ASTM C961-01

(Test Method)Standard Test Method for Lap Shear Strength of Hot-Applied Sealants

Standard Test Method for Lap Shear Strength of Hot-Applied Sealants

SCOPE

1.1 This test method covers a laboratory procedure for determining the lap shear strength of hot-applied sealants, hereinafter referred to as sealant. It also provides information on the adhesive bond of the sealants to the tested substrates.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The subcommittee with jurisdiction of this standard is not aware of any similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C961–01

Standard Test Method for

1

Lap Shear Strength of Hot-Applied Sealants

This standard is issued under the fixed designation C 961; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope measures the cohesive strength of sealants when subjected to

shear stresses, and also provides information regarding the

1.1 This test method covers a laboratory procedure for

adhesive bond to the substrates being tested.

determining the lap shear strength of hot-applied sealants,

hereinafter referred to as sealant. It also provides information

6. Apparatus

on the adhesive bond of the sealants to the tested substrates.

3

6.1 Applicator or Oven, capable of maintaining the sealant

1.2 The values stated in SI units are to be regarded as the

within 62.8°C (65°F) of the specified temperature.

standard. The values given in parentheses are for information

6.2 Substrates, of annealed glass that are 25.4 mm wide by

only.

76.2 mm long and 6.35 mm thick (1 by 3 by 0.25 in.). Other

1.3 This standard does not purport to address all of the

substrates may be used when specified (Fig. 1).

safety concerns, if any, associated with its use. It is the

1

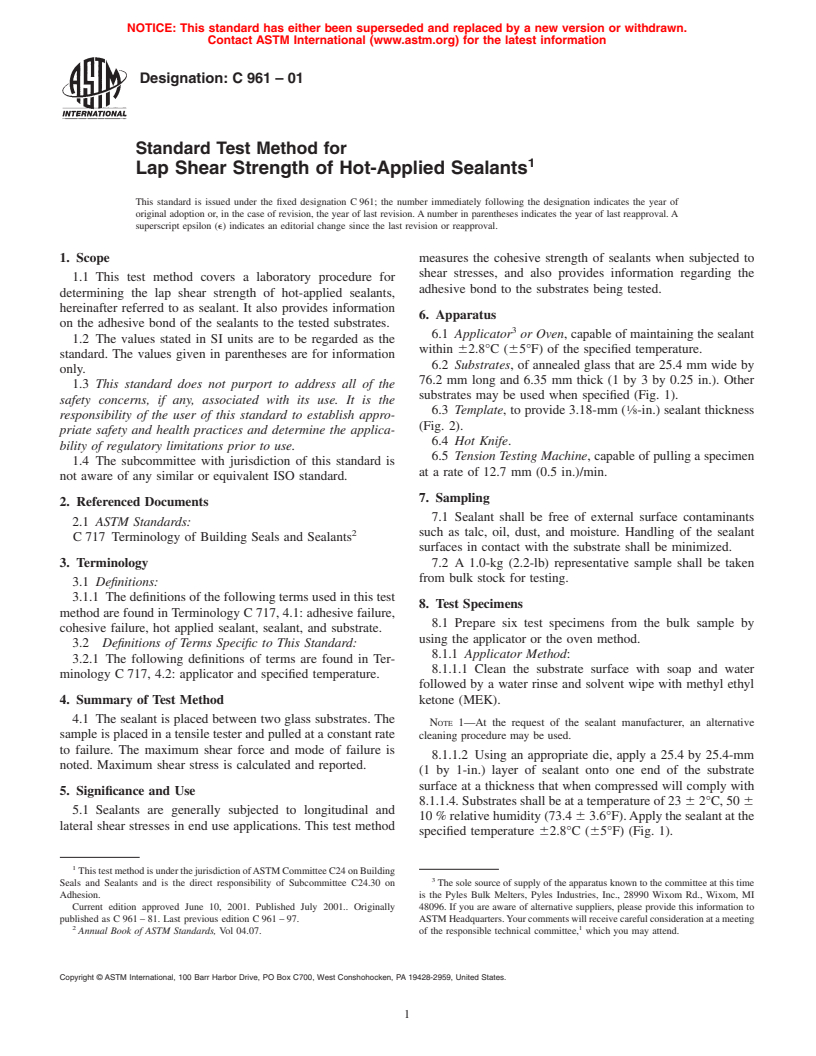

6.3 Template, to provide 3.18-mm ( ⁄8-in.) sealant thickness

responsibility of the user of this standard to establish appro-

(Fig. 2).

priate safety and health practices and determine the applica-

6.4 Hot Knife.

bility of regulatory limitations prior to use.

6.5 Tension Testing Machine, capable of pulling a specimen

1.4 The subcommittee with jurisdiction of this standard is

at a rate of 12.7 mm (0.5 in.)/min.

not aware of any similar or equivalent ISO standard.

7. Sampling

2. Referenced Documents

7.1 Sealant shall be free of external surface contaminants

2.1 ASTM Standards:

2

such as talc, oil, dust, and moisture. Handling of the sealant

C 717 Terminology of Building Seals and Sealants

surfaces in contact with the substrate shall be minimized.

3. Terminology 7.2 A 1.0-kg (2.2-lb) representative sample shall be taken

from bulk stock for testing.

3.1 Definitions:

3.1.1 The definitions of the following terms used in this test

8. Test Specimens

method are found in Terminology C 717, 4.1: adhesive failure,

8.1 Prepare six test specimens from the bulk sample by

cohesive failure, hot applied sealant, sealant, and substrate.

using the applicator or the oven method.

3.2 Definitions of Terms Specific to This Standard:

8.1.1 Applicator Method:

3.2.1 The following definitions of terms are found in Ter-

8.1.1.1 Clean the substrate surface with soap and water

minology C 717, 4.2: applicator and specified temperature.

followed by a water rinse and solvent wipe with methyl ethyl

4. Summary of Test Method ketone (MEK).

4.1 The sealant is placed between two glass substrates. The

NOTE 1—At the request of the sealant manufacturer, an alternative

sample is placed in a tensile tester and pulled at a constant rate

cleaning procedure may be used.

to failure. The maximum shear force and mode of failure is

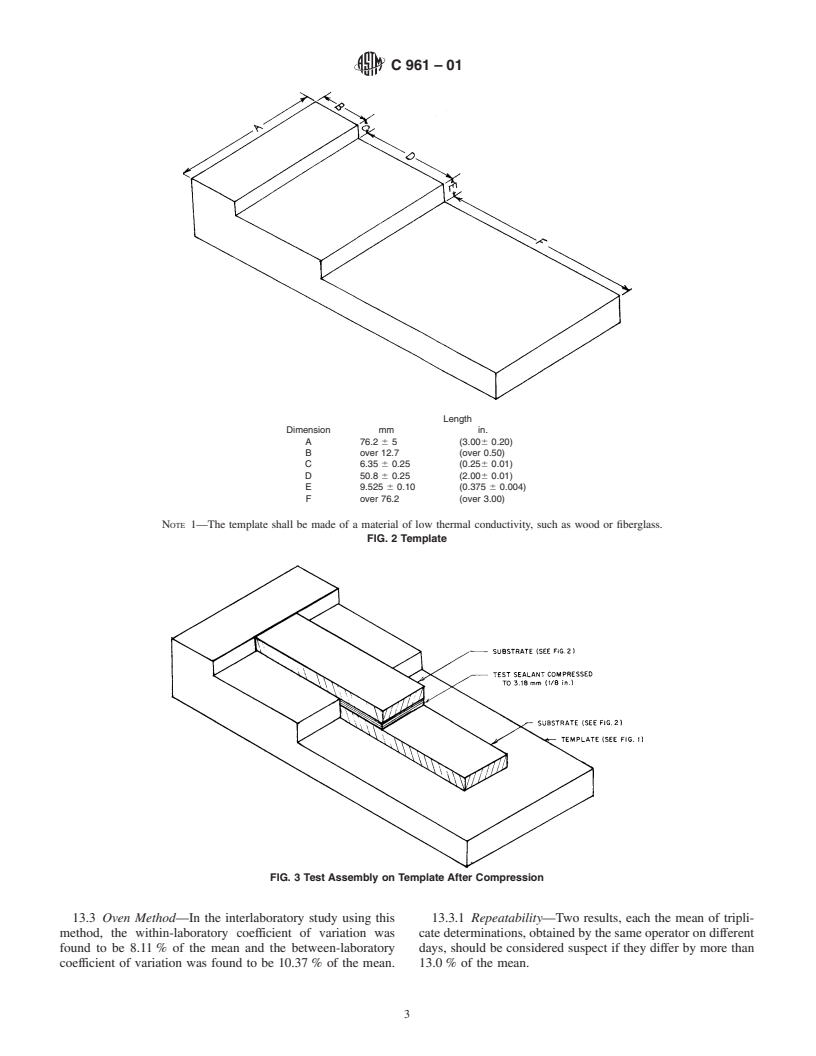

8.1.1.2 Using an appropriate die, apply a 25.4 by 25.4-mm

noted. Maximum shear stress is calculated and reported.

(1 by 1-in.) layer of sealant onto one end of the substrate

surface at a thickness that when compressed will comply with

5. Significance and Use

8.1.1.4. Substrates shall be at a temperature of 23 6 2°C, 50 6

5.1 Sealants are generally subjected to longitudinal and

10 % relative humidity (73.4 6 3.6°F).Apply the sealant at the

lateral shear stresses in end use applications. This test method

specified temperature 62.8°C (65°F) (Fig. 1).

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

3

Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on The sole source of supply of the apparatus known to the committee at this time

Adhesion. is the Pyles Bulk Melters, Pyles Industries, Inc., 28990 Wixom Rd., Wixom, MI

Current edition approved June 10, 2001. Published July 2001. Originally 48096. If you are aware of alternative suppliers, please provide this information to

published as C 961 – 81. Last previous edition C 961 – 97. ASTMHeadquarters.Yourcommentswillreceivecarefulconsiderationatameeting

2 1

Annual Book of ASTM Standards, Vol 04.07. of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C961–01

10. Procedure

10.1 Attach each specimen to the jaws of the tension testing

machine and separate at a crosshead speed of 12.7 mm (0.5

in.)/min to failure (separation) (Fig. 4). Al

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.