ASTM D5580-00

(Test Method)Standard Test Method for Determination of Benzene, Toluene, Ethylbenzene, p/m-Xylene, o-Xylene, C9 and Heavier Aromatics, and Total Aromatics in Finished Gasoline by Gas Chromatography

Standard Test Method for Determination of Benzene, Toluene, Ethylbenzene, <i>p/m</i>-Xylene, <i>o</i>-Xylene, C<sub>9</sub> and Heavier Aromatics, and Total Aromatics in Finished Gasoline by Gas Chromatography

SCOPE

1.1 This test method covers the determination of benzene, toluene, ethylbenzene, the xylenes, C9 and heavier aromatics, and total aromatics in finished motor gasoline by gas chromatography.

1.2 The aromatic hydrocarbons are separated without interferences from other hydrocarbons in finished gasoline. Nonaromatic hydrocarbons having a boiling point greater than n-dodecane may cause interferences with the determination of the C9 and heavier aromatics. For the C8 aromatics, p-xylene and m-xylene co-elute while ethylbenzene and o-xylene are separated. The C9 and heavier aromatics are determined as a single group.

1.3 This test method covers the following concentration ranges, in liquid volume %, for the preceding aromatics: benzene, 0.1 to 5 %; toluene, 1 to 15 %; individual C8 aromatics, 0.5 to 10 %; total C9 and heavier aromatics, 5 to 30 %, and total aromatics, 10 to 80 %.

1.4 Results are reported to the nearest 0.01 % by either mass or by liquid volume.

1.5 Many of the common alcohols and ethers that are added to gasoline to reduce carbon monoxide emissions and increase octane, do not interfere with the analysis. Ethers such as methyl terttert-butylether (ETBE), tert-amylmethylether (TAME), and diisopropylether (DIPE) have been found to elute from the precolumn with the nonaromatic hydrocarbons to vent. Other oxygenates, including methanol and ethanol elute before benzene and the aromatic hydrocarbons. 1-Methylcyclopentene has also been found to elute from the precolumn to vent and does not interfere with benzene.

1.6 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only; they may not be exact equivalents.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5580 – 00 An American National Standard

Standard Test Method for

Determination of Benzene, Toluene, Ethylbenzene, p/m-

Xylene, o-Xylene, C and Heavier Aromatics, and Total Aromatics

in Finished Gasoline by Gas Chromatography

This standard is issued under the fixed designation D 5580; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope bility of regulatory limitations prior to use.

1.1 This test method covers the determination of benzene,

2. Referenced Documents

toluene, ethylbenzene, the xylenes, C and heavier aromatics,

2.1 ASTM Standards:

and total aromatics in finished motor gasoline by gas chroma-

D 1298 Practice for Density, Relative Density, (Specific

tography.

Gravity) or API Gravity of Crude Petroleum and Liquid

1.2 The aromatic hydrocarbons are separated without inter-

Petroleum Products by Hydrometer Method

ferences from other hydrocarbons in finished gasoline. Non-

D 4052 Test Method for Density and Relative Density of

aromatic hydrocarbons having a boiling point greater than

Liquids by Digital Density Meter

n-dodecane may cause interferences with the determination of

D 4057 Practice for Manual Sampling of Petroleum and

the C and heavier aromatics. For the C aromatics, p-xylene

9 8

Petroleum Products

and m-xylene co-elute while ethylbenzene and o-xylene are

D 4307 Practice for Preparation of Liquid Blends for Use as

separated. The C and heavier aromatics are determined as a

Analytical Standards

single group.

E 355 Practice for Gas Chromatography Terms and Rela-

1.3 This test method covers the following concentration

tionships

ranges, in liquid volume %, for the preceding aromatics:

benzene, 0.1 to 5 %; toluene, 1 to 15 %; individual C

3. Terminology

aromatics, 0.5 to 10 %; total C and heavier aromatics, 5 to

3.1 Definitions of Terms Specific to This Standard:

30 %, and total aromatics, 10 to 80 %.

3.1.1 aromatic—any organic compound containing a ben-

1.4 Results are reported to the nearest 0.01 % by either mass

zene ring.

or by liquid volume.

3.1.2 low-volume connector—a special union for connect-

1.5 Many of the common alcohols and ethers that are added

ing two lengths of narrow bore tubing 1.6-mm (0.06-in.)

to gasoline to reduce carbon monoxide emissions and increase

outside diameter and smaller; sometimes this is referred to as

octane, do not interfere with the analysis. Ethers such as methyl

zero dead volume union.

tert-butylether (MTBE), ethyl tert-butylether (ETBE), tert-

3.1.3 narrow bore tubing—tubing used to transfer compo-

amylmethylether (TAME), and diisopropylether (DIPE) have

nents prior to or after separation; usually 0.5-mm (0.02-in.)

been found to elute from the precolumn with the nonaromatic

inside diameter and smaller.

hydrocarbons to vent. Other oxygenates, including methanol

3.1.4 split ratio—in capillary gas chromatography, the ratio

and ethanol elute before benzene and the aromatic hydrocar-

of the total flow of carrier gas to the sample inlet versus the

bons. 1-Methylcyclopentene has also been found to elute from

flow of the carrier gas to the capillary column, expressed by:

the precolumn to vent and does not interfere with benzene.

1.6 The values stated in SI units are to be regarded as split ratio 5 ~S 1 C!/C (1)

standard. The values given in parentheses are provided for

where:

information only; they may not be exact equivalents.

S 5 flow rate at the splitter vent and

1.7 This standard does not purport to address all of the

C 5 flow rate at the column outlet.

safety concerns, if any, associated with its use. It is the

3.1.5 1,2,3-tris-2-cyanoethoxypropane (TCEP)—a polar gas

responsibility of the user of this standard to establish appro-

chromatographic liquid phase.

priate safety and health practices and determine the applica-

3.1.6 wall-coated open tubular (WCOT)—a type of capil-

lary column prepared by coating the inside wall of the capillary

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.04.0L on Gas Chromatography. Annual Book of ASTM Standards, Vol 05.01.

Current edition approved Apr. 10, 2000. Published June 2000. Originally Annual Book of ASTM Standards, Vol 05.02.

published as D 5580 – 94. Last previous edition D 5580 – 95. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5580

with a thin film of stationary phase. 5. Significance and Use

5.1 Regulations limiting the concentration of benzene and

4. Summary of Test Method

the total aromatic content of finished gasoline have been

4.1 A two-column chromatographic system equipped with a

established for 1995 and beyond in order to reduce the ozone

column switching valve and a flame ionization detector is used.

reactivity and toxicity of automotive evaporative and exhaust

A reproducible volume of sample containing an appropriate

emissions. Test methods to determine benzene and the aromatic

internal standard such as 2-hexanone is injected onto a precol-

content of gasoline are necessary to assess product quality and

umn containing a polar liquid phase (TCEP). The C and

to meet new fuel regulations.

lighter nonaromatics are vented to the atmosphere as they elute

5.2 This test method can be used for gasolines that contain

from the precolumn. A thermal conductivity detector may be

oxygenates (alcohols and ethers) as additives. It has been

used to monitor this separation. The TCEP precolumn is

determined that the common oxygenates found in finished

backflushed immediately before the elution of benzene, and the

gasoline do not interfere with the analysis of benzene and other

remaining portion of the sample is directed onto a second

aromatics by this test method.

column containing a nonpolar liquid phase (WCOT). Benzene,

toluene, and the internal standard elute in the order of their

6. Apparatus

boiling points and are detected by a flame ionization detector.

6.1 Chromatographic System—See Practice E 355 for spe-

Immediately after the elution of the internal standard, the flow

cific designations and definitions. Refer to Fig. 1 for a diagram

through the nonpolar WCOT column is reversed to backflush

of the system.

the remainder of the sample (C and heavier aromatics plus C

8 10

6.1.1 Gas Chromatograph (GC), capable of operating at the

and heavier nonaromatics) from the column to the flame

conditions given inTable 1, and having a column switching and

ionization detector.

backflushing system equivalent to Fig. 1. Carrier gas pressure

4.2 The analysis is repeated a second time allowing the C

and flow control devices shall be capable of precise control

and lighter nonaromatics, benzene and toluene to elute from

when column head pressures and flow rates are low.

the polar TCEP precolumn to vent. A thermal conductivity

6.1.2 Sample Introduction System, capable of introducing a

detector may be used to monitor this separation. The TCEP

representative sample into the gas chromatographic inlet.

precolumn is backflushed immediately prior to the elution of

Microlitre syringes and automatic syringe injectors have been

ethylbenzene and the remaining aromatic portion is directed

used successfully.

into the WCOT column. The internal standard and C aromatic

6.1.3 Inlet System, (splitting type)— Split injection is nec-

components elute in the order of their boiling points and are

essary to maintain the actual chromatographed sample size

detected by a flame ionization detector. Immediately after

within the limits required for optimum column efficiency and

o-xylene has eluted, the flow through the nonpolar WCOT

detector linearity.

column is reversed to backflush the C and heavier aromatics to

6.1.3.1 Some gas chromatographs are equipped with on-

the flame ionization detector.

column injectors and autosamplers which can inject submi-

4.3 From the first analysis, the peak areas of benzene,

crolitre sample sizes. Such systems can be used provided that

toluene, and the internal standard (2-hexanone) are measured

column efficiency and detector linearity are comparable to

and recorded. Peak areas for ethylbenzene, p/m-xylene,

systems with split injection.

o-xylene, the C and heavier aromatics, and internal standard

6.1.4 Detector—A flame ionization detector (Detector A) is

are measured and recorded from the second analysis. The

backflush peak eluting from the WCOT column in the second employed for quantitation of components eluting from the

WCOT column. The flame ionization detector used for Detec-

analysis contains only C and heavier aromatics.

4.4 The flame ionization detector response, proportional to tor A shall have sufficient sensitivity and stability to detect 0.01

volume % of an aromatic compound.

the concentration of each component, is used to calculate the

amount of aromatics that are present with reference to the 6.1.4.1 It is strongly recommended that a thermal conduc-

internal standard. tivity detector be placed on the vent of the TCEP precolumn

FIG. 1 Valve Diagram, Aromatics in Gasoline

D 5580

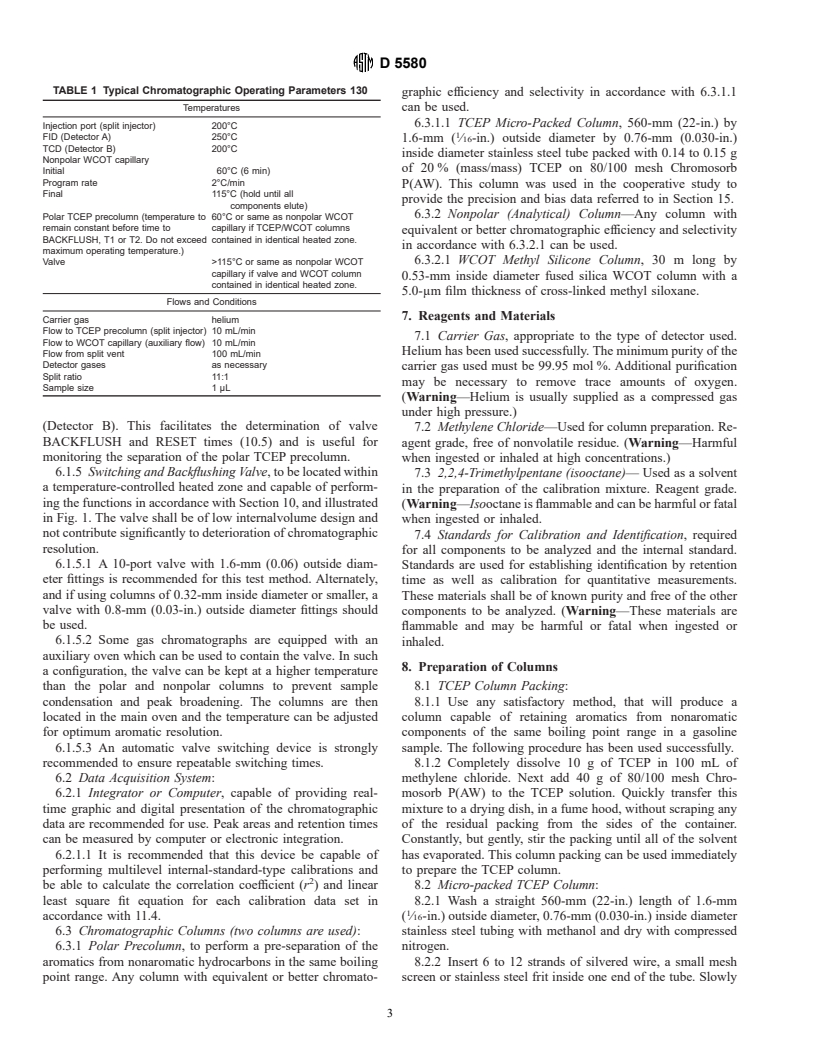

TABLE 1 Typical Chromatographic Operating Parameters 130

graphic efficiency and selectivity in accordance with 6.3.1.1

Temperatures can be used.

6.3.1.1 TCEP Micro-Packed Column, 560-mm (22-in.) by

Injection port (split injector) 200°C

FID (Detector A) 250°C

1.6-mm ( ⁄16-in.) outside diameter by 0.76-mm (0.030-in.)

TCD (Detector B) 200°C

inside diameter stainless steel tube packed with 0.14 to 0.15 g

Nonpolar WCOT capillary

of 20 % (mass/mass) TCEP on 80/100 mesh Chromosorb

Initial 60°C (6 min)

Program rate 2°C/min

P(AW). This column was used in the cooperative study to

Final 115°C (hold until all

provide the precision and bias data referred to in Section 15.

components elute)

6.3.2 Nonpolar (Analytical) Column—Any column with

Polar TCEP precolumn (temperature to 60°C or same as nonpolar WCOT

remain constant before time to capillary if TCEP/WCOT columns

equivalent or better chromatographic efficiency and selectivity

BACKFLUSH, T1 or T2. Do not exceed contained in identical heated zone.

in accordance with 6.3.2.1 can be used.

maximum operating temperature.)

6.3.2.1 WCOT Methyl Silicone Column, 30 m long by

Valve >115°C or same as nonpolar WCOT

capillary if valve and WCOT column

0.53-mm inside diameter fused silica WCOT column with a

contained in identical heated zone.

5.0-μm film thickness of cross-linked methyl siloxane.

Flows and Conditions

7. Reagents and Materials

Carrier gas helium

Flow to TCEP precolumn (split injector) 10 mL/min

7.1 Carrier Gas, appropriate to the type of detector used.

Flow to WCOT capillary (auxiliary flow) 10 mL/min

Helium has been used successfully. The minimum purity of the

Flow from split vent 100 mL/min

Detector gases as necessary

carrier gas used must be 99.95 mol %. Additional purification

Split ratio 11:1

may be necessary to remove trace amounts of oxygen.

Sample size 1 μL

(Warning—Helium is usually supplied as a compressed gas

under high pressure.)

(Detector B). This facilitates the determination of valve

7.2 Methylene Chloride—Used for column preparation. Re-

BACKFLUSH and RESET times (10.5) and is useful for

agent grade, free of nonvolatile residue. (Warning—Harmful

monitoring the separation of the polar TCEP precolumn.

when ingested or inhaled at high concentrations.)

6.1.5 Switching and Backflushing Valve, to be located within

7.3 2,2,4-Trimethylpentane (isooctane)— Used as a solvent

a temperature-controlled heated zone and capable of perform-

in the preparation of the calibration mixture. Reagent grade.

ing the functions in accordance with Section 10, and illustrated (Warning—Isooctane is flammable and can be harmful or fatal

in Fig. 1. The valve shall be of low internalvolume design and

when ingested or inhaled.

not contribute significantly to deterioration of chromatographic 7.4 Standards for Calibration and Identification, required

resolution.

for all components to be analyzed and the internal standard.

6.1.5.1 A 10-port valve with 1.6-mm (0.06) outside diam-

Standards are used for establishing identification by retention

eter fittings is recommended for this test method. Alternately,

time as well as calibration for quantitative measurements.

and if using columns of 0.32-mm inside diameter or smaller, a

These materials shall be of known purity and free of the other

valve with 0.8-mm (0.03-in.) outside diameter fittings should

components to be analyzed. (Warning—These materials are

be used.

flammable and may be harmful or fatal when ingested or

6.1.5.2 Some gas chromatographs are equipped with an

inhaled.

auxiliary oven which can be used to contain the valve. In such

8. Preparation of Columns

a configuration, the valve can be kept at a higher temperature

than the polar and nonpolar columns to prevent sample 8.1 TCEP Column Packing:

condensation and peak broadening. The columns are then 8.1.1 Use any satisfactory method, that will produce a

located in the main oven and the temperature can be adjusted column capable of retaining aromatics from nonaromatic

for optimum aromatic resolution. components of the same boiling point range in a gasoline

6.1.5.3 An automatic valve switching device is strongly sample. The following procedure has been used successfully.

recommended to ensure repeatable switching times. 8.1.2 Completely dissolve 10 g of TCEP in 100 mL of

6.2 Data Acquisition System: methylene chloride. Next add 40 g of 80/100 mesh Chro-

6.2.1 Integrator or Computer, capable of providing real- mosorb P(AW) to the TCEP solution. Quickly transfer this

time graphic and digital presentation of the chromatographic mixture to a drying dish, in a fume hood, without scraping any

data are recommended for use. Peak areas and retention times of the residual packing from the sides of the container.

can be measured by computer or electronic integration. Constantly, but gently, stir the packing until all of the solvent

6.2.1.1 It is recommended that this device be capable of

has evaporated. This column packing can be used immediately

performing multilevel internal-standard-type calibrations and to prepare the TCEP column.

be able to calculate the correlation coefficient (r ) and linear 8.2 Micro-packed TCEP Column:

least square fit equation for each calibration data set in 8.2.1 Wash a straight 560-mm (22-in.) length of 1.6-mm

accordance with 11.4. ( ⁄16-in.) outside diameter, 0.76-mm (0.030-in.) inside diameter

6.3 Chromatographic Columns (two columns are used): stainless steel tubing w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.