ASTM F3041-14(2019)

(Specification)Standard Specification for Bonded Rubber Crumb Floor Coverings

Standard Specification for Bonded Rubber Crumb Floor Coverings

SCOPE

1.1 This specification covers the requirements for the compound and physical characteristics of bonded rubber crumb floor coverings.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3041 −14 (Reapproved 2019)

Standard Specification for

Bonded Rubber Crumb Floor Coverings

This standard is issued under the fixed designation F3041; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F925 Test Method for Resistance to Chemicals of Resilient

Flooring

1.1 This specification covers the requirements for the com-

F970 Test Method for Measuring Recovery Properties of

pound and physical characteristics of bonded rubber crumb

Floor Coverings after Static Loading

floor coverings.

F1482 Practice for Installation and Preparation of Panel

1.2 The values stated in inch-pound units are to be regarded

Type Underlayments to Receive Resilient Flooring

as standard. The values given in parentheses are mathematical

F1514 TestMethodforMeasuringHeatStabilityofResilient

conversions to SI units that are provided for information only

Flooring by Color Change

and are not considered standard.

F2055 Test Method for Size and Squareness of Resilient

1.3 This standard does not purport to address all of the Floor Tile by Dial Gage Method

safety concerns, if any, associated with its use. It is the

F2199 Test Method for Determining Dimensional Stability

responsibility of the user of this standard to establish appro- and Curling Properties of Resilient Flooring after Expo-

priate safety, health, and environmental practices and deter-

sure to Heat

mine the applicability of regulatory limitations prior to use.

2.2 American National Standard:

1.4 This international standard was developed in accor-

ANSI/ASQ Z1.4 Sampling Procedures and Tables for In-

dance with internationally recognized principles on standard-

spection by Attributes

ization established in the Decision on Principles for the

3. Terminology

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3.1 Definitions:

Barriers to Trade (TBT) Committee.

3.1.1 crumb rubber, n—Material derived from reducing

rubber material into smaller granules. The granular material

2. Referenced Documents

shall (1)satisfythedefinitionofrubberinTerminologyD1566,

and (2) have been vulcanized, as defined in Terminology

2.1 ASTM Standards:

D1566 (under vulcanization), such that it becomes thermoset

D883 Terminology Relating to Plastics

as defined in Terminology D883.

D1566 Terminology Relating to Rubber

D3389 Test Method for Coated FabricsAbrasion Resistance

3.1.2 skive, vt—to cut thin layers off (leather or rubber, for

(Rotary Platform Abrader)

example); pare.

F137 Test Method for Flexibility of Resilient Flooring Ma-

3.1.3 skive marks, n—marks left on the material from the

terials with Cylindrical Mandrel Apparatus

process of skiving; blade marks; striations.

F141 Terminology Relating to Resilient Floor Coverings

3.2 For additional definitions refer to Terminology F141.

F386 Test Method for Thickness of Resilient Flooring Ma-

terials Having Flat Surfaces

4. Classification

F710 Practice for Preparing Concrete Floors to Receive

4.1 Bonded rubber crumb floor coverings covered by this

Resilient Flooring

specification shall be classified as follows:

4.1.1 Type:

1 4.1.1.1 Type I – Roll

This specification is under the jurisdiction of ASTM Committee F06 on

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80 4.1.1.2 Type II – Tile

on Specifications.

4.1.2 Class – Recycled content by weight

Current edition approved June 1, 2019. Published June 2019. Originally

4.1.2.1 Class A – Recycled content ≥80 %

approved in 2014. Last previous edition approved in 2014 as F3041-14. DOI:

4.1.2.2 Class B – Recycled content ≥50 % and <80 %

10.1520/F3041-14R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3041 − 14 (2019)

4.1.2.3 Class C – Recycled content ≥10 % and <50 % 7.4 Dimensional Stability—Test in accordance with Test

4.1.2.4 Class D – Recycled content <10 % Method F2199.

7.4.1 Bonded rubber crumb flooring shall not change in

5. Ordering Information

linear dimensions more than nominal 0.050 in. per linear foot

(60.40 %).

5.1 Thepurchasersshallstatewhetherthisspecificationisto

NOTE 5—Test Method F2199 is suitable only for tiles up to 1 in. thick.

be used, select the preferred options permitted herein, and

include the following information in the invitation to bid or 7.5 Resistance to Heat—When tested in accordance with

purchase order:

Test Method F1514, the flooring shall have an average ∆Eof

5.1.1 Title, number and date of this specification. not more than 8.00.

5.1.2 Type, class and pattern number.

7.6 Resistance to Short-Term Chemical Exposure—Test in

5.1.3 Quantity, in square feet, lineal feet or as specified.

accordance with Test Method F925 using the following

5.1.4 Roll thickness required (see 8.1.1).

chemicals, which represent an abbreviated list:

5.1.5 Roll width required (see 8.1.2).

White vinegar (5 % acetic acid)

5.1.6 Roll length required (see 8.1.2).

Rubbing alcohol (70 % isopropyl alcohol)

5.1.7 Tile thickness required (see 8.2.1).

Sodium hydroxide solution (5 % NaOH)

5.1.8 Tile size required (see 8.2.2).

Hydrochloric acid solution (5 % HCl)

5.1.9 Lot information, if other than as specified in ANSI/

Sulfuric acid solution (5 % H SO )

2 4

ASQC Z1.4.

Household ammonia solution (5 % NH OH)

5.1.10 Packing requirements, if other than as specified.

Disinfectant cleaner (5 % active phenol)

5.1.11 Palletization, if required.

The flooring shall have no more than a slight change in surface

5.1.12 Other requirements.

dulling, surface attack or color change.

NOTE 6—These basic chemicals are representative of those likely to be

6. Materials and Manufacture

found in domestic, commercial and institutional use. Many proprietary

compounds contain one or more of these basic chemicals. Should the

6.1 The color, finish and wearing surface characteristics

flooring need to be resistant to a specific chemical, this additional

shall match the sample mutually agreed upon between the

requirement should become part of the procurement document.

buyer and seller.

NOTE 1—The colors and patterns that are available are indicated in 8. Dimensions and Permissible Variations

individual manufacturer’s current catalogs. As manufactured, and due to

8.1 Type 1 material, roll:

the uncontrollable characteristics of the raw material, colors may vary

8.1.1 Thickness—The thickness of the floor covering shall

somewhat in hue or shade from the catalog.

NOTE2—Differencesincolorandtexturecanresultinshadingvariation beasspecifiedinthecontractororder.Theminimumthickness

from piece to piece. Color and texture differences or striation is inherent

shall be 0.060 in. (1.5 mm).Atolerance of 60.020 in. (60.50

in the manufacturing process and is not considered a defect.

mm) from the specified thickness shall be permitted, provided

NOTE 3—Where color match is a concern, samples from the manufac-

the product thickness does not go below the minimum thick-

turer shall be obtained to verify color or shade acceptability, or both.

ness of 0.060 in. (1.5 mm). Thickness is measured in accor-

6.2 Bonded rubber crumb flooring shall be of uniform

dance with Test Method F386.

structure and composition throughout, consisting of rubber

8.1.2 Length and Width—The length/width shall not be less

granules thoroughly and uniformly bonded to

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3041 − 14 (Reapproved 2019)

Standard Specification for

Bonded Rubber Crumb Floor Coverings

This standard is issued under the fixed designation F3041; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F925 Test Method for Resistance to Chemicals of Resilient

Flooring

1.1 This specification covers the requirements for the com-

F970 Test Method for Measuring Recovery Properties of

pound and physical characteristics of bonded rubber crumb

Floor Coverings after Static Loading

floor coverings.

F1482 Practice for Installation and Preparation of Panel

1.2 The values stated in inch-pound units are to be regarded

Type Underlayments to Receive Resilient Flooring

as standard. The values given in parentheses are mathematical

F1514 Test Method for Measuring Heat Stability of Resilient

conversions to SI units that are provided for information only

Flooring by Color Change

and are not considered standard.

F2055 Test Method for Size and Squareness of Resilient

1.3 This standard does not purport to address all of the

Floor Tile by Dial Gage Method

safety concerns, if any, associated with its use. It is the F2199 Test Method for Determining Dimensional Stability

responsibility of the user of this standard to establish appro-

and Curling Properties of Resilient Flooring after Expo-

priate safety, health, and environmental practices and deter- sure to Heat

mine the applicability of regulatory limitations prior to use.

2.2 American National Standard:

1.4 This international standard was developed in accor-

ANSI/ASQ Z1.4 Sampling Procedures and Tables for In-

dance with internationally recognized principles on standard-

spection by Attributes

ization established in the Decision on Principles for the

3. Terminology

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3.1 Definitions:

Barriers to Trade (TBT) Committee.

3.1.1 crumb rubber, n—Material derived from reducing

rubber material into smaller granules. The granular material

2. Referenced Documents

shall (1) satisfy the definition of rubber in Terminology D1566,

and (2) have been vulcanized, as defined in Terminology

2.1 ASTM Standards:

D1566 (under vulcanization), such that it becomes thermoset

D883 Terminology Relating to Plastics

as defined in Terminology D883.

D1566 Terminology Relating to Rubber

D3389 Test Method for Coated Fabrics Abrasion Resistance

3.1.2 skive, vt—to cut thin layers off (leather or rubber, for

(Rotary Platform Abrader)

example); pare.

F137 Test Method for Flexibility of Resilient Flooring Ma-

3.1.3 skive marks, n—marks left on the material from the

terials with Cylindrical Mandrel Apparatus

process of skiving; blade marks; striations.

F141 Terminology Relating to Resilient Floor Coverings

3.2 For additional definitions refer to Terminology F141.

F386 Test Method for Thickness of Resilient Flooring Ma-

terials Having Flat Surfaces

4. Classification

F710 Practice for Preparing Concrete Floors to Receive

4.1 Bonded rubber crumb floor coverings covered by this

Resilient Flooring

specification shall be classified as follows:

4.1.1 Type:

1 4.1.1.1 Type I – Roll

This specification is under the jurisdiction of ASTM Committee F06 on

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80 4.1.1.2 Type II – Tile

on Specifications.

4.1.2 Class – Recycled content by weight

Current edition approved June 1, 2019. Published June 2019. Originally

4.1.2.1 Class A – Recycled content ≥80 %

approved in 2014. Last previous edition approved in 2014 as F3041-14. DOI:

4.1.2.2 Class B – Recycled content ≥50 % and <80 %

10.1520/F3041-14R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3041 − 14 (2019)

4.1.2.3 Class C – Recycled content ≥10 % and <50 % 7.4 Dimensional Stability—Test in accordance with Test

4.1.2.4 Class D – Recycled content <10 % Method F2199.

7.4.1 Bonded rubber crumb flooring shall not change in

5. Ordering Information

linear dimensions more than nominal 0.050 in. per linear foot

(60.40 %).

5.1 The purchasers shall state whether this specification is to

NOTE 5—Test Method F2199 is suitable only for tiles up to 1 in. thick.

be used, select the preferred options permitted herein, and

include the following information in the invitation to bid or

7.5 Resistance to Heat—When tested in accordance with

purchase order: Test Method F1514, the flooring shall have an average ΔE of

5.1.1 Title, number and date of this specification.

not more than 8.00.

5.1.2 Type, class and pattern number.

7.6 Resistance to Short-Term Chemical Exposure—Test in

5.1.3 Quantity, in square feet, lineal feet or as specified.

accordance with Test Method F925 using the following

5.1.4 Roll thickness required (see 8.1.1).

chemicals, which represent an abbreviated list:

5.1.5 Roll width required (see 8.1.2).

White vinegar (5 % acetic acid)

5.1.6 Roll length required (see 8.1.2).

Rubbing alcohol (70 % isopropyl alcohol)

5.1.7 Tile thickness required (see 8.2.1).

Sodium hydroxide solution (5 % NaOH)

5.1.8 Tile size required (see 8.2.2).

Hydrochloric acid solution (5 % HCl)

5.1.9 Lot information, if other than as specified in ANSI/

Sulfuric acid solution (5 % H SO )

2 4

ASQC Z1.4.

Household ammonia solution (5 % NH OH)

5.1.10 Packing requirements, if other than as specified.

Disinfectant cleaner (5 % active phenol)

5.1.11 Palletization, if required.

The flooring shall have no more than a slight change in surface

5.1.12 Other requirements.

dulling, surface attack or color change.

NOTE 6—These basic chemicals are representative of those likely to be

6. Materials and Manufacture

found in domestic, commercial and institutional use. Many proprietary

compounds contain one or more of these basic chemicals. Should the

6.1 The color, finish and wearing surface characteristics

flooring need to be resistant to a specific chemical, this additional

shall match the sample mutually agreed upon between the

requirement should become part of the procurement document.

buyer and seller.

8. Dimensions and Permissible Variations

NOTE 1—The colors and patterns that are available are indicated in

individual manufacturer’s current catalogs. As manufactured, and due to

8.1 Type 1 material, roll:

the uncontrollable characteristics of the raw material, colors may vary

8.1.1 Thickness—The thickness of the floor covering shall

somewhat in hue or shade from the catalog.

NOTE 2—Differences in color and texture can result in shading variation be as specified in the contract or order. The minimum thickness

from piece to piece. Color and texture differences or striation is inherent

shall be 0.060 in. (1.5 mm). A tolerance of 60.020 in. (60.50

in the manufacturing process and is not considered a defect.

mm) from the specified thickness shall be permitted, provided

NOTE 3—Where color match is a concern, samples from the manufac-

the product thickness does not go below the minimum thick-

turer shall be obtained to verify color or shade acceptability, or both.

ness of 0.060 in. (1.5 mm). Thickness is measured in accor-

6.2 Bonded rubber crumb flooring shall be of uniform

dance with Test Method F386.

structure and composition throughout, consisting of rubber

8.1.2 Length and Width—The length/width shall not be less

granules thoroughly and uniformly bonded together.

than as marked on the label, package or as specified in the

contract or order.

7. Pe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3041 − 14 F3041 − 14 (Reapproved 2019)

Standard Specification for

Bonded Rubber Crumb Floor Coverings

This standard is issued under the fixed designation F3041; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for the compound and physical characteristics of bonded rubber crumb floor

coverings.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units values given in parentheses are for

information only.mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1566 Terminology Relating to Rubber

D3389 Test Method for Coated Fabrics Abrasion Resistance (Rotary Platform Abrader)

F137 Test Method for Flexibility of Resilient Flooring Materials with Cylindrical Mandrel Apparatus

F141 Terminology Relating to Resilient Floor Coverings

F386 Test Method for Thickness of Resilient Flooring Materials Having Flat Surfaces

F710 Practice for Preparing Concrete Floors to Receive Resilient Flooring

F925 Test Method for Resistance to Chemicals of Resilient Flooring

F970 Test Method for Measuring Recovery Properties of Floor Coverings after Static Loading

F1482 Practice for Installation and Preparation of Panel Type Underlayments to Receive Resilient Flooring

F1514 Test Method for Measuring Heat Stability of Resilient Flooring by Color Change

F2055 Test Method for Size and Squareness of Resilient Floor Tile by Dial Gage Method

F2199 Test Method for Determining Dimensional Stability and Curling Properties of Resilient Flooring after Exposure to Heat

2.2 American National Standard:

ANSI/ASQ Z1.4 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Definitions:

3.1.1 crumb rubber, n—Material derived from reducing rubber material into smaller granules. The granular material shall (1)

satisfy the definition of rubber in Terminology D1566, and (2) have been vulcanized, as defined in Terminology D1566 (under

vulcanization), such that it becomes thermoset as defined in Terminology D883.

3.1.2 skive, vt—to cut thin layers off (leather or rubber, for example); pare.

This specification is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80 on

Specifications.

Current edition approved March 1, 2014June 1, 2019. Published March 2014June 2019. DOI: 10.1520/F3041-14Originally approved in 2014. Last previous edition

approved in 2014 as F3041-14. DOI: 10.1520/F3041-14R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3041 − 14 (2019)

3.1.3 skive marks, n—marks left on the material from the process of skiving; blade marks; striations.

3.2 For additional definitions refer to Terminology F141.

4. Classification

4.1 Bonded rubber crumb floor coverings covered by this specification shall be classified as follows:

4.1.1 Type:

4.1.1.1 Type I – Roll

4.1.1.2 Type II – Tile

4.1.2 Class – Recycled content by weight

4.1.2.1 Class A – Recycled content ≥80 %

4.1.2.2 Class B – Recycled content ≥50 % and <80 %

4.1.2.3 Class C – Recycled content ≥10 % and <50 %

4.1.2.4 Class D – Recycled content <10 %

5. Ordering Information

5.1 The purchasers shall state whether this specification is to be used, select the preferred options permitted herein, and include

the following information in the invitation to bid or purchase order:

5.1.1 Title, number and date of this specification.

5.1.2 Type, class and pattern number.

5.1.3 Quantity, in square feet, lineal feet or as specified.

5.1.4 Roll thickness required (see 8.1.1).

5.1.5 Roll width required (see 8.1.2).

5.1.6 Roll length required (see 8.1.2).

5.1.7 Tile thickness required (see 8.2.1).

5.1.8 Tile size required (see 8.2.2).

5.1.9 Lot information, if other than as specified in ANSI/ASQC Z1.4.

5.1.10 Packing requirements, if other than as specified.

5.1.11 Palletization, if required.

5.1.12 Other requirements.

6. Materials and Manufacture

6.1 The color, finish and wearing surface characteristics shall match the sample mutually agreed upon between the buyer and

seller.

NOTE 1—The colors and patterns that are available are indicated in individual manufacturer’s current catalogs. As manufactured, and due to the

uncontrollable characteristics of the raw material, colors may vary somewhat in hue or shade from the catalog.

NOTE 2—Differences in color and texture can result in shading variation from piece to piece. Color and texture differences or striation is inherent in

the manufacturing process and is not considered a defect.

NOTE 3—Where color match is a concern, samples from the manufacturer shall be obtained to verify color or shade acceptability, or both.

6.2 Bonded rubber crumb flooring shall be of uniform structure and composition throughout, consisting of rubber granules

thoroughly and uniformly bonded together.

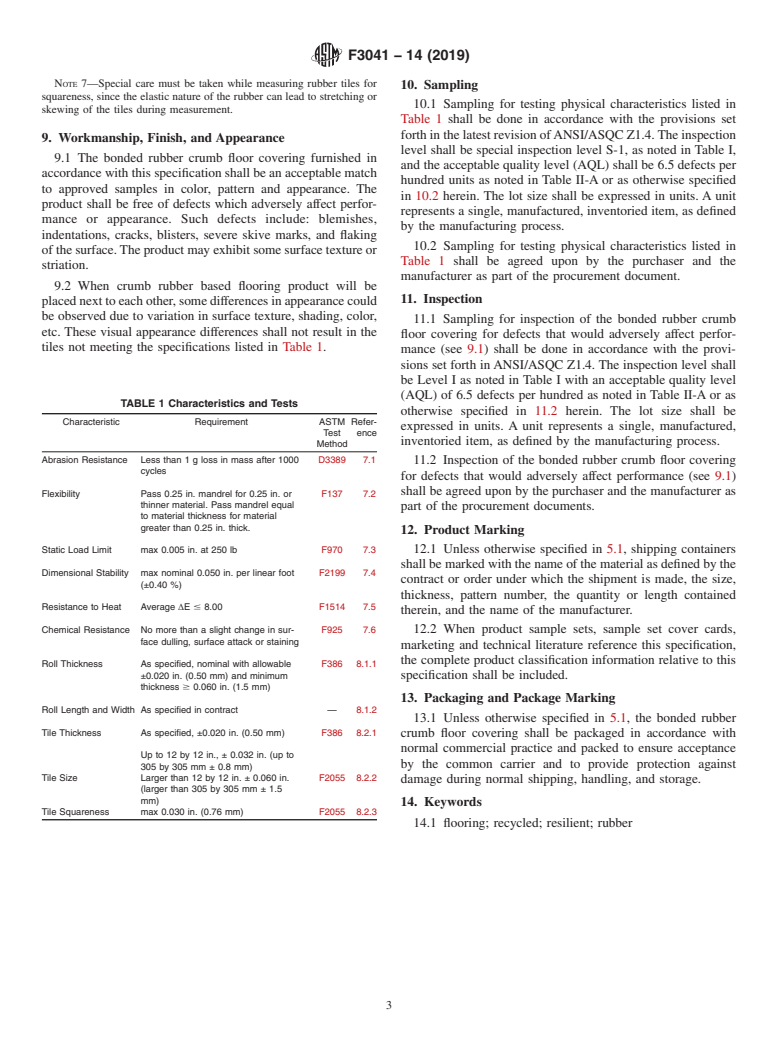

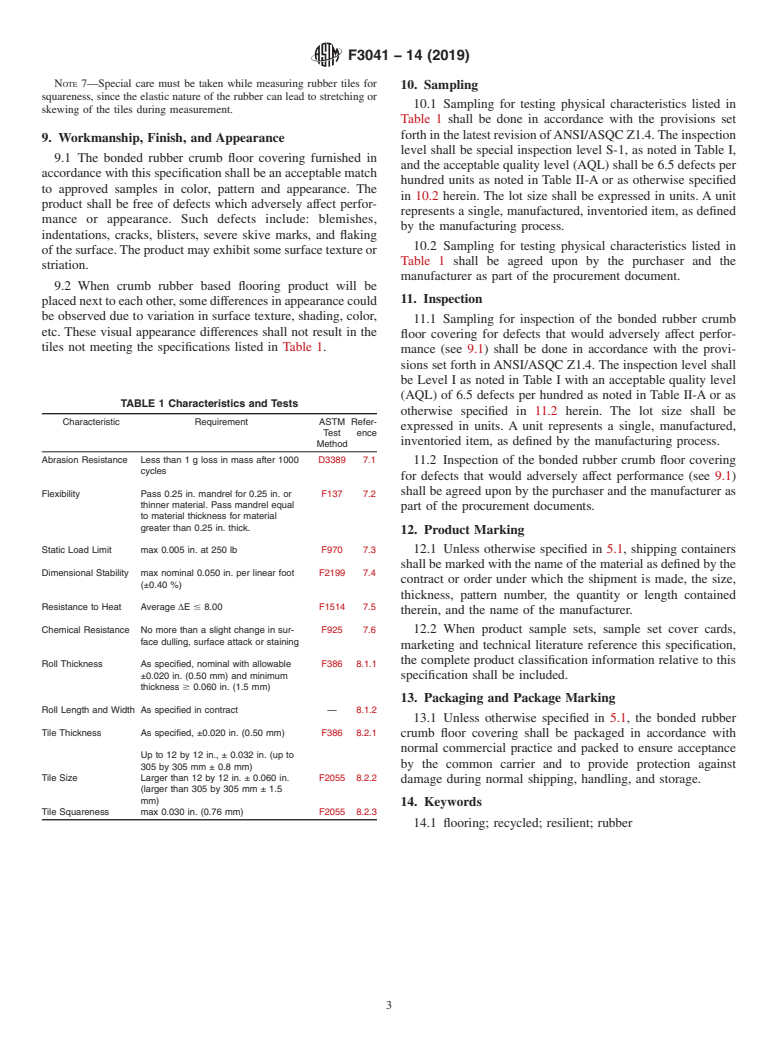

7. Performance Requirements

7.1 Abrasion Resistance—Test in accordance with Test Method D3389 method B and with the abrader equipped with H-18

wheels and a load of 500 g. The flooring shall not lose more than 1 g after 1000 cycles.

7.2 Flexibility:

7.2.1 Material measuring 0.25 in. (6.35 mm) or thinner—Test in accordance with Test Method F137, both face-in and face-out,

using a 0.25 in. (6.35 mm) mandrel. The flooring shall show no tears, flakes, or splitting of the product matrix.

7.2.2 Material measuring more than 0.25 in. (6.35 mm)—Test in accordance with Test Method F137, both face-in and face-out,

using a mandrel of the same diameter as the material thickness. The flooring shall show no tears, flakes or splitting of the product

matrix.

7.3 Static Load Limit—Test in accordance with Test Method F970, with an applied load of 250 lb (113.4 kg).

7.3.1 Bonded rubber crumb flooring shall have a residual indentation of not more than 0.005 in. (0.127 mm).

NOTE 4—Test Method F970 is suitable only for tiles up to 1 in. thick.

7.4 Dimensional Stability—Test in accordance with Test Method F2199.

7.4.1 Bonded rubber crumb flooring shall not change in linear dimensions more than nominal 0.050 in. per linear foot (60.40

%).

NOTE 5—Test Method F2199 is suitable only for tiles up to 1 in. thick.

F3041 − 14 (2019)

7.5 Resistance to Heat—When tested in accordance with Test Method F1514, the flooring shall have an average ΔE of not more

than 8.00.

7.6 Resistance to Short-Term Chemical Exposure—Test in accordance with Test Method F925 using the following chemicals,

which represent an abbreviated list:

White vinegar (5 % acetic acid)

Rubbing alcohol (70

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.