ASTM D6466-99

(Test Method)Standard Test Method for Diameter of Wool and Other Animal Fibers By Sirolan-Laserscan Fiber Diameter Analyser

Standard Test Method for Diameter of Wool and Other Animal Fibers By Sirolan-Laserscan Fiber Diameter Analyser

SCOPE

1.1 This test method covers a procedure, using the Sirolan-Laserscan, for the determination of the average fiber diameter and the fiber diameter variation in wool and other animal fibers in their various forms.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6466 – 99

Standard Test Method for

Diameter of Wool and Other Animal Fibers By Sirolan-

Laserscan Fiber Diameter Analyser

This standard is issued under the fixed designation D 6466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Official Standards of the United States for Grades of

Wool, Section 31.0

1.1 This test method covers a procedure, using the Sirolan-

Measurement Method for Determining Grade of Wool, Sec-

Laserscan, for the determination of the average fiber diameter

tion 31.204

and the fiber diameter variation in wool and other animal fibers

Official Standards of the United States for Grades of Wool

in their various forms.

Top, Section 31.1

1.2 The values stated in SI units are to be regarded as the

Measurement Method for Determining Grade of Wool

standard.

Top, Section 31.301

1.3 This standard does not purport to address all of the

IWTO-8 Method of Determining Wool Fiber Diameter by

safety concerns, if any, associated with its use. It is the

the Projection Microscope

responsibility of the user of this standard to establish appro-

IWTO-12 Measurement of the Mean and Distribution of

priate safety and health practices and determine the applica-

Fibre Diameter Using the Sirolan-Laserscan Fibre Diam-

bility of regulatory limitations prior to use.

eter Analyser

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions:

D 123 Terminology Relating to Textiles

3.1.1 average fiber diameter, n—the arithmetic width of a

D 584 Test Method for Wool Content of Raw Wool—

group of fibers.

Laboratory Scale

3.1.1.1 Discussion—In wool and other animal fibers, all

D 1060 Practice for Core Sampling of Raw Wool in Pack-

animal fibers, regardless of species, can be measured using the

ages for Determination of Percentage of Clean Wool Fiber

Sirolan-Laserscan to determine average fiber diameter.

Present

3.1.2 grade, n—in wool and mohair, a numerical designa-

D 1776 Practice for Conditioning Textiles for Testing

tion used in classification of fibers in their raw, semi-processed

D 2130 Test Method for Diameter of Wool and Other

2 and processed forms based on average fiber diameter and

Animal Fibers by Microprojection

variation of fiber diameter.

D 2252 Specification for Fineness of Types of Alpaca

3.1.3 snippet, n—a wool or other animal fiber which has

D 2816 Test Method for Cashmere Coarse–Hair Content in

been cut to a specified length.

Cashmere

3.1.4 For definitions of other textile terms used in this test

D 3991 Specifications for Fineness of Wool or Mohair and

method, refer to Terminology D 123.

Assignment of Grade

D 3992 Specifications for Fineness of Wool Top or Mohair

4. Summary of Test Method

Top and Assignment of Grade

4.1 This test method describes procedures for sampling

E 126 Test Method for Inspection and Verification of Hy-

4 various forms of wool, the reduction of the sample to small test

drometers

specimens, and measurement of the diameter of a number of

E 1750 Guide for Use of Water Triple Point Cells

fibers from the test specimens using the Laserscan. Snippets

2.2 Federal Standards:

cut from the various forms of wool are cleaned where required,

and dispersed in a mixture of isopropanol and water. The

suspension of snippets is transported through a measuring cell

This test method is under the jurisdiction of ASTM Committee D–13 on

Textiles and is the direct responsibility of Subcommittee D13.13 on Wool and Wool

Felt.

Current edition approved Oct. 10, 1999. Published November 1999. Federal Register, Vol 30, No. 161, Aug. 20, 1965, pp. 10829–10833.

2 6

Annual Book of ASTM Standards, Vol 07.01. Federal Register, Vol 33, No. 248, Dec. 21, 1968, pp. 19073–19076.

3 7

Annual Book of ASTM Standards, Vol 07.02. International Wool Textile Organization, International Wool Secretariat, Com-

Annual Book of ASTM Standards, Vol 14.03. mercial Development Department, Valley Drive, Ilkley, LS298PB, England.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6466

which is positioned in a beam of laser light. The reduction in 6.1.2 A means of measuring the reduction of light intensity

intensity of the laser beam as the individual snippets pass of the beam due to the passage of a snippet and converting this

through the beam of light, approximately 500 µm in diameter, to digital form.

is sensed by a detector and transformed, using a calibration

6.1.3 A system for discrimination against the measurement

look-up table, into a diameter in micrometres. Each diameter

of fibers that do not properly intersect the beam and contami-

measurement is allocated to a diameter class, and when the

nants such as fiber fragments, dirt, and vegetable matter

specified number of fibers has been measured, the class

particles.

contents are statistically analysed to produce the mean and

6.1.4 A computing system to transform and collate results.

standard deviation of fiber diameter for the specimen. Full

6.2 Fiber Sectioning Device—One or more of the follow-

distribution data are also available in the form of a printed

ing:

histogram. 8

6.2.1 Guillotine —Fig. 2, having two parallel cutting edges

between 1.8 and 2.0 mm apart.

5. Significance and Use 8

6.2.2 Minicore —Fig. 3, a cylindrical sample holder, de-

5.1 This test method is considered satisfactory for accep-

signedforlargesamples,inwhichasampleismanuallypacked

tance testing of commercial shipments of wool and other

and a coring head which is driven pneumatically into the

animal fibers in raw and sliver form because current estimates

sample. The sample is compacted by a spring-loaded platen

of between-laboratory precision are acceptable. In cases of

and 6 minicore tubes with 2-mm diameter tips pass through

disagreement arising from differences in values reported by the

perforations in the platen when the force supplied by the

purchaser and the supplier when using this test method for

pneumatic cylinder exceeds the force (300 N) from the

acceptance testing, Test Method D 2130 shall be used as a

preloaded spring.At the end of the stroke, the cutting tips have

referee method.

penetrated to within 0.5 mm of the base of the sample holder.

5.2 This test method may be used for determining compli-

The sample collected by the minicore tubes is automatically

ance with average fiber diameter and diameter variation to

expelled into a collection device upon retraction of the coring

assign grades when determining conformance of shipments to

head.

material specifications given in Specifications D 2252, D 2816,

6.2.3 Heavy-Duty Sectioning Device —Fig. 4, comprised of

D 3991, and D 3992.

ametalplatewithslotandcompressingkey,andequippedwith

5.3 Theproceduresfordeterminingmeanfiberdiameterand

a propulsion mechanism by which the fiber bundle may be

standard deviation of fiber diameter provided in this test

extruded for sectioning. The device is designed to hold a sliver

methodandinIWTOMethod12-93areinessentialagreement.

of top or equivalent bulk of fibers.

6. Apparatus and Materials

6.1 Fiber Diameter Analyser —Fig. 1, consisting of the

Sirolan-Laserscan analyser, minicorer, and guillotine obtainable from Loptex

following:

S.r.l.,Via L. Leoni 20, 2210 0 COMO (Italia).Tel: 39 31 273502; Fax: 39 1 273255.

6.1.1 A means of transporting fiber snippets in an 9

Obtainable from MICO Instruments, 1944 Main St., P.O. Box 451, Marshfield

isopropanol/water mixture through a laser beam. Hills, MA 02051-0451.

FIG. 1 Block Diagram of Laserscan System

D 6466

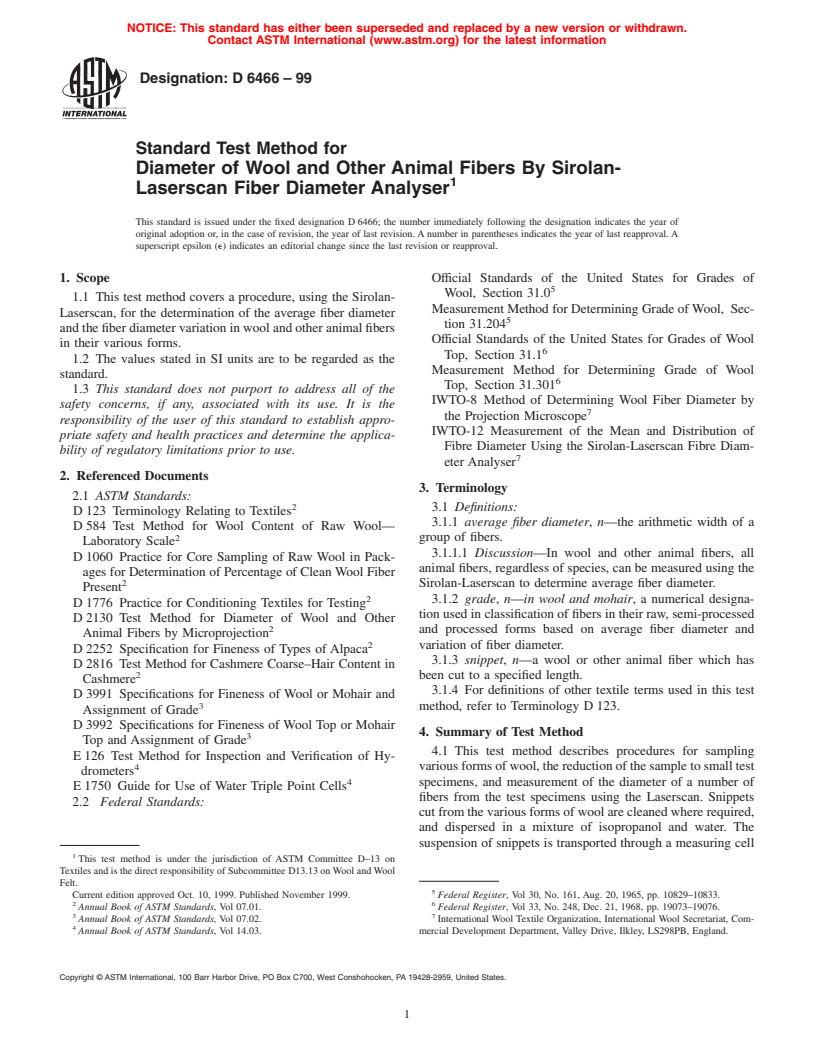

FIG. 2 Guillotine

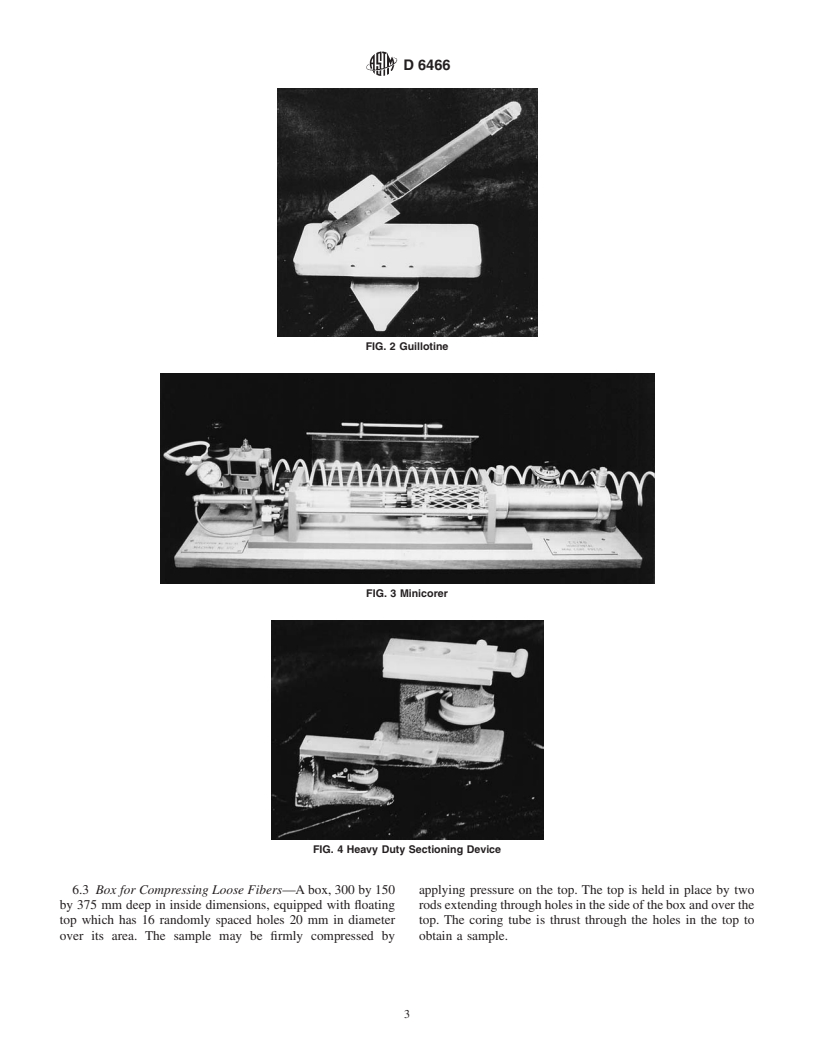

FIG. 3 Minicorer

FIG. 4 Heavy Duty Sectioning Device

6.3 Box for Compressing Loose Fibers—Abox, 300 by 150 applying pressure on the top. The top is held in place by two

by 375 mm deep in inside dimensions, equipped with floating rodsextendingthroughholesinthesideoftheboxandoverthe

top which has 16 randomly spaced holes 20 mm in diameter top. The coring tube is thrust through the holes in the top to

over its area. The sample may be firmly compressed by obtain a sample.

D 6466

6.4 Pressure Coring Tube —A 13-mm inside-diameter 9.1.3 Piles of Graded or Sorted Wool—Sample piles of

metaltube,approximately760mmlong,reamedandtappedon graded or sorted wool by taking from random locations in the

one end to hold a sharp 10 or 13-mm diameter cutting tip. The pile at lease 50 handfuls of wool, the aggregate mass of which

tube is fitted with a “T” cross bar about 500 mm long. shall be at least 1.5 kg. If the wool is in fleece form and a test

6.5 Core Extruder—A6-mm wood dowel or aluminum rod isneededforonlythemajorsort,takethesampleinaccordance

slightlylongerthanthecoringtubetopushthesamplefromthe with 9.1.2.

tube. 9.1.4 Card Sliver—Sample the wool card sliver by drawing

6.6 Apparatus for Measuring the Water Content of Isopro- ten 600-mm lengths at random from the lot, preferably during

panol. the carding operation.

6.6.1 Hydrometer, for the range density from 0.800 to 0.900 9.1.5 Top—Sample the top by drawing from each 9000 kg

Mg/m and calibrated in accordance with Test Method E 126. or fraction thereof, four sections of sliver, each of which shall

6.6.2 Thermometer, for the range from 0 to 50°C and be at least1min length and taken from different balls of top

calibrated in accordance with Guide E 1750. selected at random. Take only one ball from any one bale or

6.7 Calibration Standards, for instrument calibration. carton. For broken top, take an equivalent aggregate length of

6.7.1 Current Interwoollabs III Standard Tops, for wood. sliver at random.

6.7.2 Current International Mohair Association Standard

10. Test Samples and Test Specimens, Number and

Tops, for mohair.

Preparation

7. Reagents

10.1 Test Samples (one from each laboratory sampling

unit):

7.1 The following reagents are used:

10.1.1 Grease Wool, Pulled Wool, and Scoured Wool:

7.1.1 Water, distilled, or equivalent.

10.1.1.1 Sub-Coring—Randomly pack the core or hand

7.1.2 Alcohol, isopropyl (CH CH CH OH).

3 2 2

sample (see 9.1.1, 9.1.2, and 9.1.3), into a suitable container

7.1.3 Petroleum Spirit, boiling range from 40 to 70°C, for

(see 6.3) and compress to approximately 14 kPa by loading a

cleaning sliver subsamples.

weight of 667 N on the floating top. By means of a pressure

7.1.4 1,1,1 Trichlorethane (CH CCl ), for cleaning sliver

3 3

coring tube (6.4) extract at least five cores to provide a test

subsamples.

specimen of at least 20 g of scoured wool. Scour or otherwise

8. Hazards clean the test specimen in accordance with Test Method D 584

if it is grease wool or pulled wool.

8.1 Refer to the manufacturer’s material safety data sheet

10.1.1.2 Gridding, Core Test Residue—If the sample com-

(MSDS) for information on handling, storage, use, and dis-

prises an adequate amount of scoured wool resulting from core

posal of chemicals used in this test method.

testing a lot for clean wool fiber present (see 9.1.1), divide the

9. Sampling sample into 40 portions of approximately equal size. From

each portion, draw at random at least 0.5 g. Mix or blend these

9.1 Loose Fibers—The test method for obtaining a repre-

40 portions to form the test specimen.

sentative sample of wool differs according to circumstances.

10.1.1.3 Gridding and Machine Blending—For samples

The sampling procedures and major circumstances encoun-

other than those specified in 10.1.1 and 10.1.2, divide the

tered are as follows:

sample into 40 portions of approximately equal size. From

9.1.1 Lots of Packaged, Grease, Pulled, or Scoured Wool—

each portion draw at random a sufficient quantity of fiber to

Take core samples in accordance with Practice D 1060. Clean

provide a clean test specimen of 20 g. Scour or otherwise clean

or scour the raw wool sample in accordance with Test Method

the specimen of grease or pulled wool.

D 584. If a representative portion of the scoured wool core

10.1.2 Card Sliver—Strip off portions of each of the ten

sample resulting from the test for clean wool fiber present is

600-mm lengths of sliver (see 9.1.4). Combine these portions

available, it may be used for fiber diameter determination. If

to form a composite sliver about 600 mm in length. This

core sampling is not feasible, take at random, by hand, at least

constitutes the test specimen.

50 handfuls of wool from not less than 10 % of the packages.

10.1.3 Top—Each of the four sections of sliver comprising

The aggregate mass of the sample shall be at least 1.5 kg.

the sample (see 9.1.5) constitutes a test specimen.

9.1.2 Major Sort—Packaged grease wool in fleece from

10.2 Test Specimens:

which a diameter test is needed, hand sample by drawing one

10.2.1 Testonetestspecimenfromeachbulksubsampleand

ormorehandfulsofwoolfromthemajorsortportionofatleast

two specimens from each sliver and top subsample. Prepare

50 fleeces taken at random from the lot. The aggregate mass of

approximately 0.3 g test specimens by cutting enough fiber

the sample shall be at least 1.5 kg.

snippets to measure the diameters of 2000 fiber segments for

each test specimen measured. Obtain snippets using a minicore

10 (10.2.1.1) or guillotine (10.2.1.2). Where required to achieve

Obtainable from Yocom-McColl Testing Laboratories, Inc., 540 West Elk

the necessary quantity of snippets, combine snippets from one

Place,Denver,CO80216andAcroAssociates,Inc.,163MerrimacSt.,Woburn,MA

01801.

sliver subsample or bulk subsample to form the test specimen.

Available from Interwoollabs Secretariat, Boit 14, Rue du Luxembourg 19/21,

10.2.1.1 Minicore (Applicable to Raw Wool, Card Sliver, or

1040 Brussels, Belgium.

Top)—Minicoreeachsliversubsampleoreachbulksubsample,

Available from International Mohair Association, Mohair House, 68 The

Grove, Ilkley, West Yorkshire, LS29 9PA, England, U.K. as appropriate, using cutting tips between 1.8 and 2.0 mm in

D 6466

diameter. If the whole sliver subsample or bulk subsample 13. Procedure

cannot fit into the minicore, divide the coring sample into

13.1 A single operator is sufficient for Sirolan-Laserscan

approximately equal portions of a size to give at least 2000

testing.

accepted counts. Where appropriate, samples of greasy wool

13.2 Premeasurement Checks—At the start of each mea-

shall be scoured by the procedures outlined in Test Method

surement session, ensure that the instrument is set up in

D 584 before minicoring. (Snippets from tops, aqueous

accordance with the operating conditions at calibration. Mea-

scoured or carbo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.