ASTM B557-15(2023)

(Test Method)Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

SIGNIFICANCE AND USE

4.1 Tension tests provide information on the strength and ductility of materials under uniaxial tensile stresses. This information may be useful in comparisons of materials, alloy development, quality control, and design under certain circumstances.

4.2 The results of tension tests of specimens machined to standardized dimensions from selected portions of a part or material may not totally represent the strength and ductility properties of the entire end product or its in-service behavior in different environments.

4.3 These test methods are considered satisfactory for acceptance testing of commercial shipments and have been used extensively in the trade for this purpose.

SCOPE

1.1 These test methods cover the tension testing of wrought and cast aluminum- and magnesium-alloy products, with the exception of aluminum foil,2 and are derived from Test Methods E8, which cover the tension testing of all metallic materials.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: Foil is sheet metal less than 0.0079 in. thick. There is an overlap in the thickness range 0.006 to 0.0079 in. defined for foil and sheet. Sheet products in this thickness range are supplied to sheet product specifications and foil products in this thickness range are supplied to foil product specifications. Exceptions to the provisions of these test methods may need to be made in individual specifications or test methods for a particular material.

Note 2: A complete metric companion to Test Methods B557 has been developed—Test Methods B557M; therefore, no metric equivalents are presented in these test methods.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B557 − 15 (Reapproved 2023)

Standard Test Methods for

Tension Testing Wrought and Cast Aluminum- and

1

Magnesium-Alloy Products

This standard is issued under the fixed designation B557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 These test methods cover the tension testing of wrought

B209 Specification for Aluminum and Aluminum-Alloy

and cast aluminum- and magnesium-alloy products, with the

2

Sheet and Plate (Metric) B0209_B0209M

exception of aluminum foil, and are derived from Test

E4 Practices for Force Calibration and Verification of Test-

Methods E8, which cover the tension testing of all metallic

ing Machines

materials.

E6 Terminology Relating to Methods of Mechanical Testing

1.2 The values stated in inch-pound units are to be regarded

E8 Test Methods for Tension Testing of Metallic Materials

as standard. No other units of measurement are included in this

[Metric] E0008_E0008M

standard.

E29 Practice for Using Significant Digits in Test Data to

1.3 This standard does not purport to address all of the

Determine Conformance with Specifications

safety concerns, if any, associated with its use. It is the

E83 Practice for Verification and Classification of Exten-

responsibility of the user of this standard to establish appro-

someter Systems

priate safety, health, and environmental practices and deter-

E345 Test Methods of Tension Testing of Metallic Foil

mine the applicability of regulatory limitations prior to use.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

NOTE 1—Foil is sheet metal less than 0.0079 in. thick. There is an

E1012 Practice for Verification of Testing Frame and Speci-

overlap in the thickness range 0.006 to 0.0079 in. defined for foil and

sheet. Sheet products in this thickness range are supplied to sheet product

men Alignment Under Tensile and Compressive Axial

specifications and foil products in this thickness range are supplied to foil

Force Application

product specifications. Exceptions to the provisions of these test methods

may need to be made in individual specifications or test methods for a

3. Terminology

particular material.

3.1 The definitions of terms relating to tension testing

NOTE 2—A complete metric companion to Test Methods B557 has been

developed—Test Methods B557M; therefore, no metric equivalents are

appearing in Terminology E6 shall be considered as applying

presented in these test methods.

to the terms used in these test methods.

1.4 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 4.1 Tension tests provide information on the strength and

Development of International Standards, Guides and Recom-

ductility of materials under uniaxial tensile stresses. This

mendations issued by the World Trade Organization Technical information may be useful in comparisons of materials, alloy

Barriers to Trade (TBT) Committee.

development, quality control, and design under certain circum-

stances.

4.2 The results of tension tests of specimens machined to

1

These test methods are under the jurisdiction of ASTM Committee B07 on standardized dimensions from selected portions of a part or

Light Metals and Alloys and are the direct responsibility of Subcommittee B07.05

on Testing.

3

Current edition approved April 1, 2023. Published April 2023. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1971. Last previous edition approved in 2015 as B557 – 15. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/B0557-15R23. Standards volume information, refer to the standard’s Document Summary page on

2

For test methods of tension testing of aluminum foil, see Test Methods E345. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B557 − 15 (2023)

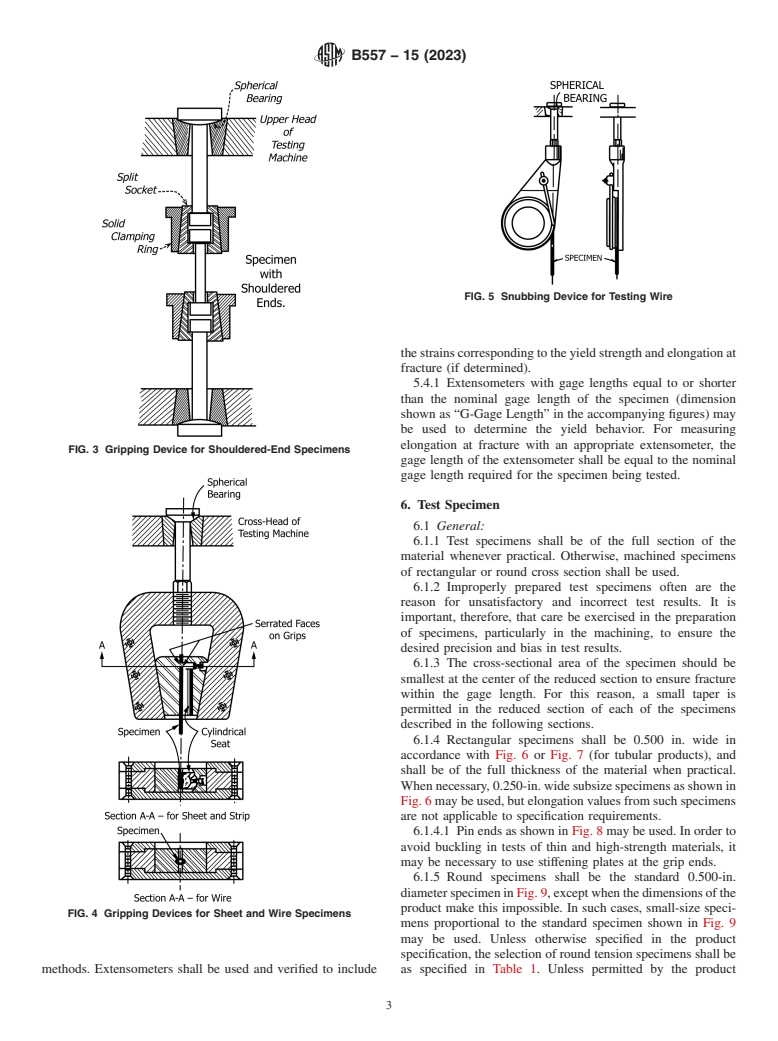

material may not totally represent the strength and ductility the specimens, when under load, shall be as nearly as possible

properties of the entire end product or its

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.