ASTM G5-13e1

(Test Method)Standard Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements

Standard Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements

SIGNIFICANCE AND USE

3.1 The availability of a standard procedure, standard material, and a standard plot should make it easy for an investigator to check his techniques. This should lead to polarization curves in the literature which can be compared with confidence.

3.2 Samples of a standard ferritic Type 430 stainless steel (UNS S43000) used in obtaining standard reference plot are available for those who wish to check their own test procedure and equipment.3

3.3 Standard potentiodynamic polarization plots are shown for a lot of material originally purchased in 1992. This test method is not applicable for standard material purchased before 1992. These reference data are based on the results from different laboratories that followed the standard procedure, using that material in 1.0 N H2SO4. The four sigma probability bands for current density values are shown at each potential to indicate the acceptable range of values.

3.4 This test method may not be appropriate for polarization testing of all materials or in all environments.

3.5 This test method is intended for use in evaluating the accuracy of a given electrochemical test apparatus, not for use in evaluating materials performance. Therefore, the use of the plots in Fig. 1 is not recommended to evaluate alloys other than Type 430, or lots of Type 430 other than those available through Metal Samples. The use of the data in this test method in this manner is beyond the scope and intended use of this test method. Users of this test method are advised to evaluate test results relative to the scatter bands corresponding to the particular lot of Type 430 stainless steel that was tested.

SCOPE

1.1 This test method covers an experimental procedure for checking experimental technique and instrumentation. If followed, this test method will provide repeatable potentiodynamic anodic polarization measurements that will reproduce data determined by others at other times and in other laboratories provided all laboratories are testing reference samples from the same lot of Type 430 stainless steel.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: G5 − 13

StandardReference Test Method for

Making Potentiodynamic Anodic Polarization

1

Measurements

This standard is issued under the fixed designation G5; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Updated research report footnote in Section 7 editorially in August 2013.

1. Scope investigator to check his techniques. This should lead to

polarization curves in the literature which can be compared

1.1 This test method covers an experimental procedure for

with confidence.

checking experimental technique and instrumentation. If

followed, this test method will provide repeatable potentiody- 3.2 Samples of a standard ferritic Type 430 stainless steel

namic anodic polarization measurements that will reproduce (UNS S43000) used in obtaining standard reference plot are

data determined by others at other times and in other labora- available for those who wish to check their own test procedure

3

tories provided all laboratories are testing reference samples and equipment.

from the same lot of Type 430 stainless steel.

3.3 Standard potentiodynamic polarization plots are shown

1.2 Units—The values stated in SI units are to be regarded for a lot of material originally purchased in 1992. This test

asstandard.Nootherunitsofmeasurementareincludedinthis method is not applicable for standard material purchased

standard. before1992.Thesereferencedataarebasedontheresultsfrom

different laboratories that followed the standard procedure,

1.3 This standard does not purport to address all of the

usingthatmaterialin1.0NH SO .Thefoursigmaprobability

2 4

safety concerns, if any, associated with its use. It is the

bands for current density values are shown at each potential to

responsibility of the user of this standard to establish appro-

indicate the acceptable range of values.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.4 Thistestmethodmaynotbeappropriateforpolarization

testing of all materials or in all environments.

2. Referenced Documents

3.5 This test method is intended for use in evaluating the

2

2.1 ASTM Standards:

accuracy of a given electrochemical test apparatus, not for use

E1338Guide for Identification of Metals and Alloys in

in evaluating materials performance. Therefore, the use of the

Computerized Material Property Databases

plotsinFig.1isnotrecommendedtoevaluatealloysotherthan

G3Practice for Conventions Applicable to Electrochemical

Type 430, or lots of Type 430 other than those available

Measurements in Corrosion Testing

through Metal Samples.The use of the data in this test method

G107Guide for Formats for Collection and Compilation of

inthismannerisbeyondthescopeandintendeduseofthistest

Corrosion Data for Metals for Computerized Database

method. Users of this test method are advised to evaluate test

Input

results relative to the scatter bands corresponding to the

particular lot of Type 430 stainless steel that was tested.

3. Significance and Use

4. Apparatus

3.1 The availability of a standard procedure, standard

material, and a standard plot should make it easy for an

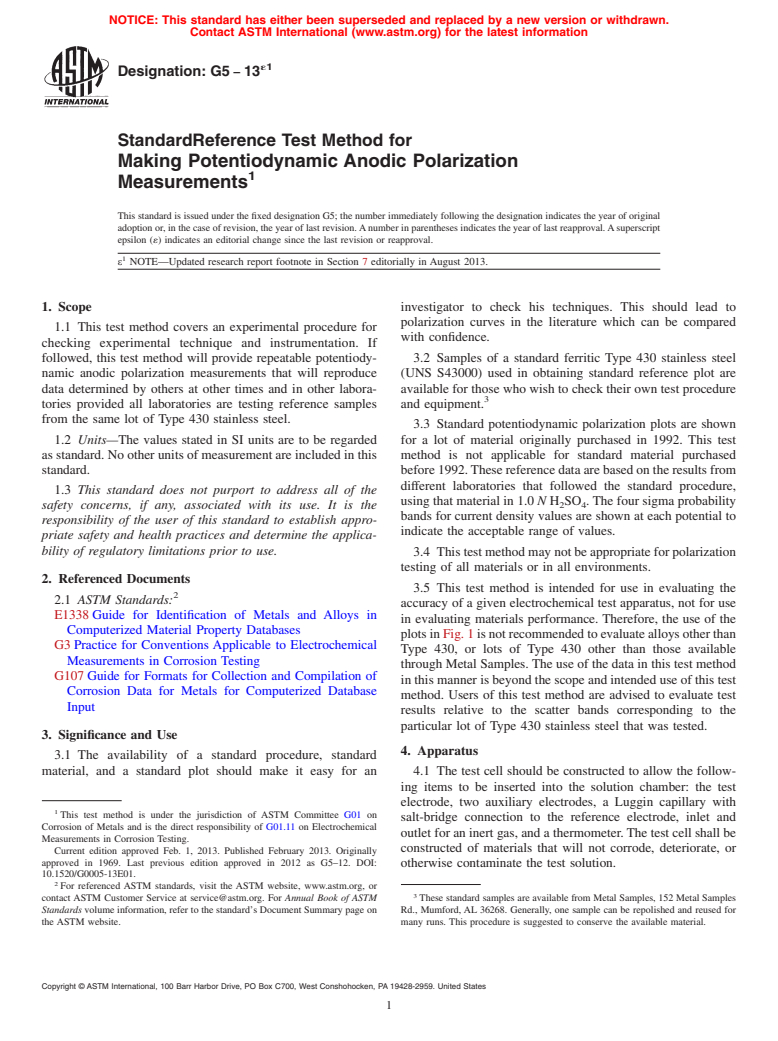

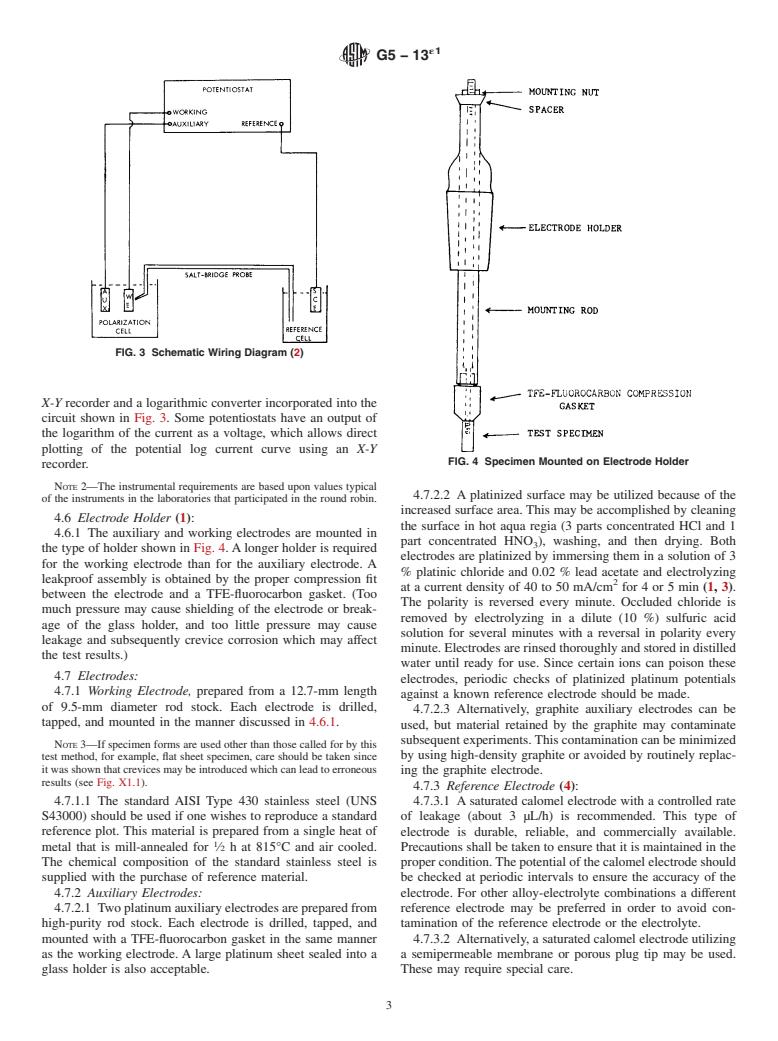

4.1 The test cell should be constructed to allow the follow-

ing items to be inserted into the solution chamber: the test

electrode, two auxiliary electrodes, a Luggin capillary with

1

This test method is under the jurisdiction of ASTM Committee G01 on

salt-bridge connection to the reference electrode, inlet and

Corrosion of Metals and is the direct responsibility of G01.11 on Electrochemical

outletforaninertgas,andathermometer.Thetestcellshallbe

Measurements in Corrosion Testing.

constructed of materials that will not corrode, deteriorate, or

Current edition approved Feb. 1, 2013. Published February 2013. Originally

approved in 1969. Last previous edition approved in 2012 as G5–12. DOI:

otherwise contaminate the test solution.

10.1520/G0005-13E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM These standard samples are available from Metal Samples, 152 Metal Samples

Standards volume information, refer to the standard’s Document Summary page on Rd., Mumford,AL 36268. Generally, one sample can be repolished and reused for

the ASTM website. many runs. This procedure is suggested to conserve the available material.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

G5−13

2

CURRENT DENSITY (µA/cm )

FIG. 1 Typical Standard Potentiodynamic Anodic Pol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.