ASTM F1750-11(2015)

(Specification)Standard Specification for Paintball Marker Threaded-Propellant Source Interface

Standard Specification for Paintball Marker Threaded-Propellant Source Interface

ABSTRACT

This specification covers the male and female threaded connectors used to interface a propellant source to a paintball marker. The male connector shall incorporate a means for propellant shutoff that shall meet the maximum leakage requirement. When the male and female connectors are joined and pressurized, together they shall meet the maximum leakage specification. The male and female connector shall conform to the physical envelope described. The male connector may contain, as a means of propellant shutoff, a valve core to provide for an automatic shutoff of flow at the time of disconnection. The female connector shall have a provision for the self venting of residual gas pressure prior to the disconnection of the threaded interface.

SCOPE

1.1 This specification covers the male and female threaded connectors used to interface a propellant source with a working pressure of 10 342 kPa (1800 psig) or less to a paintball marker.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1750 −11(Reapproved 2015) An American National Standard

Standard Specification for

Paintball Marker Threaded-Propellant Source Interface

This standard is issued under the fixed designation F1750; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Connector Gender Assignment

1.1 This specification covers the male and female threaded 3.1 The female connector is that connector which is config-

connectorsusedtointerfaceapropellantsourcewithaworking uredaspartofthepaintballmarkerconformingtoSpecification

pressure of 10342 kPa (1800 psig) or less to a paintball

F2272.

marker.

3.2 The male connector is that connector which is config-

1.2 The values stated in SI units are to be regarded as

ured as part of the propellant source.

standard. The values given in parentheses are for information

only.

4. Materials and Manufacture

1.3 This standard does not purport to address all of the

4.1 The male and female connectors shall be made from

safety concerns, if any, associated with its use. It is the

materials that are compatible with CO , compressed air, or

responsibility of the user of this standard to establish appro-

gaseous nitrogen. The materials and processes used to manu-

priate safety and health practices and determine the applica-

facture male and female connectors shall result in items with

bility of regulatory limitations prior to use.

mechanicalstrengthsufficienttopassa20684-kPa(3000-psig)

proof pressure check without failure or any degradation to

2. Referenced Documents

function.

2.1 ASTM Standards:

4.2 The O-ring seal shall be made from an elastomer

D2240TestMethodforRubberProperty—DurometerHard-

compatiblewithCO ,compressedair,orgaseousnitrogen.The

ness

O-ring seal shall have a hardness that will register a Type A

F2272Specification for Paintball Markers

durometer reading of 90 6 5. The O-ring shall conform

2.2 ANSI Standard:

dimensionally to MS28775-015 and conform to Test Method

ANSI Y14.5M–1994Dimensioning and Tolerancing

D2240.

2.3 CGA Standard:

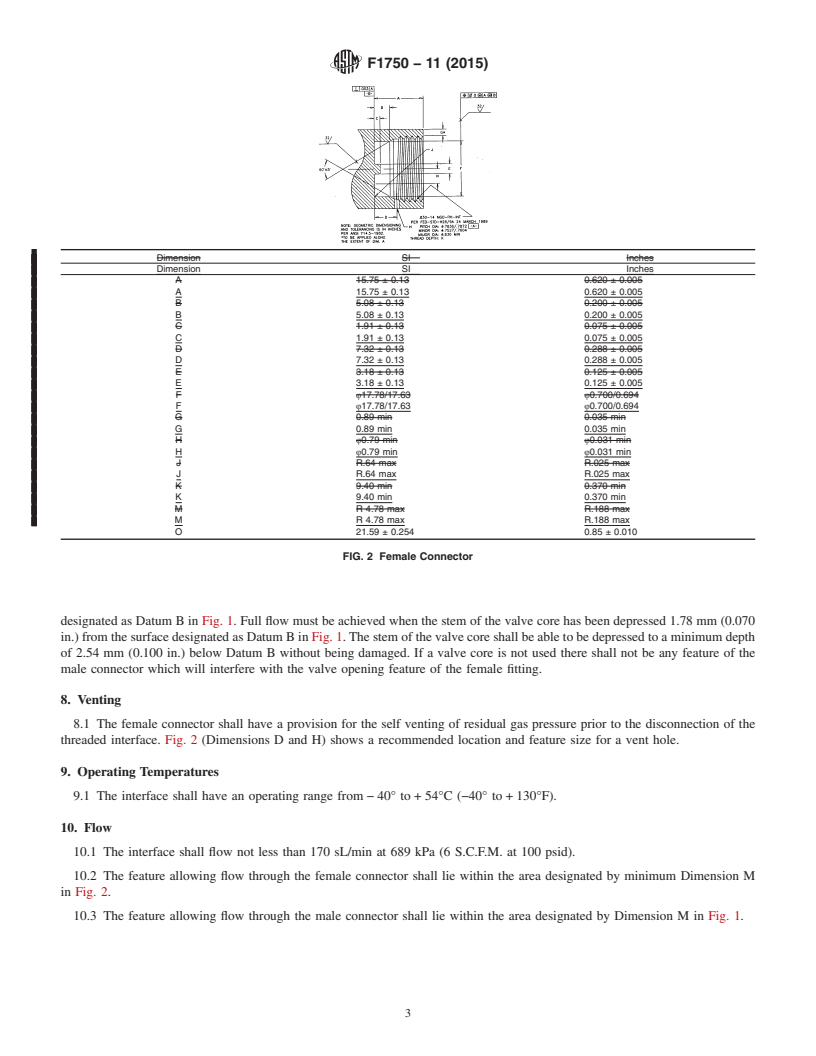

4.3 The O-ring seal shall be installed on the male connector

CGA-320.825-14NGO-RH-EXT (Flat Nipple)

in the groove described by Dimensions C and K on Fig. 1.

2.4 Federal Standard:

FED-STD-H28/9A24 March 1989 Federal Standard Screw-

4.4 The male and female connectors shall not have any

Thread Standards for Federal Services Section 9 Gas

sharp edges or hanging burrs. All sharp edges will be broken

Cylinder Valve Outlet and Inlet Threads

R.38 MAX (R.015 MAX).

2.5 Military Standard:

MS28775O-Ring Dash Sizes

5. Performance

5.1 The interface is intended for use with compressed air,

This specification is under the jurisdiction ofASTM Committee F08 on Sports

gaseous nitrogen, or CO .

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.24 on Paintball and Equipment. 5.2 The maximum operating pressure of the interface is

Current edition approved April 1, 2015. Published August 2015. Originally

10342 kPa (1800 psig).

approved in 1996. Last previous edition approved in 2011 as F1750–11. DOI:

10.1520/F1750-11R15.

5.3 The maximum allowable leakage at 10342 kPa (1800

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

psig) is 0.1 cm /min.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5.4 The male connector shall incorporate a means for

the ASTM website.

propellant shutoff that shall meet the maximum leakage re-

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

quirement.

4th Floor, New York, NY 10036.

Available from Compressed Gas Association (CGA), 1725 Jefferson Davis

5.5 When the male and female connectors are joined and

Hwy., Suite 1004, Arlington, VA 22202-4102.

pressurized, together they shall meet the maximum leakage

AvailablefromU.S

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1750 − 11 F1750 − 11 (Reapproved 2015) An American National Standard

Standard Specification for

Paintball Marker Threaded-Propellant Source Interface

This standard is issued under the fixed designation F1750; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the male and female threaded connectors used to interface a propellant source with a working

pressure of 10 342 kPa (1800 psig) or less to a paintball marker.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D2240 Test Method for Rubber Property—Durometer Hardness

F2272 Specification for Paintball Markers

2.2 ANSI Standard:

ANSI Y14.5M–1994 Dimensioning and Tolerancing

2.3 CGA Standard:

CGA-320 .825-14NGO-RH-EXT (Flat Nipple)

2.4 Federal Standard:

FED-STD-H28/9A 24 March 1989 Federal Standard Screw-Thread Standards for Federal Services Section 9 Gas Cylinder Valve

Outlet and Inlet Threads

2.5 Military Standard:

MS28775 O-Ring Dash Sizes

3. Connector Gender Assignment

3.1 The female connector is that connector which is configured as part of the paintball marker conforming to Specification

F2272.

3.2 The male connector is that connector which is configured as part of the propellant source.

4. Materials and Manufacture

4.1 The male and female connectors shall be made from materials that are compatible with CO , compressed air, or gaseous

nitrogen. The materials and processes used to manufacture male and female connectors shall result in items with mechanical

strength sufficient to pass a 20 684-kPa (3000-psig) proof pressure check without failure or any degradation to function.

4.2 The O-ring seal shall be made from an elastomer compatible with CO , compressed air, or gaseous nitrogen. The O-ring

seal shall have a hardness that will register a Type A durometer reading of 90 6 5. The O-ring shall conform dimensionally to

MS28775-015 and conform to Test Method D2240.

This specification is under the jurisdiction of ASTM Committee F08 on Sports Equipment Equipment, Playing Surfaces, and Facilities and is the direct responsibility

of Subcommittee F08.24 on Paintball and Equipment.

Current edition approved March 1, 2011April 1, 2015. Published March 2011August 2015. Originally approved in 1996. Last previous edition approved in 20102011 as

F1750 – 05 (2010).F1750 – 11. DOI: 10.1520/F1750-11.10.1520/F1750-11R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

Available from Compressed Gas Association (CGA), 1725 Jefferson Davis Hwy., Suite 1004, Arlington, VA 22202-4102.

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1750 − 11 (2015)

4.3 The O-ring seal shall be installed on the male connector in the groove described by Dimensions C and K on Fig. 1.

4.4 The male and female connectors shall not have any sharp edges or hanging burrs. All sharp edges will be broken R.38 MAX

(R.015 MAX).

5. Performance

5.1 The interface is intended for use with compressed air, gaseous nitrogen, or CO .

5.2 The maximum operating pressure of the interface is 10 342 kPa (1800 psig).

5.3 The maximum allowable leakage at 10 342 kPa (1800 psig) is 0.1 cm /min.

5.4 The male connector shall incorporate a means for propellant shutoff that shall meet the maximum leakage requirement.

5.5 When the male and female

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.