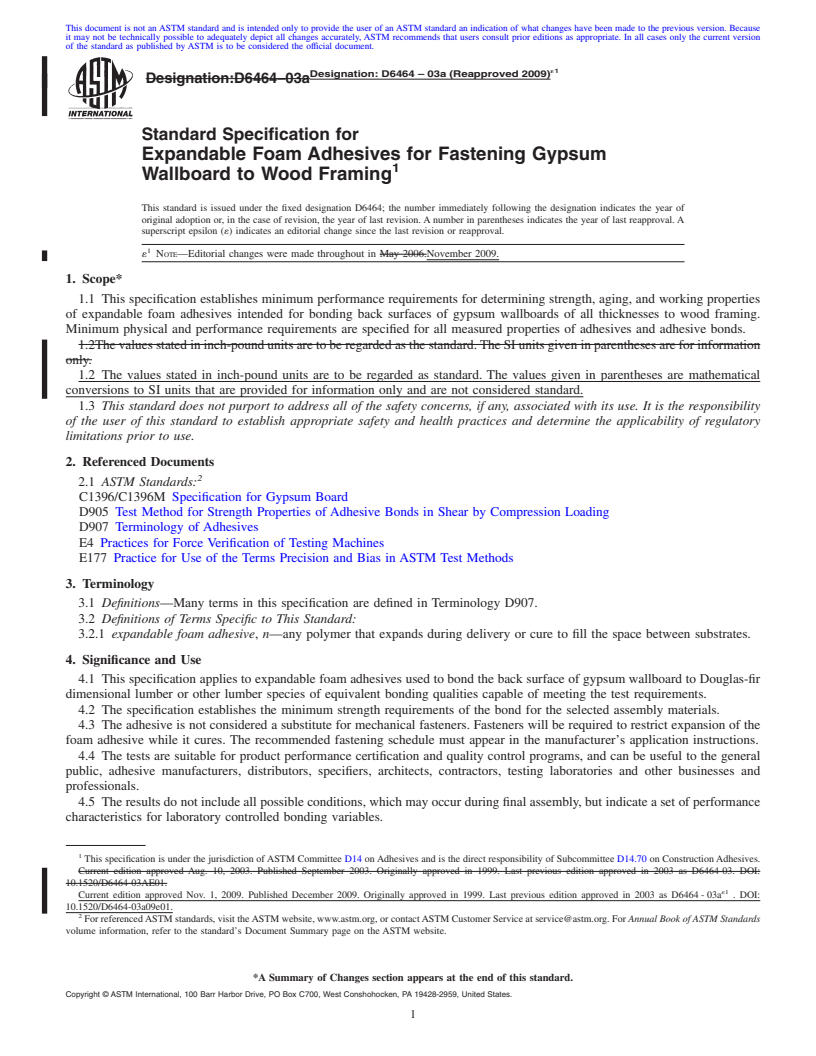

FIG. 3Predrilled Shear Test Specimen Prior to Assembly

10.1.2.1 Sand the face of the ⁄4-in. (19-mm) thick plywood

smooth with garnet paper and wipe the sanded surface free of

dust. Drill two pilot holes through the wallboard-plywood

FIG. 2Shear Strength Test Specimen Assembly

laminate. Use a standard 0.125 in. (3.175 mm) drill bit and

locate each pilot hole at ⁄8-in. (9.5 mm) from the sides and

7.17 Scaffolding Nails—6d, double-head, smooth shaft,

⁄8-in. (22-mm) from the overlapped end.

0.113-in. (2.870-mm) diameter 2 in. (51 mm) long.

10.1.2.2 Apply the adhesive on the sanded surface with the

8. Sampling self-contained delivery system set at the manufacturer’s rec-

ommended bead size. The amount of adhesive should be

8.1 The test adhesive sample size of 1 qt (approximately 1

sufficient to cover the entire bond area without gaps in the

L) is a minimum amount to complete one full series of testing.

adhesive.

The sample is to be handled and stored according to the

10.1.2.3 Allow an open time of 30 6 5 s upon completion

manufacturers recommendations. The sample is to be repre-

of spreading.

sentative of the final product for which recognition is sought.

10.1.2.4 Squarely position the wallboard-plywood laminate

1 1

on the coated plywood overlapping exactly 2 ⁄2 6 ⁄16 in. (63.5

9. Conditioning of Materials and Adhesives

2 2

mm), thus forming the approximate 10 in. (64.5 cm ) bonded

9.1 Standard condition will be defined as being 73 6 2°F

area (see Fig. 3).

(23 6 1°C) and 50 6 5% relative humidity.

10.1.2.5 Insert six wire spacers (No. 20 gage) at least 2 in.

9.2 Condition the Douglas-fir lumber, plywood, gypsum

(51 mm) long into the adhesive bondline joint. Position the

wallboard, and plain manila file folder for 48 h as described in

spacers so that they are at each end of the test region.With the

9.1. (The Douglas-fir lumber and plywood should not vary by

test specimen positioned horizontally on a firm surface and the

0.5% after consecutive weighings.)

wallboard plywood laminate piece on top, install two 6d

scaffolding nails into the predrilled pilot holes.

10. Test Methods

NOTE 2—The pilot hole diameter should be slightly larger than the nail

10.1 Shear Strength (Rate-of-Shear Strength Development):

diameter. This is necessary to prevent the laminate from binding against

10.1.1 Preparation of Wallboard-Plywood Laminates—The

the nail shaft and interfering with the uniform compression at the bond

gypsum wallboard must be reinforced with plywood. The

line. Carefully and uniformly set the nails into the lower plywood piece.

Drive the nails until the scaffold head initially encounters the wallboard-

plywood reinforced gypsum wallboard is referred to as the

plywood laminate.

wallboard-plywood laminate. Each laminate is made by bond-

1 1

ing the front surface of a piece of 4 by 3 ⁄2 by ⁄2 in. (101.6 by 10.1.2.6 After the adhesive has hardened, remove the scaf-

3 23

88.9by12.7mm)thickwallboardtoa ⁄4 or ⁄32in.(19or18.3 folding nails. Remove the spacers and cut away the excess

mm) thick plywood piece of the same dimensions with a adhesive from the bonded edges. Do not disturb the alignment

commercially available adhesive. The grain of the wallboard of the bond line.

backsurfacefacingpapershallrunparallelwiththe3 ⁄2in.(89 10.1.3 Shear Strength—Dynamic Loading Determination—

mm) direction. Cure the adhesive in accordance with the Following the appropriate conditioning, test the specimen in

adhesive manufacturer’s recommendations. Condition the shearusingacompression-sheartestfixtureasshowninFig.2.

wallboard-plywood laminate to a constant weight in accor- The bottom edge of the wallboard-plywood laminate shall rest

dance with 9.2. on a self-aligning seat as the test loading is simultaneously

10.1.2 Preparation of Test Assembly—Prepare the test as- appliedtothetopedgeoftheplywood.Thestressappliedmust

1 3 23

sembly by bondinga4by3 ⁄2 by ⁄4 or ⁄32 in. (102 by 89 by be parallel and uniformly distributed to the joint (shear plane)

19 mm) piece of plywood (7.3) to the previously prepared and must require careful orientation using shims and self-

laminate as follows and shown in Fig. 3. aligning apparatus as necessary. Determine the shear strength

´1

D6464−03a (2009)

atacrossheadspeedof0.2in.(5.1mm)/min.Observationsare 10.1.7.4 At the end of each condition’s 24-h period, exam-

made during stress application to ensure the test assembly ine each test specimen assembly for bond separation and

maintains proper alignment throughout the test. The test slippage between the wallboard-plywood laminate and the

fixtures cannot in any way cause stress measurement error(s) plywood adherend. Slippage or separation at the bond line of

such as with binding or friction. Report the maximum shear the adhesive is considered a failure. Report the results of

strength and the average shear strengths for the 24 h, the 14 analysisforeachofthefivestaticloadsheartestspecimensfor

day, and the cyclic exposure test conditions. both conditions.

10.1.4 Shear Strength After 24 h:

10.2 Tensile Strength (Rate of Strength Development):

10.1.4.1 Prepare five test assemblies using the procedure in

10.2.1 Preparation of Wallboard-Plywood Laminates—

10.1.1 and 10.1.2.

Prepare the laminates using the same procedure in 10.1.1, but

10.1.4.2 After aging the assemblies 24 6 1 h at standard

with 4 by 4 in. (101.6 by 101.6 mm) gypsum wallboard and

condition (9.1), determine the shear strength in accordance

plywood shims, or without plywood shim as shown in Fig. 1.

with 10.1.3.

Drill one pilot hole with a 0.125 in. (3.2 mm) drill bit through

10.1.5 Shear Strength After 14 Days:

thecenterofthewallboard–plywoodlaminate.Thepilotholeis

10.1.5.1 Prepare five test assemblies using the procedure in

for the installation of the 6d scaffolding nail to be used for the

10.1.1 and 10.1.2.

Douglas-fir wood block connection.

10.1.5.2 After aging the assemblies 14 days at standard

1 1 1

10.2.1.1 Prepare the 1 ⁄2 by 1 ⁄2 by 3 ⁄2 in. (38 by 38 by 89

condition (9.1), determine the shear strength in accordance

mm) Douglas-fir wood block by drilling a pilot hole for the

with 10.1.3.

wood screw with eyelet at the exact center end of test machine

10.1.6 Shear Strength After Cycl

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6464 – 03a (Reapproved 2009)

Designation:D6464–03a

Standard Specification for

Expandable Foam Adhesives for Fastening Gypsum

Wallboard to Wood Framing

This standard is issued under the fixed designation D6464; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made throughout in May 2006.November 2009.

1. Scope*

1.1 This specification establishes minimum performance requirements for determining strength, aging, and working properties

of expandable foam adhesives intended for bonding back surfaces of gypsum wallboards of all thicknesses to wood framing.

Minimum physical and performance requirements are specified for all measured properties of adhesives and adhesive bonds.

1.2The values stated in inch-pound units are to be regarded as the standard.The SI units given in parentheses are for information

only.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C1396/C1396M Specification for Gypsum Board

D905 Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading

D907 Terminology of Adhesives

E4 Practices for Force Verification of Testing Machines

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

3. Terminology

3.1 Definitions—Many terms in this specification are defined in Terminology D907.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 expandable foam adhesive, n—any polymer that expands during delivery or cure to fill the space between substrates.

4. Significance and Use

4.1 This specification applies to expandable foam adhesives used to bond the back surface of gypsum wallboard to Douglas-fir

dimensional lumber or other lumber species of equivalent bonding qualities capable of meeting the test requirements.

4.2 The specification establishes the minimum strength requirements of the bond for the selected assembly materials.

4.3 The adhesive is not considered a substitute for mechanical fasteners. Fasteners will be required to restrict expansion of the

foam adhesive while it cures. The recommended fastening schedule must appear in the manufacturer’s application instructions.

4.4 The tests are suitable for product performance certification and quality control programs, and can be useful to the general

public, adhesive manufacturers, distributors, specifiers, architects, contractors, testing laboratories and other businesses and

professionals.

4.5 The results do not include all possible conditions, which may occur during final assembly, but indicate a set of performance

characteristics for laboratory controlled bonding variables.

This specification is under the jurisdiction ofASTM Committee D14 onAdhesives and is the direct responsibility of Subcommittee D14.70 on ConstructionAdhesives.

Current edition approved Aug. 10, 2003. Published September 2003. Originally approved in 1999. Last previous edition approved in 2003 as D6464-03. DOI:

10.1520/D6464-03AE01.

´1

Current edition approved Nov. 1, 2009. Published December 2009. Originally approved in 1999. Last previous edition approved in 2003 as D6464 - 03a . DOI:

10.1520/D6464-03a09e01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D6464 – 03a (2009)

D6464–03a

5. Adhesive Physical Property Requirements

5.1 Open Assembly Time—These adhesives have a distinct open assembly time and this time must be agreed upon by the user

and the manufacturer.

5.2 Storage Life—The adhesive shall remain serviceable and meet all the requirements of this specification for not less than six

months after delivery, when stored in original unopened containers at temperatures ranging from 40 to 85°F

(4 to 30°C).

6. Adhesive Properties and Performance

6.1 The adhesives shall conform to the requirements summarized in Table 1.

7. Materials and Apparatus for Conducting Tests

7.1 Adhesives—The adhesive shall be an expandable foam adhesive.

7.2 Gypsum Wallboard— ⁄2 in. (12.7 mm) thick, complying with Specification C1396/C1396M; the dimensions are specified in

each test.

3 23

7.3 Plywood— ⁄4 or ⁄32 in. (19.0(19 or 18.3 mm)-thick U.S. Product Standard PS-1-95 grade marked stamped, commercial

plywood, Exterior, Group 1 Species,A-AorA-B grade face and back veneers. The test specimen dimensions are specified in each

test.

1 1 1

7.4 Douglas-Fir Lumber—1 ⁄2 by 1 ⁄2 by 3 ⁄2 in. (38.0(38 by 38.038 by 89.089 mm), clear, dry lumber, (moisture content of 8

to 10 %), with the bonding surface free of bark, knots, splits, and pitch.

NOTE 1—The tensile test will use one of the ends of the block as a bonding surface and should be an edge grain face.

7.5 Tensile Test Fixture—An assembly of one, 5 by 5 in. (127 by 127 mm)-by-mm) by ⁄2 in. (6.35 mm) thick steel plate and

1 1 1

two 6 in. long sections of 1 ⁄2 by 1 ⁄2 (38.1 by 38.1 mm) by ⁄4 in. (6.4 mm) thick steel angles (Fig. 1).

7.6 Garnet Paper—No. 120 grit, 3/0.

1 3 23

7.7 Plywood Shim—4 by 3 ⁄2 in. or 4 by 4 in. (101.6 by 88.9 mm or 101.6 by 101.6 mm) piece of ⁄4-in. (19-mm) or ⁄32-in.

TABLE 1 Adhesive Properties and Performance Requirements

Test Method Section Property Condition Requirements

Rate of shear strength 10.1.4 shear strength 24hatRT 10 psi (69 kPa) min

Rate of shear strength 10.1.4 shear strength 24 h at STD. COND. 10 psi (69 kPa) min

10.1.5 shear strength 14 days at RT 40 psi (276 kPa) min

10.1.5 shear strength 14 days at STD. COND. 40 psi (276 kPa) min

10.1.6 shear strength 14 days at RT, + cyclic 32 psi (220 kPa) min

10.1.6 shear strength 14 days at STD. COND., + cyclic 32 psi (220 kPa) min

lab exposure, + 2 days at RT

lab exposure, + 2 days at STD. COND.

10.1.7 resistance to static load in shear (a)40lb(178 N) for24hatRT no bond separation

10.1.7 resistance to static load in shear (a) 40 lb (178 N) for 24 h at STD. COND. no bond separation

(b) 20 lb (89 N) for 24 h at 100°F no bond separation

(b) 20 lb (89 N) for 24 h at 100°F (38°C) no bond separation

Rate of strength development 10.2.2 tensile strength 24hatRT 15 psi (103 kPa) min

Rate of strength development 10.2.2 tensile strength 24 h at STD. COND. 15 psi (103 kPa) min

10.2.2 tensile strength 14 days at RT 25 psi (172 kPa) min

10.2.2 tensile strength 14 days at STD. COND. 25 psi (172 kPa) min

Adhesive open-time determination 10.3 open time 24hatRT 75 % paper transfer, min

Adhesive open-time determination 10.3 open time 24 h at STD. COND. 75 % paper transfer, min

Substrate wet-out by adhesive

1. Plywood 10.4.1 wet out spatula applied good wetting property

2. Wallboard 10.4.2 wet out spatula applied good wetting property

Adhesive aging 10.5 accelerated aging 500 h at 158°F no cracking or chipping

Adhesive aging 10.5 accelerated aging 500 h at 158°F (70°C) no cracking or chipping

Freeze thaw stability † 10.6 low temperature storage 3 cycles of no change in workability; 10 psi

24hat0°F+24hatRT (69 kPa) shear strength, min

Freeze thaw stability † 10.6 low temperature storage 3 cycles of 24 h at 0°F + 24 h at no change in workability; 10 psi

STD. COND. (69 kPa) shear strength, min

Suitability of a laminating adhesive 10.7 compatibility 24 h at 100°F no blistering, vinyl-film

for vinyl-covered wallboard discoloration, or bond failure

Suitability of a laminating adhesive 10.7 compatibility 24 h at 100°F (38°C) no blistering, vinyl-film

for vinyl-covered wallboard discoloration, or bond failure

Suitability for Stain Resistance for 10.8 staining 1hatRT no swelling or discoloration

Vinyl-covered wallboard

Suitability for Stain Resistance for 10.8 staining 1 h at STD. COND. no swelling or discoloration

Vinyl-covered wallboard

Bridging 10.9 gap-filling 48hatRT intact adhesive bond line, report

length and paper failure %

Bridging 10.9 gap-filling 48 h at STD. COND. intact adhesive bond line, report

length and paper failure %

† Corrected editorially.

´1

D6464 – 03a (2009)

D6464–03a

FIG. 1 Tensile Strength Test Specimen Assembly

(18.3-mm)- thick U.S. Product Standard PS-1-95 grade marked stamped, commercial plywood, Exterior, Group 1 Species,A-Aor

A-B grade face and back veneers.

7.8 Manila Folder—Plain manila paper, 11 point weight, (0.011-in. (0.28-mm) thick).

7.9 Vinyl-Covered Wallboard—A manufactured product consisting of gypsum wallboard with 2 mil minimum thickness vinyl

overlay bonded to the wallboard front face.

7.10 1-Pt and 1-Gal Non-Reactive Metal Can.

7.11 Food Wrap Polyethylene Film—0.8 mil thickness sheet.

7.12 Steel Mandrel—1.0—1 in. (25.4 mm) diameter steel rod or pipe section with smooth and uniform surface.

7.13 Tension Rod—A steel rod for connecting the tensile test specimen assembly to the test machine.

7.14 Testing Machine—Any suitable testing machine that is capable of operation at a constant rate of motion of the moveable

head and has an accuracy of 61 % when calibrated in accordance with Practices E4 requirements.

7.15 Compression Shear Test Fixture—A compression-shear apparatus that is similar to, but of a larger scale than the fixture

recommended in Test Method D905. A similar fixture is shown in Fig. 2.

1 3

7.16 Wood Screw with Eyelet—#6by1 ⁄2 in. (38.1 mm) long, ⁄8 in. (19.5 mm) inside diameter eyelet.

7.17 Scaffolding Nails—6d, double-head, smooth shaft, 0.113–-in. (2.870-mm) diameter 2 in. (51 mm) long.

8. Sampling

8.1 The test adhesive sample size of 1 qt (approximately

1 L) is a minimum amount to complete one full series of testing. The sample is to be handled and stored according to the

FIG. 2 Shear Strength Test Specimen Assembly

´1

D6464 – 03a (2009)

D6464–03a

manufacturers recommendations. The sample is to be representative of the final product for which recognition is sought.

9. Conditioning of Materials and Adhesives

9.1 Standard condition will be defined as being 73 6 2°F (23 6 1°C) and 50 6 5 % relative humidity.

9.2 ConditiontheDouglas-firlumber,plywood,gypsumwallboard,andplainmanilafilefolderfor48hasdescribedin9.1.(The

Douglas-fir lumber and plywood should not vary by 0.5 % after consecutive weighings.)

10. Test Methods

10.1 Shear Strength (Rate-of-Shear Strength Development):

10.1.1 Preparation of Wallboard-Plywood Laminates—The gypsum wallboard must be reinforced with plywood. The plywood

reinforcedgypsumwallboardisreferredtoasthewallboard-plywoodlaminate.Eachlaminateismadebybondingthefrontsurface

1 1 3 23

ofapieceof4by3 ⁄2by ⁄2in.(101.6by88.9by12.7mm)thickwallboardtoa ⁄4 or ⁄32in.(19.0(19or18.3mm)thickplywood

piece of the same dimensions with a commercially available adhesive. The grain of the wallboard back surface facing paper shall

run parallel with the 3 ⁄2 in. (89.0)(89 mm) direction. Cure the adhesive in accordance with the adhesive manufacturer’s

recommendations. Condition the wallboard-plywood laminate to a constant weight in accordance with 9.2.

1 3 23

10.1.2 Preparation of Test Assembly—Prepare the test assembly by bondinga4by3 ⁄2 by ⁄4 or ⁄32 in. (102.0(102 by 89.089

by 19.019 mm) piece of plywood (7.3) to the previously prepared laminate as follows and shown in Fig. 3.

10.1.2.1 Sand the face of the ⁄4-in. (19.0-mm)(19-mm) thick plywood smooth with garnet paper and wipe the sanded surface

free of dust. Drill two pilot holes through the wallboard-plywood laminate. Use a standard 0.125 in. (3.175 mm) drill bit and locate

3 7

each pilot hole at ⁄8-in. (9.5 mm) from the sides and ⁄8-in. (22.2 mm)(22-mm) from the overlapped end.

10.1.2.2 Apply the adhesive on the sanded surface with the self-contained delivery system set at the manufacturer’s

recommended bead size. The amount of adhesive should be sufficient to cover the entire bond area without gaps in the adhesive.

10.1.2.3 Allow an open time of 30 6 5 s upon completion of spreading.

10.1.2.4Squarely10.1.2.4 Squarely position the wallboard-plywood laminate on the coated plywood overlapping exactly 2 ⁄2 6

⁄16 in.

2 2

(63.5 mm), thus forming the approximate 10 in. (64.5 cm ) bonded area (see Fig. 3).

10.1.2.5Insertfour10.1.2.5 Insertsixwirespacers(No.20gage)atleast2in.(51.0-mm)(51mm)longintotheadhesivebondline

joint. Position the spacers so that they are at each end of the test region. With the test specimen positioned horizontally on a firm

surface and the wallboard plywood laminate piece on top, install two 6d scaffolding nails into the predrilled pilot holes.

NOTE 2—The pilot hole diameter should be slightly larger than the nail diameter. This is necessary to prevent the laminate from binding against the

nail shaft and interfering with the uniform compression at the bond line. Carefully and uniformly set the nails into the lower plywood piece. Drive the

nails until the scaffold head initially encounters the wallboard-plywood laminate.

10.1.2.6 After the adhesive has hardened, remove the scaffolding nails. Remove the spacers and cut away the excess adhesive

from the bonded edges. Do not disturb the alignment of the bond line.

10.1.3 Shear Strength—Dynamic Loading Determination—Following the appropriate conditioning, test the specimen in shear

using a compression-shear test fixture as shown in Fig. 2. The bottom edge of the wallboard-plywood laminate shall rest on a

self-aligning seat as the test loading is simultaneously applied to the top edge of the plywood. The stress applied must be parallel

and uniformly distributed to the joint (shear plane) and must require careful orientation using shims and self-aligning apparatus

as necessary. Determine the shear strength at a cross head speed of 0.2 in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.