ASTM D5749-01(2012)

(Specification)Standard Specification for Reinforced and Plain Gummed Tape for Sealing and Securing

Standard Specification for Reinforced and Plain Gummed Tape for Sealing and Securing

ABSTRACT

This specification covers reinforced (Type I) and plain (Type II) paper gummed adhesive tapes used for securing and banding paper products and sealing fiberboard boxes. Type I gummed tape may be strippable (Class 1) or nonstrippable (Class 2), while Type II paper-backed gummed tape, whether Grade A (light duty), B (medium duty), or C (heavy duty), is nonstrippable. The tapes shall be manufactured from kraft paper, but the use of recycled pulp in the paper is encouraged as well, and the adhesive used must not have an offensive odor and shall conform to the environmental considerations specified. Type I tapes shall consist of two strips of paper in roll form, while Type II tapes shall consist of one strip of paper in roll form. Upon manufacture, the tape shall be clean and free of folds, sharp creases, tears, cuts, and holes. The tapes shall be examined for visual defects, defects in roll construction, and defects in dimensions. Tests for adhesiveness, tensile strength, and elongation shall be performed as well, and shall conform to the physical properties specified.

SCOPE

1.1 This specification covers plain and reinforced paper gummed adhesive tapes suitable for securing and banding paper products and closing fiberboard boxes.

1.2 This specification is intended to replace Fed. Specs. CID A-A-1492, CID A-A-1671, and PPP-T-45 in part.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5749 −01 (Reapproved 2012)

Standard Specification for

Reinforced and Plain Gummed Tape for Sealing and

Securing

This standard is issued under the fixed designation D5749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 TAPPI Standards:

T401Fiber Analysis of Paper and Paperboard

1.1 This specification covers plain and reinforced paper

T410Weight per Unit Area (Basis Weight or Substance)

gummed adhesive tapes suitable for securing and banding

T414InternalTearingResistanceofPaper(Elmendorf-Type

paper products and closing fiberboard boxes.

Method)

1.2 ThisspecificationisintendedtoreplaceFed.Specs.CID

UM 575Water Resistance of Adhesive Bond in Laminated

A-A-1492, CID A-A-1671, and PPP-T-45 in part.

Paper and Paperboard

2.3 ANSI/ASQC Standards:

1.3 The values stated in SI units are to be regarded as

ANSI/ASQCZ1.4Sampling Procedures and Tables for In-

standard. The values given in parentheses are for information

spection by Attributes

only.

ANSI/ASQCZ1.9 Sampling Procedures and Tables for

1.4 The following safety hazards caveat pertains only to the

Inspection by Variables for Percent Defective

test methods portion, Section 11, of this specification: This

2.4 Federal Specifications:

standard does not purport to address all of the safety concerns,

PPP-T-45Tape, Gummed, Paper, Reinforced and Plain, for

if any, associated with its use. It is the responsibility of the user

Sealing and Securing

of this standard to establish appropriate safety and health

PPP-T-681Tape, Gummed, Packaging and Packing of

practices and determine the applicability of regulatory limita-

CID A-A-1492 Commercial Item Description Tape,

tions prior to use.

Gummed, Paper, Plain

CID A-A-1671 Commercial Item Description Tape,

2. Referenced Documents

Gummed, (Paper, Reinforced, Laminated)

2.1 ASTM Standards:

2.5 ISO Standard:

D685Practice for Conditioning Paper and Paper Products

ISO 9002Quality Systems Model for Quality Assurance in

for Testing (Withdrawn 2010)

Production and Installations

D828Test Method for Tensile Properties of Paper and

3. Terminology

PaperboardUsingConstant-Rate-of-ElongationApparatus

(Withdrawn 2009)

3.1 Definitions—General definitions for packaging and dis-

D996Terminology of Packaging and Distribution Environ-

tribution environments are found in Terminology D996.

ments

D1974Practice for Methods of Closing, Sealing, and Rein- 4. Classification

forcing Fiberboard Boxes

4.1 Type I Reinforced, Laminated:

D3951Practice for Commercial Packaging

4.1.1 Class 1—Strippable.

4.1.2 Class 2—Nonstrippable.

4.2 Type II Plain, Single Ply, Strippable:

This specification is under the jurisdiction of ASTM Committee D10 on

4.2.1 Grade A—Light duty, for lightweight packages.

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

4.2.2 Grade B—Medium duty, for medium-sized packages.

Labels.

Current edition approved April 1, 2012. Published May 2012. Originally

approved in 1995. Last previous edition approved in 2006 as D5749–01(2006).

DOI: 10.1520/D5749-01R12. Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Standards volume information, refer to the standard’s Document Summary page on 4th Floor, New York, NY 10036, http://www.ansi.org.

the ASTM website. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

The last approved version of this historical standard is referenced on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.astm.org. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5749−01 (2012)

4.2.3 Grade C—Heavy duty, for heavy-duty packages. film of paper from the tape on the test paper, when tested in

accordance with 13.6.1.

5. Significance and Use

7.3.2 Type I, Class 2, and Type II adhesive shall be capable

of being quickly activated with water. The wetted adhesive

5.1 Type I is a reinforced gummed tape which may be

shall show pronounced tackiness and shall cause the tape to

strippable (Class 1) or nonstrippable (Class 2). It is intended

remain so firmly affixed that it cannot be removed without

for use in Methods 2C2, 2C3, and any other methods in

failure of either the tape or paper when tested in accordance

Practice D1974.

with 13.6.1.

5.2 Type II is a plain paper-backed nonstrippable gummed

7.4 Reinforcing Materials—The reinforcing fibers used in

tape. It is intended for use in Methods 2C4, 2C5, and other

fabricatingTypeItapesshallbecomposedofglassofsuchsize

methods in Practice D1974.

as to permit the reinforced tape to meet the requirements set

forth in Table 2 when tested as described in 13.5.

6. Ordering Information

7.5 Laminating Materials—The laminating material for

6.1 The inquiry or order shall include the following:

TypeItapeshallbenon-asphaltic,waterresistant,flexible,and

6.1.1 ASTM designation and date of issue,

non-staining. Water resistance of the finished tape shall be

6.1.2 Type, class, and grade required (5.1),

tested in accordance with TAPPI UM575.

6.1.3 When core plugs are required (7.7),

6.1.4 If tape is to be wound gummed side out (7.7),

7.6 Construction—Type I tape shall consist of two strips of

6.1.5 Roll width and length (9.1 and 9.2),

paperinrollform,securelylaminatedtogetherwithreinforcing

6.1.6 Acceptance sampling plan and desired acceptance

fibers embedded in the laminate. The reinforcing laminated

quality level (Section 12),

tapeshallbecompletelyanduniformlycoatedononesidewith

6.1.7 When backing certification is required (15.1),

an adhesive.

6.1.8 When testing and inspection certification is required

7.6.1 The tape shall be reinforced by crosswise reinforcing

(15.1),

fibers spaced not less than 2 fibers/50 mm (1 in.) on average

6.1.9 Levelofpackagingandpackingifotherthancommer-

andbylengthwisefibersspacednotmorethananaverageof25

cial (Section 17), and 1

mm ( ⁄2 in.) apart. If a diamond pattern is employed for

6.1.10 When packaging for shipments to the U.S. Govern-

crosswisereinforcement,thespacingbetweentheparallelsides

ment (17.2). 1

of the diamond shall not be more than 32 mm (1 ⁄4 in.). The

three-way tape shall be reinforced in both the machine direc-

7. Materials and Manufacture

tion and cross direction with reinforcing fibers spaced not less

7.1 The materials used in the construction of the tape shall than 2 fibers/50 mm (1 in.) on average, in addition to the

be such as to ensure performance of the tape over the range of diamond-patterned reinforcement.

−55 to+71°C (−65 to+160°F) and shall conform to the 7.6.2 Type II tapes, all grades, shall consist of one strip of

requirements of this specification. paper in roll form of the applicable grade, completely and

uniformly coated on one side with an adhesive.

7.2 Paper:

7.7 Rolls—Unless otherwise specified, the tape shall be

7.2.1 Stock—The paper used in the fabrication of the tape

shall be a kraft paper. The use of recycled pulp in the paper is evenlywoundandtightlywoundinrollswiththegummedside

encouraged. in (6.1.4). Type II shall be wound on a core having sufficient

7.2.2 Weight—The weight of the paper prior to gumming rigidity to prevent distortion of the roll under normal condi-

shall conform to the requirement of Table 1, when tested as tions of transportation and use.The inside diameter of the core

described in TAPPI T410. shall be not less than 13 mm ( ⁄2 in.). When specified, Type II

tape shall have the core secure with a plug (6.1.3). Type I tape

7.3 Adhesives—The adhesives used shall not have an offen-

shall not be required to have a core. The end of the outer leaf

sive odor (dry or wet) and shall meet the environmental

of the tape shall be adhered to the next layer to prevent

considerations of 16.1.

unwinding. The tape in each roll shall be furnished in one

7.3.1 Type I, Class 1 adhesive shall be capable of being

continuouslengthandhavenomorethanthreesplicesperroll.

quickly activated with water. The wetted adhesive shall show

pronounced tackiness and shall cause the tape to remain so

TABLE 2 Physical Properties

firmly affixed that it cannot be removed without leaving a thin

Tensile Strength, kN/m Tearing Resistance, grams

A

width (lb/in.) min force mN min

Type

Machine Cross Machine Cross

TABLE 1 Weight of Ungummed Paper

B

direction direction direction direction

Minimum Weight

Type I 11 (63) 5.25 (30 )

Type II

(24 × 36 — 5500 sheets) g/m2 lb

Grade A 4.5 (26) 540(55 ) 647 (66)

Type I, Classes 1 and 2 49 55

Grade B 8 (45) 1109 (113) 1315 (134)

Type II

Grade C 12 (68) 1991 (203) 2197 (224)

Grade A 57 35

A

Grade B 98 60 This requirement does not apply to tapes less than 63 mm (2 ⁄2 in.) in width.

B

Grade C 146 90

This requirement does not apply to tapes less than 76 mm (3 in.) in width.

D5749−01 (2012)

Allsplicesshallbeneatlyandevenlymadewithglueandshall acceptance comply with all the requirements of the contract or

not separate upon unwinding. order. Sampling in quality conformance does not authorize

submission of known defective material, either indicated or

8. Physical Properties

actual, nor does it commit the buyer to accept defective

material.

8.1 The tape shall meet the physical property requirements

in Table 2.

13.3 Test of Component Materials:

13.3.1 Paper—The paper component shall be tested for the

9. Dimensions, Mass, and Permissible Variations

stock requirements in 7.2.1 as described in TAPPI T401 and

9.1 ThewidthoftherollforTypeIshallbe38.5,50,and75

for basis weight requirements in 7.2.2 as described in TAPPI

mm(1 ⁄2,2,and3in.);ForTypeII25,38.5,50,and75mm(1,

T410. The lot shall consist of all paper received at one time

1 ⁄2, 2, and 3 in.).

fromonesourceofsupplyforuseinfabricationofonetypeand

9.1.1 A width tolerance of 61.5 mm (6 ⁄16 in.) shall be

grade of tape. The lot size shall be expressed in units of

allowed on all widths.

kilograms (pounds). The sample unit shall be 0.65 m (1000

in. ) of paper. The sample size shall be as described in 12.1.

9.2 Length:

The test reports shall include all values upon which results are

9.2.1 Type I—The length of the roll shall be 115 or 140 m

based. There shall be no failures to meet the composite or lot

(375 or 450 ft) or other commercially available lengths, as

average requirements. A composite shall consist of small

specified (6.1.5).

portionstakenfromallsampleunitsandcombinedintoasingle

9.2.2 Type II—The length of the ClassAroll shall be 245 m

sample.

(800 ft) when wound gummed side out, 150 m (500 ft) when

13.3.2 Reinforcing Material—The manufacturer shall sub-

woundgummedsidein,orothercommerciallyavailablelength

mitacertificationofcompliancestatingthatthecompositionof

(6.1.5). The length of the Class B roll shall be 185 or 300 m

the reinforcing material used in Type I tape is in conformance

(600 or 800 ft), or other commercially available length (6.1.5).

with the requirements of 7.4.

The length of the Class C roll shall be 115 m (375 ft), or other

13.3.3 Laminating Material—The manufacturer shall sub-

commercially available length (6.1.5).

mit a certification of conformance stating that the laminate of

Type I conforms to the requirements of 7.5 as applicable.

10. Workmanship, Finish, and Appearance

10.1 Thetapeshallbecleanandfreeoffolds,sharpcreases, 13.4 Inspection for the End Item—The end item shall be

examined for defects at the inspection levels and acceptable

tears, cuts, and holes. The adhesive coating shall cover the

entireareaofonesideofthetape.Thetapeshallbecleanlycut quality levels set forth in 13.4.1. Random samples shall be

drawn from each lot of the end item for inspection for

without nicks or ragged edges and shall conform to the levels

of quality established in this specification. examination of visual, roll construction, and dimensions. The

lot size shall be expressed in units of rolls for examination in

11. Specimen Preparation and Number of Tests

13.4.1, 13.4.2, and 13.4.3.

13.4.1 Examination for Visual Defects—Thesampleunitfor

11.1 Specimen preparation shall be as specified in the

thisexaminationshallbe(1yd)oftapefromtheroll.Onlyone

appropriate test method.

sample unit shall be taken from any roll. The sample shall be

11.2 The number of tests per unit of product shall be as

positionedrandomlyinallrollsexamined,andtherollsshallbe

specified in the appropriate test method or Table 2.

randomly selected from the lot. (See Table 3.)

13.4.2 Examination for Defects in Roll Construction—The

12. Sampling

sample unit for this examination shall be one roll. (See Table

12.1 Inspection Levels—The acceptance sampling plan in-

4.)

spection level shall be as specified in the purchase order or

13.4.3 Examination of Defects in Dimensions—The sample

contract. If not otherwise specified (6.1.9), ANSI/ASQC 1.4

unit for this examination shall be one roll. (See Table 5.)

and ANSI/ASQC 1.9 shall be used with an acceptable quality

13.5 Testing End Item—The end item shall be tested for the

limit (AQL) of 4%.

applicable characteristics in Table 6. The lot size for purposes

of determining the sample size shall be expressed in units of

13. Test Methods

13.1 Responsibility for Inspection—Unless otherwise speci-

fiedinthecontractororder,themanufacturerisresponsiblefor

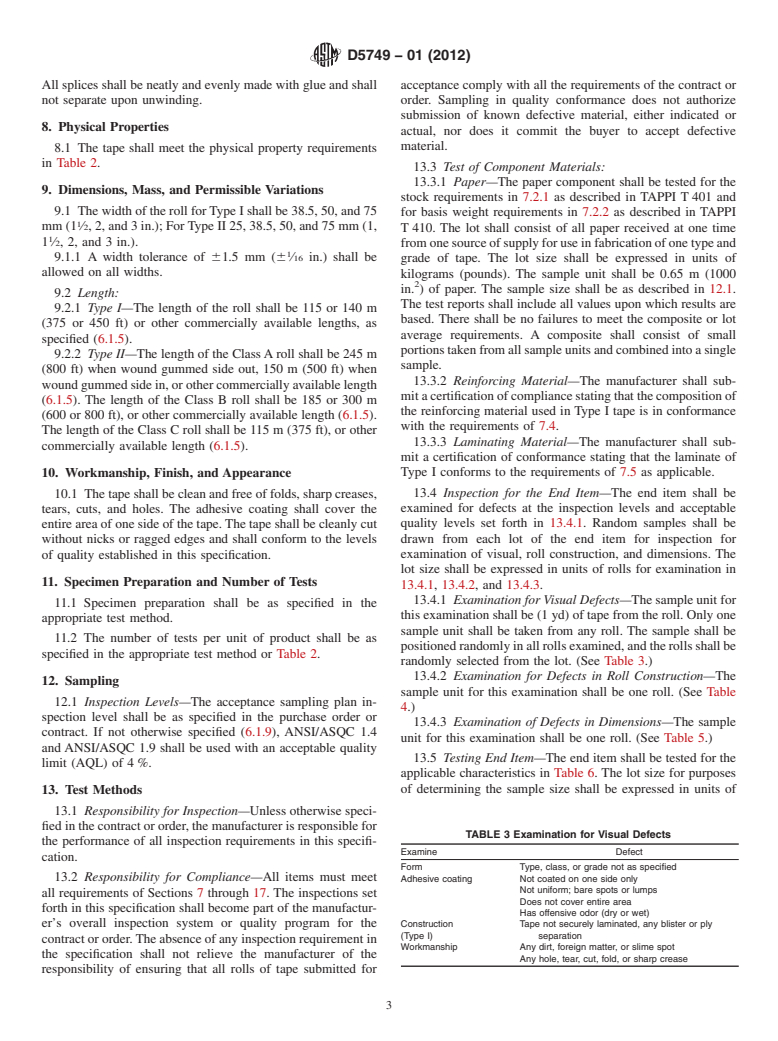

TABLE 3 Examination for Visual Defects

the performance of all inspection requirements in this specifi-

Examine Defect

cation.

Form Type, class, or grade not as specified

13.2 Responsibility for Compliance—All items must meet

Adhesive coating Not coated on one side only

Not uniform; bare spots or lumps

all requirements of Sections 7 through 17. The inspections set

Does not cover entire area

forth in this specification shall become part of the manufactur-

Has offensive odor (dry or wet)

er’s overall inspection system or quality program for the Construction Tape not securely laminated, any blister or ply

(Type I) separation

contractororder.Theabsenceofanyinspectionrequirementin

Workmanship Any dirt, foreign matter, or slime spot

the specification shall not relieve the manufacturer of the

Any hole, tear, cut, fold, or sharp crease

responsibility of ensuring that all rolls of tape submitted for

D5749−01 (2012)

TABLE 4 Examination for Defects in Roll Construction

13.6.2 Adhes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.