ASTM G208-12(2020)

(Practice)Standard Practice for Evaluating and Qualifying Oilfield and Refinery Corrosion Inhibitors Using Jet Impingement Apparatus

Standard Practice for Evaluating and Qualifying Oilfield and Refinery Corrosion Inhibitors Using Jet Impingement Apparatus

SIGNIFICANCE AND USE

5.1 Selection of corrosion inhibitor for oilfield and refinery applications involves qualification of corrosion inhibitors in the laboratory (see Guide G170). Field conditions should be simulated in the laboratory in a fast and cost-effective manner.

5.2 Oilfield and refinery corrosion inhibitors should provide protection over a range of flow conditions from stagnant to that found during typical production conditions. The inhibitors are not equally effective over all flow conditions, so it is important to determine the flow conditions in which they are effective.

5.3 Severity of hydrodynamic conditions depends on the type of laboratory methodology. Typically, rotating cylinder electrode is effective up to 20 Pa of wall shear stress, rotating cage (RC) is effective between 20 and 200 Pa of wall shear stress, and jet impingement (JI) is effective at wall shear stress above 200 Pa (1)3 of wall shear stress.

5.4 The JI test system is relatively inexpensive and uses simple flat specimens.

5.5 In this practice, a general procedure is presented to obtain reproducible results using JI simulating the effects of different types of coupon materials; inhibitor concentrations; oil, gas, and brine compositions; temperature; pressure; and flow. Erosive effects predominate when the flow rate is very high (typically above 500 Pa) or when sand or solid particles are present; however, this practice does not cover the erosive effects.

SCOPE

1.1 This practice covers a generally accepted procedure to use the jet impingement (JI) apparatus for evaluating corrosion inhibitors for oilfield and refinery applications in defined flow conditions.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:G208 −12 (Reapproved 2020)

Standard Practice for

Evaluating and Qualifying Oilfield and Refinery Corrosion

Inhibitors Using Jet Impingement Apparatus

This standard is issued under the fixed designation G208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G31 Guide for Laboratory Immersion Corrosion Testing of

Metals

1.1 This practice covers a generally accepted procedure to

G46 Guide for Examination and Evaluation of Pitting Cor-

use the jet impingement (JI) apparatus for evaluating corrosion

rosion

inhibitors for oilfield and refinery applications in defined flow

G59 Test Method for Conducting Potentiodynamic Polariza-

conditions.

tion Resistance Measurements

1.2 The values stated in SI units are to be regarded as

G96 Guide for Online Monitoring of Corrosion in Plant

standard. No other units of measurement are included in this

Equipment (Electrical and Electrochemical Methods)

standard.

G102 Practice for Calculation of Corrosion Rates and Re-

1.3 This standard does not purport to address all of the lated Information from Electrochemical Measurements

safety concerns, if any, associated with its use. It is the

G106 Practice for Verification of Algorithm and Equipment

responsibility of the user of this standard to establish appro- for Electrochemical Impedance Measurements

priate safety, health, and environmental practices and deter-

G111 Guide for Corrosion Tests in High Temperature or

mine the applicability of regulatory limitations prior to use. High Pressure Environment, or Both

1.4 This international standard was developed in accor-

G170 Guide for Evaluating and Qualifying Oilfield and

dance with internationally recognized principles on standard- Refinery Corrosion Inhibitors in the Laboratory

ization established in the Decision on Principles for the

G184 Practice for Evaluating and Qualifying Oil Field and

Development of International Standards, Guides and Recom- Refinery Corrosion Inhibitors Using Rotating Cage

mendations issued by the World Trade Organization Technical

G185 Practice for Evaluating and Qualifying Oil Field and

Barriers to Trade (TBT) Committee. RefineryCorrosionInhibitorsUsingtheRotatingCylinder

Electrode

2. Referenced Documents

G193 Terminology and Acronyms Relating to Corrosion

2.1 ASTM Standards:

3. Terminology

D1141 Practice for the Preparation of Substitute Ocean

Water

3.1 Theterminologyusedhereinshallbeinaccordancewith

D1193 Specification for Reagent Water

Terminology D4410, Guide G170, and Terminology G193.

D4410 Terminology for Fluvial Sediment

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

4. Summary of Practice

sion Test Specimens

4.1 Thispracticeprovidesamethodforevaluatingcorrosion

G5 Reference Test Method for Making Potentiodynamic

inhibitor efficiency in jet impingement (JI) apparatus. The

Anodic Polarization Measurements

method uses a well-defined impinging jet set up and mass loss

G16 Guide for Applying Statistics to Analysis of Corrosion

or electrochemical techniques to measure corrosion rates.

Data

Measurements are made using three different experimental

designs and at several flow rates to evaluate the inhibitor

performance under increasingly severe hydrodynamic condi-

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory tions.

Corrosion Tests.

Current edition approved Nov. 1, 2020. Published November 2020. Originally

5. Significance and Use

approved in 2012. Last previous edition approved in 2016 as G208 – 12 (2016).

DOI: 10.1520/G0208-12R20.

5.1 Selection of corrosion inhibitor for oilfield and refinery

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

applicationsinvolvesqualificationofcorrosioninhibitorsinthe

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

laboratory (see Guide G170). Field conditions should be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. simulated in the laboratory in a fast and cost-effective manner.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G208−12 (2020)

TABLE 1 Parameters to be Reported Along with Test Results

Parameter Units Remarks

Solution chemistry

Material chemistry

Solution density

Solution viscosity

Temperature C or F or K

Pressure psi or kPa For elevated pressure experiments

Jet velocity m/s or cm/s or inch/s

Specimen type ring or disc

Disc diameter mm or cm or m For disc electrodes only

ring diameter (inner) mm or cm or m For ring electrodes only

ring diameter (outer) mm or cm or m For ring electrodes only

radial distance mm or cm or m

Distance between jet and the nozzle mm or cm or m

Rotation speed RPM

Electrode diameter or radius mm or cm or m

Volume of container cm

Volume of solution cm

Tafel constants, anodic, cathodic For electrochemical measurements

Description of counter electrode (size, shape, and For electrochemical measurements

distance from the working electrode)

Initial mass mg or g For mass loss measurements

Final mass mg or g For mass loss measurements

Corrosion rate in absence of inhibitor mpy or mm/yr

Inhibitor efficiency, at each inhibitor concentration %

Number of specimens

Volume of solution/surface area of the electrode cm

Inhibitor type continuous or batch

Inhibitor concentration ppm or vol/vol or mass/volume or mass/mass

Description of EIS model Provide the model and elements (for electrochemical

measurements)

Solution conductivity Siemens For electrochemical measurements

Presence of oil yes or no

If oil is present, volume of oil cm

Duration of experiments Minutes, hour, day

Type of reference electrode For electrochemical measurements

Number of specimens

5.2 Oilfield and refinery corrosion inhibitors should provide 6. Apparatus

protectionoverarangeofflowconditionsfromstagnanttothat

6.1 The actual hydrodynamic conditions in the tests must be

found during typical production conditions. The inhibitors are

known to enable comparison of results with those obtained in

not equally effective over all flow conditions, so it is important

other tests or predictions of inhibitor performance in practical

to determine the flow conditions in which they are effective.

operating systems. Hydrodynamic parameters in jet impinge-

5.3 Severity of hydrodynamic conditions depends on the ment are described in Annex A1. These hydrodynamic rela-

type of laboratory methodology. Typically, rotating cylinder tionships are valid only for a specific range and are influenced

electrode is effective up to 20 Pa of wall shear stress, rotating by the geometry and orientation of specimen and apparatus.A

cage (RC) is effective between 20 and 200 Pa of wall shear minor change in any one parameter drastically alters the

stress, and jet impingement (JI) is effective at wall shear stress hydrodynamic parameters.

above 200 Pa (1) of wall shear stress.

6.2 A proper experimental design must consider the jet

5.4 The JI test system is relatively inexpensive and uses velocity, radial distance, radius of the electrode (ring or disc),

simple flat specimens. distance between jet nozzle and the electrode, and jet nozzle

diameter. Some typical parameters for describing jet impinge-

5.5 In this practice, a general procedure is presented to

mentapparatusarelistedinTable1.Agoodlaboratorypractice

obtain reproducible results using JI simulating the effects of

would be to control, record, and report all the system specifi-

different types of coupon materials; inhibitor concentrations;

cations.

oil, gas, and brine compositions; temperature; pressure; and

flow. Erosive effects predominate when the flow rate is very 6.3 Depending on the geometry of apparatus and size and

high (typically above 500 Pa) or when sand or solid particles shape of the specimens there are three jet impingement

are present; however, this practice does not cover the erosive apparatus designs.

effects. 6.3.1 Design 1:

6.3.1.1 In this design, the working electrode is a disc and is

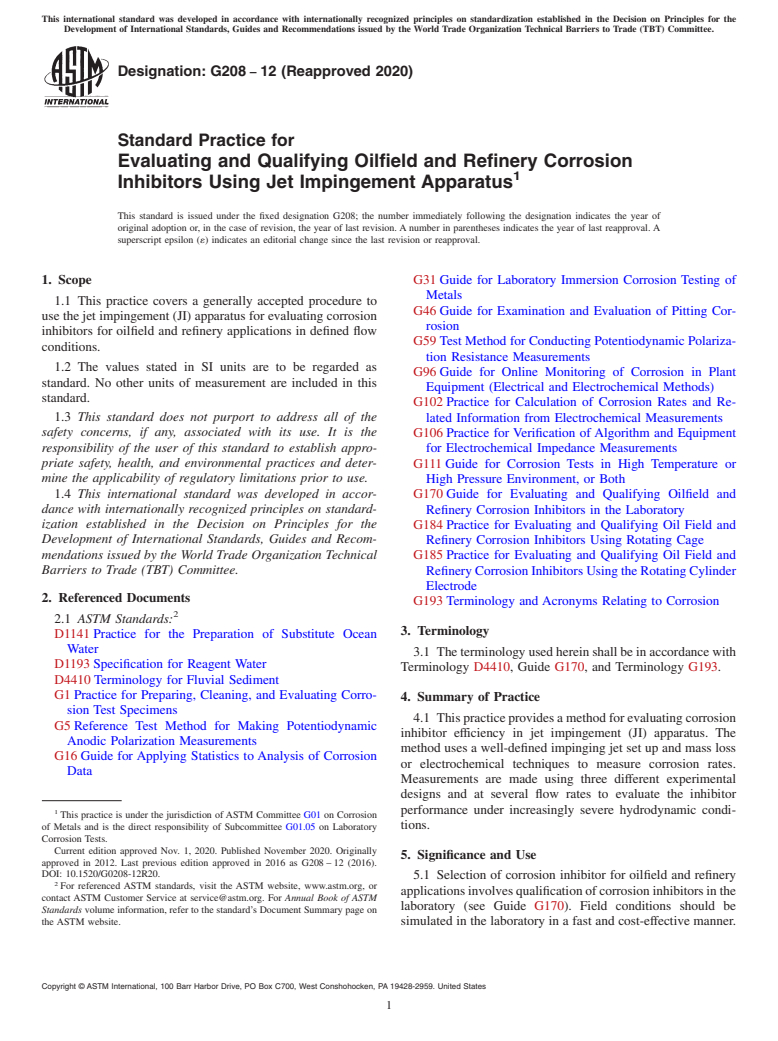

exposed only to the stagnation region (Fig. 1)(2-4). Typical

diameter of the jet nozzle is 0.6 cm and is placed axis-

The boldface numbers in parentheses refer to a list of references at the end of

this standard. symmetric to the specimen (working electrode). The diameter

G208−12 (2020)

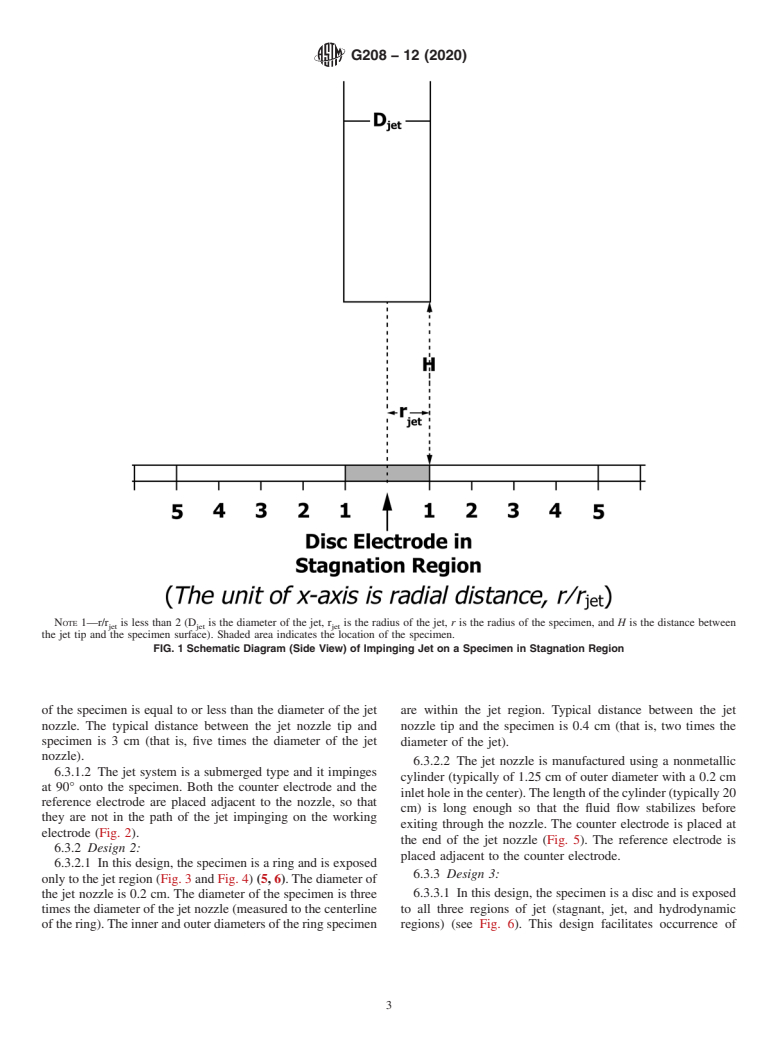

NOTE 1—r/r is less than 2 (D is the diameter of the jet, r is the radius of the jet, r is the radius of the specimen, and H is the distance between

jet jet jet

the jet tip and the specimen surface). Shaded area indicates the location of the specimen.

FIG. 1Schematic Diagram (Side View) of Impinging Jet on a Specimen in Stagnation Region

of the specimen is equal to or less than the diameter of the jet are within the jet region. Typical distance between the jet

nozzle. The typical distance between the jet nozzle tip and

nozzle tip and the specimen is 0.4 cm (that is, two times the

specimen is 3 cm (that is, five times the diameter of the jet

diameter of the jet).

nozzle).

6.3.2.2 The jet nozzle is manufactured using a nonmetallic

6.3.1.2 The jet system is a submerged type and it impinges

cylinder (typically of 1.25 cm of outer diameter with a 0.2 cm

at 90° onto the specimen. Both the counter electrode and the

inletholeinthecenter).Thelengthofthecylinder(typically20

reference electrode are placed adjacent to the nozzle, so that

cm) is long enough so that the fluid flow stabilizes before

they are not in the path of the jet impinging on the working

exiting through the nozzle. The counter electrode is placed at

electrode (Fig. 2).

the end of the jet nozzle (Fig. 5). The reference electrode is

6.3.2 Design 2:

placed adjacent to the counter electrode.

6.3.2.1 In this design, the specimen is a ring and is exposed

6.3.3 Design 3:

only to the jet region (Fig. 3 and Fig. 4) (5, 6).The diameter of

6.3.3.1 In this design, the specimen is a disc and is exposed

the jet nozzle is 0.2 cm. The diameter of the specimen is three

times the diameter of the jet nozzle (measured to the centerline to all three regions of jet (stagnant, jet, and hydrodynamic

regions) (see Fig. 6). This design facilitates occurrence of

ofthering).Theinnerandouterdiametersoftheringspecimen

G208−12 (2020)

NOTE 1—Figure not to scale. Shaded area indicates the location of the specimen.

FIG. 2Schematic Diagram of Experimental Test Cell (Design 1)

localized corrosion as the specimen is under the influence of 6.5 For atmospheric pressure experiment, an apparatus con-

various regions (stagnation, wall jet, and hydrodynamic re-

structed from acrylic, PFTE, or an inert material shall be used.

gions).

For experiments above atmospheric pressure, an apparatus that

6.3.3.2 The diameter of the jet nozzle is 0.64 cm. The

can withstand high pressure without leakage must be used.

diameter of the specimen is five times the diameter of the jet

Such high-temperature, high-pressure jet impingement (HTH-

nozzle. Typical distance between the jet nozzle tip and the

PJI) system is constructed using corrosion-resistant alloy

specimen is 3.2 cm (that is, five times the diameter of the jet)

(CRA).

(7, 8).

6.6 For all designs, the apparatus must contain ports for

NOTE 1—The larger size of the specimen may also enable it to be used

specimen, counter electrode, reference electrode, inlet and

as a mass loss coupon.

outlet. Additional ports enable measurement of pH and tem-

6.3.3.3 The counter electrode is placed on the return path of

perature during the experiment and draining of the test solution

the jet to avoid interference with the jet flow (Fig. 7).

aftertheexperiment.Bothinletandoutletportsshouldbefitted

Reference electrode is placed in the side of the jet arm.

with a Y joint, so that the apparatus is connected to both a gas

6.3.3.4 This design uses multiple specimens (typically four)

cylinder and the preparation apparatus. In Design 1 and 2, a

(Fig. 8). The jet is created in a central cell with four arms

pump that creates the jet should be placed between the

containingfournozzles.Theimpellerishousedinthecellbody

preparation and experimental apparatus. In Design 3, the pump

and is driven by a motor magnetically coupled to the impeller

should be placed inside the apparatus itself.

shaft. Fluid from the cell is forced by the impeller through the

nozzles and is recirculated to the cell. All moving parts of the

6.7 The suggested components can be modified, simplified,

pump are located inside the central cell (7).

or made more sophisticated to fit the needs of a particular

6.4 For all designs, the relationship between the motor investigation. The suggested apparatus is basic and the appa-

speed that creates the jet and the flow rate shall be established. ratus is limited only by the judgment and ingenuity of the

A procedure to establish such a relationship is described in

investigator.

Annex A2.

G208−12 (2020)

NOTE 1—(r is the radius of jet, D is the diameter of jet nozzle, and H is the distance between jet nozzle and the specimen). Shaded area indicates

jet jet

the location of the specimen.

FIG. 3Schematic Diagram (Side View) of Impinging Jet on a Specimen in Wall Jet Region

7. Preparation of Test Specimens 7.3 Theappropriateringordiscspecimenshallbemachined

andsnuglyfittedintothePTFEsampleholderorsampleholder

7.1 Methods for preparing specimens for tests and for

made from any other appropriate material, with no gap

removing specimens after the test are described in Practice G1.

between the sample and the holder. If necessary, a very small

7.2 The specimen shall be made of the material (for

amount of epoxy should be used to fit the specimen into the

example, carbon steel) for which the inhibitor is being evalu-

holder. The presence of a gap will create crevice corrosion as

ated. Corrosion rates and inhibitor performance change by

well as change the flow pattern. The end cap is screwed in or

severalordersofmagnitudeassurfaceroughnesschangesfrom

attached tightly so that only the disc or ring of known area is

rough to fine. The surface roughness shall be kept the same

exposedtothesolution.Electricalconnectionshallbeprovided

during inhibitor screening and, if possible, the surface rough-

at the back of the specimen through spring connections.

ness

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.