ASTM F1147-05(2011)

(Test Method)Standard Test Method for Tension Testing of Calcium Phosphate and Metallic Coatings

Standard Test Method for Tension Testing of Calcium Phosphate and Metallic Coatings

SIGNIFICANCE AND USE

The tensile test method is recommended for tension testing of calcium phosphate/substrate or porous metal coating/substrate combinations and can provide information on the adhesive or cohesive strength of coatings under (uniaxial) tensile stress.

The test method may be useful for comparative evaluation of adhesive or cohesive strengths of a variety of types of coatings. Coatings may be applied using a variety of methods, including but not limited to plasma-spraying and sintering. Information developed using this test method may be useful for certain quality control and design purposes.

The test should not be considered to provide an intrinsic value for utilization directly in making calculations such as determining the ability of a coating to withstand specified environmental stresses.

Processing variables such as substrate preparation prior to coating, surface texture, coating technique variables or postcoating heat treatment variables may introduce a significant effect on the results of the tension test. The specimen being evaluated must be representative of the actual end use coating.

SCOPE

1.1 This test method covers tension testing of calcium phosphate and metallic porous coatings adhering to dense metal substrates at ambient temperatures. It assesses the degree of adhesion of coatings to substrates, or the internal cohesion of a coating in tension normal to the surface plane.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1147 − 05 (Reapproved 2011)

Standard Test Method for

Tension Testing of Calcium Phosphate and Metallic

Coatings

This standard is issued under the fixed designation F1147; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope component to a tensile load. In the case of the calcium

phosphate coatings, the components to be tested must be

1.1 This test method covers tension testing of calcium

bonded together by use of a polymeric adhesive. In the case of

phosphate and metallic porous coatings adhering to dense

the metallic coatings, the components may either be bonded

metalsubstratesatambienttemperatures.Itassessesthedegree

with the adhesive, or sintered together.The adhesive may be in

of adhesion of coatings to substrates, or the internal cohesion

film form or bulk form, but it must have a minimum bulk

of a coating in tension normal to the surface plane.

tensile strength of 34.5 MPa (5000 psi) or as great as the

1.2 The values stated in inch-pound units are to be regarded

minimum required adhesion or cohesion strength of the

as standard. The values given in parentheses are mathematical

coating, whichever is greater.

conversions to SI units that are provided for information only

4.2 The tensile load must be applied normal to the plane of

and are not considered standard.

the coating utilizing a tension machine which is capable of

1.3 This standard does not purport to address all of the

determining the maximum strength of the coating or coating

safety concerns, if any, associated with its use. It is the

attachment to the substrate interface.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 The tensile test method is recommended for tension

2. Referenced Documents

testingofcalciumphosphate/substrateorporousmetalcoating/

substrate combinations and can provide information on the

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines adhesive or cohesive strength of coatings under (uniaxial)

tensile stress.

E6 Terminology Relating to Methods of Mechanical Testing

E8 Test Methods for Tension Testing of Metallic Materials

5.2 The test method may be useful for comparative evalu-

F1501 Test Method for Tension Testing of Calcium Phos-

ation of adhesive or cohesive strengths of a variety of types of

phate Coatings (Withdrawn 2000)

coatings. Coatings may be applied using a variety of methods,

including but not limited to plasma-spraying and sintering.

3. Terminology

Informationdevelopedusingthistestmethodmaybeusefulfor

3.1 The definitions of terms relating to tension testing

certain quality control and design purposes.

appearing in Terminology E6 shall be considered as applying

5.3 The test should not be considered to provide an intrinsic

to the terms used in this test method.

value for utilization directly in making calculations such as

4. Summary of Test Method

determining the ability of a coating to withstand specified

4.1 The tensile test method consists of subjecting a speci- environmental stresses.

men assembly composed of one coated and one uncoated

5.4 Processing variables such as substrate preparation prior

to coating, surface texture, coating technique variables or

This test method is under the jurisdiction ofASTM Committee F04 on Medical

postcoating heat treatment variables may introduce a signifi-

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

cant effect on the results of the tension test. The specimen

F04.15 on Material Test Methods.

Current edition approved Oct. 1, 2011. Published October 2011. Originally being evaluated must be representative of the actual end use

approved in 1988. Last previous edition approved in 2005 as F1147 – 05. DOI:

coating.

10.1520/F1147-05R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6. Apparatus

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6.1 Testing Machines—Machines used for testing shall con-

the ASTM website.

3 form to the requirements of Practices E4. The loads used in

The last approved version of this historical standard is referenced on

www.astm.org. determining tensile strength and yield strength shall be within

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1147 − 05 (2011)

the loading range of the testing machine as defined in Practices 7.1.2 In instances where porosity extends to the coating

E4. See also Test Methods E8. substrate interface, the bonding agent shall be sufficiently

viscous and application to the coating sufficiently careful to

6.2 Gripping Devices:

assure that it will not penetrate through the coating to the

6.2.1 General—Various types of grips may be used to

substrate. The FM 1000 Adhesive Film with a thickness of

transmit the load applied to the specimens by the testing

0.25 mm (0.01 inc.) has proven satisfactory for this test. If a

machine. To ensure axial tensile stress, it is important that the

material other than FM 1000 is used, or the condition of the

specimen axis coincide with the centerline of the heads of the

FM 1000 is unknown, it must be tested to establish its

testingmachineandthatthecoatingtestplanebeperpendicular

equivalence fresh FM 1000. Testing should be performed

to the axial load.Any departure from this requirement (that is,

without the presence of the coating to establish the perfor-

any eccentric loading) will introduce bending stresses that are

mance of the adhesive.

not included in the usual stress calculation (force/cross-

sectional area).

8. Test Specimens

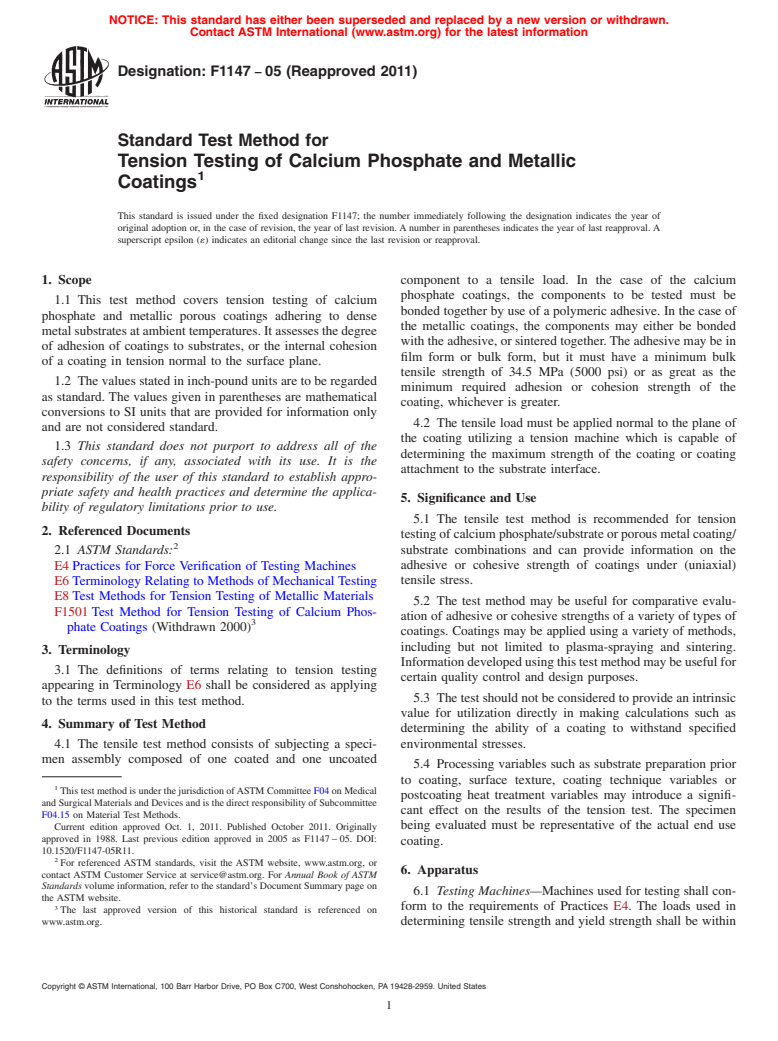

6.2.2 Yoke and Dowel Pin Grips—Aschematic diagram of a

8.1 General:

typical gripping device for specimens with holes drilled for pin

8.1.1 In order to ensure precision and accuracy in test

loading is illustrated in Fig. 1. There should be two perpen-

dicular pins in order to maximize off axis loading. results, it is important that care be exercised in the preparation

of specimens, both in machining and in the case of multi-part

7. Materials

specimens, in the assembly. Specimen components must be

properly aligned in order that generated stresses be purely

7.1 Adhesive Bonding Agent—A polymeric adhesive bond-

axial, that is, normal to the coated surface.

ing agent in film form, or filled viscous adhesive cement, when

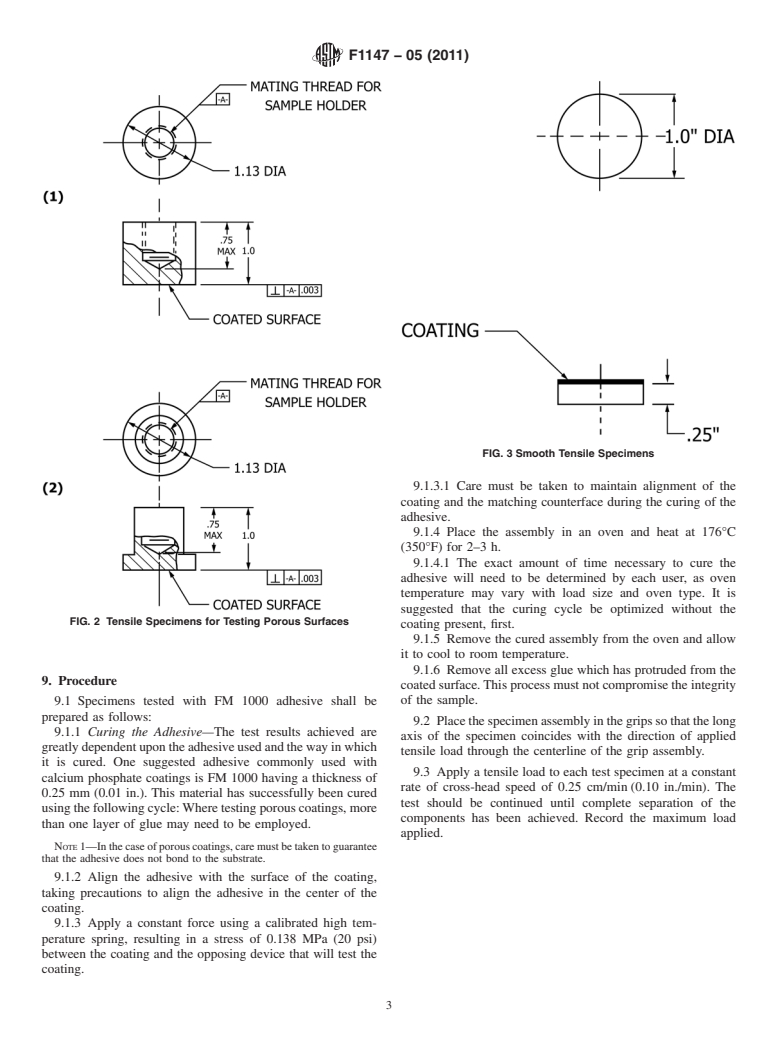

8.1.2 Tensile-Type Specimens—Three general types of test

used, shall be identified and shall meet the following require-

specimens are illustrated in Figs. 2 and 3. A complete,

ments.

assembledtestassemblyconsistseitheroftwosolidpieces;one

7.1.1 The bonding agent shall be capable of bonding the

with a coated surface and the other with an uncoated surface or

coatingonthetestspecimencomponentswithatensilestrength

three solid pieces; two with uncoated surfaces and one with a

that is at least 34.5 MPa (5000 psi) or as great as the minimum

coating applied on one side. The uncoated surface may be

required adhesion or cohesion strength of the coating.

roughened to aid in the bonding of the adhesive.

8.1.3 The cross-sectional area of the substrate upon which

2 2

the coating is applied shall be nominal 5.07 cm (0.78 in. ).

When specimens of another cross-sectional area are used, the

data must be demonstrated to be equivalent to a 5.07 cm

standard cross-sectional area, and the specimen size should be

reported.

8.1.4 Alltestspecimensforcoatingcharacterizationshallbe

prepared from indicative coating lots, using production feed-

stock lots and be coated on the same equipment used for actual

implants.

8.2 Specimen Coating Preparation:

8.2.1 Coatings may be applied by any one of a number of

techniques. The coating should consist of a layer which is

mechanically or chemically attached and covers the surface.

8.2.2 All thermal treatments normally performed on the

devices should be performed on the test specimens.

8.2.3 If employed, passivation and sterilization techniques

should be consistent with those used for actual devices.

8.2.3.1 If the passivation and sterilization processes can be

shown not to influence the tensile strength, these steps may be

eliminated.

8.2.4 Inspection—Before testing, visual inspections should

be performed on 100 % of the test specimens. Lack of coating

in highly stressed regions, as well as non-uniform coating

appearance, shall be cause for specimen rejection.

The sole source of supply of the apparatus known to the committee at this time

is Cytec Engineered Materials, Inc., 1300 Revolution St., Havre de Grace, MD

21078. If you are aware of alternative suppliers, please provide this information to

FIG. 1 Yoke and Dowel Pin Grips for Tensile Testing Porous Sur- ASTM International Headquarters. Your comments will receive careful consider-

faces ation at a meeting of the responsible technical committee, which you may attend.

F1147 − 05 (2011)

FIG. 3 Smooth Tensile Specimens

9.1.3.1 Care must be taken to maintain alignment of the

coating and the matching counterface during the curing of the

adhesive.

9.1.4 Place the assembly in an oven and heat at 176°C

(350°F) for 2–3 h.

9.1.4.1 The exact amount of time necessary to cure the

adhesive will need to be determined by each user, as oven

temperature may vary with load size and oven type. It is

suggested that the curing cycle be optimized without the

FIG. 2 Tensile Specimens for Testing Porous Surfaces

coating present, first.

9.1.5 Remove the cured assembly from the oven and allow

it to cool to room temperature.

9.1.6 Remove all excess glue which has protruded from the

9. Procedure

coated surface.This process must not compromise the integrity

of the sample.

9.1 Specimens tested with FM 1000 adhesive shall be

prepared as follows:

9.2 Placethespecimenassemblyinthegripssothatthelong

9.1.1 Curing the Adhesive—The test results achieved are

axis of the specimen coincides with the direction of applied

greatlydependentupontheadhesiveusedandthewayinwhich

tensile load through the centerline of the grip assembly.

it is cured. One suggested adhesive commonly used with

9.3 Apply a tensile load to each test specimen at a constant

calcium phosphate coatings is FM 1000 having a thickness of

rate of cross-head speed of 0.25 cm/min (0.10 in./min). The

0.25 mm (0.01 in.). This material has successfully been cured

test should be continued until complete separation of the

usingthefollowingcycle:Wheretestingporouscoatings,more

components has been achieved. Record the maximum load

than one layer of glue may need to be employed.

applied.

NOTE1—Inthecaseofporouscoatings,caremustbetakentoguarantee

that the adhesive does not bond to the substrate.

9.1.2 Align the adhesive with the surface of the coating,

taking precautions to align the adhesive in the center of the

coating.

9.1.3 Apply a constant force using a calibrated high tem-

perature spring, resulting in a stress of 0.138 MPa (20 psi)

between the coating and the opposing device that will test the

coating.

F1147 − 05 (2011)

10. Calculation 12.1.2 Reproducibility—For independent results obtained

by different operators working in different laboratories on

10.1 Calculate the substrate area upon which the coating is

2 2 nominally-identical test materials, the reproducibility standard

applied to the nearest 0.006 cm (0.001 in. ). Record peak

deviation (S ) was 772 lbf/in. (5.32 MPa). Any two such

R

(failure) load and calculate failing stress in MPa (psi) of

results (would be expected to differ by more than) 2160 lbf/in.

adhesive bond area as follows:

(14.8 MPa) only 1 time in 20.

S 5 F/A (1)

NOTE 2—The precision study under 12.1 was conducted using coupons

where:

which had a one square inch area (1.13 in. diameter). The bead tensile

strength was intentionally lowered for this round robin comparison to

S = adhesion or cohesion strength,

produce coating fractures rather than glue failures in the coupons.

F = maximum load to failure, and

A = cross-sectional area. 12.2 Precision (HA Coating)—The precision of this test

method was established by an interlaboratory comparison

11. Report

among seven (7) laboratories. The substrate of the specimens

tested was titanium-6aluminum-4vanadium, which was

11.1 The report shall include the following information:

hydroxylapatite-coated. The mean tensile strength was 8405

11.1.1 Identification of the materials used in the specimen,

lbf/in. (58.0) MPa for all samples tested by all laboratories.

including bonding agent if used.

12.2.1 Repeatability—For replicate results obtained by the

11.1.2 Identification of methods used to apply the coating

same operator on nominally-identical test materials, the repeat-

including coating method, heat-treatment, or other data if

ability standard deviation S was 1016 lbf/in. (7.0 MPa). Any

available, including date, cycle number, and time and tempera- r

two such results (would be expected to differ by more than)

ture of the run.

2845 lbf/in. (19.6 MPa) only one time in 20.

11.1.3 Dimensional data including the bond cross-sectional

12.2.2 Reproducibility—For independent results obtained

area and the thickness of the porous or other coated layer.

by different operators working in different laboratories on

11.1.4 Number of specimens tested.

nominally-identical test materials, the reproducibility standard

11.1.5 Report all values for the failure load, including

deviation (S ) was 1758 lbf/in. (12.1 MPa). Any two such

maximum, minimum, and mean. R

results (would be expected to differ by more than) 4922 lbf/in.

11.1.6 The mode of failure (for example, cohesive versus

(33.9 MPa) only one time in 20.

adhesive) for each test specimen.

NOTE 3—The precision study under 12.2 was run using a cross-head

12. Precision and Bias

speed of 0.05 in./min (0.12 cm/min).

12.1 Precision (beaded F75)—The precision of this test

12.3 Bias—Sincethemeasurementofporous-coatingtensile

method was established by an interlaboratory comparison

strength by this test method is a destructive test measurement

among six (6) laboratories. The specimens tested were

unique to each individual test sample, no independent deter-

sintered-beadcoatingsofF75(cobalt-chromium-molybdenum)

mination of a “correct” or “reference” value is possible. Thus,

alloy on F75 substrates. The population mean tensile strength

no statements regarding the deviatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.