ASTM D4874-95(2001)

(Test Method)Standard Test Method for Leaching Solid Material in a Column Apparatus

Standard Test Method for Leaching Solid Material in a Column Apparatus

SCOPE

1.1 This test method is a standard laboratory procedure for generating aqueous leachate from materials using a column apparatus. It provides a leachate suitable for organic analysis of semivolatile and nonvolatile compounds as well as inorganic analyses.

1.2 The column apparatus is designed and constructed of materials chosen to enhance the leaching of low concentrations of semivolatile and nonvolatile organic constituents as well as to maximize the leaching of metallic species from the solid. Analysis of column effluent provides information on the leaching characteristics of material under the conditions used in the test.

1.3 This test method provides for the passage of an aqueous fluid through materials of known mass in a saturated up-flow mode.

1.4 It is intended that the sample used in the procedure be physically, chemically, and biologically representative of the material.

1.5 This test method does not produce results that can be used as the sole basis for (1) engineering design of a disposal site, or (2) the characterization of wastes based on their leaching characteristics.

1.6 This test method has the following limitations

1.6.1 Maximum particle size is 10 mm (0.4 in.). Particle size reduction is not recommended. Large-diameter material (cinders, rocks, and so forth) should be removed prior to packing the column to ensure adequate compaction.

1.6.2 Test materials containing densely immiscible organic material may result in phase separation and lead to column plugging.

1.6.3 This test method does not differentiate between dissolved constituents and sub-70-µm particulates that pass through the pores of the end plates.

1.6.4 This test method is not applicable to the leachability characterization of materials with regard to volatile compounds.

1.6.5 This test method is not applicable to the characterization of materials that dissolve in water to a degree that significantly impacts the void volume in the column or the determination of the specific gravity of the material.

1.7 Application of this test method to materials with initial low permeability, or to those that lose permeability over the course of the test, may result in long testing periods.

1.8 The values stated in SI units are to be regarded as the standard. The values given in parentheses are in approximate inch-pound equivalents.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4874 – 95 (Reapproved 2001)

Standard Test Method for

Leaching Solid Material in a Column Apparatus

This standard is issued under the fixed designation D 4874; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope significantly impacts the void volume in the column or the

determination of the specific gravity of the material.

1.1 This test method is a standard laboratory procedure for

1.7 Application of this test method to materials with initial

generating aqueous leachate from materials using a column

low permeability, or to those that lose permeability over the

apparatus.Itprovidesaleachatesuitablefororganicanalysisof

course of the test, may result in long testing periods.

semivolatile and nonvolatile compounds as well as inorganic

1.8 The values stated in SI units are to be regarded as the

analyses.

standard. The values given in parentheses are in approximate

1.2 The column apparatus is designed and constructed of

inch-pound equivalents.

materials chosen to enhance the leaching of low concentrations

1.9 This standard does not purport to address all of the

of semivolatile and nonvolatile organic constituents as well as

safety concerns, if any, associated with its use. It is the

to maximize the leaching of metallic species from the solid.

responsibility of the user of this standard to establish appro-

Analysis of column effluent provides information on the

priate safety and health practices and determine the applica-

leaching characteristics of material under the conditions used

bility of regulatory limitations prior to use.

in the test.

1.3 This test method provides for the passage of an aqueous

2. Referenced Documents

fluid through materials of known mass in a saturated up-flow

2.1 ASTM Standards:

mode.

C 819 Test Method for Specific Surface Area of Carbon or

1.4 It is intended that the sample used in the procedure be

Graphite

physically, chemically, and biologically representative of the

D 422 Test Method for Particle Size Analysis of Soils

material.

D 698 Test Method for Laboratory Compaction Character-

1.5 This test method does not produce results that can be

istics of Soil Using Standard Effort (12 400 ft-lbf/ft ) (600

used as the sole basis for (1) engineering design of a disposal

kN-m/m )

site, or (2) the characterization of wastes based on their

D 854 Test Method for Specific Gravity of Soils

leaching characteristics.

D 1125 Test Methods for Electrical Conductivity and Re-

1.6 This test method has the following limitations:

sistivity of Water

1.6.1 Maximumparticlesizeis10mm(0.4in.).Particlesize

D 1129 Terminology Relating to Water

reduction is not recommended. Large-diameter material (cin-

D 1293 Test Methods for pH of Water

ders, rocks, and so forth) should be removed prior to packing

D 1498 PracticeforOxidation-ReductionPotentialofWater

the column to ensure adequate compaction.

D 1888 Test Methods for Particulate and Dissolved Matter

1.6.2 Test materials containing densely immiscible organic

in Water

material may result in phase separation and lead to column

D 2216 TestMethodforLaboratoryDeterminationofWater

plugging.

(Moisture) Content of Soil and Rock

1.6.3 This test method does not differentiate between dis-

D 2434 Test Method for Permeability of Granular Soils

solved constituents and sub-70-µm particulates that pass

(Constant Head)

through the pores of the end plates.

D 3370 Practices for Sampling Water

1.6.4 This test method is not applicable to the leachability

D 3694 Practice for Preparation of Sample Containers and

characterization of materials with regard to volatile com-

for Preservation of Organic Constituents

pounds.

D 4253 TestMethodsforMaximumIndexDensityandUnit

1.6.5 This test method is not applicable to the characteriza-

Weight of Soils Using a Vibratory Table

tion of materials that dissolve in water to a degree that

This test method is under the jurisdiction of ASTM Committee D34 on Waste

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Management and is the direct responsibility of Subcommittee D34.01.04 on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Ancillary Topics.

Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 10, 1995. Published December 1995. Originally

the ASTM website.

published as D 4874 – 89. Last previous edition D 4874 – 89.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4874 – 95 (2001)

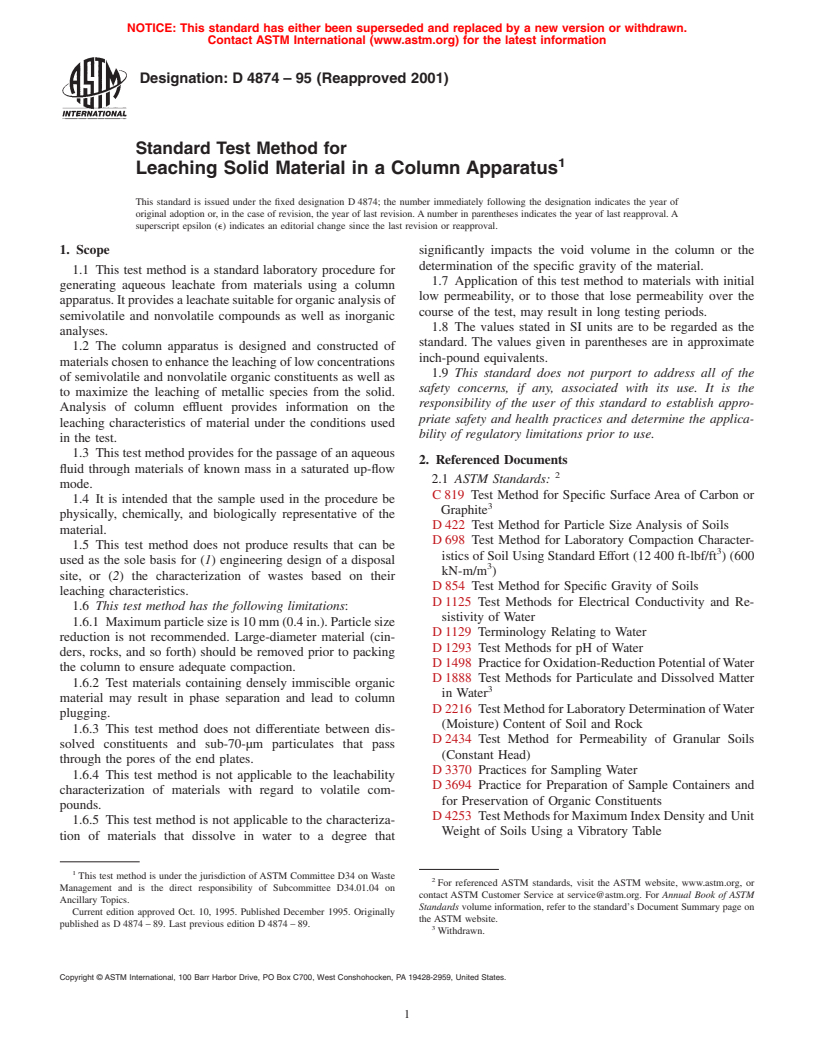

FIG. 1 Column Apparatus

E 691 Practice for Conducting an Interlaboratory Study to leaching is necessary in the selection of appropriate conditions.

Determine the Precision of a Test Method References (1-3) provide useful information on these prin-

ciples.

3. Terminology

4.3 The column apparatus is constructed of materials that

3.1 Definition:

permit the generation of a leachate which is suitable for low

3.1.1 reagent water—as defined in SW-846, Method 1311, concentration organic analysis for semivolatile and nonvolatile

5.2.

compounds as well as inorganic species.

3.1.2 void volume—the volume between the solid particles

5. Apparatus (See Fig. 1)

in a bed of granular material. Also called the interstitial

volume. 5.1 Columns:

3.2 Several terms used in this test method are defined in 5.1.1 Thecolumnbodyisconstructedofglasspipe,300mm

Terminology D 1129. (12 in.) in length, with an inside diameter of 100 mm (4 in.).

The cylinder wall must be of sufficient thickness, approxi-

4. Significance and Use

mately 6 mm ( ⁄4 in.), to withstand the operating pressure.

4.1 This test method is intended to provide an aqueous 5.1.2 End plates are constructed of stainless steel. They are

leaching of a material in a dynamic partitioning manner. attached by means of eight, 6-mm ( ⁄4-in.) threaded rods or any

4.2 Specific operating conditions for the column can be other means which ensures a leakproof seal.

selected to satisfy the objectives of individual studies. An 5.1.3 Gaskets, one at each end of the column, are con-

understanding of the fundamental principles governing column structed of chemically inert materials, and are as thin as

4 5

SW-846, 3rd ed., Method 1311, Available from USEPA, Office of Solid Waste The boldface numbers in parentheses refer to the list of references at the end of

and Emergency Response, Washington, DC 20460. this standard.

D 4874 – 95 (2001)

possible while still providing a good seal. The gasket diameter 7. Safety Precaution

should overlap the inside column diameter by 3 mm ( ⁄8 in.) to

7.1 General operating pressure should not exceed 275.8 kPa

prevent the gasket from being forced out while under pressure.

(40 psig) with materials as defined herein. Other inert materials

Techniques other than gaskets for providing a seal between the

areavailablethatcanbeusedtomanufacturethecolumnwhich

columnandendplatesareallowedprovidedthetechniqueused

will withstand pressures above 275.8 kPa (40 psig).

is specified in the report.

8. Sampling

5.1.4 Flow distribution disks must be constructed of sin-

tered stainless steel, with a nominal pore diameter of 70 µm.

8.1 Sampling must be performed so as to obtain a represen-

Thediskthicknessshallbe6mm( ⁄4in.),withadiameterequal

tative sample of the material.

totheinsidediameterofthecolumn,approximately100mm(4

8.2 Where no specific sampling methods are available,

in.). The disk shall have eight evenly spaced grooves; each of

sampling methods for materials of physical form similar to the

which is 3 mm ( ⁄8 in.) wide, 3 mm deep and 50 mm (2 in.)

material shall be used.

long. These grooves shall be positioned in a ray originating

8.3 Aminimumsampleof5000g,orthreecolumnvolumes,

from the center of the disk.

whichever is larger, shall be sent to the laboratory for each

5.1.5 Tubing used in the apparatus shall be of inert materi- column.

als, for example, glass, stainless steel, polytetrafluoroethylene 8.4 Samples must be kept in closed containers appropriate

lined. The outer diameter shall be 6 mm ( ⁄4 in.). to the sample type and otherwise protected if necessary prior to

5.1.6 Substitutionofmaterialsofconstructionofthecolumn testing to prevent sample contamination or constituent change

or loss. Where it is desired to test biologically or chemically

or any of its parts is acceptable, as long as it is demonstrated

that levels of contamination for analyte(s) of interest are equal active samples in their existing state, any sample storage

required should be at 4°C (Practice D 3370) and the leaching

to or less than those specified. Any modification of the

apparatus as described in this test method must be justified, should be started within8hof sample collection. Where

appropriate, the tester may modify a test portion before

documented, and delineated in the report.

leaching to simulate the results of biological or chemical

5.2 Pressurized Reservoir Vessel, which is used to contain

activity in the field. Record the storage conditions, sampling

the leaching fluid, is constructed with requirements similar to

procedures, handling practices, and any abnormal sampling

thoseoftheleachingcolumnwiththefollowingexceptions:(1)

conditions in the report.

no diffusion disks are used, and (2) it is equipped with a top

port for refilling the fluid.

9. Preparation of Apparatus

5.3 Balance, 10-kg capacity, with a 1-g sensitivity.

9.1 The assembled apparatus is shown in Fig. 1.

5.4 Compressed Gas Source, prepurified nitrogen or argon

9.2 Column Preparation:

with a two-stage delivery regulator (0 to 350 kPa) (0 to 50

9.2.1 Before use, clean all parts of the test apparatus that

psig), and a pressure gage capable of measuring the pressure in

will contact the waste material, leaching fluid, or product

theheadspaceoftheliquidreservoirtowithin 67kPa(1psig).

leachate.

9.2.1.1 Clean the sintered disks by boiling them for 15 min

6. Reagents and Materials

in reagent water, followed by a backflush with reagent water.

6.1 American Chemical Society (ACS) Reagent grade

Then saturate the disks with concentrated sulfuric acid and

chemicals or equivalent are preferred.

soak until all residues are removed. Then vacuum or pressure

6.2 Other grades of chemicals may be used, provided that

removetheexcessacidwithreagentwater.Next,pumpordraw

the reagent is of sufficiently high purity to permit its use

either acetone or methanol through the disks, followed by

without compromising the objectives of the testing.

either hexane or methylene chloride. Permit disks to air dry.

6.3 Demonstration of acceptability through reagent blank

9.2.1.2 Clean the column apparatus by washing it with a

data at or below the quantitation limits for all analytes of

nonionic surfactant soap and water. Rinse with tap water and

interest is required.

follow with a reagent water rinse. Then rinse it with either

6.4 Unless otherwise indicated, references to reagent water acetone or methanol, followed by a rinse with either hexane or

mean water as defined in SW-846, Method 1311, 5.2. See

methylene chloride. Permit the apparatus to air dry.

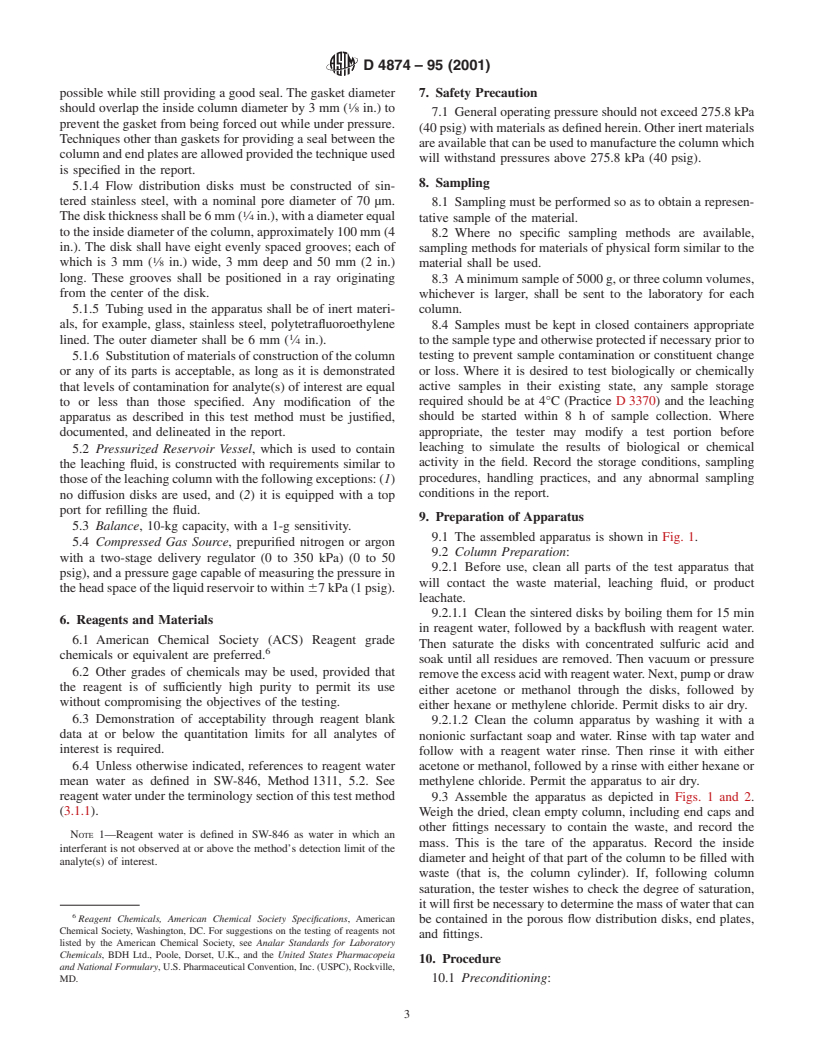

reagent water under the terminology section of this test method 9.3 Assemble the apparatus as depicted in Figs. 1 and 2.

(3.1.1).

Weigh the dried, clean empty column, including end caps and

other fittings necessary to contain the waste, and record the

NOTE 1—Reagent water is defined in SW-846 as water in which an

mass. This is the tare of the apparatus. Record the inside

interferant is not observed at or above the method’s detection limit of the

diameter and height of that part of the column to be filled with

analyte(s) of interest.

waste (that is, the column cylinder). If, following column

saturation, the tester wishes to check the degree of saturation,

itwillfirstbenecessarytodeterminethemassofwaterthatcan

Reagent Chemicals, American Chemical Society Specifications, American

be contained in the porous flow distribution disks, end plates,

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

and fittings.

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

10. Procedure

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

MD. 10.1 Preconditioning:

D 4874 – 95 (2001)

FIG. 2 Packing Configuration

10.1.1 Prepare a test portion of waste in a manner that 10.1.4 Curing—Aging may be necessary for those materials

simulates the state the waste is in or will be in as it undergoes thatundergophysicalorchemicalchangeswithtimeinorderto

leaching in the field. Preparation of the test portion may obtain a specimen (test portion) representative of the desired

include such factors as curing, and adjustment of moisture conditions. Curing may be accomplished in the field before

content and density. For such adjustments, the following testing in the column to produce a physical and chemical state

procedures can be used where appropriate. representative of the waste as it undergoes leaching in the field.

10.1.2 Moisture Content— Adjust the moisture content to Note and record field conditions of temperature, humidity, and

that defined in the disposal scenario by dewatering or adding atmospheric pressure. Record the duration of the curing pro-

reagent water to the material. Increase moisture content to that cess and report with the test data.

defined in the disposal scenario by addition of reagent water. 10.1.5 Particle Size— Ensure that the particle size distribu-

Note and record the volume of reagent water added. If the tion of the waste as placed in the column is representative of

concentration of any trace analyte of concern found in the that expected in field placement. Interpretation of results is

reagent water exceeds the reporting (quantitation) limit for the based in part on a knowledge of the particle size distribution

volume added, note this on the report form. Decrease moisture and surface area of the material. Maximum particle diameter

content by determining scenario temperature (normally less must not exceed ⁄10 of the inside diameter of the column.

than 60°C) and drying the material at the temperature for a Particle size reduction is not recommended. An evaluation of

specified time interval. Determine actual moisture content of the particle characteristics of size distribution and surface area

the waste as it is placed in the column using Test Method may b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.