ASTM B1019-21

(Test Method)Standard Test Method for Determination of Surface Oxides on Copper Rod(for Electrical Purposes)

Standard Test Method for Determination of Surface Oxides on Copper Rod<brk/>(for Electrical Purposes)

SIGNIFICANCE AND USE

5.1 The copper oxides layer present on the surface of the copper rod has a detrimental effect on both final surface quality of the copper wire produced by cold drawing of the rod, and on the drawing process itself leading to wire breaks and excessive wear of the drawing dies. Thus, it is critical to use adequate cleaning techniques during the copper rod manufacturing process in order to limit the depth of the residual copper oxide layer on the finished rod, and it is necessary to have a method to accurately measure the copper oxide depth.

5.2 This test method is the most common test method used by continuous casting and rolling mills to measure the depth of residual surface oxides after the copper rod has been cleaned.

5.3 Applicability of the test method for any other purpose or product has not been evaluated. Suitability beyond the stated scope shall be evaluated before use.

SCOPE

1.1 This specification established a quantitative, laboratory conducted, electrolytic reduction method to determine the thickness of surface copper oxide films on copper rod produced to Specification B49 for further fabrication into electrical conductors.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B1019 − 21

Standard Test Method for

Determination of Surface Oxides on Copper Rod

1

(for Electrical Purposes)

This standard is issued under the fixed designation B1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This specification established a quantitative, laboratory

E1601Practice for Conducting an Interlaboratory Study to

conducted, electrolytic reduction method to determine the

Evaluate the Performance of an Analytical Method

thicknessofsurfacecopperoxidefilmsoncopperrodproduced

E2480Practice for Conducting an Interlaboratory Study to

to Specification B49 for further fabrication into electrical

Determine the Precision of a Test Method with Multi-

conductors.

Valued Measurands

1.2 The values stated in SI units are to be regarded as

E2653Practice for Conducting an Interlaboratory Study to

standard. No other units of measurement are included in this

Determine Precision Estimates for a Fire Test Method

standard.

with Fewer Than Six Participating Laboratories

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 For definitions of related terms to copper and copper

priate safety, health, and environmental practices and deter-

alloys, refer to Terminology B846.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

4. Summary of Test Method

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

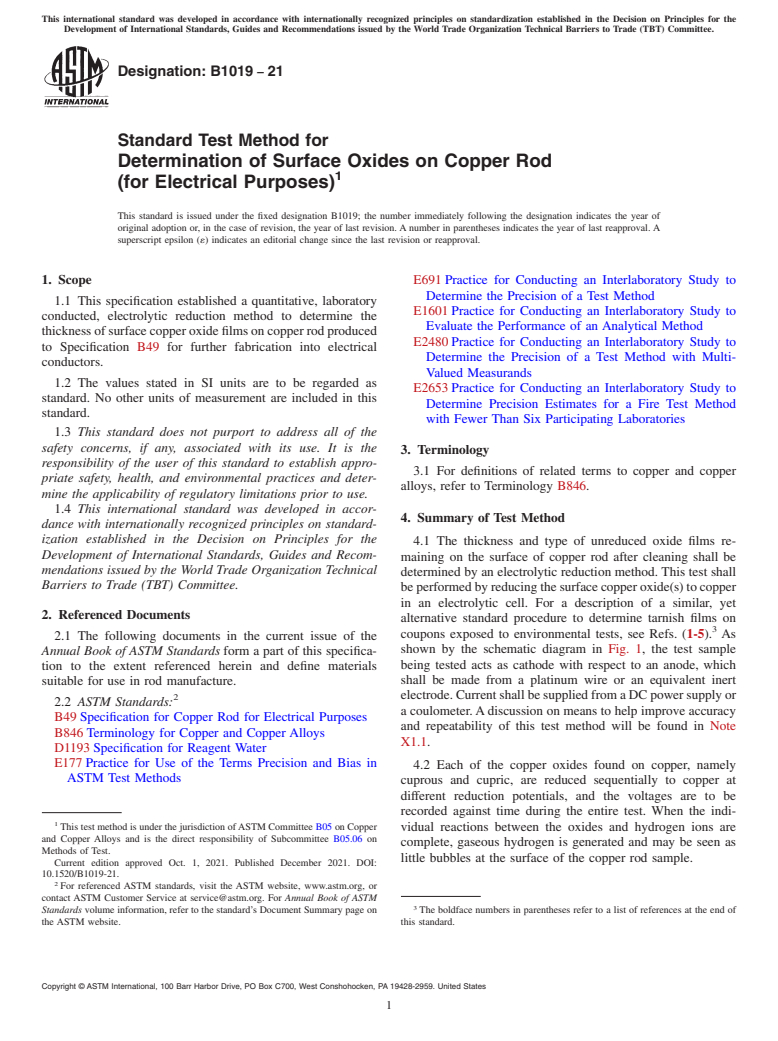

4.1 The thickness and type of unreduced oxide films re-

Development of International Standards, Guides and Recom-

maining on the surface of copper rod after cleaning shall be

mendations issued by the World Trade Organization Technical

determined by an electrolytic reduction method.This test shall

Barriers to Trade (TBT) Committee.

beperformedbyreducingthesurfacecopperoxide(s)tocopper

in an electrolytic cell. For a description of a similar, yet

2. Referenced Documents

alternative standard procedure to determine tarnish films on

3

coupons exposed to environmental tests, see Refs. (1-5). As

2.1 The following documents in the current issue of the

shown by the schematic diagram in Fig. 1, the test sample

Annual Book of ASTM Standardsform a part of this specifica-

being tested acts as cathode with respect to an anode, which

tion to the extent referenced herein and define materials

shall be made from a platinum wire or an equivalent inert

suitable for use in rod manufacture.

2 electrode.CurrentshallbesuppliedfromaDCpowersupplyor

2.2 ASTM Standards:

a coulometer.Adiscussion on means to help improve accuracy

B49Specification for Copper Rod for Electrical Purposes

and repeatability of this test method will be found in Note

B846Terminology for Copper and Copper Alloys

X1.1.

D1193Specification for Reagent Water

E177Practice for Use of the Terms Precision and Bias in

4.2 Each of the copper oxides found on copper, namely

ASTM Test Methods

cuprous and cupric, are reduced sequentially to copper at

different reduction potentials, and the voltages are to be

recorded against time during the entire test. When the indi-

1

This test method is under the jurisdiction ofASTM Committee B05 on Copper

vidual reactions between the oxides and hydrogen ions are

and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on

complete, gaseous hydrogen is generated and may be seen as

Methods of Test.

little bubbles at the surface of the copper rod sample.

Current edition approved Oct. 1, 2021. Published December 2021. DOI:

10.1520/B1019-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to a list of references at the end of

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B1019 − 21

FIG. 1 Schematic Illustration Showing Electrolytic Reduction Test Method

5.3 Applicabilityofthetestmethodforanyotherpurposeor

product h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.