ASTM A1081/A1081M-12

(Test Method)Standard Test Method for Evaluating Bond of Seven-Wire Steel Prestressing Strand

Standard Test Method for Evaluating Bond of Seven-Wire Steel Prestressing Strand

SIGNIFICANCE AND USE

5.1 Prestressing steel strand is used in pre-tensioned and post-tensioned concrete construction.

5.2 In pre-tensioned concrete applications, the prestressing steel strand is expected to transfer prestressing forces to the structural member via the adhesion (that is, bond) of the exposed wire strand surfaces to the surrounding cementitous material.

5.3 Manufacturing processes, subsequent handling, and storage conditions can influence the strand bond.

5.4 Prestressing steel strand is used in construction applications with a variety of concrete mixtures. Developing tests and threshold values for the performance of the strand in each of these unique mixtures is impractical.

SCOPE

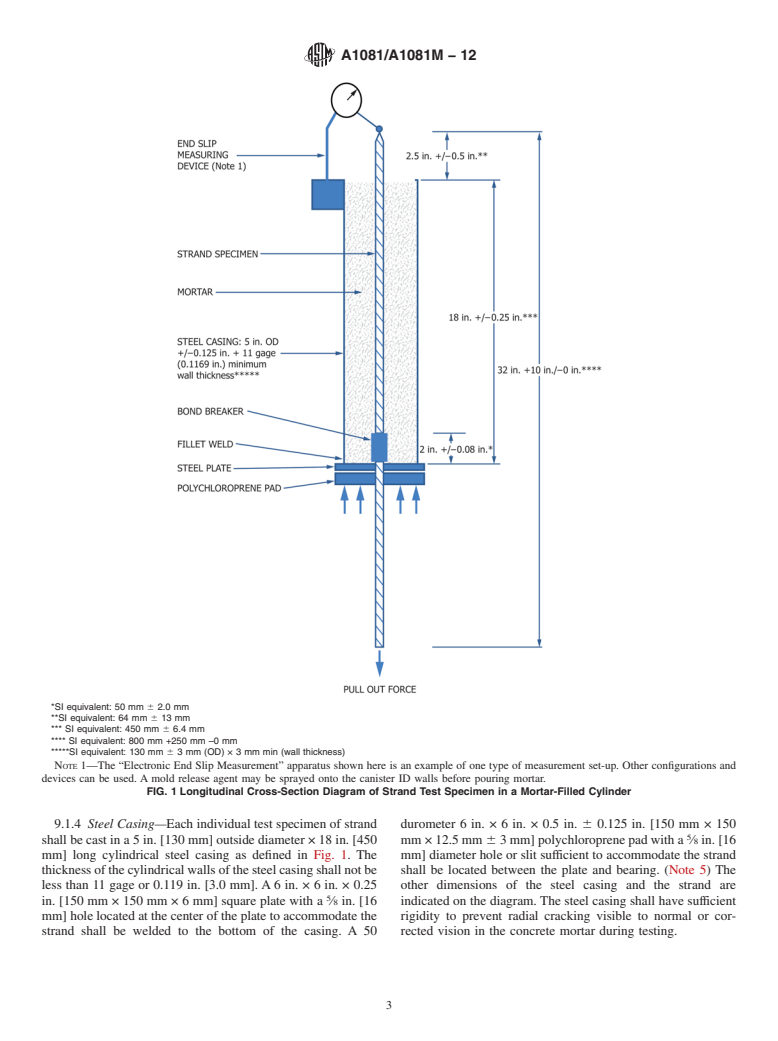

1.1 This test method describes procedures for determining the bond of seven-wire steel prestressing strand. The bond determined by this test method is stated as the tensile force required to pull the strand through the cured mortar in a cylindrical steel casing. The result of the test is the tensile force measured on the loaded-end of the strand corresponding to a movement of 0.1 in. (2.5 mm) at the free-end of the strand.

1.2 This test method is applicable either in inch-pound units (as Specification A1081) or SI units (as Specification A1081M).

1.3 The values stated in either inch-pound units or in SI units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A1081/A1081M − 12

StandardTest Method for

Evaluating Bond of Seven-Wire Steel Prestressing Strand

This standard is issued under the fixed designation A1081/A1081M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C192/C192MPractice for Making and Curing ConcreteTest

Specimens in the Laboratory

1.1 This test method describes procedures for determining

C1437Test Method for Flow of Hydraulic Cement Mortar

the bond of seven-wire steel prestressing strand. The bond

determined by this test method is stated as the tensile force

3. Terminology

required to pull the strand through the cured mortar in a

cylindricalsteelcasing.Theresultofthetestisthetensileforce

3.1 Definitions:

measured on the loaded-end of the strand corresponding to a

3.1.1 bond—the adhesion of strand to concrete or mortar.

movement of 0.1 in. (2.5 mm) at the free-end of the strand.

3.1.2 bond breaker—a product wrapped around strand to

1.2 Thistestmethodisapplicableeitherininch-poundunits

prevent strand-to-concrete bond over the installed length.

(as Specification A1081) or SI units (as Specification

Extruded polystyrene foam pipe insulation is commonly used

A1081M).

for this purpose.

1.3 The values stated in either inch-pound units or in SI

3.1.3 manufactured length—a length of strand that is manu-

units are to be regarded separately as standard.Within the text,

factured in one continuous length.

SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system

3.1.4 mortar—a mixture of cement, fine aggregate (that is,

shall be used independently of the other. Combining values

sand) and water.

from the two systems may result in non-conformance with the

3.1.5 strand—all references to strand in this test method

specification.

shall be interpreted to be Specification A416/A416M seven-

1.4 This standard does not purport to address all of the

wire prestressing steel strand with nominal diameters of 0.500

safety concerns, if any, associated with its use. It is the

in. [12.70 mm] or 0.600 in. [15.24 mm].

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.6 test specimen—an assembly consisting of one steel

bility of regulatory limitations prior to use. casing, one sample of strand and mortar.

2. Referenced Documents 4. Summary of Test Method

2.1 ASTM Standards:

4.1 Six samples of seven-wire steel prestressing strand with

A416/A416M Specification for Steel Strand, Uncoated

nominal diameters of 0.500 in. [12.7 mm] or 0.600 in. [15.24

Seven-Wire for Prestressed Concrete

mm] are selected from a single continuous length. Each of the

C33/C33MSpecification for Concrete Aggregates

six strand samples are individually cast in a steel cylinder

C109/C109MTest Method for Compressive Strength of

casingwithaspecifiedcementmortar.Thestrandisexposedon

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

both ends of the cylinder with a designated loaded-end and

Specimens)

free-end. Once the mortar reaches a specified compressive

C150/C150MSpecification for Portland Cement

strength, the cylinder with the embedded steel strand is loaded

into a tensile testing machine. The designated loaded-end of

the steel strand is gripped by the tensile testing machine and

This test method is under the jurisdiction of ASTM Committee A01 on Steel,

pulled away from the cylinder at a specified displacement rate.

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

The tensile force on the loaded-end of the strand is measured

A01.05 on Steel Reinforcement.

alongwiththecorrespondingdisplacementofthefree-end.The

CurrenteditionapprovedNov.15,2012.PublishedJanuary2013.DOI:10.1520/

A1081_A1081M.

resultofthetestisthetensileforcemeasuredattheloaded-end

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of the strand corresponding to a movement of 0.1 in. [2.5 mm]

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

at the free-end of the strand. The results of each sample test in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the set of six are reported individually and as an average.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1081/A1081M − 12

5. Significance and Use 8.2 Mortar Preparation—The preparation of the materials

and procedure used to mix the mortar shall be performed in

5.1 Prestressing steel strand is used in pre-tensioned and

conformance with Practice C192/C192M (Note 2) with the

post-tensioned concrete construction.

following exceptions:

5.2 In pre-tensioned concrete applications, the prestressing

8.2.1 Aggregates, other than sand, shall not be used.

steel strand is expected to transfer prestressing forces to the

8.2.2 Admixtures shall not be used.

structural member via the adhesion (that is, bond) of the

8.3 Mortar Performance Requirements—The mortar shall

exposed wire strand surfaces to the surrounding cementitous

be tested in conformance with Practice C192/C192M with the

material.

following exceptions and additional requirements.

5.3 Manufacturing processes, subsequent handling, and

8.3.1 Slump—No measurements required.

storage conditions can influence the strand bond.

8.3.2 Air Content—No measurements required.

5.4 Prestressing steel strand is used in construction applica-

8.3.3 Flow—Mortar flow shall be measured in accordance

tions with a variety of concrete mixtures. Developing tests and

with the procedures inTest Method C1437.The flow rate shall

threshold values for the performance of the strand in each of

be greater than or equal to 100% but shall not exceed 125%.

these unique mixtures is impractical.

8.3.4 Strength—Mortar strength shall be evaluated in con-

formance with Test Method C109/C109M using 2 in. [50 mm]

6. Apparatus

mortar cubes. Before starting the test and after a minimum of

6.1 A dial gauge or position transducer with a minimum

22 hours curing time, mean mortar cube strength shall not be

precision of 0.001 in (0.025 mm).

lessthan4500psi[31MPa].Duringperformanceofthestrand

6.2 A tensile testing machine with the following function- bond test and within 24 hours 6 2 hours of mortar mixing,

mean mortar cube strengths shall be between 4 500 psi [31

ality:

6.2.1 Controlled loading rate based on cross-head displace- MPa] and 5 000 psi [34.5 MPa] (Note 3).

ment.

NOTE2—PracticeC192/C192Misdescribedasastandardpracticetobe

6.2.2 Gripping device without torsional restraint. The lack

used for concrete test specimens.As outlined in 8.1, only fine aggregates

of torsion restraint and satisfaction of this requirement shall be

(that is, sand) are included in the mixture along with cement and water.

verifiedbydemonstratingtheabilitytotwisttheactuatororthe Because coarse aggregates are not included, this mixture is defined as

“mortar” and not “concrete.” Aside from this difference and a few other

test specimen by hand or by manual lever. (Note 1)

exceptions noted in Section 8, the practices documented in Practice

NOTE1—Intestingtodevelopthetestmethod,hydraulicactuatorswere C192/C192M are to be applied when making the mortar used in this test

employed to apply tension force to the strand.The nature of the hydraulic method.

actuators generally allows the piston to rotate with minimal resistance

NOTE 3—The ability to consistently achieve the specified mortar

(since the piston floats on hydraulic fluid). Neither a roller bearing nor a

strengths can be a challenge for testing facilities with limited mortar

ball bearing is required though one may be necessary if the pull-out force

experience and/or limited mixing and curing facilities and multiple trial

is applied through a mechanism where twist is restrained.

batches may be required to develop appropriate mixes. If mean mortar

strengths are less than the 4 500 psi [31 MPa] when the strand bond test

is performed, the strand bond test results will be biased to provide lower

7. Sampling of Strand

bond test values than if the mortar was within the specified range. For the

7.1 Six samples of prestressing steel strand are needed for

purpose of comparing the bond test results of this test method against a

this test. Each sample shall be at least 32 in. [800 mm] long. minimum threshold value, a bond test result that exceeds a minimum

threshold value with a mean mortar strength less than 4 500 psi [31 MPa]

7.2 Samplesshallbecollectedfromthesamereelorreelless

should be accepted as meeting a specified minimum threshold value.

pack of strand (typically 3.5 tons [3 metric tons]) or the same

If mortar strengths are greater than the 5 000 psi [34.5 MPa] when the

manufactured length of strand (typically 20–28 tons [18–25 strandbondtestisperformed,thestrandbondtestresultswillbebiasedto

providehigherbondtestvaluesthanifthemortarwaswithinthespecified

metric tons]).

range. For the purpose of comparing the bond test results of this test

7.3 The surface condition of the strand samples shall be

methodagainstaminimumthresholdvalue,abondtestresultthatisbelow

aminimumthresholdvaluewithameanmortarstrengthgreaterthan5000

representative of the strand intended for use in bonded appli-

psi [34.5 MPa] should be considered as failing to meet the specified

cations. Care shall be taken to prevent the introduction of

minimum threshold value.

surfacecontaminantswhichmayalterthebondperformanceof

the strand. For qualification of a manufacturing process,

9. Preparation of Test Specimens

sample surface shall be in the as-manufactured condition.

9.1 Materials:

8. Mortar Requirements

9.1.1 Strand Samples—Strand sample requirements are de-

fined in Se

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.