ASTM F2220-14

(Specification)Standard Specification for Headforms

Standard Specification for Headforms

ABSTRACT

This specification covers the materials, sizing, and manufacturing details of test headforms for use in the testing of protective headgear. This specification identifies the requirements for five test headform size codes: A, E, J, M, and O. All datum levels shall be quoted relative to the reference plane. The headforms shall be symmetrical about the midsagittal plane. Internal geometry may be defined to satisfy the requirements of the individual test specifications. The impact headforms shall be made of K1A-F magnesium, with the prescribed zirconium and magnesium composition, and shall conform to the specified requirements for: external dimensions, performance (resonant frequency), mass, and center of gravity. All impact headforms shall be marked with: headform size, basic plane, reference plane, and midsagittal (longitudinal) and coronal (transverse) planes through the vertical axis. Other headforms shall be made of material of sufficient strength and stiffness to maintain their geometry during testing and shall comply to the external dimension requirements.

SCOPE

1.1 This standard specifies the materials, sizing, and manufacturing details of test headforms for use in the testing of protective headgear. Details of the exterior dimension of the headforms are included.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2220 −14 AnAmerican National Standard

Standard Specification for

Headforms

This standard is issued under the fixed designation F2220; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification identifies the headforms used for testing protective headgear in individualASTM

International test methods and performance standards (standard specifications).This specification was

closely based on ISO DIS 6220, which was never published as an International Standard and is no

longer available. EN 960, a published standard, is also based on ISO DIS 6220 and has been used as

a basis for this standard.

1. Scope the superior rims of the right and left external auditory

meatuses. The transverse plane corresponds to the coronal

1.1 This standard specifies the materials, sizing, and manu-

plane (see Figs. 1 and 2).

facturing details of test headforms for use in the testing of

protective headgear. Details of the exterior dimension of the

3.1.3 impact headforms, n—headforms used for impact

headforms are included.

testingofprotectiveheadgear.Impactheadformsshallconform

to the external dimension defined in this specification. These

1.2 The values stated in SI units are to be regarded as

headforms shall meet the material, dimensions, mass, and

standard. No other units of measurement are included in this

center of gravity requirements of this specification. These

standard.

headforms shall include surface markings corresponding to the

2. Referenced Documents

basic, coronal, midsagittal, and reference planes.

2.1 ASTM Standards:

3.1.4 midsagittal plane, n—ananatomicalplaneperpendicu-

B92/B92M Specification for Unalloyed Magnesium Ingot

lar to the basic plane and containing the midpoint of the line

and Stick For Remelting

connecting the notches of the right and left inferior orbital

2.2 Other Standards:

ridgesandthemidpointofthelineconnectingthesuperiorrims

EN 960 Headforms for Use in the Testing of Protective

of the right and left external auditory meatuses (see Figs. 1 and

Helmets

2).

3. Terminology 3.1.5 other (reference) headforms, n—headforms used for

other testing, other than impact, of protective headgear. They

3.1 Definitions:

shall conform to the external dimension requirements of each

3.1.1 basic plane, n—an anatomical plane that includes the

particular headform size, as specified in this specification.

superior rim of the external auditory meatuses (upper edge of

Reference headforms shall be made of material of sufficient

the external openings of the ear) and the inferior margin of the

strengthandstiffnesstomaintaintheirgeometryduringtesting.

orbit (the lowest point of the floor of the eye socket) (see Figs.

Full-chin headforms will be used as necessary. Reference

1 and 2).

headforms shall include surface markings corresponding to the

3.1.2 coronal plane, n—an anatomical plane perpendicular

basic, coronal, midsagittal, and reference planes and the vision

to both the basic and midsagittal planes and passing through

points.

3.1.6 reference plane, n—a plane marked on the headforms

This specification is under the jurisdiction ofASTM Committee F08 on Sports

ataspecifieddistanceaboveandparalleltothebasicplane(see

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Fig. 2).

Subcommittee F08.53 on Headgear and Helmets.

Current edition approved Nov. 1, 2014. Published December 2014. Originally

approved in 2002. Last previous edition approved in 2012 as F2220 – 12. DOI:

4. Classification

10.1520/F2220-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 This specification identifies the requirements for six test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

headform sizes: F2220-A, F2220-C, F2220-E, F2220-J,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. F2220-M, and F2220-O.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2220−14

5.2 Dimensions—The external dimensions that the head-

forms must conform to are identified in Annex A1. The

segment lengths from the intersection of the coronal plane,

midsagittal plane and the reference plane of the test headform

to the intersection of a horizontal angle and a point at each

datum level above the reference plane are given. The exact

geometryoftheexternalsurfacemaybedeterminedbyaspline

function or other curve fitting algorithm in order to produce a

smoothandcontinuousouterheadformsurface.Theheadforms

shall be symmetrical about the midsagittal plane. Internal

geometry may be defined to satisfy the requirements of the

individual test specifications.The resulting headform must still

comply with the other requirements of this specification.

6. Impact Headforms

6.1 Materials and Manufacture—The impact headforms

shall be made of K1A-F magnesium (nominal composition

0.7 % Zr, balance Mg; Specification B92/B92M, Grade

9980A).

6.2 Performance Requirements—The impact headforms

shall not have resonant frequencies below 2000 Hz.

6.3 Mass—The total mass of the drop assembly (including

the instrumented headform and supporting assembly) shall be

FIG. 1Anatomical Planes

described in the specific test method for evaluating protective

headgear.The mass of the impact headform may be adjusted to

accommodate the specific test method requirements.

6.4 Center of Gravity—The center of gravity of the impact

headform shall lie at a point on the central vertical axis, 12.7

mm above the reference plane.

6.5 Product Marking—All impact headforms shall be

marked with:

6.5.1 Headform size;

6.5.2 Basic plane;

6.5.3 Reference plane; and

6.5.4 Midsagittal (longitudinal) and coronal (transverse)

planes through the vertical axis.

7. Other (Reference) Headforms

7.1 Materials and Manufacture—Other headforms shall be

FIG. 2Impact Headform—Basic, Reference, Midsagittal Planes

made of material of sufficient strength and stiffness to maintain

their geometry during testing.

5. Dimensions

8. Keywords

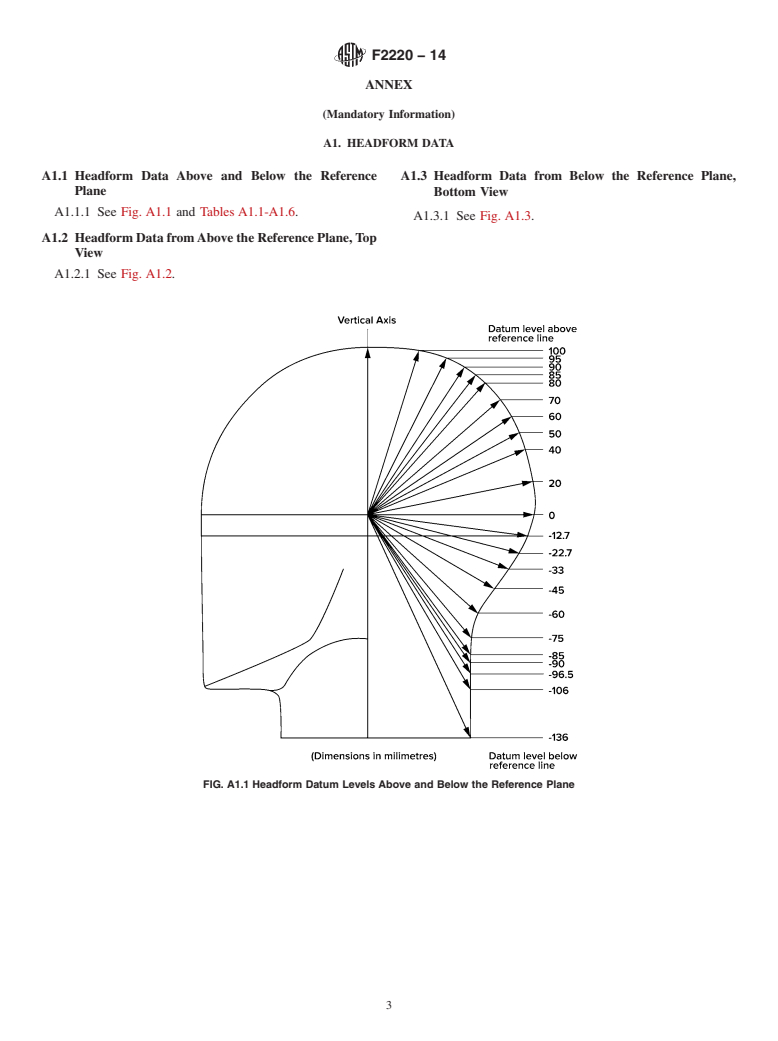

5.1 Datum Levels—All datum levels are quoted relative to

the reference plane (“0” level) and are given in mm. 8.1 headform(s); helmet(s); protective headgear

F2220−14

ANNEX

(Mandatory Information)

A1. HEADFORM DATA

A1.1 Headform Data Above and Below the Reference A1.3 Headform Data from Below the Reference Plane,

Plane

Bottom View

A1.1.1 See Fig. A1.1 and Tables A1.1-A1.6.

A1.3.1 See Fig. A1.3.

A1.2 Headform Data from Above the Reference Plane, Top

View

A1.2.1 See Fig. A1.2.

FIG. A1.1Headform Datum Levels Above and Below the Reference Plane

F2220−14

TABLE A1.1 External Dimensions for Full Headform Size F2220-A

NOTE 1—Angles in degrees, to be measured with an uncertainty of measurement not exceeding 0,20°. Segment lengths in millimetres, with a tolerance

of ±1.0 %.

NOTE 2—The jaw line should be radiused along its length to eliminate any sharp edges. The base of the neck shall be squared off perpendicular to the

central vertical axis.

Angle

F2220 - A

0° 15° 30° 45° 60° 75° 90° 105° 120° 135° 150° 165° 180°

Front Rear

85 88.2 88.1 88.0 87.9 87.9 88.0 88.2 88.7 89.7 91.3 92.5 93.0 92.7

80 88.2 88.3 88.4 88.0 87.2 86.8 86.9 87.7 89.2 91.4 93.5 93.4 93.2

Height

70 89.8 90.0 89.9 88.0 85.7 84.6 84.5 85.8 87.9 90.6 93.1 93.2 93.1

Above

60 90.6 90.6 90.2 86.7 83.5 81.8 81.7 83.3 86.1 89.3 92.3 92.6 92.5

Reference

50 90.1 90.1 89.5 84.7 80.9 78.7 78.5 80.5 83.7 87.5 91.0 91.8 91.6

Plane

40 89.1 89.0 88.2 82.4 78.1 76.0 75.6 77.7 81.2 85.6 89.5 90.9 90.7

(mm)

30 87.7 86.8 84.9 78.0 72.8 70.1 69.7 72.5 76.3 81.2 86.2 88.9 89.0

20 88.0 86.5 83.0 75.5 70.0 67.0 66.5 69.5 73.5 78.5 84.0 87.0 88.0

Reference

0 88.2 88.1 88.0 87.9 87.9 88.0 88.2 88.7 89.7 91.3 92.5 93.0 92.7

Plane

-11.1 88.7 87.2 83.2 75.3 69.4 66.9 66.9 69.4 72.9 77.8 82.3 85.2 85.7

-19.9 90.2 90.2 84.9 76.6 69.4 66.1 64.6 67.5 70.4 75.2 79.5 82.4 82.9

-30.6 93.2 94.6 86.6 77.8 71.8 69.1 63.8 65.6 68.7 73.2 77.3 79.6 80.1

Depth -39.4 96.4 97.8 88.3 79.9 74.3 71.8 66.8 67.7 70.1 73.0 76.0 78.2 77.7

Below -52.5 102.5 103.8 93.2 85.1 80.1 75.3 73.5 73.9 75.0 77.1 79.0 79.7 78.6

Reference -65.6 109.8 111.0 100.0 92.3 87.9 84.0 82.8 83.1 83.4 84.0 84.3 85.0 85.3

Plane -74.4 115.2 116.4 104.6 97.2 94.3 90.2 89.9 90.2 90.5 91.1 91.3 91.9 92.2

(mm) -78.8 118.1 119.2 106.4 100.6 93.1 93.3 93.6 93.9 94.1 94.7 95.0 95.5 95.8

-84.4 121.9 123.0 109.3 96.8 97.8 98.1 98.4 98.6 98.9 99.4 99.7 100.2 100.5

-92.8 127.9 130.7 104.3 104.3 105.2 105.4 105.7 105.9 106.1 106.6 106.9 107.4 107.6

-119.0 127.9 127.9 128.1 128.1 128.9 129.1 129.3 129.5 129.7 130.1 130.3 130.7 130.9

Distance from reference plane to top of headform: 89.7 mm

Depth to basic plane: -24.0 mm

TABLE A1.2 External Dimensions for Full Headform Size F2220-C

NOTE 1—Angles in degrees, to be measured with an uncertainty of measurement not exceeding 0,20°. Segment lengths in millimetres, with a tolerance

of ±1.0 %.

NOTE 2—The jaw line should be radiused along its length to eliminate any sharp edges. The base of the neck shall be squared off perpendicular to the

central vertical axis.

Angle

F2220 - C

0° 15° 30° 45° 60° 75° 90° 105° 120° 135° 150° 165° 180°

Front Rear

90 92.3 92.2 92.0 91.9 91.9 91.9 92.1 92.5 93.2 94.1 94.9 95.2 95.1

85 92.1 92.0 91.8 91.4 90.9 90.7 90.9 91.7 93.0 94.8 96.2 96.4 96.3

Height

80 92.4 92.4 92.3 91.4 90.2 89.7 89.9 90.9 92.6 95.0 96.6 96.9 96.9

Above

70 93.8 93.5 93.1 91.0 88.5 87.4 87.6 88.9 91.3 94.3 96.3 96.9 96.9

Reference

60 94.2 93.7 93.0 89.8 86.3 84.6 84.6 86.3 89.3 92.8 95.3 96.2 96.3

Plane

50 93.8 93.1 92.2 87.9 83.6 81.5 81.4 83.5 86.9 90.8 93.9 95.1 95.5

(mm)

40 93.1 92.1 90.8 85.7 80.7 78.6 78.6 80.7 84.2 88.7 92.4 94.1 94.9

20 91.8 90.1 87.8 81.5 75.4 72.9 72.4 75.4 79.6 84.5 89.1 91.9 92.7

Reference

0 91.5 89.5 86.0 79.0 72.5 70.0 69.5 72.5 77.0 82.0 87.5 90.5 91.5

Plane

-11.5 92.2 90.2 86.3 77.9 71.9 69.5 69.5 71.9 75.4 80.8 85.3 88.3 88.7

-20.6 93.8 93.3 87.9 79.2 72.0 68.7 67.2 69.6 73.0 78.3 82.6 85.5 86.0

-31.8 96.9 97.8 89.8 80.5 74.2 71.9 66.1 68.3 71.5 76.0 80.1 82.4 82.8

Depth -40.8 100.2 101.1 91.1 82.3 77.2 74.2 69.3 70.1 72.6 75.9 78.9 81.0 80.6

Below -54.4 106.5 107.3 96.7 88.3 82.9 78.1 76.3 76.7 77.7 79.9 81.7 82.5 81.7

Reference -68 114.0 114.8 103.5 95.5 91.4 87.1 85.6 86.2 87.8 87.1 87.5 88.1 88.4

Plane -77.1 119.7 120.4 108.3 100.8 97.7 93.3 93.0 93.6 93.8 94.4 94.7 95.3 95.6

(mm) -81.7 122.7 123.4 110.2 102.9 96.3 96.6 96.8 97.4 97.7 98.2 98.5 99.0 99.3

-87.6 126.7 127.4 113.4 100.6 101.4 101.6 101.9 102.4 102.5 103.1 103.4 104.0 104.1

-96.2 132.8 133.5 108.0 108.2 108.9 109.1 109.4 109.8 110.0 110.5 110.8 111.3 111.4

-123.4 132.6 132.6 132.8 133.0 133.5 133.7 133.9 134.3 134.4 134.9 135.1 135.5 135.6

Distance from reference plane to top of headform: 91.2 mm

Depth to basic plane: -25.0 mm

F2220−14

TABLE A1.3 External Dimensions for Full Headform Size F2220-E

NOTE 1—Angles in degrees, to be measured with an uncertainty of measurement not exceeding 0,20°. Segment lengths in millimetres, with a tolerance

of ±1.0 %.

NOTE 2—The jaw line should be radiused along its length to eliminate any sharp edges. The base of the neck shall be squared off perpendicular to the

central vertical axis.

Angle

F2220 - E

0° 15° 30° 45° 60° 75° 90° 105° 120° 135° 150° 165° 180°

Front Rear

95 95.5 95.5 95.5 95.5 95.5 95.6 95.7 95.9 96.1 96.3 96.4 96.4 96.4

90 94.4 94.4 94.3 94.3 94.4 94.5 94.7 95.2 96.1 97.5 98.8 99.2 99.1

85 94.5 94.6 94.7 94.4 93.7 93.5 93.7 94.4 95.6 97.7 99.5 99.9 99.8

Height

Above 80 95.3 95.4 95.5 94.5 93.1 92.5 92.7 93.7 95.1 97.6 99.7 100.1 100.0

Reference 70 96.8 97.0 96.4 94.2 91.5 90.2 90.2 91.5 93.7 96.8 99.5 100.0 99.8

Plane 60 97.1 97.3 96.2 92.9 89.4 87.4 87.3 89.0 91.8 95.3 98.7 99.2 99.1

(mm)

50 96.5 96.8 95.3 91.0 86.8 84.4 84.2 86.2 89.4 93.4 97.5 98.2 98.2

40 95.7 95.8 93.9 88.8 84.2 81.3 81.6 83.8 86.9 91.4 96.3 97.3 97.3

20 94.5 93.6 91.2 84.6 79.1 76.2 76.0 78.7 82.5 87.4 92.8 95.3 95.7

Reference

0 94.5 93.0 90.0 82.0 76.5 73.5 73.0 76.0 80.0 85.0 91.0 94.0 94.5

Plane

-11.9 95.2 93.8 89.3 80.4 74.0 71.5 71.5 74.0 77.9 83.4 87.8 91.3 91.8

-21.3 96.9 96.4 91.0 82.3 74.1 70.8 69.4 72.2 75.1 80.4 85.2 88.1 88.6

-32.8 100.0 101.0 92.5 83.2 76.9 74.1 68.4 70.6 73.7 78.2 82.8 85.1 85.5

Depth -42.1 103.5 104.4 94.4 85.1 79.6 76.6 71.3 72.5 74.9 78.3 81.7 83.4 83.0

Below -56.2 109.9 110.8 99.8 90.9 85.5 80.4 79.0 79.0 80.0 82.6 84.4 85.2 84.4

Reference -70.2 117.7 118.5 106.8 98.8 94.0 89.8 88.6 89.2 89.5 89.8 90.1 90.7 91.1

Plane -79.6 123.6 124.3 111.8 104.0 100.9 96.5 96.2 96.8 97.0 97.3 97.6 98.2 98.5

(mm) -84.3 126.6 127.4 113.8 106.1 99.6 99.8 100.1 100.7 100.9 101.2 101.5 102.0 102.3

-90.4 130.8 131.5 117.1 103.8 104.8 105.0 105.3 105.8 106.1 106.3 106.6 107.1 107.4

-99.3 137.1 139.9 111.4 111.6 112.6 112.8 113.0 113.5 113.8 114.0 114.2 114.7 115.0

-127.4 136.9 136.9 137.0 137.2 138.0 138.2 138.4 138.8 139.0 139.2 139.4 139.8 140.0

Distance from reference plane to top of headform: 96.0 mm

Depth to basic plane: -26.0 mm

TABLE A1.4 External Dimensions for Full Headform Size F2220-J

NOTE 1—Angles in degrees, to be measured with an uncertainty of measurement not exceeding 0,20°. Segment lengths in millimetres, with a tolerance

of ±1.0 %.

NOTE 2—The jaw line should be radiused along its length to eliminate any sharp edges. The base of the neck shall be squared off perpendicular to the

central vertical axis.

Angle

F2220 - J

0° 15° 30° 45° 60° 75° 90° 105° 120° 135° 150° 165° 180°

Front Rear

102.5 102.5 102.5 102.5 102.5 102.5 102.5 102.5 102.5 102.5 102.5 102.5 102.5 102.5

100 102.0 101.9 101.8 101.7 101.6 101.7 101.9 102.2 102.8 103.6 104.4 104.8 104.7

95 102.0 101.8 101.4 101.0 100.7 100.6 100.9 101.7 102.9 104.5 105.9 106.4 106.3

Height 90 102.3 102.2 101.7 100.9 100.1 99.8 100.1 101.0 102.6 104.7 106.4 107.0 106.9

Above 85 102.8 102.6 102.1 100.9 99.5 98.9 99.15 100.3 102.1 104.5 106.5 107.1 107.1

Reference 80 103.2 103.0 102.3 100.7 98.8 97.8 98.1 99.4 101.5 104.0 106.3 107.1 107.0

Plane 70 103.5 103.1 102.1 99.8 96.9 95.4 95.6 97.2 99.7 102.8 105.5 106.5 106.4

(mm)

60 103.1 102.6 101.3 97.9 94.6 92.6 92.9 94.7 97.6 101.1 104.3 105.5 105.5

50 102.6 101.7 100.0 96.5 92.0 89.7 90.1 92.1 95.2 99.3 102.9 104.4 104.5

40 101.5 100.7 98.5 94.3 89.2 86.9 87.3 89.5 92.9 97.4 101.3 103.3 103.4

20 100.6 99.2 95.8 90.1 84.6 81.9 82.0 84.5 88.5 94.0 98.5 101.3 101.6

Reference

0 101.0 99.5 95.5 88.5 82.5 79.5 79.5 82.0 86.0 92 .0 97.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2220 − 12 F2220 − 14 An American National Standard

Standard Specification for

Headforms

This standard is issued under the fixed designation F2220; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification identifies the headforms used for testing protective headgear in individual ASTM

International test methods and performance standards (standard specifications). This specification was

closely based on ISO DIS 6220, which was never published as an International Standard and is no

longer available. EN 960, a published standard, is also based on ISO DIS 6220 and has been used as

a basis for this standard.

1. Scope

1.1 This standard specifies the materials, sizing, and manufacturing details of test headforms for use in the testing of protective

headgear. Details of the exterior dimension of the headforms are included.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

2. Referenced Documents

2.1 ASTM Standards:

B92/B92M Specification for Unalloyed Magnesium Ingot and Stick For Remelting

2.2 Other Standards:

EN 960 Headforms for Use in the Testing of Protective Helmets

3. Terminology

3.1 Definitions:

3.1.1 basic plane, n—an anatomical plane that includes the superior rim of the external auditory meatuses (upper edge of the

external openings of the ear) and the inferior margin of the orbit (the lowest point of the floor of the eye socket) (see Figs. 1 and

2).

3.1.2 coronal plane, n—an anatomical plane perpendicular to both the basic and midsagittal planes and passing through the

superior rims of the right and left external auditory meatuses. The transverse plane corresponds to the coronal plane (see Figs. 1

and 2).

3.1.3 impact headforms, n—headforms used for impact testing of protective headgear. Impact headforms shall conform to the

external dimension defined in this specification. These headforms shall meet the material, dimensions, mass, and center of gravity

requirements of this specification. These headforms shall include surface markings corresponding to the basic, coronal, midsagittal,

and reference planes.

3.1.4 midsagittal plane, n—an anatomical plane perpendicular to the basic plane and containing the midpoint of the line

connecting the notches of the right and left inferior orbital ridges and the midpoint of the line connecting the superior rims of the

right and left external auditory meatuses (see Figs. 1 and 2).

3.1.5 other (reference) headforms, n—headforms used for other testing, other than impact, of protective headgear. They shall

conform to the external dimension requirements of each particular headform size, as specified in this specification. Reference

headforms shall be made of material of sufficient strength and stiffness to maintain their geometry during testing. Full-chin

This specification is under the jurisdiction of ASTM Committee F08 on Sports Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.53 on Headgear and Helmets.

Current edition approved Nov. 1, 2012Nov. 1, 2014. Published January 2013December 2014. Originally approved in 2002. Last previous edition approved in 20112012

as F2220 – 11.F2220 – 12. DOI: 10.1520/F2220-12.10.1520/F2220-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2220 − 14

FIG. 1 Anatomical Planes

FIG. 2 Impact Headform—Basic, Reference, Midsagittal Planes

headforms will be used as necessary. Reference headforms shall include surface markings corresponding to the basic, coronal,

midsagittal, and reference planes and the vision points.

3.1.6 reference plane, n—a plane marked on the headforms at a specified distance above and parallel to the basic plane (see Fig.

2).

4. Classification

4.1 This specification identifies the requirements for six test headform sizes: F2220A,-A, F2220C,-C, F2220E,-E, F2220J,-J,

F2220M,-M, and F2220O. The size codes used for headforms relate to the nominal inside circumference of helmets (see -O.Table

1). The nominal inside circumference values refer to the internal circumference of the helmet measured at a datum level 12.7 mm

above the reference plane.

5. Dimensions

5.1 Datum Levels—All datum levels are quoted relative to the reference plane (“0” level) and are given in mm.

F2220 − 14

5.2 Dimensions—The external dimensions that the headforms must conform to are identified in Annex A1. The segment lengths

from the intersection of the coronal plane, midsagittal plane and the reference plane of the test headform to the intersection of a

horizontal angle and a point at each datum level above the reference plane are given. The exact geometry of the external surface

may be determined by a spline function or other curve fitting algorithm in order to produce a smooth and continuous outer

headform surface. The headforms shall be symmetrical about the midsagittal plane. Internal geometry may be defined to satisfy

the requirements of the individual test specifications. The resulting headform must still comply with the other requirements of this

specification.

6. Impact Headforms

6.1 Materials and Manufacture—The impact headforms shall be made of K1A-F magnesium (nominal composition 0.7 % Zr,

balance Mg; Specification B92/B92M, Grade 9980A).

6.2 External Dimensions—Impact headforms shall comply with the exterior dimensions given in Annex A1. The spherical

coordinates of the horizontal half-sections at each datum level above the reference plane are given.

6.2 Performance Requirements—The impact headforms shall not have resonant frequencies below 2000 Hz.

6.3 Mass—The total mass of the drop assembly (including the instrumented headform and supporting assembly) shall be

described in the specific test method for evaluating protective headgear. The mass of the impact headform may be adjusted to

accommodate the specific test method requirements.

6.4 Center of Gravity—The center of gravity of the impact headform shall lie at a point on the central vertical axis, 12.7 mm

above the reference plane.

6.5 Product Marking—All impact headforms shall be marked with:

6.5.1 Headform size;

6.5.2 Basic plane;

6.5.3 Reference plane; and

6.5.4 Midsagittal (longitudinal) and coronal (transverse) planes through the vertical axis.

7. Other (Reference) Headforms

7.1 Materials and Manufacture—Other headforms shall be made of material of sufficient strength and stiffness to maintain their

geometry during testing.

7.2 External Dimensions—Other headforms shall comply with the external dimensions given in Annex A1. The spherical

coordinates of the horizontal half-sections at each datum level are given.

7.2.1 Product Marking—All headforms shall be marked with:

7.2.1.1 Headform size;

7.2.1.2 Basic plane;

7.2.1.3 Reference plane;

7.2.1.4 Midsagittal (longitudinal) and coronal (transverse) planes through the vertical axis; and

7.2.1.5 Two points located on the basic plane equally spaced 31 mm each side of the point defined by the intersection of the

basic and midsagittal planes at the front of the headform.

8. Keywords

8.1 headform(s); helmet(s); protective headgear

ANNEX

(Mandatory Information)

A1. HEADFORM DATA ABOVE THE REFERENCE PLANE

A1.1 Headform Data Above and Below the Reference Plane A1.1 See Tables A1.1-A1.6.

A1.1.1 See Fig. A1.1 and Tables A1.1-A1.6.

A1.2 Headform Data from Above the Reference Plane, Top View

A1.2.1 See Fig. A1.2.

F2220 − 14

A1.3 Headform Data from Below the Reference Plane, Bottom View

A1.3.1 See Fig. A1.3.

FIG. A1.1 Headform Datum Levels Above and Below the Reference Plane

F2220 − 14

TABLE A1.1 Spherical Coordinates for Full Headform Size 495

NOTE 1—V = Vertical angle above or below the reference plane; H = Angle of vertical slice, measured in horizontal plane, from front of mid-sagittal

plane.

NOTE 1—Angles in degrees, to be measured with an uncertainty of measurement not exceeding 0,20°. Radii in millimetres, with a tolerance of

0,5 % and measured with an uncertainty of measurement not exceeding 0,1 mm.

NOTE 2—The jaw line shall be radiused along its length with a nominal 5 mm radius. The base of the neck shall be squared off perpendicular to the

central vertical axis.

NOTE 4—The surface corresponding to the radii shown in italics lies below the jaw line.

Angle H

1 - 495

0 15 30 45 60 75 90 105 120 135 150 165

90 89,3 89,3 89,3 89,3 89,3 89,3 89,3 89,3 89,3 89,3 89,3 89,3 89,3

80 88,2 88,0 88,0 88,1 88,3 88,7 88,8 89,1 89,8 90,1 90,8 90,9 90,8

70 87,7 87,7 87,7 87,7 87,5 87,4 87,6 88,4 89,8 91,1 92,1 92,4 92,3

Angle V 60 88,5 88,5 88,6 87,6 86,2 85,3 85,6 86,9 88,8 91,3 93,0 93,2 93,2

above 50 89,8 89,8 89,8 87,2 84,3 82,6 82,6 84,4 87,0 90,4 93,1 93,2 93,2

40 90,4 90,3 90,1 85,8 81,4 79,0 78,9 81,1 84,4 88,7 92,3 92,4 92,5

30 89,8 89,6 88,8 83,1 77,8 74,9 74,7 77,2 81,3 86,1 90,5 91,3 91,5

20 88,4 87,8 86,2 79,7 73,8 70,8 70,6 73,4 77,6 82,9 88,2 89,9 90,3

10 87,4 86,2 83,8 76,5 70,6 67,4 67,3 70,3 74,2 79,8 85,6 88,5 89,0

Reference

0 87,8 86,1 82,7 75,2 69,5 66,4 66,2 69,0 73,1 78,4 83,8 87,2 87,8

Plane

10 89,2 88,2 83,9 75,3 69,0 66,6 66,6 68,8 72,0 77,0 81,0 83,8 84,3

20 93,5 94,7 86,0 77,0 69,9 66,6 63,9 66,3 69,2 73,5 77,4 79,8 80,4

30 101,4 102,9 89,8 79,4 73,3 70,5 64,1 65,8 68,9 73,0 76,5 78,3 77,7

40 114,7 116,2 98,5 86,5 78,9 72,4 68,6 69,3 71,8 74,9 77,3 78,4 77,4

Angle V

46 126,5 128,2 104,5 92,8 84,8 76,6 73,7 74,3 76,0 78,4 79,9 80,8 80,5

Below

50 122,5 123,7 108,4 96,8 90,4 81,9 78,7 79,5 80,7 82,6 83,7 84,7 84,9

52 119,3 120,4 108,5 98,6 93,7 85,0 81,8 82,7 83,8 85,5 86,5 87,6 88,1

55 114,9 116,0 107,0 99,0 93,7 89,2 87,5 88,6 89,6 91,2 92,1 93,4 94,2

60 108,6 109,5 105,0 98,1 99,6 99,7 100,2 101,8 103,0 104,7 105,7 107,5 108,5

65 113,2 115,1 111,9 113,4 117,4 117,5 118,8 120,6 122,1 124,2 125,4 127,3 128,3

TABLE A1.1 External Dimensions for Full Headform Size F2220-A

NOTE 1—Angles in degrees, to be measured with an uncertainty of measurement not exceeding 0,20°. Segment lengths in millimetres, with a tolerance

of ±1.0 %.

NOTE 2—The jaw line should be radiused along its length to eliminate any sharp edges. The base of the neck shall be squared off perpendicular to the

central vertical axis.

Angle

F2220 - A

0° 15° 30° 45° 60° 75° 90° 105° 120° 135° 150° 165° 180°

Front Rear

85 88.2 88.1 88.0 87.9 87.9 88.0 88.2 88.7 89.7 91.3 92.5 93.0 92.7

80 88.2 88.3 88.4 88.0 87.2 86.8 86.9 87.7 89.2 91.4 93.5 93.4 93.2

Height

70 89.8 90.0 89.9 88.0 85.7 84.6 84.5 85.8 87.9 90.6 93.1 93.2 93.1

Above

60 90.6 90.6 90.2 86.7 83.5 81.8 81.7 83.3 86.1 89.3 92.3 92.6 92.5

Reference

50 90.1 90.1 89.5 84.7 80.9 78.7 78.5 80.5 83.7 87.5 91.0 91.8 91.6

Plane

40 89.1 89.0 88.2 82.4 78.1 76.0 75.6 77.7 81.2 85.6 89.5 90.9 90.7

(mm)

30 87.7 86.8 84.9 78.0 72.8 70.1 69.7 72.5 76.3 81.2 86.2 88.9 89.0

20 88.0 86.5 83.0 75.5 70.0 67.0 66.5 69.5 73.5 78.5 84.0 87.0 88.0

Reference

0 88.2 88.1 88.0 87.9 87.9 88.0 88.2 88.7 89.7 91.3 92.5 93.0 92.7

Plane

-11.1 88.7 87.2 83.2 75.3 69.4 66.9 66.9 69.4 72.9 77.8 82.3 85.2 85.7

-19.9 90.2 90.2 84.9 76.6 69.4 66.1 64.6 67.5 70.4 75.2 79.5 82.4 82.9

-30.6 93.2 94.6 86.6 77.8 71.8 69.1 63.8 65.6 68.7 73.2 77.3 79.6 80.1

Depth -39.4 96.4 97.8 88.3 79.9 74.3 71.8 66.8 67.7 70.1 73.0 76.0 78.2 77.7

Below -52.5 102.5 103.8 93.2 85.1 80.1 75.3 73.5 73.9 75.0 77.1 79.0 79.7 78.6

Reference -65.6 109.8 111.0 100.0 92.3 87.9 84.0 82.8 83.1 83.4 84.0 84.3 85.0 85.3

Plane

-74.4 115.2 116.4 104.6 97.2 94.3 90.2 89.9 90.2 90.5 91.1 91.3 91.9 92.2

(mm) -78.8 118.1 119.2 106.4 100.6 93.1 93.3 93.6 93.9 94.1 94.7 95.0 95.5 95.8

-84.4 121.9 123.0 109.3 96.8 97.8 98.1 98.4 98.6 98.9 99.4 99.7 100.2 100.5

-92.8 127.9 130.7 104.3 104.3 105.2 105.4 105.7 105.9 106.1 106.6 106.9 107.4 107.6

-119.0 127.9 127.9 128.1 128.1 128.9 129.1 129.3 129.5 129.7 130.1 130.3 130.7 130.9

Distance from reference plane to top of headform: 89.7 mm

Depth to basic plane: -24.0 mm

F2220 − 14

TABLE A1.2 Spherical Coordinates for Full Headform Size 515

NOTE 1—V = Vertical angle above or below the reference plane; H = Angle of vertical slice, measured in horizontal plane, from front of mid-sagittal

plane.

NOTE 1—Angles in degrees, to be measured with an uncertainty of measurement not exceeding 0,20°. Radii in millimetres, with a tolerance of

0,5 % and measured with an uncertainty of measurement not exceeding 0,1 mm.

NOTE 2—The jaw line shall be radiused along its length with a nominal 5 mm radius. The base of the neck shall be squared off perpendicular to the

central vertical axis.

NOTE 4—The surface corresponding to the radii shown in italics lies below the jaw line.

Angle H

1 - 515

0 15 30 45 60 75 90 105 120 135 150 165

90 92,5 92,5 92,5 92,5 92,5 92,5 92,5 92,5 92,5 92,5 92,5 92,5 92,5

80 91,4 91,2 91,2 91,3 91,6 92,0 92,0 92,4 93,1 93,4 94,0 94,1 94,1

70 90,9 90,9 90,9 90,9 90,7 90,6 90,8 91,6 93,0 94,3 95,4 95,6 95,6

Angle V 60 91,7 91,7 91,7 90,8 89,5 88,6 88,8 90,1 92,0 94,5 96,3 96,5 96,4

above 50 93,0 93,0 93,0 90,4 87,5 85,8 85,8 87,7 90,3 93,7 96,4 96,4 96,4

40 93,6 93,5 93,3 89,0 84,7 82,3 82,2 84,4 87,7 91,9 95,5 95,7 95,7

30 93,0 92,8 92,0 86,4 81,0 81,0 78,2 78,0 78,0 80,5 84,6 89,3 94,7

20 91,6 91,0 89,5 83,0 77,1 74,1 73,9 76,7 80,9 86,2 91,4 93,1 93,5

10 90,6 89,4 87,1 79,8 73,9 70,8 70,6 73,6 77,5 83,1 88,9 91,7 92,3

Reference

0 91,1 89,4 86,0 78,4 72,7 69,7 69,4 72,1 76,3 81,6 87,0 90,4 91,1

Plane

10 92,5 91,5 86,9 78,0 71,4 69,0 69,1 71,2 74,6 79,7 83,9 86,8 87,3

20 96,9 98,1 89,1 79,7 72,4 69,0 66,2 68,7 71,7 76,2 80,2 82,7 83,3

30 105,2 106,6 93,0 82,3 75,9 73,0 66,5 68,2 71,4 75,6 79,3 81,1 80,5

40 118,9 120,4 102,1 89,6 81,7 75,1 71,1 71,8 74,3 77,6 80,0 81,2 80,2

Angle V

46 131,1 132,8 108,2 96,1 87,8 79,3 76,4 77,1 78,7 81,2 82,8 83,7 83,3

Below

50 126,7 127,6 112,3 100,3 93,6 84,7 81,6 82,4 83,6 85,6 86,7 87,7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.