ASTM F2019-03(2009)

(Practice)Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Pulled in Place Installation of Glass Reinforced Plastic (GRP) Cured-in-Place Thermosetting Resin Pipe (CIPP)

Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Pulled in Place Installation of Glass Reinforced Plastic (GRP) Cured-in-Place Thermosetting Resin Pipe (CIPP)

SIGNIFICANCE AND USE

This practice is for use by designers and specifiers, regulatory agencies, owners and inspection organizations who are involved in the rehabilitation of conduits through the use of a resin-impregnated fabric tube, pulled in place through an existing conduit and subsequently inflated and cured. As for any standard practice, modifications may be required for specific job conditions.

SCOPE

1.1 This practice covers the procedures for the reconstruction of pipelines and conduits (4 to 48 in. (100 to 1200 mm) diameter) by the pulled-in place installation of a resin-impregnated, flexible fabric tube into an existing conduit followed by inflation with compressed air (see Fig. 1). The resin/fabric tube can be cured by either the flow through the fabric tube of mixed air and steam or by use of ultraviolet light. When cured, the finished cured-in-place pipe will be continuous and tight fitting. This reconstruction process can be used in a variety of gravity flow applications such as sanitary sewers, storm sewers, process piping, electrical conduits, ventilation systems, and pressure applications.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F2019–03 (Reapproved 2009)

Standard Practice for

Rehabilitation of Existing Pipelines and Conduits by the

Pulled in Place Installation of Glass Reinforced Plastic

1

(GRP) Cured-in-Place Thermosetting Resin Pipe (CIPP)

This standard is issued under the fixed designation F2019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1600 Terminology for Abbreviated Terms Relating to

Plastics

1.1 This practice covers the procedures for the reconstruc-

D1682 Methods of Test for Breaking Load and Elongation

tion of pipelines and conduits (4 to 48 in. (100 to 1200 mm)

3

of Textile Fabrics

diameter) by the pulled-in place installation of a resin-

D3039/D3039M Test Method for Tensile Properties of

impregnated, flexible fabric tube into an existing conduit

Polymer Matrix Composite Materials

followed by inflation with compressed air (see Fig. 1). The

D3567 Practice for Determining Dimensions of “Fiber-

resin/fabric tube can be cured by either the flow through the

glass” (Glass-Fiber-Reinforced Thermosetting Resin) Pipe

fabrictubeofmixedairandsteamorbyuseofultravioletlight.

and Fittings

When cured, the finished cured-in-place pipe will be continu-

D5813 Specification for Cured-In-Place Thermosetting

ous and tight fitting.This reconstruction process can be used in

Resin Sewer Piping Systems

a variety of gravity flow applications such as sanitary sewers,

F412 Terminology Relating to Plastic Piping Systems

storm sewers, process piping, electrical conduits, ventilation

F1216 Practice for Rehabilitation of Existing Pipelines and

systems, and pressure applications.

Conduits by the Inversion and Curing of a Resin-

1.2 The values stated in inch-pound units are to be regarded

Impregnated Tube

as standard. The values given in parentheses are mathematical

F1417 Test Method for Installation Acceptance of Plastic

conversions to SI units that are provided for information only

Gravity Sewer Lines Using Low-Pressure Air

and are not considered standard.

F1743 Practice for Rehabilitation of Existing Pipelines and

1.3 This standard does not purport to address all of the

Conduits by Pulled-in-Place Installation of Cured-in-Place

safety concerns, if any, associated with its use. It is the

Thermosetting Resin Pipe (CIPP)

responsibility of the user of this standard to establish appro-

2.2 AWWA Standard:

priate safety and health practices and determine the applica-

4

Manual on Cleaning and Lining Water Mains, M28

bility of regulatory limitations prior to use.

2.3 NASSCO Standard:

2. Referenced Documents

Recommended Specifications for Sewer Collection System

5

2

Rehabilitation

2.1 ASTM Standards:

D543 Practices for Evaluating the Resistance of Plastics to

3. Terminology

Chemical Reagents

3.1 General:

D578 Specification for Glass Fiber Strands

3.1.1 Definitions are in accordance with Terminology F412.

D638 Test Method for Tensile Properties of Plastics

Abbreviations are in accordance with Abbreviations D1600,

D790 Test Methods for Flexural Properties of Unreinforced

unless otherwise indicated.

and Reinforced Plastics and Electrical Insulating Materials

3.2 Definitions of Terms Specific to This Standard:

3.2.1 calibration hose—an impermeable bladder installed

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

inside the fabric tube, and inflated with air or steam, or both to

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

Trenchless Plastic Pipeline Technology.

Current edition approved Aug. 1, 2009. Published November 2009. Originally

3

approved in 2000. Last previous edition approved in 2003 as F2019 – 03. DOI: Withdrawn. The last approved version of this historical standard is referenced

10.1520/F2019-03R09. on www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican Water WorksAssociation (AWWA), 6666 W. Quincy

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Ave., Denver, CO 80235, http://www.awwa.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from National Association of Sewer Service Companies, 423 W.

the ASTM website. King Street, Suite 3000, Chambersburg, PA 17201

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2019–03 (2009)

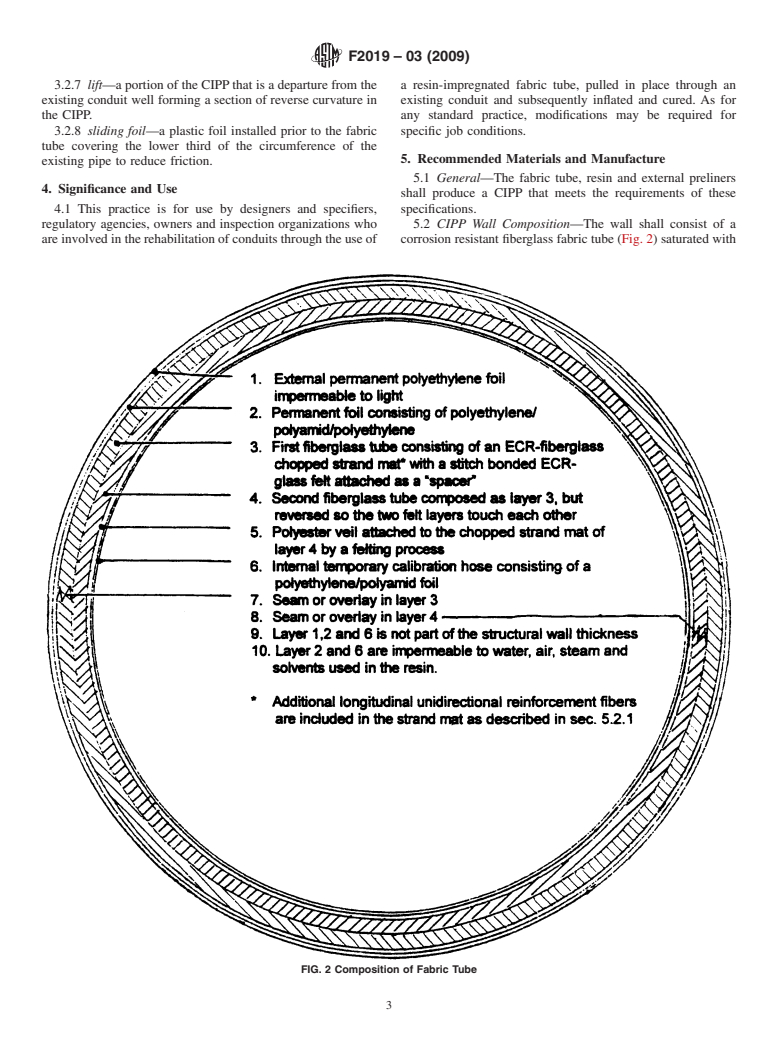

FIG. 1 Cured-In-Place Pipe Installation Method (Air/Steam)

press the tube firmly against the wall of the existing pipe until 3.2.4 dry spot—an area of the fabric tube, wh

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F2019–00 Designation: F 2019 – 03 (Reapproved 2009)

Standard Practice for

Rehabilitation of Existing Pipelines and Conduits by the

Pulled in Place Installation of Glass Reinforced Plastic

1

(GRP) Cured-in-Place Thermosetting Resin Pipe (CIPP)

This standard is issued under the fixed designation F 2019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the procedures for the reconstruction of pipelines and conduits (4 to 48 in. (100 to 1200 mm) diameter)

by the pulled-in place installation of a resin-impregnated, flexible fabric tube into an existing conduit followed by inflation with

compressed air (see Fig. 1). The resin/fabric tube is cured by flow through the fabric tube of mixed air and steam. When cured,

the finished cured-in-place pipe will be continuous and tight fitting. This reconstruction process can be used in a variety of gravity

flow applications such as sanitary sewers, storm sewers, process piping, electrical conduits and ventilation systems.

1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformational

purposes only. ). The resin/fabric tube can be cured by either the flow through the fabric tube of mixed air and steam or by use

of ultraviolet light. When cured, the finished cured-in-place pipe will be continuous and tight fitting. This reconstruction process

can be used in a variety of gravity flow applications such as sanitary sewers, storm sewers, process piping, electrical conduits,

ventilation systems, and pressure applications.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 543 Testing Method of Resistance of Plastics to Chemical Reagents Practices for Evaluating the Resistance of Plastics to

Chemical Reagents

D 578 Specifications for Glass Fiber Strands

D 638 TestingTest Method for Tensile Properties of Plastics

D 790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D 1600 Terminology for Abbreviated Terms Relating to Plastics

3

D 1682 Test Method for Breaking Load and Elongation of Textile Fabrics

D 3039/D 3039M Test Method for Tensile Properties of Polymer Matrix Composite Materials

D 3567 Practice for Determining Dimensions of Fiberglass (Glass-Fiber-Reinforced Thermosetting Resin) Pipe (RTRP) and

Fittings

5

D 5813 Specification for Cured-in-Place Thermosetting Resin Sewer Pipe

Specification for Cured-In-Place Thermosetting Resin Sewer Piping Systems

F 412 Terminology Relating to Plastic Piping Systems

F 1216 PracticeforRehabilitationofExistingPipelinesandConduitsbytheInversionandCuringofaResin-ImpregnatedTube

5

F 1417 Test Method for InstallationAcceptance of Gravity Plastic Sewer Lines Using Low PressureAir Testing Test Method

for Installation Acceptance of Plastic Gravity Sewer Lines Using Low-Pressure Air

1

This practice is under the jurisdiction of ASTM Committee F-17 F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.67 on Trenchless

Plastic Pipeline Technology.

Current edition approved May 10, 2000. Published August 2000.

Current edition approved Aug. 1, 2009. Published November 2003. Originally approved in 2000. Last previous edition approved in 2003 as F 2019 – 03.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 07.01.

3

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.