ASTM F1524-95(2007)

(Guide)Standard Guide for Use of Advanced Oxidation Process for the Mitigation of Chemical Spills

Standard Guide for Use of Advanced Oxidation Process for the Mitigation of Chemical Spills

SCOPE

1.1 This guide covers the considerations for advanced oxidation processes (AOPs) in the mitigation of spilled chemicals and hydrocarbons dissolved into ground and surface waters.

1.2 This guide addresses the application of advanced oxidation alone or in conjunction with other technologies.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. In addition, it is the responsibility of the user to ensure that such activity takes place under the control and direction of a qualified person with full knowledge of any potential safety and health protocols.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1524 − 95(Reapproved 2007)

Standard Guide for

Use of Advanced Oxidation Process for the Mitigation of

Chemical Spills

This standard is issued under the fixed designation F1524; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.5 radical species—a powerful oxidizing agent, princi-

pally the hydroxyl radical, that reacts rapidly with virtually all

1.1 This guide covers the considerations for advanced

organic compounds to oxidize and eventually lead to their

oxidation processes (AOPs) in the mitigation of spilled chemi-

complete mineralization.

cals and hydrocarbons dissolved into ground and surface

2.1.6 scavengers—atermusedforsubstancesthatreactwith

waters.

hydroxyl radicals that do not yield species that propagate the

1.2 This guide addresses the application of advanced oxi-

chain reaction for contaminant destruction. Scavengers can be

dation alone or in conjunction with other technologies.

either organic or inorganic compounds.

1.3 This standard does not purport to address all of the

3. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1 General—Thisguidecontainsinformationregardingthe

priate safety and health practices and determine the applica-

use of AOPs to oxidize and eventually mineralize hazardous

bility of regulatory limitations prior to use.Inaddition,itisthe

materials that have entered surface and groundwater as the

responsibility of the user to ensure that such activity takes

result of a spill. Since much of this technology development is

placeunderthecontrolanddirectionofaqualifiedpersonwith

still at the benchscale level, these guidelines will only refer to

full knowledge of any potential safety and health protocols.

those units that are currently applied at a field scale level.

3.2 Oxidizing Agents:

2. Terminology

3.2.1 Hydroxyl Radical (OH)—The OH radical is the most

2.1 Definitions of Terms Specific to This Standard:

common oxidizing agent employed by this technology due to

2.1.1 advanced oxidation processes (AOPs)—ambient tem-

its powerful oxidizing ability. When compared to other oxi-

perature processes that involve the generation of highly reac-

dants such as molecular ozone, hydrogen peroxide, or

tive radical species and lead to the oxidation of waterborne

hypochlorite, its rate of attack is commonly much faster. In

contaminants (usually organic) in surface and ground waters. 6 9

fact, it is typically one million (10 ) to one billion (10 ) times

2.1.2 inorganic foulants—compounds,suchasiron,calcium

fasterthanthecorrespondingattackwithmolecularozone (1).

and manganese, that precipitate throughout a treatment unit

The three most common methods for generating the hydroxyl

and cause reduced efficiency by fouling the quartz sleeve that

radical are described in the following equations:

protects the lamp in photolytic oxidation AOP systems or the

H O 1hv→2OH· (1)

2 2

fibreglass mesh that is coated withTiO in photocatalyticAOP

2O 1H O→→2OH·13O (2)

3 2 2 2

systems.

12 13 2

Fe 1H O→→OH·Fe 1OH Fenton’s Reaction (3)

~ !

2 2

2.1.3 mineralization—the complete oxidation of an organic

compound to carbon dioxide, water, and acid compounds, that

3.2.1.1 Hydrogen peroxide is the preferred oxidant for

is, hydrochloric acid if the compound is chlorinated.

photolyticoxidationsystemssinceozonewillencouragetheair

stripping of solutions containing volatile organics (2). Capital

2.1.4 photoreactor—the core of the photoreactor is a UV

lamp that emits light in the broad range of 200 to 400 nm andoperatingcostsarealsotakenintoaccountwhenadecision

on the choice of oxidant is made.

wavelength range.

3.2.1.2 Advancedoxidationtechnologyhasalsobeendevel-

oped based on the anatase form of titanium dioxide. This

This guide is under the jurisdiction of ASTM Committee F20 on Hazardous method by which the photocatalytic process generates hy-

Substances and Oil Spill Response and is the direct responsibility of Subcommittee

droxyl radicals is described in the following equations:

F20.22 on Mitigation Actions.

Current edition approved Nov. 1, 2007. Published November 2007. Originally

approved in 1994. Last previous edition approved in 2001 as F1524–95 (2001). Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

DOI: 10.1520/F1524-95R07. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1524 − 95 (2007)

1 2

TiO 1hv1H O→OH·1H 1e (4) 4.4 pH Adjustment—Adjusting the pH of the solution prior

2 2

2 2 to treatment may significantly affect the performance of the

2e 12O 12H O→2OH·1O 12OH (5)

2 2 2

treatment. A feed solution at a pH of 9 will tend to cause

3.2.2 Photolysis—Destruction pathways, besides the hy-

precipitation of most inorganics, while a pH of 5 will cause

droxyl radical attack, are very important for the more refrac-

themtoremaininsolutionthroughoutthetreatmentprocess.In

tory compounds such as chloroform, carbon tetrachloride,

situations where the inorganics are in a relatively low concen-

trichloroethane, and other chlorinated methane or ethane com-

tration(lowpartspermillion),onewouldtendtolowerthepH,

pounds. A photoreactor’s ability to destroy these compounds

while a higher pH would be preferable at the higher concen-

photochemically will depend on its output level at specific

trations where the inorganics could be separated and removed.

wavelengths. Since most of these lamps are proprietary,

4.5 System Fouling—Generally, inorganic foulants, such as

preliminary benchscale testing becomes crucial when dealing

iron,manganese,andcalcium,intheppmrange,causereduced

with these compounds.

flow, increased pressure and low performance of a treatment

3.3 AOP Treatment Techniques:

system. This phenomenon is common in most organic treat-

3.3.1 Advancedoxidationprocesses(AOPs)maybeapplied

ment units regardless of the mechanism employed. Pretreat-

alone or in conjunction with other treatment techniques as

ment systems usually involve chemical addition (that is, pH

follows:

adjustment) or membrane technology, or both, as they are

3.3.1.1 Following a pretreatment step. The pretreatment

generally the most economical and effective for inorganic

process can be either a physical or chemical process for the

removal. Preliminary benchscale testing is commonly used to

removal of inorganic or organic scavengers from the contami-

determine the applicability and the cost-effectiveness of the

nated stream prior to AOP destruction.

different pretreatment systems.

3.3.1.2 Following a preconcentration step. Due to the in-

4.6 Off-Gas Analysis—Organic analysis of the exiting gas-

crease in likelihood of radical or molecule contact, very dilute

eous stream will assist the operator in modifying system

solutionscanbetreatedcosteffectivelyusingAOPsafterbeing

parameters to maximize system performance and efficiency.

concentrated.

This technique is also beneficial during preliminary testing as

3.4 AOP Treatment Applications—Advanced oxidation pro-

it provides an indication of the AOP technology’s ability to

cesses (AOPs) are most cost effective for those waste streams destroy the compounds as compared to simply stripping them

containing organic compounds at concentrations below 1%

from the water phase into the air.

(10000 ppm).This figure will vary depending upon the nature

4.7 Destruction Rate Constants—The reaction of the OH

of the compounds and whether there is competition for the

radical with organic compounds is largely dependent upon the

oxidizing agent.

rate constant.Alist (3) of reaction rates for common contami-

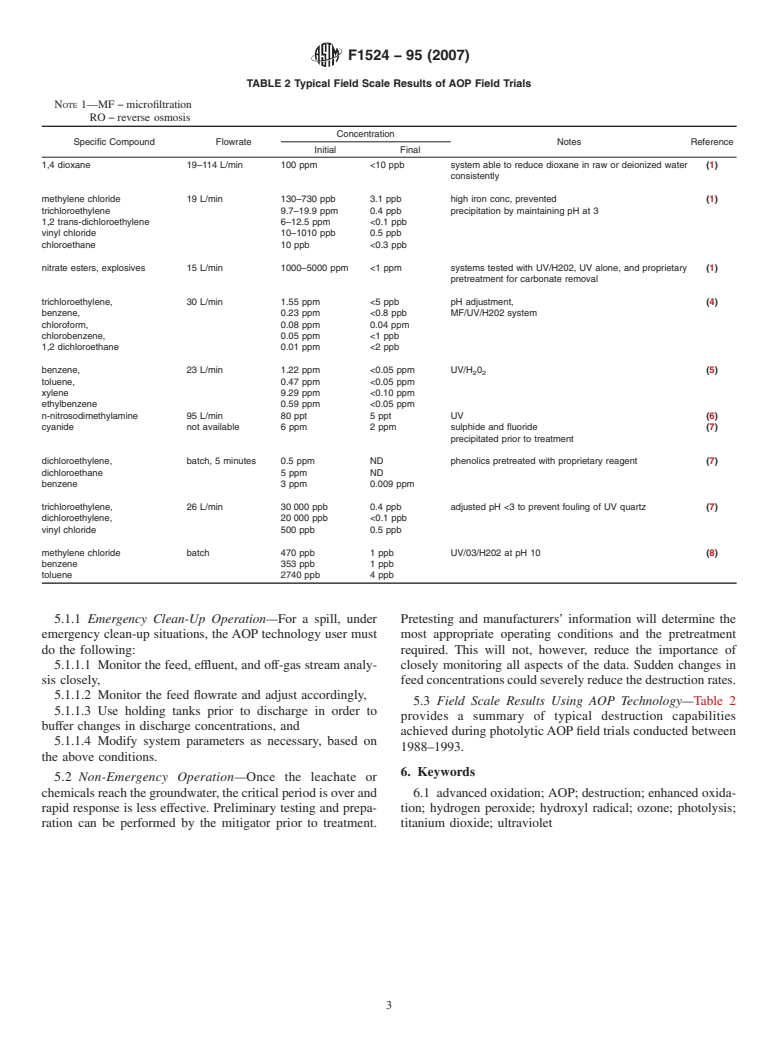

nants is shown in Table 1.

4. Constraints on Usage

5. Practical Applicat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.