ASTM F964-13(2019)

(Specification)Standard Specification for Rigid Poly (Vinyl Chloride) (PVC) Exterior Profiles Used for Fencing and Railing

Standard Specification for Rigid Poly (Vinyl Chloride) (PVC) Exterior Profiles Used for Fencing and Railing

ABSTRACT

This specification deals with rigid poly vinyl-chloride (PVC) exterior profiles used for agricultural, commercial, residential fencing and railing. The material used in these exterior profiles is limited to rigid poly (vinyl chloride) (PVC) compounds in a single homogeneous extrusion or in a coextrusion of two or more PVC compounds in distinct layers. Loadbearing characteristics for fence and railing assemblies are not addressed within this specification (for example, windload, horizontal or vertical guardrail loading). Materials shall be tested and shall conform to requirements for the material properties and physical properties, including dimensional tolerances, extrusion quality, and weatherability. Methods for testing and for identifying exterior profile extrusions, such as impact resistance, warp, dimensional stability, and impact test on weathered specimen that comply with this specification are also provided.

SIGNIFICANCE AND USE

4.1 The purpose of this specification is to establish a recognized standard of quality for rigid poly vinyl chloride (PVC) exterior profiles for use in assembling agricultural, commercial, and residential fencing and railing. The term “PVC fence” refers to complete fencing and railings systems in which the primary structural members such as posts, rails, spindles, pickets, and gates are made from PVC exterior profiles. Accessory components (not included in this specification), including bolts, screws, hinges, latches, caps, and brackets, may be made from PVC or non-PVC materials, or both. The information contained in this specification is intended to be helpful to producers, distributors, and users and to promote understanding between purchasers and sellers.

SCOPE

1.1 This specification establishes requirements for the material properties and physical properties, including dimensional tolerances, extrusion quality, and weatherability, of rigid poly vinyl-chloride (PVC) exterior profiles used for agricultural, commercial, residential fencing and railing. Methods for testing and for identifying exterior profile extrusions that comply with this specification are also provided.

Note 1: Information with regard to application, assembly, and installation should be obtained from the manufacturer or in accordance with Practice F1999, or both.

Note 2: Loadbearing characteristics for fence and railing assemblies are not addressed within this specification (for example, windload, horizontal or vertical guardrail loading).

1.2 The material used in these exterior profiles is limited to rigid poly (vinyl chloride) (PVC) compounds in a single homogeneous extrusion or in a coextrusion of two or more PVC compounds in distinct layers.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F964 −13 (Reapproved 2019)

Standard Specification for

Rigid Poly (Vinyl Chloride) (PVC) Exterior Profiles Used for

Fencing and Railing

ThisstandardisissuedunderthefixeddesignationF964;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification establishes requirements for the ma- 2.1 ASTM Standards:

terialpropertiesandphysicalproperties,includingdimensional D618Practice for Conditioning Plastics for Testing

tolerances, extrusion quality, and weatherability, of rigid poly D635Test Method for Rate of Burning and/or Extent and

vinyl-chloride (PVC) exterior profiles used for agricultural, Time of Burning of Plastics in a Horizontal Position

commercial, residential fencing and railing. Methods for test- D696TestMethodforCoefficientofLinearThermalExpan-

ing and for identifying exterior profile extrusions that comply sion of Plastics Between −30°C and 30°C with a Vitreous

with this specification are also provided. Silica Dilatometer

D883Terminology Relating to Plastics

NOTE 1—Information with regard to application, assembly, and instal-

D1435Practice for Outdoor Weathering of Plastics

lation should be obtained from the manufacturer or in accordance with

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

Practice F1999, or both.

NOTE 2—Loadbearing characteristics for fence and railing assemblies

tics

are not addressed within this specification (for example, windload,

D1898Practice for Sampling of Plastics (Withdrawn 1998)

horizontal or vertical guardrail loading).

D2565Practice for Xenon-Arc Exposure of Plastics In-

1.2 The material used in these exterior profiles is limited to

tended for Outdoor Applications

rigid poly (vinyl chloride) (PVC) compounds in a single

D4216Specification for Rigid Poly(Vinyl Chloride) (PVC)

homogeneous extrusion or in a coextrusion of two or more

and Related PVC and Chlorinated Poly(Vinyl Chloride)

PVC compounds in distinct layers.

(CPVC) Building Products Compounds

D4226Test Methods for Impact Resistance of Rigid Poly-

1.3 The values stated in inch-pound units are to be regarded

(Vinyl Chloride) (PVC) Building Products

as the standard. The values in parentheses are provided for

D4726Specification for Rigid Poly(Vinyl Chloride) (PVC)

information only.

Exterior-Profile Extrusions Used forAssembled Windows

1.4 This standard does not purport to address all of the

and Doors

safety concerns, if any, associated with its use. It is the

F1999Practice for Installation of Rigid Poly(Vinyl Chlo-

responsibility of the user of this standard to establish appro-

ride) (PVC) Fence Systems

priate safety, health, and environmental practices and deter-

G154Practice for Operating Fluorescent Ultraviolet (UV)

mine the applicability of regulatory limitations prior to use.

Lamp Apparatus for Exposure of Nonmetallic Materials

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Terminology

ization established in the Decision on Principles for the

3.1 General—DefinitionsareinaccordancewithTerminolo-

Development of International Standards, Guides and Recom-

gies D883 and D1600, unless otherwise indicated.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.2 Definitions of Terms Specific to This Standard:

1 2

This specification is under the jurisdiction ofASTM Committee F14 on Fences For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee F14.30 on Rigid Polymer Fence contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Systems. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2019. Published June 2019. Originally the ASTM website.

approved in 1994. Last previous edition approved in 2013 as F964–13. DOI: The last approved version of this historical standard is referenced on

10.1520/F0964-13R19. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F964−13 (2019)

3.2.1 capstock—the outer layer in a coextrusion exposed to Compounds that have higher cell classification because one or

weathering. morepropertiesaresuperiortothoseinthespecifiedcompound

are acceptable.

3.2.2 coextrusion—the process of coextruding profiles from

two or more concentric streams of PVC compounds. 5.3 Color—Thecoloroftheprofilesshallbeasagreedupon

between the purchaser and the seller. The color specified shall

NOTE 3—Separate PVC materials may be coextruded to form a

be uniform throughout a single material extrusion or through-

multi-layered profile with each layer having different physical character-

out the capstock layer of a coextruded profile for profiles

istics such as strength and weathering.

intended to be of uniform color.

3.2.3 color-hold guidelines—predictive target color regions

within a three-dimensional model which constitute acceptable 5.4 The extruded profiles shall be free from visible cracks,

voids, or foreign inclusions.

appearance retention levels of color change resulting from

weathering of specific product type and color.

5.5 The PVC compound, when tested in accordance with

Test Method D635, shall not exceed an average extent of burn

NOTE4—Commercialproductswhichdemonstrateweatheringbehavior

within reasonable conformance to these target guidelines during a 2–year of 4 in. (100 mm), with an average time of burn not to exceed

test period can be anticipated to weather without exhibiting unacceptable

10 s.Asample thickness of 0.090 6 0.009 in. (2.3 6 0.2 mm)

color changes during the service life of the product.

shall be used.

3.2.4 longitudinal bow—refers to bow along the span. Lon-

NOTE 5—The flammability testing data, conclusions, and recommen-

gitude is measured along the span.

dations of Test Method D635 relate solely to the measurement and

descriptionofthepropertiesofmaterials,products,orsystemsinresponse

3.2.5 reworked material—material from the manufacturer’s

toheatandflameundercontrolledlaboratoryconditionsandshouldnotbe

facility of known, compatible composition meeting the mate-

used for the description or appraisal of the fire hazard of materials,

rial requirement of this specification that has been reground,

products, or systems under actual fire conditions.

pelletized, or solvated after having been previously processed

NOTE 6—No recycled (post consumer waste) may be used in the

by molding, extrusion, and so forth. production of fence profiles.

5.6 Reworked Material—Clean reworked material may be

3.2.6 single layer profile—profiles extruded from a single

used, provided that the fence profiles produced in whole or in

PVC compound. Weathering and other physical characteristics

part from the reworked materials meet all of the requirements

are uniform throughout the profile.

of this specification.

3.2.7 substrate—inner layer(s) of a coextrusion not exposed

5.7 The PVC compound in extruded section shall maintain

to weathering.

uniform color and be free of any visual surface or structural

3.2.8 temperate northern climate—in weather testing, a

changes,suchaspeeling,chipping,cracking,flaking,orpitting

North American metropolitan area testing site located within

after weathering for six months and one year for white and for

73 to 100° W longitude and 37 to 45° N latitude.

six months, one year, and two years for all other colors in hot,

dry climate such as Phoenix,AZ; a hot humid climate, such as

4. Significance and Use

Miami, FL; and a temperate northern climate, when tested in

4.1 The purpose of this specification is to establish a

accordance with 7.1.1 – 7.1.4.

recognized standard of quality for rigid poly vinyl chloride

5.8 The PVC compound shall have a minimum impact

(PVC) exterior profiles for use in assembling agricultural,

resistance of 0.6 in.-lb/mil (2670 J/m) after weathering six

commercial, and residential fencing and railing. The term

monthsandoneyearinahot,dryclimatesuchasPhoenix,AZ;

“PVCfence”referstocompletefencingandrailingssystemsin

a hot, humid climate, such as Miami, FL; and a temperate

which the primary structural members such as posts, rails,

northernclimate,whentestedinaccordancewith7.1.1–7.1.4.

spindles, pickets, and gates are made from PVC exterior

5.9 The PVC compound shall have successfully met the

profiles. Accessory components (not included in this

weathering requirements prescribed in 5.7 and 5.8 for six

specification), including bolts, screws, hinges, latches, caps,

months at each climatic testing site prior to use in production

and brackets, may be made from PVC or non-PVC materials,

of exterior-profile extrusions, when tested in accordance with

or both. The information contained in this specification is

7.1.1 – 7.1.4.

intended to be helpful to producers, distributors, and users and

NOTE 7—The six-month test requirement constitutes a screening

to promote understanding between purchasers and sellers.

process to eliminate catastrophic failure.

5. Materials and Manufacture

6. Physical Requirements

5.1 The rigid poly vinyl chloride (PVC) compound for

6.1 Length, Height, and Width—The specified length,

exterior-profile extrusions meeting the requirements of this

height, and width of the fencing profiles shall be as agreed

specification are categorized by the cell class requirements in

upon between the purchaser and the seller, or by established

accordance with Specification D4216.

internal process control standards. The actual length shall be

5.2 ThePVCcompoundsusedfortheproductsmeetingthis within 6 ⁄4 in. (6.4 mm) of the specified length and the actual

specification shall meet a minimum cell class of 1-20233-23 height and width shall be within ⁄16 in. (1.6 mm) of the

for PVC profiles and 3-20233-23 for PVC substrate with specified height and width when measured in accordance with

alernate capstock materials as defined in Specification D4216. 8.4 and 8.5.

F964−13 (2019)

TABLE 1 Allowable Bow for Common Length Extrusions as

6.2 Weight Tolerance—Profile extrusion weight shall not be

Measured per 8.7

more than 10% below the specified profile weight indicated in

Profile Length Allowable Bow per Piece

the manufacturer’s specifications.

72 in. 0.141 in.

96 in. 0.250 in.

6.3 Impact Resistance—All profiles are to be tested in

144 in. 0.563 in.

accordance with Test Methods D4226, Procedure “B,” using

192 in. 1.000 in.

impactorC.125.Flatsectionsoftheprofileextrusionshallhave

240 in. 1.563 in.

a minimum impact failure of 1.5 in. lb/mil (6675 J/m).

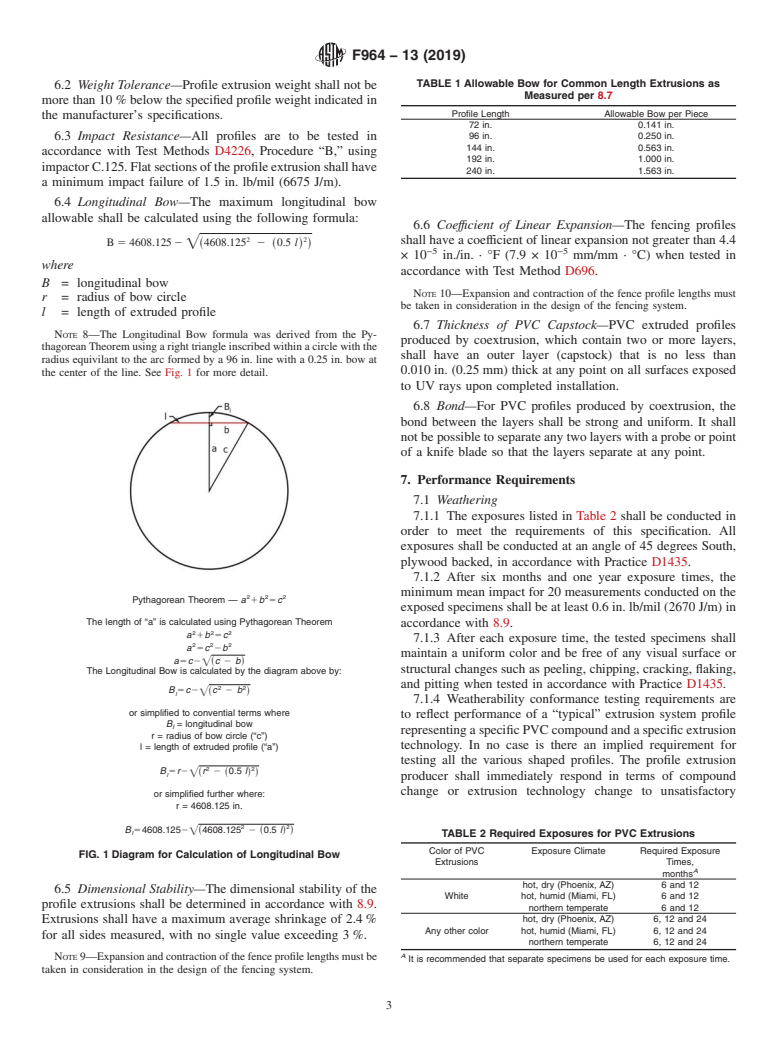

6.4 Longitudinal Bow—The maximum longitudinal bow

allowable shall be calculated using the following formula:

6.6 Coeffıcient of Linear Expansion—The fencing profiles

2 2

shall have a coefficient of linear expansion not greater than 4.4

=

B 5 4608.125 2 ~4608.125 2 ~0.5 l! !

−5 −5

×10 in./in. · °F (7.9 × 10 mm/mm · °C) when tested in

where

accordance with Test Method D696.

B = longitudinal bow

NOTE 10—Expansion and contraction of the fence profile lengths must

r = radius of bow circle

be taken in consideration in the design of the fencing system.

l = length of extruded profile

6.7 Thickness of PVC Capstock—PVC extruded profiles

NOTE 8—The Longitudinal Bow formula was derived from the Py-

produced by coextrusion, which contain two or more layers,

thagoreanTheoremusingarighttriangleinscribedwithinacirclewiththe

shall have an outer layer (capstock) that is no less than

radius equivilant to the arc formed by a 96 in. line with a 0.25 in. bow at

0.010in. (0.25mm) thick at any point on all surfaces exposed

the center of the line. See Fig. 1 for more detail.

to UV rays upon completed installation.

6.8 Bond—For PVC profiles produced by coextrusion, the

bond between the layers shall be strong and uniform. It shall

notbepossibletoseparateanytwolayerswithaprobeorpoint

of a knife blade so that the layers separate at any point.

7. Performance Requirements

7.1 Weathering

7.1.1 The exposures listed in Table 2 shall be conducted in

order to meet the requirements of this specification. All

exposures shall be conducted at an angle of 45 degrees South,

plywood backed, in accordance with Practice D1435.

7.1.2 After six months and one year exposure times, the

minimum mean impact for 20 measurements conducted on the

2 2 2

Pythagorean Theorem — a 1b 5c

exposedspecimensshallbeatleast0.6in.lb/mil(2670J/m)in

The length of “a” is calculated using Pythagorean Theorem

accordance with 8.9.

2 2 2

a 1b 5c

7.1.3 After each exposure time, the tested specimens shall

2 2 2

a 5c 2b

maintain a uniform color and be free of any visual surface or

a5c2 sc 2 bd

œ

The Longitudinal Bow is calculated by the diagram above by: structural changes such as peeling, chipping, cracking, flaking,

and pitting when tested in accordance with Practice D1435.

2 2

B5c2 sc 2 b d

l œ

7.1.4 Weatherability conformance testing requirements are

or simplified to convential terms where

to reflect performance of a “typical” extrusion system profile

B = longitudinal bow

l

representingaspecificPVCcompoundandaspecificextrusion

r = radius of bow circle (“c”)

technology. In no case is there an implied requirement for

l = length of extruded profile (“a”)

testing all the various shaped profiles. The profile extrusion

2 2

B5r2 sr 2 s0.5 ld d

l œ

producer shall immediately respond in terms of compound

change or extrusion technology change to unsatisfactory

or simplified further where:

r = 4608.125 in.

2 2

B54608.1252 s4608.125 2 s0.5 ld d

l

œ

TABLE 2 Required Exposures for PVC Extrusions

Color of PVC Exposure Climate Required Exposure

FIG. 1Diagram for Calculation of Longitudinal Bow

Extrusions Times,

A

months

hot, dry (Phoenix, AZ) 6 and 12

6.5 Dimensional Stability—The dimensional stability of the

White hot, humid (Miami, FL) 6 and 12

profile extrusions shall be determined in accordance with 8.9.

northern temperate 6 and 12

hot, dry (Phoenix, AZ) 6, 12 and 24

Extrusions shall have a maximum average shrinkage of 2.4%

Any other color hot, humid (Miami, FL) 6, 12 and 24

for all sides measured, with no single value exceeding 3%.

northern temperate 6, 12 and 24

A

NOTE9—Expansionandcontractionofthefenceprofilelengthsmustbe

It is recommended that separate specimens be used for each exposure time.

taken in consideration in the design of the fencing system.

F964−13 (2019)

weatherability behavior of the profiles under test in a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.