ASTM F2055-09

(Test Method)Standard Test Method for Size and Squareness of Resilient Floor Tile by Dial Gage Method

Standard Test Method for Size and Squareness of Resilient Floor Tile by Dial Gage Method

SIGNIFICANCE AND USE

Both dimension and squareness of resilient floor tile are important considerations, because installed flooring may exhibit an objectionable appearance when either or both characteristics deviate from established tolerances. This test method provides a means of determining actual dimensions and squareness by using a single apparatus and procedure.

SCOPE

1.1 This test method covers the determination of both dimensions (length and width) and squareness of resilient floor tile. This test method is intended for use with square tiles ranging from a nominal 9 in. (226 mm) to 40 in. (1016 mm) in dimension.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2055–09

Standard Test Method for

Size and Squareness of Resilient Floor Tile by Dial Gage

1

Method

This standard is issued under the fixed designation F2055; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of both

dimensions (length and width) and squareness of resilient floor

tile. This test method is intended for use with square tiles

ranging from a nominal 9 in. (226 mm) to 40 in. (1016 mm) in

dimension.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

information only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

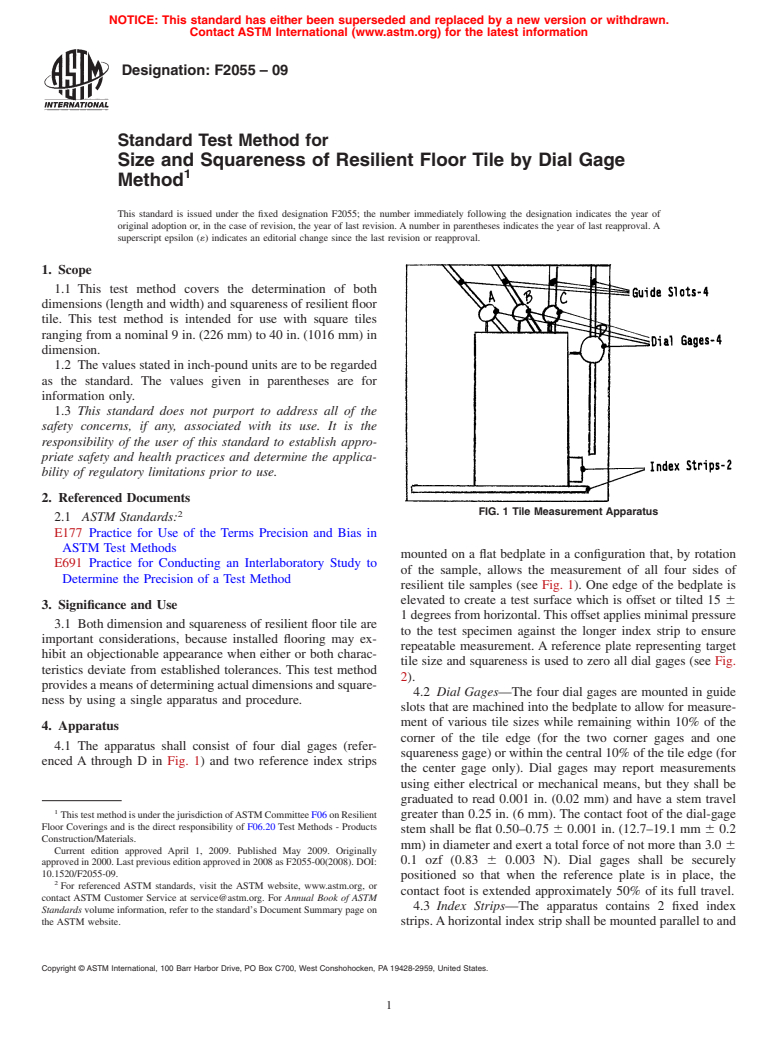

FIG. 1 Tile Measurement Apparatus

2

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

mounted on a flat bedplate in a configuration that, by rotation

E691 Practice for Conducting an Interlaboratory Study to

of the sample, allows the measurement of all four sides of

Determine the Precision of a Test Method

resilient tile samples (see Fig. 1). One edge of the bedplate is

elevated to create a test surface which is offset or tilted 15 6

3. Significance and Use

1 degrees from horizontal.This offset applies minimal pressure

3.1 Both dimension and squareness of resilient floor tile are

to the test specimen against the longer index strip to ensure

important considerations, because installed flooring may ex-

repeatable measurement. A reference plate representing target

hibit an objectionable appearance when either or both charac-

tile size and squareness is used to zero all dial gages (see Fig.

teristics deviate from established tolerances. This test method

2).

providesameansofdeterminingactualdimensionsandsquare-

4.2 Dial Gages—The four dial gages are mounted in guide

ness by using a single apparatus and procedure.

slots that are machined into the bedplate to allow for measure-

ment of various tile sizes while remaining within 10% of the

4. Apparatus

corner of the tile edge (for the two corner gages and one

4.1 The apparatus shall consist of four dial gages (refer-

squareness gage) or within the central 10% of the tile edge (for

enced A through D in Fig. 1) and two reference index strips

the center gage only). Dial gages may report measurements

using either electrical or mechanical means, but they shall be

graduated to read 0.001 in. (0.02 mm) and have a stem travel

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient

greater than 0.25 in. (6 mm). The contact foot of the dial-gage

Floor Coverings and is the direct responsibility of F06.20 Test Methods - Products

stem shall be flat 0.50–0.75 6 0.001 in. (12.7–19.1 mm 6 0.2

Construction/Materials.

mm) in diameter and exert a total force of not more than 3.0 6

Current edition approved April 1, 2009. Published May 2009. Originally

0.1 ozf (0.83 6 0.003 N). Dial gages shall be securely

approved in 2000. Last previous edition approved in 2008 as F2055-00(2008). DOI:

10.1520/F2055-09.

positioned so that when the reference plate is in place, the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact foot is extended approximately 50% of its full travel.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.3 Index Strips—The apparatus contains 2 fixed index

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. strips.Ahorizontal index strip shall be mounted parallel to and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2055–09

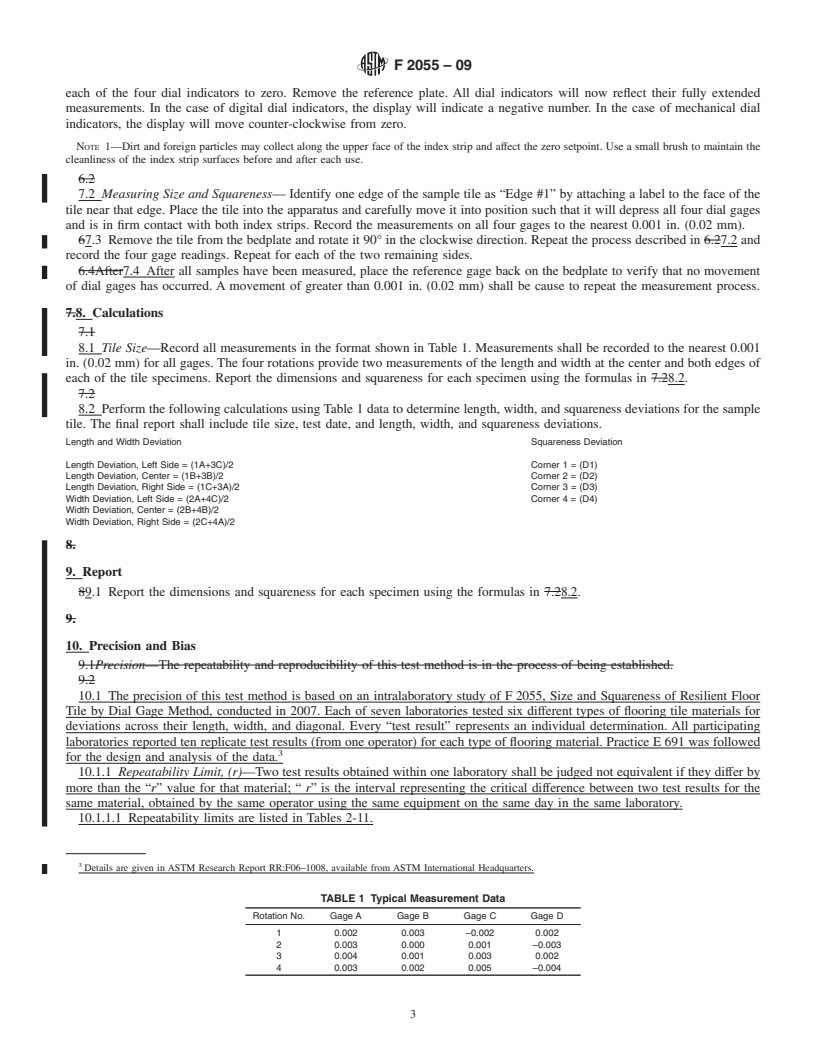

dial gages and is in firm contact with both index strips. Record

the measurements on all four gages to the nearest 0.001 in.

(0.02 mm).

7.3 Removethetilefromthebedplateandrotateit90°inthe

clockwise direction. Repeat the process described in 7.2 and

record the four gage readings. Repeat for each of the two

remaining sides.

7.4 After all samples have been measured, place the refer-

ence gage back on the bedplate to verify that no movement of

dial gages has occurred. A movement of greater than 0.001 in.

(0.02 mm) shall be cause to repeat the measurement process.

8. Calculations

A: Tile Target Dimension 6 0.001 in. (0.02 mm)

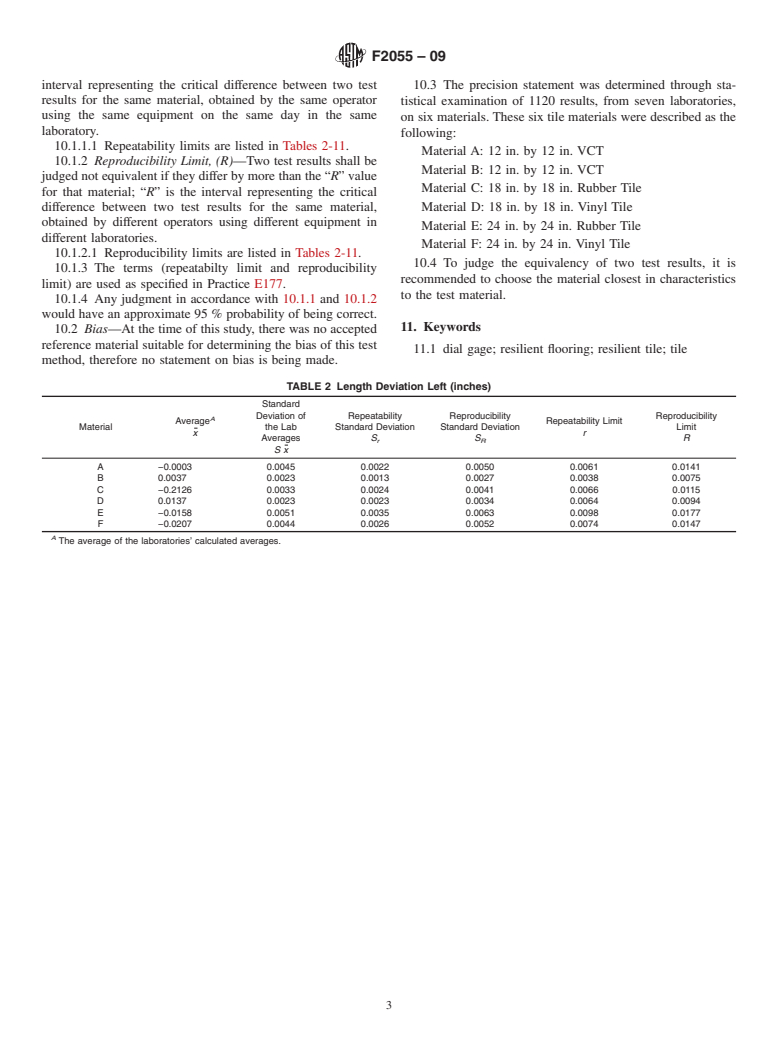

8.1 Tile Size—Record all measurements in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2055–00 (Reapproved 2008) Designation:F2055–09

Standard Test Method for

Size and Squareness of Resilient Floor Tile by Dial Gage

1

Method

This standard is issued under the fixed designation F 2055; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of both dimensions (length and width) and squareness of resilient floor tile. This

test method is intended for use with square tiles ranging from a nominal 9 in. (226 mm) to 40 in. (1016 mm) in dimension.

1.2 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Significance and Use

2.1Both dimension and squareness of resilient floor tile are important considerations, because installed flooring may exhibit an

objectionable appearance when either or both characteristics deviate from established tolerances. This test method provides a

means of determining actual dimensions and squareness by using a single apparatus and procedure. Referenced Documents

2

2.1 ASTM Standards:

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Significance and Use

3.1 Both dimension and squareness of resilient floor tile are important considerations, because installed flooring may exhibit an

objectionable appearance when either or both characteristics deviate from established tolerances. This test method provides a

means of determining actual dimensions and squareness by using a single apparatus and procedure.

4. Apparatus

3.1The4.1 The apparatus shall consist of four dial gages (referenced A through D in Fig. 1) and two reference index strips

mounted on a flat bedplate in a configuration that, by rotation of the sample, allows the measurement of all four sides of resilient

tile samples (see Fig. 1). One edge of the bedplate is elevated to create a test surface which is offset or tilted 15 6 1 degrees from

horizontal. This offset applies minimal pressure to the test specimen against the longer index strip to ensure repeatable

measurement. A reference plate representing target tile size and squareness is used to zero all dial gages (see Fig. 2).

3.2

4.2 Dial Gages—The four dial gages are mounted in guide slots that are machined into the bedplate to allow for measurement

of various tile sizes while remaining within 10% of the corner of the tile edge (for the two corner gages and one squareness gage)

or within the central 10% of the tile edge (for the center gage only). Dial gages may report measurements using either electrical

or mechanical means, but they shall be graduated to read 0.001 in. (0.02 mm) and have a stem travel greater than 0.25 in. (6 mm).

The contact foot of the dial-gage stem shall be flat 0.50–0.75 6 0.001 in. (12.7–19.1 mm 6 0.2 mm) in diameter and exert a total

force of not more than 3.0 6 0.1 ozf (0.83 6 0.003 N). Dial gages shall be securely positioned so that when the reference plate

is in place, the contact foot is extended approximately 50% of its full travel.

3.3

4.3 Index Strips—The apparatus contains 2 fixed index strips. A horizontal index strip shall be mounted parallel to and just

inside the lower edge of the bedplate. It shall be 1.5 6 0.1 in. (38 6 3 mm) greater in length and a minimum of twice the thickness

1

This test method is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of F06.20 Test Methods - Products

Construction/Materials.

Current edition approved MayApril 1, 2008.2009. Published July 2008.May 2009. Originally approved in 2000. Last previous edition approved in 20002008 as

F 2055-00(2008).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr H

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.