ASTM B743-06

(Specification)Standard Specification for Seamless Copper Tube in Coils

Standard Specification for Seamless Copper Tube in Coils

ABSTRACT

This standard specification establishes the requirements for seamless copper tube coils, suitable for use in refrigeration and air conditioning or other uses, such as oil lines and gasoline lines. The material of manufacture shall be cast billet, bar, tube and so forth of Copper Alloys No. C10200, C10300, C10800, C12000, or C12200. The tube shall be manufactured by such hot and cold working processes needed to produce a homogeneous, uniform wrought structure. The tube shall be cold drawn to the prescribed finish size and wall thickness. When the cold-drawn temper is required, the final drawing operation shall conform to the specified temper properties. When the annealed temper is required, the tube shall be annealed after the final cold draw to the specified temper properties. The product shall conform to the prescribed electrical mass resistivity, tensile strength, yield strength, Rockwell hardness, and expansion. Each tube shall be subjected to an eddy-current test. Particular coppers shall be tested to meet the cuprous oxide, embrittlement, and cleanness requirements.

SCOPE

1.1 This specification establishes the requirements for seamless copper tube in coils, suitable for use in refrigeration and air conditioning or other uses, such as oil lines and gasoline lines.

1.2 UnitsThe values stated in inch-pound units are standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

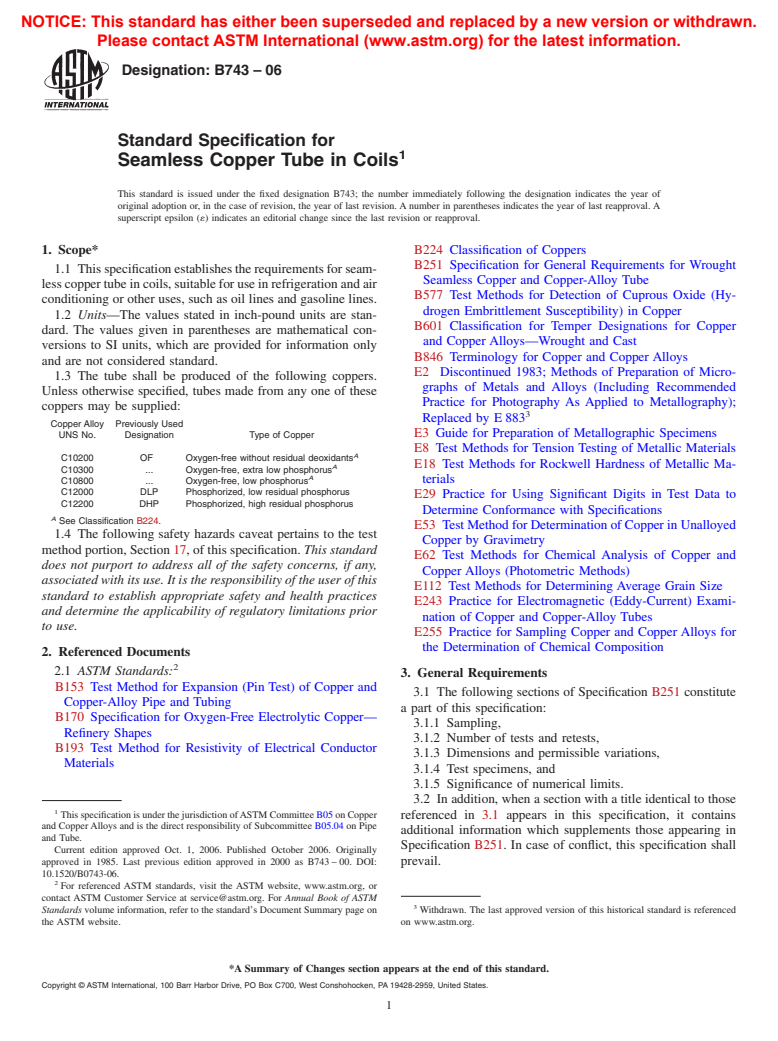

1.3 The tube shall be produced of the following coppers. Unless otherwise specified, tubes made from any one of these coppers may be supplied:

The following safety hazards caveat pertains to the test method portion, Section 17, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: B743 – 06

Standard Specification for

1

Seamless Copper Tube in Coils

This standard is issued under the fixed designation B743; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B224 Classification of Coppers

B251 Specification for General Requirements for Wrought

1.1 Thisspecificationestablishestherequirementsforseam-

Seamless Copper and Copper-Alloy Tube

lesscoppertubeincoils,suitableforuseinrefrigerationandair

B577 Test Methods for Detection of Cuprous Oxide (Hy-

conditioning or other uses, such as oil lines and gasoline lines.

drogen Embrittlement Susceptibility) in Copper

1.2 Units—The values stated in inch-pound units are stan-

B601 Classification for Temper Designations for Copper

dard. The values given in parentheses are mathematical con-

and Copper Alloys—Wrought and Cast

versions to SI units, which are provided for information only

B846 Terminology for Copper and Copper Alloys

and are not considered standard.

E2 Discontinued 1983; Methods of Preparation of Micro-

1.3 The tube shall be produced of the following coppers.

graphs of Metals and Alloys (Including Recommended

Unless otherwise specified, tubes made from any one of these

Practice for Photography As Applied to Metallography);

coppers may be supplied:

3

Replaced by E 883

Copper Alloy Previously Used

E3 Guide for Preparation of Metallographic Specimens

UNS No. Designation Type of Copper

E8 Test Methods for Tension Testing of Metallic Materials

A

C10200 OF Oxygen-free without residual deoxidants

E18 Test Methods for Rockwell Hardness of Metallic Ma-

A

C10300 . Oxygen-free, extra low phosphorus

A

terials

C10800 . Oxygen-free, low phosphorus

C12000 DLP Phosphorized, low residual phosphorus

E29 Practice for Using Significant Digits in Test Data to

C12200 DHP Phosphorized, high residual phosphorus

Determine Conformance with Specifications

A

See Classification B224.

E53 Test Method for Determination of Copper in Unalloyed

1.4 The following safety hazards caveat pertains to the test

Copper by Gravimetry

method portion, Section 17, of this specification. This standard

E62 Test Methods for Chemical Analysis of Copper and

does not purport to address all of the safety concerns, if any,

Copper Alloys (Photometric Methods)

associated with its use. It is the responsibility of the user of this

E112 Test Methods for Determining Average Grain Size

standard to establish appropriate safety and health practices

E243 Practice for Electromagnetic (Eddy-Current) Exami-

and determine the applicability of regulatory limitations prior

nation of Copper and Copper-Alloy Tubes

to use.

E255 Practice for Sampling Copper and Copper Alloys for

the Determination of Chemical Composition

2. Referenced Documents

2

2.1 ASTM Standards:

3. General Requirements

B153 Test Method for Expansion (Pin Test) of Copper and

3.1 The following sections of Specification B251 constitute

Copper-Alloy Pipe and Tubing

a part of this specification:

B170 Specification for Oxygen-Free Electrolytic Copper—

3.1.1 Sampling,

Refinery Shapes

3.1.2 Number of tests and retests,

B193 Test Method for Resistivity of Electrical Conductor

3.1.3 Dimensions and permissible variations,

Materials

3.1.4 Test specimens, and

3.1.5 Significance of numerical limits.

3.2 In addition, when a section with a title identical to those

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

referenced in 3.1 appears in this specification, it contains

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

additional information which supplements those appearing in

and Tube.

Specification B251. In case of conflict, this specification shall

Current edition approved Oct. 1, 2006. Published October 2006. Originally

approved in 1985. Last previous edition approved in 2000 as B743 – 00. DOI: prevail.

10.1520/B0743-06.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

B743 – 06

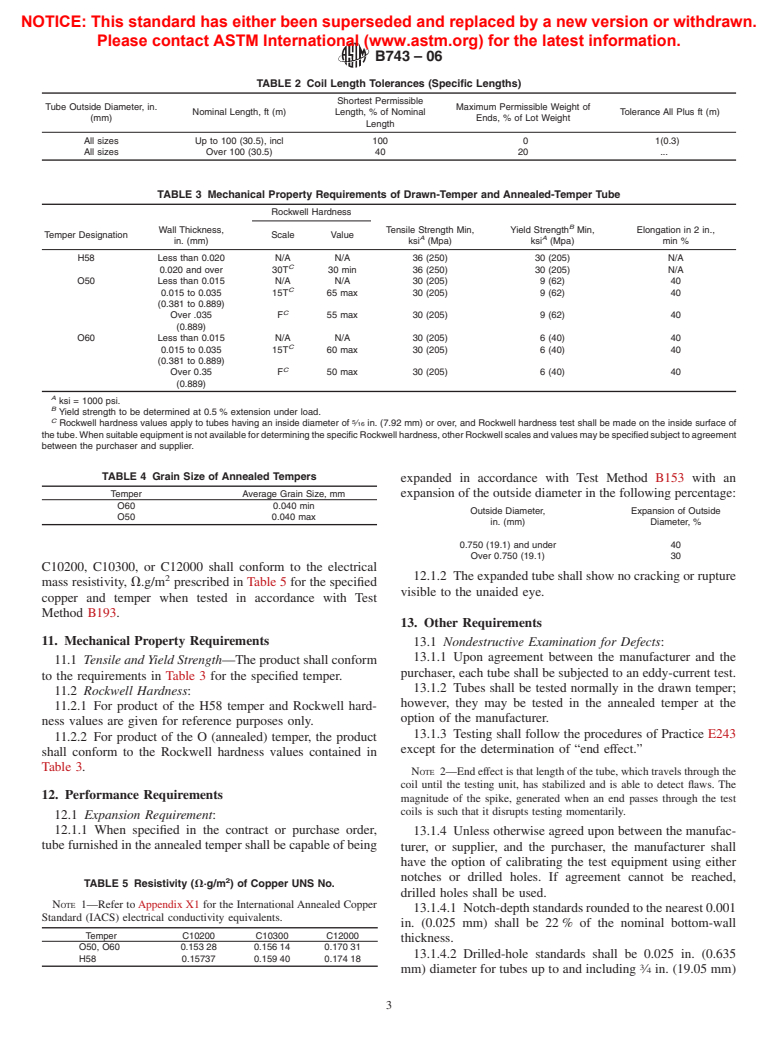

NOTE

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.