ASTM D7226-13

(Test Method)Standard Test Method for Determining the Viscosity of Emulsified Asphalts Using a Rotational Paddle Viscometer

Standard Test Method for Determining the Viscosity of Emulsified Asphalts Using a Rotational Paddle Viscometer

SIGNIFICANCE AND USE

5.1 The viscosity of emulsified asphalts characterizes their flow properties and affects their utility at 50°C or at other temperatures. The sprayability and workability of an emulsified asphalt are directly related to its viscosity for many applications. The material must be thin enough to be sprayed yet thick enough such that it will not flow from the crown or grade of the road. For mixing grade emulsified asphalts the viscosity will affect its workability and resulting film thickness on the aggregate. This test method is useful to measure the apparent viscosity of emulsified asphalt at a temperature of 50°C, 25°C, or another agreed-upon temperature. The preset temperature and rotational speed at 100 RPM allow for an automated and consistent determination of an emulsified asphalt viscosity within a short time.

SCOPE

1.1 This test method utilizes the rotational paddle viscometer to measure the viscosity of emulsified asphalt. It is applicable to all the emulsified asphalts described in Specifications D977 and D2397.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7226 −13

Standard Test Method for

Determining the Viscosity of Emulsified Asphalts Using a

1

Rotational Paddle Viscometer

This standard is issued under the fixed designation D7226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 25°C, or other agreed-upon temperatures. A microprocessor

circuitry system functioning in tandem with a temperature

1.1 This test method utilizes the rotational paddle viscom-

probe and equipped with internal electronic sensors detects and

eter to measure the viscosity of emulsified asphalt. It is

analyzes the preset temperature. A paddle is immersed in the

applicable to all the emulsified asphalts described in Specifi-

emulsified asphalt sample and is rotated at 100 RPM. The

cations D977 and D2397.

apparent viscosity of the sample is obtained and read from the

1.2 The values stated in SI units are to be regarded as

electronic display or an optional printer.

standard. No other units of measurement are included in this

standard.

5. Significance and Use

1.3 This standard does not purport to address all of the

5.1 The viscosity of emulsified asphalts characterizes their

safety concerns, if any, associated with its use. It is the

flow properties and affects their utility at 50°C or at other

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- temperatures. The sprayability and workability of an emulsi-

bility of regulatory limitations prior to use. fied asphalt are directly related to its viscosity for many

applications. The material must be thin enough to be sprayed

2. Referenced Documents

yet thick enough such that it will not flow from the crown or

2

2.1 ASTM Standards:

grade of the road. For mixing grade emulsified asphalts the

D140 Practice for Sampling Bituminous Materials

viscosity will affect its workability and resulting film thickness

D977 Specification for Emulsified Asphalt

on the aggregate. This test method is useful to measure the

D2397 Specification for Cationic Emulsified Asphalt

apparent viscosity of emulsified asphalt at a temperature of

E11 Specification for Woven Wire Test Sieve Cloth and Test

50°C, 25°C, or another agreed-upon temperature. The preset

Sieves

temperature and rotational speed at 100 RPM allow for an

automated and consistent determination of an emulsified as-

3. Terminology

phalt viscosity within a short time.

3.1 Definitions:

3.1.1 viscosity, n—ratio of shear stress to shear rate.

6. Apparatus

3.1.1.1 Discussion—The SI unit of viscosity is the Pascal

3

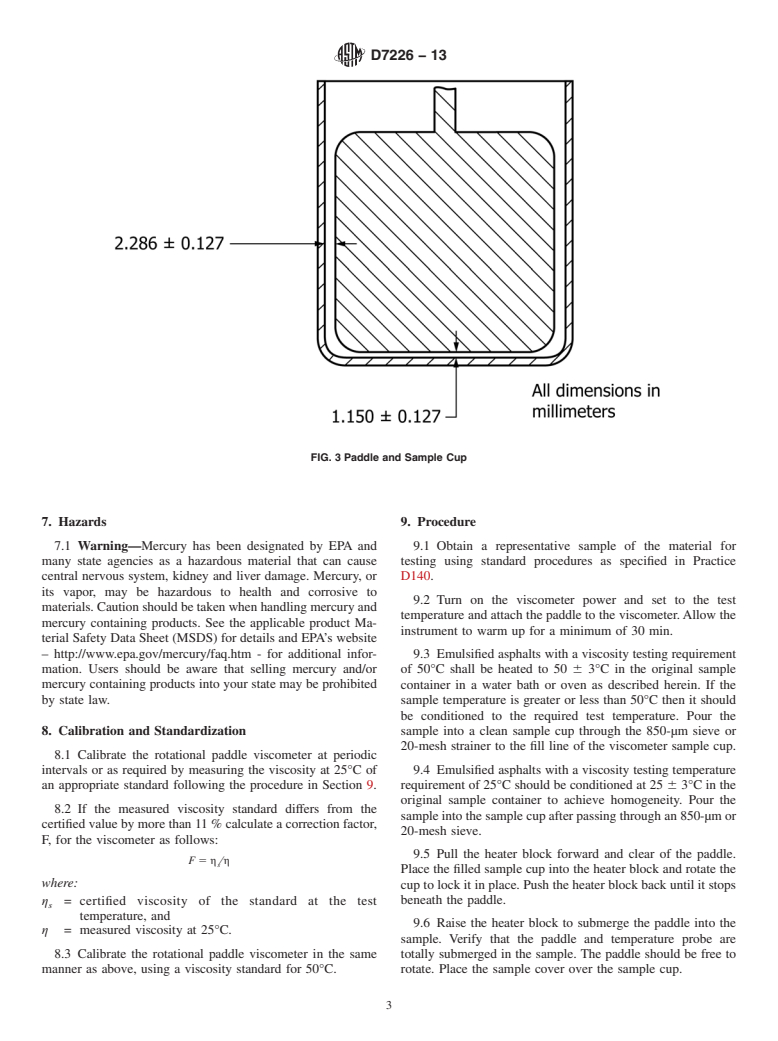

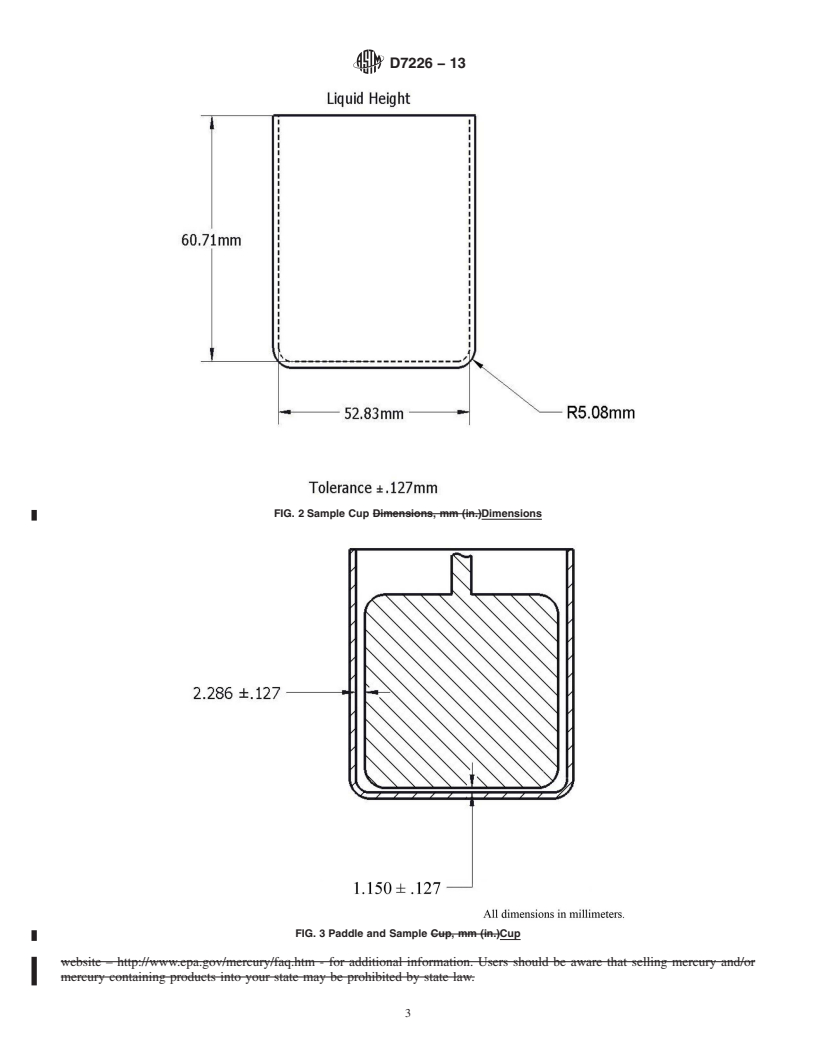

6.1 The rotational paddle viscometer test system consists of

second (Pa·s).

a paddle, temperature probe, sample cup, the sample cup cover,

4. Summary of Test Method

a means of controlling the sample temperature to within

4.1 The rotational paddle viscometer method is used to 60.1°C and a readout system to display viscosity. The dimen-

measure the apparent viscosity of emulsified asphalt at 50°C, sions of the sample cup and paddle are shown in Figs. 1-3.

6.2 Thermometer—Any thermometric device can be used to

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

monitor the temperature of the sample being conditioned for

and Paving Materials and is the direct responsibility of Subcommittee D04.42 on

testing.

Emulsified Asphalt Test.

Current edition approved Dec. 1, 2013. Published January 2014. Originally

6.3 Sieve—An 850-µm sieve or a 20-mesh strainer of wire

approved in 2006. Last previous edition approved in 2011 as D7226 – 11. DOI:

10.1520/D7226-13.

cloth, framed or unframed, conforming to Specification E11 is

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

used.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6.4 Oven/Water Bath—An oven/water bath capable of main-

the ASTM website.

2 taining the required testing temperature within the limit of

3

The centimetre gram second (cgs) unit of viscosity is the poise (dynes/cm ) and

is equivalent to 0.1 Pa·s. One centipoise (cP) is one millipascal second (mPa·s). 63°C.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7226−13

FIG. 1Paddle Dimensions

FIG. 2Sample Cup Dimensions

2

---------------------- Page: 2 ----------------------

D7226−13

FIG. 3Paddle and Sample Cup

7. Hazards 9. Procedure

7.1 Warning—Mercury has been designated by EPA and 9.1 Obtain a representative sample of the material for

many s

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7226 − 11 D7226 − 13

Standard Test Method for

Determining the Viscosity of Emulsified Asphalts Using a

1

Rotational Paddle Viscometer

This standard is issued under the fixed designation D7226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method uses a paddle rotational utilizes the rotational paddle viscometer to measure the apparent viscosity of

emulsified asphalt with viscosities between 30 and 1500 mPa·s (centipoises) at 50°C (122°F). asphalt. It is applicable to all the

emulsified asphaltasphalts described in Specifications D977 and D2397.

1.2 The values givenstated in SI units are to be considered the standard. The values given in parentheses are for information

only.regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D140 Practice for Sampling Bituminous Materials

D977 Specification for Emulsified Asphalt

D2397 Specification for Cationic Emulsified Asphalt

D7496 Test Method for Viscosity of Emulsified Asphalt by Saybolt Furol Viscometer

E1 Specification for ASTM Liquid-in-Glass Thermometers

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Terminology

3.1 Definitions:

3.1.1 viscosity, n—ratio of shear stress to shear rate.

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.42 on Emulsified

Asphalt Test.

Current edition approved Dec. 1, 2011Dec. 1, 2013. Published January 2012January 2014. Originally published 2006 approved in 2006. Last previous edition approved

in 2011 as D7226D7226 – 11.–06. DOI: 10.1520/D7226-11.10.1520/D7226-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

3 2

The SI unit of viscosity is the Pascal second (Pa·s).The centimetre gram second (cgs) unit of viscosity is the poise (dynes/cm )

and is equivalent to 0.1 Pa·s. One centipoise (cP) is one millipascal second (mPa·s).

4. Summary of Test Method

4.1 The paddle rotational viscometer for this test paddle viscometer method is used to measure the apparent viscosity of

emulsified asphalt at 50°C (122°F) between 30 and 1500 mPa·s (cP). 50°C, 25°C, or other agreed-upon temperatures. A

3

Emulsions are sensitive to RPM, therefore, the manufacturer has preset the instrument to run at 100 RPM.

3

No accurate predictable conversion from mPa seconds to Saybolt Furol Seconds (SFS) is available at thisThe centimetre gram second (cgs) unit of viscosity is the poise

2

(dynes/cm time. However, an empirical correlation between SFS and mPa seconds can be obtained by performing the respective viscosity measurements on the appropriate

equipment.) and is equivalent to 0.1 Pa·s. One centipoise (cP) is one millipascal second (mPa·s).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7226 − 13

microprocessor circuitry system functioning in tandem with a temperature probe and equipped with internal electronic sensors

detects and analyzes the preset temperature. A paddle is immersed in the emulsified asphalt sample and is rotated at 100 RPM. The

apparent viscosity of the sample is obtained within 5 min and read from the electronic display or an optional printer.

5. Significance and Use

5.1 The viscosity of emulsified asphalts characterizes their flow properties and affects their utility at 50°C (122°F) or at other

temperatures. An emulsified asphalt The sprayability and workability is of an emulsified asphalt are directly related to theirits

viscosity for many applications types. applications. The material must be thin enough to be sprayed yet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.