ASTM C1341-13(2018)

(Test Method)Standard Test Method for Flexural Properties of Continuous Fiber-Reinforced Advanced Ceramic Composites

Standard Test Method for Flexural Properties of Continuous Fiber-Reinforced Advanced Ceramic Composites

SIGNIFICANCE AND USE

5.1 This test method is used for material development, quality control, and material flexural specifications. Although flexural test methods are commonly used to determine design strengths of monolithic advanced ceramics, the use of flexure test data for determining tensile or compressive properties of CFCC materials is strongly discouraged. The nonuniform stress distributions in the flexure test specimen, the dissimilar mechanical behavior in tension and compression for CFCCs, low shear strengths of CFCCs, and anisotropy in fiber architecture all lead to ambiguity in using flexure results for CFCC material design data (1-4).3 Rather, uniaxial-forced tensile and compressive tests are recommended for developing CFCC material design data based on a uniformly stressed test condition.

5.2 In this test method, the flexure stress is computed from elastic beam theory with the simplifying assumptions that the material is homogeneous and linearly elastic. This is valid for composites where the principal fiber direction is coincident/transverse with the axis of the beam. These assumptions are necessary to calculate a flexural strength value, but limit the application to comparative type testing such as used for material development, quality control, and flexure specifications. Such comparative testing requires consistent and standardized test conditions, that is, test specimen geometry/thickness, strain rates, and atmospheric/test conditions.

5.3 Unlike monolithic advanced ceramics which fracture catastrophically from a single dominant flaw, CFCCs generally experience “graceful” fracture from a cumulative damage process. Therefore, the volume of material subjected to a uniform flexural stress may not be as significant a factor in determining the flexural strength of CFCCs. However, the need to test a statistically significant number of flexure test specimens is not eliminated. Because of the probabilistic nature of the strength of the brittle matrices and of the ceramic...

SCOPE

1.1 This test method covers the determination of flexural properties of continuous fiber-reinforced ceramic composites in the form of rectangular bars formed directly or cut from sheets, plates, or molded shapes. Three test geometries are described as follows:

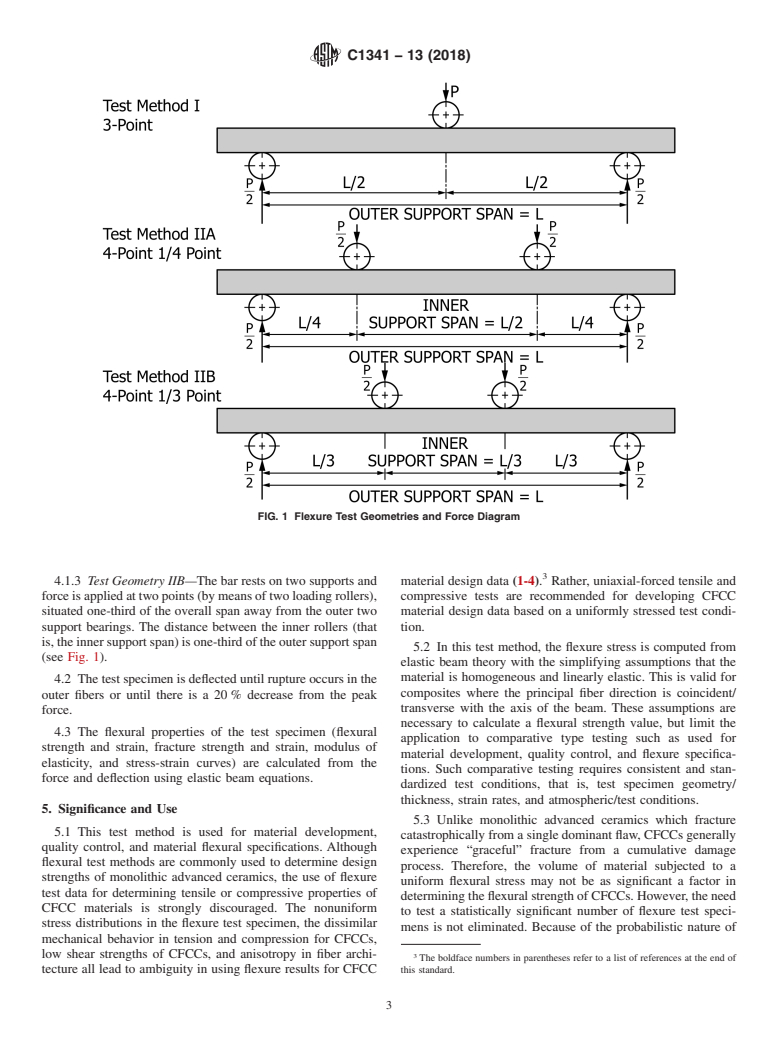

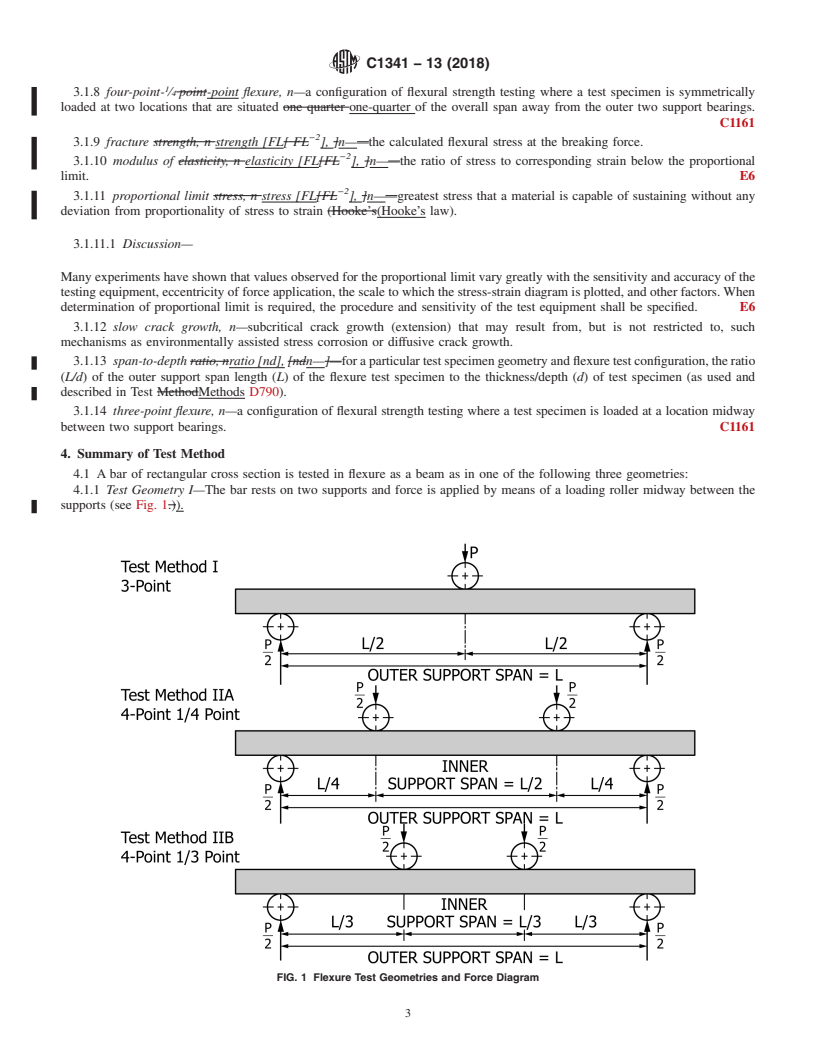

1.1.1 Test Geometry I—A three-point loading system utilizing center point force application on a simply supported beam.

1.1.2 Test Geometry IIA—A four-point loading system utilizing two force application points equally spaced from their adjacent support points, with a distance between force application points of one-half of the support span.

1.1.3 Test Geometry IIB—A four-point loading system utilizing two force application points equally spaced from their adjacent support points, with a distance between force application points of one-third of the support span.

1.2 This test method applies primarily to all advanced ceramic matrix composites with continuous fiber reinforcement: unidirectional (1D), bidirectional (2D), tridirectional (3D), and other continuous fiber architectures. In addition, this test method may also be used with glass (amorphous) matrix composites with continuous fiber reinforcement. However, flexural strength cannot be determined for those materials that do not break or fail by tension or compression in the outer fibers. This test method does not directly address discontinuous fiber-reinforced, whisker-reinforced, or particulate-reinforced ceramics. Those types of ceramic matrix composites are better tested in flexure using Test Methods C1161 and C1211.

1.3 Tests can be performed at ambient temperatures or at elevated temperatures. At elevated temperatures, a suitable furnace is necessary for heating and holding the test specimens at the desired testing temperatures.

1.4 This test method includes the following:

Section

Scope

1

Referenced Documents

2

Terminology

3

Summary of Test Method

...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1341 − 13 (Reapproved 2018)

Standard Test Method for

Flexural Properties of Continuous Fiber-Reinforced

1

Advanced Ceramic Composites

This standard is issued under the fixed designation C1341; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

Referenced Documents 2

Terminology 3

1.1 This test method covers the determination of flexural

Summary of Test Method 4

properties of continuous fiber-reinforced ceramic composites Significance and Use 5

Interferences 6

in the form of rectangular bars formed directly or cut from

Apparatus 7

sheets, plates, or molded shapes. Three test geometries are

Precautionary Statement 8

Test Specimens 9

described as follows:

Procedures 10

1.1.1 Test Geometry I—A three-point loading system utiliz-

Calculation of Results 11

ing center point force application on a simply supported beam.

Report 12

1.1.2 Test Geometry IIA—A four-point loading system uti- Precision and Bias 13

Keywords 14

lizing two force application points equally spaced from their

References

adjacent support points, with a distance between force appli-

CFCC Surface Condition and Finishing Annex A1

Conditions and Issues in Hot Loading of Test Annex A2

cation points of one-half of the support span.

Specimens into Furnaces

1.1.3 Test Geometry IIB—A four-point loading system uti-

Toe Compensation on Stress-Strain Curves Annex A3

lizing two force application points equally spaced from their

Corrections for Thermal Expansion in Flexural Annex A4

Equations

adjacent support points, with a distance between force appli-

Example of Test Report Appendix X1

cation points of one-third of the support span.

1.5 The values stated in SI units are to be regarded as the

1.2 This test method applies primarily to all advanced

standard in accordance with IEEE/ASTM SI 10.

ceramic matrix composites with continuous fiber reinforce-

1.6 This standard does not purport to address all of the

ment: unidirectional (1D), bidirectional (2D), tridirectional

safety concerns, if any, associated with its use. It is the

(3D), and other continuous fiber architectures. In addition, this

responsibility of the user of this standard to establish appro-

test method may also be used with glass (amorphous) matrix

priate safety, health, and environmental practices and deter-

composites with continuous fiber reinforcement. However,

mine the applicability of regulatory limitations prior to use.

flexural strength cannot be determined for those materials that

1.7 This international standard was developed in accor-

do not break or fail by tension or compression in the outer

dance with internationally recognized principles on standard-

fibers. This test method does not directly address discontinuous

ization established in the Decision on Principles for the

fiber-reinforced, whisker-reinforced, or particulate-reinforced

Development of International Standards, Guides and Recom-

ceramics. Those types of ceramic matrix composites are better

mendations issued by the World Trade Organization Technical

tested in flexure using Test Methods C1161 and C1211.

Barriers to Trade (TBT) Committee.

1.3 Tests can be performed at ambient temperatures or at

elevated temperatures. At elevated temperatures, a suitable

2. Referenced Documents

furnace is necessary for heating and holding the test specimens

2

2.1 ASTM Standards:

at the desired testing temperatures.

C1145 Terminology of Advanced Ceramics

1.4 This test method includes the following:

C1161 Test Method for Flexural Strength of Advanced

Section

Ceramics at Ambient Temperature

Scope 1

C1211 Test Method for Flexural Strength of Advanced

Ceramics at Elevated Temperatures

1

This test method is under the jurisdiction of ASTM Committee C28 on

Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on

2

Ceramic Matrix Composites. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2018. Published July 2018. Originally approved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1996. Last previous edition approved in 2013 as C1341 – 13. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

C1341-13R18. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1341 − 13 (2018)

C1239 Practice for Reporting Uniaxial Strength Data and form a useful engineering material possessing

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1341 − 13 C1341 − 13 (Reapproved 2018)

Standard Test Method for

Flexural Properties of Continuous Fiber-Reinforced

1

Advanced Ceramic Composites

This standard is issued under the fixed designation C1341; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of flexural properties of continuous fiber-reinforced ceramic composites in the

form of rectangular bars formed directly or cut from sheets, plates, or molded shapes. Three test geometries are described as

follows:

1.1.1 Test Geometry I—A three-point loading system utilizing center point force application on a simply supported beam.

1.1.2 Test Geometry IIA—A four-point loading system utilizing two force application points equally spaced from their adjacent

support points, with a distance between force application points of one half one-half of the support span.

1.1.3 Test Geometry IIB—A four-point loading system utilizing two force application points equally spaced from their adjacent

support points, with a distance between force application points of one third one-third of the support span.

1.2 This test method applies primarily to all advanced ceramic matrix composites with continuous fiber reinforcement:

uni-directional (1-D), bi-directional (2-D), tri-directional (3-D),unidirectional (1D), bidirectional (2D), tridirectional (3D), and

other continuous fiber architectures. In addition, this test method may also be used with glass (amorphous) matrix composites with

continuous fiber reinforcement. However, flexural strength cannot be determined for those materials that do not break or fail by

tension or compression in the outer fibers. This test method does not directly address discontinuous fiber-reinforced,

whisker-reinforced, or particulate-reinforced ceramics. Those types of ceramic matrix composites are better tested in flexure using

Test Methods C1161 and C1211.

1.3 Tests can be performed at ambient temperatures or at elevated temperatures. At elevated temperatures, a suitable furnace

is necessary for heating and holding the test specimens at the desired testing temperatures.

1.4 This test method includes the following:

Section

Scope 1

Referenced Documents 2

Terminology 3

Summary of Test Method 4

Significance and Use 5

Interferences 6

Apparatus 7

Precautionary Statement 8

Test specimens 9

Test Specimens 9

Procedures 10

Calculation of Results 11

Report 12

Precision and Bias 13

Keywords 14

References

CFCC Surface Condition and Finishing Annex A1

Conditions and Issues in Hot Loading of Test Annex A2

specimens into Furnaces

Conditions and Issues in Hot Loading of Test Annex A2

Specimens into Furnaces

Toe Compensation on Stress-Strain Curves Annex A3

1

This test method is under the jurisdiction of ASTM Committee C28 on Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on Ceramic Matrix

Composites.

Current edition approved Feb. 15, 2013July 1, 2018. Published April 2013July 2018. Originally approved in 1996. Last previous edition approved in 20062013 as

C1341 – 06.C1341 – 13. DOI: 10.1520/C1341-13.10.1520/C1341-13R18.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1341 − 13 (2018)

Corrections for Thermal Expansion in Flexural Annex A4

Equations

Example of Test Report Appendix X1

1.5 The values stated in SI units are to be regarded as the standard in accordance with IEEE/ASTM SI 10.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C1145 Terminology of Advanced Ceramics

C1161 Test M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.