ASTM B251/B251M-17

(Specification)Standard Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

Standard Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

ABSTRACT

This specification covers a group of general requirements for wrought seamless copper and copper alloy tube. The material shall be produced by either hot or cold working operations, or both, and shall be finished, unless otherwise specified, by such cold working and annealing or heat treatment as necessary to meet the properties specified. Dimensional requirements such as wall thickness are specified. The sampling requirements including lot size, portion size, and selection of sample pieces are given. Requirements for chemical analysis, and tension, microscopical examination, Rockwell hardness, grain size, expansion (pin), mercurous nitrate, and electrical resistivity tests are detailed. The material shall conform to the prescribed chemical composition, hardness, electrical resistivity, tensile strength, yield strength, elongation, and grain size.

SCOPE

1.1 This specification covers a group of general requirements common to several wrought product specifications. Unless otherwise specified in the purchase order, or in an individual specification, these general requirements shall apply to copper and copper-alloy tube supplied under Specifications B68/B68M, B75/B75M, B135/B135M, B466/B466M, B643 and B743.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B251/B251M −17

Standard Specification for

General Requirements for Wrought Seamless Copper and

1

Copper-Alloy Tube

This standard is issued under the fixed designation B251/B251M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B154 Test Method for Mercurous Nitrate Test for Copper

Alloys

1.1 This specification covers a group of general require-

B170 Specification for Oxygen-Free Electrolytic Copper—

ments common to several wrought product specifications.

Refinery Shapes

Unless otherwise specified in the purchase order, or in an

B193 Test Method for Resistivity of Electrical Conductor

individual specification, these general requirements shall apply

Materials

to copper and copper-alloy tube supplied under Specifications

B428 Test Method for Angle of Twist in Rectangular and

B68/B68M, B75/B75M, B135/B135M, B466/B466M, B643

Square Copper and Copper Alloy Tube

and B743.

B466/B466M Specification for Seamless Copper-Nickel

1.2 The values stated in either SI units or inch-pound units

Pipe and Tube

are to be regarded separately as standard. The values stated in

B643 Specification for Copper-Beryllium Alloy Seamless

each system are not necessarily exact equivalents; therefore, to

Tube

ensure conformance with the standard, each system shall be

B743 Specification for Seamless Copper Tube in Coils

used independently of the other, and values from the two

B846 Terminology for Copper and Copper Alloys

systems shall not be combined.

E3 Guide for Preparation of Metallographic Specimens

1.3 This international standard was developed in accor- E8/E8M Test Methods for Tension Testing of Metallic Ma-

dance with internationally recognized principles on standard-

terials

ization established in the Decision on Principles for the E18 Test Methods for Rockwell Hardness of Metallic Ma-

Development of International Standards, Guides and Recom-

terials

mendations issued by the World Trade Organization Technical E29 Practice for Using Significant Digits in Test Data to

Barriers to Trade (TBT) Committee.

Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed

2. Referenced Documents

Copper by Gravimetry

2.1 The following documents of the issue in effect on date E62 Test Methods for Chemical Analysis of Copper and

3

CopperAlloys (Photometric Methods) (Withdrawn 2010)

of material purchase form a part of this specification to the

extent referenced herein: E112 Test Methods for Determining Average Grain Size

E255 Practice for Sampling Copper and Copper Alloys for

2

2.2 ASTM Standards:

the Determination of Chemical Composition

B68/B68M Specification for Seamless Copper Tube, Bright

E478 Test Methods for ChemicalAnalysis of CopperAlloys

Annealed

B75/B75M Specification for Seamless Copper Tube

3. Terminology

B135/B135M Specification for Seamless Brass Tube

3.1 For definitions of terms related to copper and copper

B153 Test Method for Expansion (Pin Test) of Copper and

alloys, refer to Terminology B846.

Copper-Alloy Pipe and Tubing

4. Materials and Manufacture

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.1 The material shall be of such quality and purity that the

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

finished product shall have the properties and characteristics

and Tube.

Current edition approved Oct. 1, 2017. Published November 2017. Originally

prescribed in the applicable product specification listed in

approved in 1951. Last previous edition approved in 2010 as B251 – 10. DOI:

Section 1.

10.1520/B0251_B0251M-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B251/B251M−17

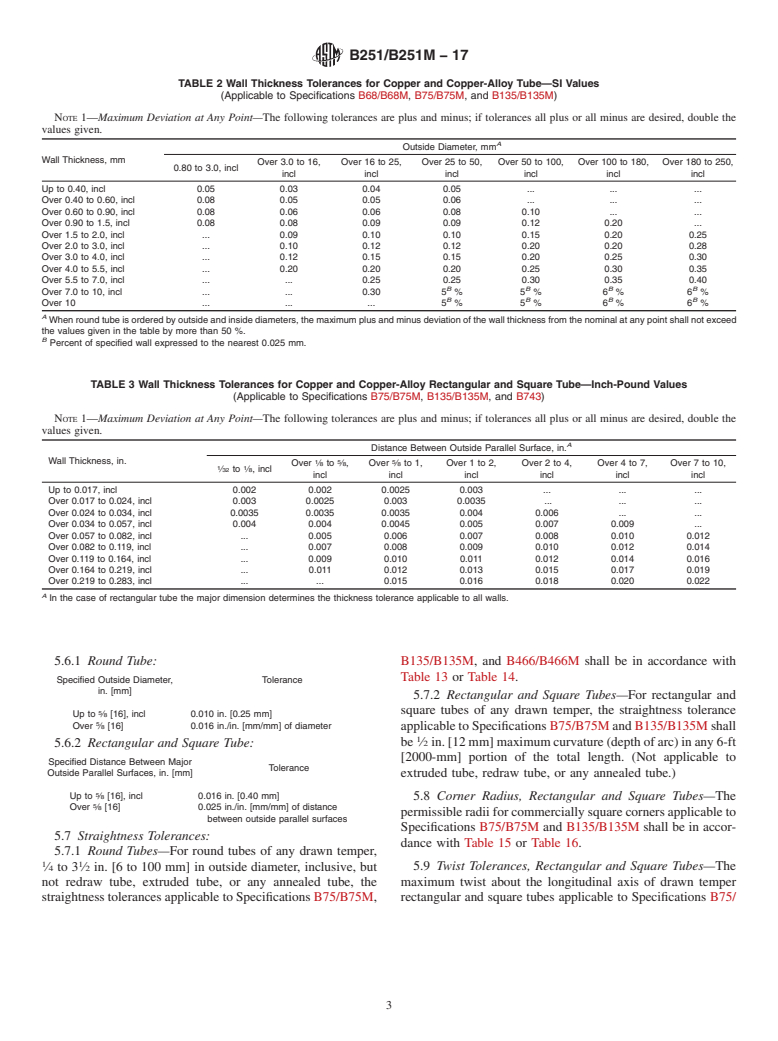

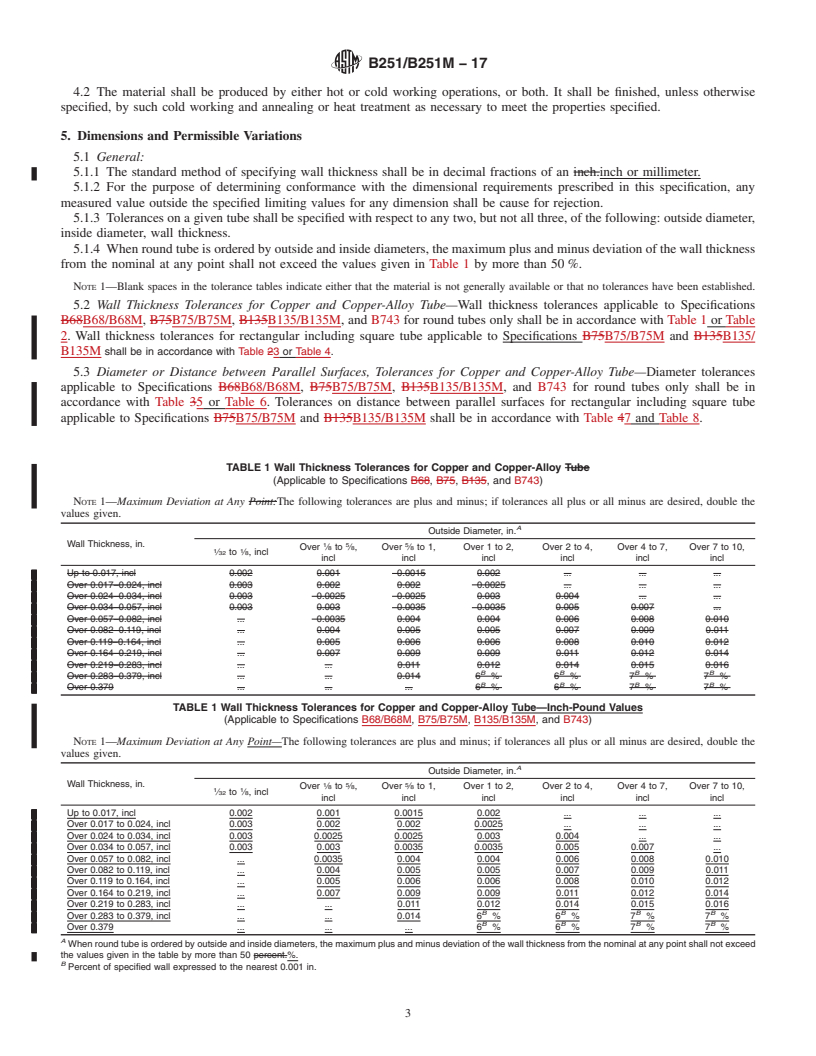

4.2 The material shall be produced by either hot or cold 5.4 Roundness (Applicable to Specifications B75/B75M,

working operations, or both. It shall be finished, unless B135/B135M, and B466/B466M)—For drawn unannealed tube

otherwise specified, by such cold working and annealing or

instraig

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B251 − 10 B251/B251M − 17

Standard Specification for

General Requirements for Wrought Seamless Copper and

1

Copper-Alloy Tube

This standard is issued under the fixed designation B251;B251/B251M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers a group of general requirements common to several wrought product specifications. Unless

otherwise specified in the purchase order, or in an individual specification, these general requirements shall apply to copper and

copper-alloy tube supplied under Specifications B68B68/B68M, B75B75/B75M, B135B135/B135M, B466/B466M, B643 and

B743.

NOTE 1—This specification B251 is the inch-pound companion to B251M; therefore, no SI equivalents are presented in the specification.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B68B68/B68M Specification for Seamless Copper Tube, Bright Annealed

B75B75/B75M Specification for Seamless Copper Tube

B135B135/B135M Specification for Seamless Brass Tube [Metric] B0135_B0135M

B153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B154 Test Method for Mercurous Nitrate Test for Copper Alloys

B170 Specification for Oxygen-Free Electrolytic Copper—Refinery Shapes

B193 Test Method for Resistivity of Electrical Conductor Materials

B428 Test Method for Angle of Twist in Rectangular and Square Copper and Copper Alloy Tube

B466/B466M Specification for Seamless Copper-Nickel Pipe and Tube

B643 Specification for Copper-Beryllium Alloy Seamless Tube

B743 Specification for Seamless Copper Tube in Coils

B846 Terminology for Copper and Copper Alloys

E3 Guide for Preparation of Metallographic Specimens

E8E8/E8M Test Methods for Tension Testing of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 1, 2010Oct. 1, 2017. Published November 2010November 2017. Originally approved in 1951. Last previous edition approved in 20022010

as B251 – 02.B251 – 10. DOI: 10.1520/B0251-10.10.1520/B0251_B0251M-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B251/B251M − 17

3

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods) (Withdrawn 2010)

E112 Test Methods for Determining Average Grain Size

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys

3. Terminology

3.1 Definitions:

3.1.1 average diameter (for round tubes only)—the average of the maximum and minimum outside diameters, or maximum and

minimum inside diameters, whichever is applicable, as determined at any one cross section of the tube

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.