ASTM A997-98(2003)e1

(Practice)Standard Practice for Investment Castings, Surface Acceptance Standards, Visual Examination

Standard Practice for Investment Castings, Surface Acceptance Standards, Visual Examination

SCOPE

1.1 This practice covers the acceptance criteria for surface inspection of investment castings by visual examination.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

Designation: A 997 – 98 (Reapproved 2003)

Standard Practice for

Investment Castings, Surface Acceptance Standards, Visual

Examination

This standard is issued under the fixed designation A 997; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

ϵ NOTE—Table 1 was editorially corrected in June 2006.

1. Scope 3.1.5 Additional acceptance criteria as applicable to all or

portions of the casting surface.

1.1 This practice covers the acceptance criteria for surface

inspection of investment castings by visual examination.

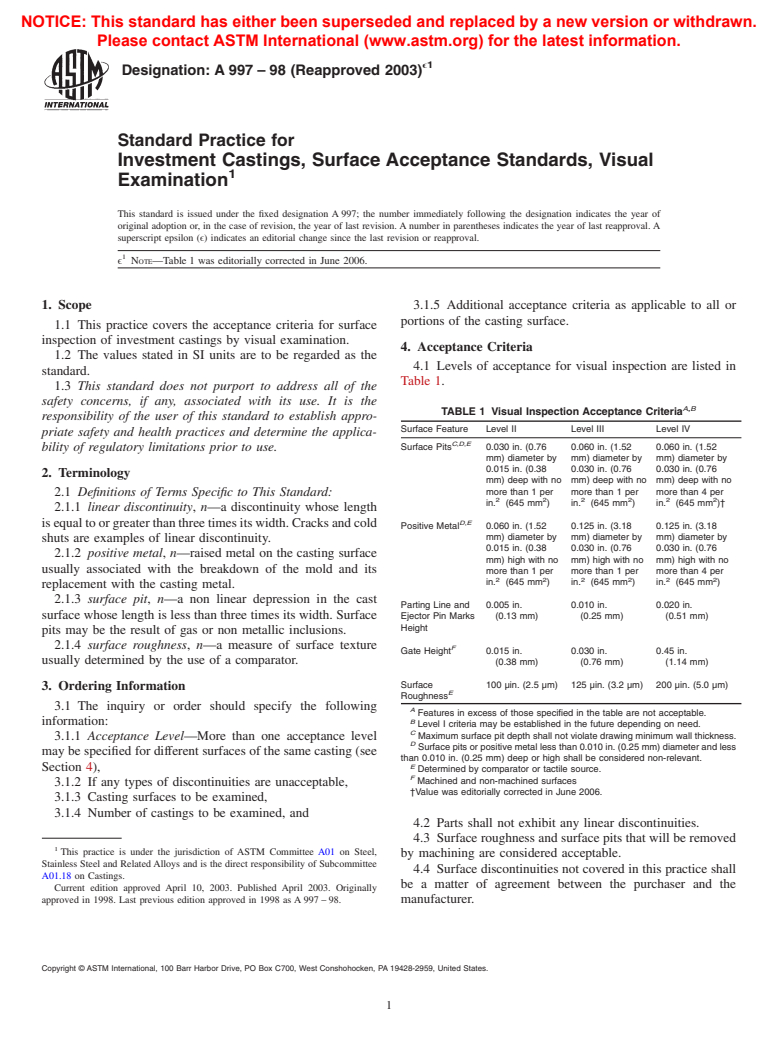

4. Acceptance Criteria

1.2 The values stated in SI units are to be regarded as the

4.1 Levels of acceptance for visual inspection are listed in

standard.

Table 1.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

A,B

TABLE 1 Visual Inspection Acceptance Criteria

responsibility of the user of this standard to establish appro-

Surface Feature Level II Level III Level IV

priate safety and health practices and determine the applica-

C,D,E

Surface Pits 0.030 in. (0.76 0.060 in. (1.52 0.060 in. (1.52

bility of regulatory limitations prior to use.

mm) diameter by mm) diameter by mm) diameter by

0.015 in. (0.38 0.030 in. (0.76 0.030 in. (0.76

2. Terminology

mm) deep with no mm) deep with no mm) deep with no

more than 1 per more than 1 per more than 4 per

2.1 Definitions of Terms Specific to This Standard:

2 2 2 2 2 2

(645 mm ) (645 mm ) (645 mm )†

in. in. in.

2.1.1 linear discontinuity, n—a discontinuity whose length

D,E

is equal to or greater than three times its width. Cracks and cold

Positive Metal 0.060 in. (1.52 0.125 in. (3.18 0.125 in. (3.18

mm) diameter by mm) diameter by mm) diameter by

shuts are examples of linear discontinuity.

0.015 in. (0.38 0.030 in. (0.76 0.030 in. (0.76

2.1.2 positive metal, n—raised metal on the casting surface

mm) high with no mm) high with no mm) high with no

usually associated with the breakdown of the mold and its

more than 1 per more than 1 per more than 4 per

2 2 2 2 2 2

in. (645 mm ) in. (645 mm ) in. (645 mm )

replacement with the casting metal.

2.1.3 surface pit, n—a non linear depression in the cast

Parting Line and 0.005 in. 0.010 in. 0.020 in.

surface whose length is less than three times its width. Surface

Ejector Pin Marks (0.13 mm) (0.25 mm) (0.51 mm)

Height

pits may be the result of gas or non metallic inclusions.

2.1.4 surface roughness, n—a measure of surface texture F

Gate Height 0.015 in. 0.030 in. 0.45 in.

usually determined by the use of a comparator.

(0.38 mm) (0.76 mm) (1.14 mm)

Surface 100 µin. (2.5 µm) 125 µin. (3.2 µm) 200 µin. (5.0 µm)

3. Ordering Information

E

Roughness

3.1 The inquiry or order should specify the following

A

Features in excess of those specified in the table are not

...

This May Also Interest You

SIGNIFICANCE AND USE

4.1 This practice shall be used when ultrasonic inspection is required by the order or specification for inspection purposes where the acceptance of the forging is based on limitations of the number, amplitude, or location of discontinuities, or a combination thereof, which give rise to ultrasonic indications.

4.2 The acceptance criteria shall be clearly stated as order requirements.

SCOPE

1.1 This practice for ultrasonic examination covers turbine and generator steel rotor forgings covered by Specifications A469/A469M, A470/A470M, A768/A768M, and A940/A940M. This practice shall be used for contact testing only.

1.2 This practice describes a basic procedure of ultrasonically inspecting turbine and generator rotor forgings. It does not restrict the use of other ultrasonic methods such as reference block calibrations when required by the applicable procurement documents nor is it intended to restrict the use of new and improved ultrasonic test equipment and methods as they are developed.

1.3 This practice is intended to provide a means of inspecting cylindrical forgings so that the inspection sensitivity at the forging center line or bore surface is constant, independent of the forging or bore diameter. To this end, inspection sensitivity multiplication factors have been computed from theoretical analysis, with experimental verification. These are plotted in Fig. 1 (bored rotors) and Fig. 2 (solid rotors), for a true inspection frequency of 2.25 MHz, and an acoustic velocity of 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s]. Means of converting to other sensitivity levels are provided in Fig. 3. (Sensitivity multiplication factors for other frequencies may be derived in accordance with X1.1 and X1.2 of Appendix X1.)

FIG. 1 Bored Forgings

Note 1: Sensitivity multiplication factor such that a 10 % indication at the forging bore surface will be equivalent to a 1/8 in. [3 mm] diameter flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s].

FIG. 2 Solid Forgings

Note 1: Sensitivity multiplication factor such that a 10 % indication at the forging centerline surface will be equivalent to a 1/8 in. [3 mm] diameter flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s].

FIG. 3 Conversion Factors to Be Used in Conjunction with Fig. 1 and Fig. 2 if a Change in the Reference Reflector Diameter is Required

1.4 Considerable verification data for this method have been generated which indicate that even under controlled conditions very significant uncertainties may exist in estimating natural discontinuities in terms of minimum equivalent size flat-bottom holes. The possibility exists that the estimated minimum areas of natural discontinuities in terms of minimum areas of the comparison flat-bottom holes may differ by 20 dB (factor of 10) in terms of actual areas of natural discontinuities. This magnitude of inaccuracy does not apply to all results but should be recognized as a possibility. Rigid control of the actual frequency used, the coil bandpass width if tuned instruments are used, and so forth, tend to reduce the overall inaccuracy which is apt to develop.

1.5 This practice for inspection applies to solid cylindrical forgings having outer diameters of not less than 2.5 in. [64 mm] nor greater than 100 in. [2540 mm]. It also applies to cylindrical forgings with concentric cylindrical bores having wall thicknesses of 2.5 [64 mm] in. or greater, within the same outer diameter limits as for solid cylinders. For solid sections less than 15 in. [380 mm] in diameter and for bored cylinders of less than 7.5 in. [190 mm] wall thickness the transducer used for the inspection will be different than the transducer used for larger sections.

1.6 Supplementary requirements of an optional nature are provided for use at the option of the...

- Standard8 pagesEnglish languagesale 15% off

- Standard8 pagesEnglish languagesale 15% off

ABSTRACT

This practice covers the examination procedures for the contact, pulse-echo ultrasonic examination of heavy steel forgings by the straight and angle-beam techniques. An ultrasonic, pulsed, reflection type of instrument shall be used and shall provide linear presentation for at least 75% of the screen height. The 5% linearity referred to is descriptive of the screen presentation of amplitude. The electronic apparatus shall contain an attenuator, search units, transducers, couplants, reference blocks, and DGS scales. The forging shall be machined to provide cylindrical surfaces for radial examination in the case of round forgings. The ends of the forgings shall be machined perpendicular to the axis of the forging for the axial examination. Faces of disk and rectangular forgings shall be machined flat and parallel to one another. The procedures to be performed are as follows: ultrasonic examination of the forgings; straight-beam examination with establishment of the instrument sensitivity and calibration either by the reflection, reference-block technique, or DGS method; and angle-beam examination used for rings and hollow forgings.

SIGNIFICANCE AND USE

4.1 This practice shall be used when ultrasonic inspection is required by the order or specification for inspection purposes where the acceptance of the forging is based on limitations of the number, amplitude, or location of discontinuities, or a combination thereof, which give rise to ultrasonic indications.

4.2 The ultrasonic quality level shall be clearly stated as order requirements.

SCOPE

1.1 This practice2 covers the examination procedures for the contact, pulse-echo ultrasonic examination of steel forgings by the straight and angle-beam techniques. The straight beam techniques include utilization of the DGS (Distance Gain-Size) method. See Appendix X3.

1.2 This practice is to be used whenever the inquiry, contract, order, or specification states that forgings are to be subject to ultrasonic examination in accordance with Practice A388/A388M.

1.3 Supplementary requirements of an optional nature are provided for use at the option of the purchaser. The supplementary requirements shall apply only when specified individually by the purchaser in the purchase order or contract.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This practice and the applicable material specifications are expressed in both inch-pound units and SI units. However, unless the order specifies the applicable “M” specification designation [SI units], the material shall be furnished to inch-pound units.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard9 pagesEnglish languagesale 15% off

- Standard9 pagesEnglish languagesale 15% off

ABSTRACT

This test method covers the procedures for the standard practice of performing magnetic particle examination on steel forgings. The inspection medium shall consist of finely divided ferromagnetic particles, whose size, shape and magnetic properties, both individually and collectively, shall be taken into account. Forgings may be magnetized in the longitudinal or circular direction by employing the surge or continuous current flow methods. Magnetization may be applied by passing current through the piece or by inducing a magnetic field by means of a central conductor, such as a prod or yoke, or by coils. While the material is properly magnetized, the magnetic particles may be applied by either the dry method, wet method, or fluorescent method. The parts shall also be sufficiently demagnetized after inspection so that residual or leakage fields will not interfere with future operations to which the steel forgings shall be used for. Indications to be evaluated are grouped into three broad classes, namely: surface defects, which include laminar defects, forging laps and folds, flakes (thermal ruptures caused by entrapped hydrogen), heat-treating cracks, shrinkage cracks, grinding cracks, and etching or plating cracks; subsurface defects, which include stringers of nonmetallic inclusions, large nonmetallics, cracks in underbeads of welds, and forging bursts; and nonrelevant or false indications, which include magnetic writing, changes in section, edge of weld, and flow lines.

SIGNIFICANCE AND USE

4.1 For ferromagnetic materials, magnetic particle examination is widely specified for the detection of surface and near surface discontinuities such as cracks, laps, seams, and linearly oriented nonmetallic inclusions. Such examinations are included as mandatory requirements in some forging standards such as Specification A508/A508M.

4.2 Use of direct current or rectified alternating (full or half wave) current as the power source for magnetic particle examination allows detection of subsurface discontinuities.

SCOPE

1.1 This practice2 covers a procedure for magnetic particle examination of steel forgings. The procedure will produce consistent results upon which acceptance standards can be based. This practice does not contain acceptance standards or recommended quality levels.

1.2 Only direct current or rectified alternating (full or half wave) current shall be used as the electric power source for any of the magnetizing methods. Alternating current is not permitted because its capability to detect subsurface discontinuities is very limited and therefore unsuitable.

1.2.1 Portable battery powered electromagnetic yokes are outside the scope of this practice.

Note 1: Guide E709 may be utilized for magnetic particle examination in the field for machinery components originally manufactured from steel forgings.

1.3 The minimum requirements for magnetic particle examination shall conform to practice standards of Practice E1444/E1444M. If the requirements of this practice are in conflict with the requirements of Practice E1444/E1444M, the requirements of this practice shall prevail.

1.4 This practice and the applicable material specifications are expressed in both inch-pound units and SI units. However, unless the order specifies the applicable “M” specification designation [SI units], the material shall be furnished to inch-pound units.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices ...

- Standard8 pagesEnglish languagesale 15% off

- Standard8 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers ultrasonic angle-beam procedure and acceptance standards for the detection of internal discontinuities not laminar in nature and of surface imperfections in a steel plate. This specification is intended for use only as a supplement to specifications which provide straight-beam ultrasonic examination. The ultrasonic frequency for the examination shall be the highest frequency that permits detection of the required calibration notch.

SCOPE

1.1 This specification2 covers an ultrasonic angle-beam procedure and acceptance standards for the detection of internal discontinuities not laminar in nature and of surface imperfections in a steel plate. This specification is intended for use only as a supplement to specifications which provide straight-beam ultrasonic examination.

Note 1: An internal discontinuity that is laminar in nature is one whose principal plane is parallel to the principal plane of the plate.

1.2 Individuals performing examinations in accordance with this specification shall be qualified and certified in accordance with the requirements of the latest edition of ASNT SNT-TC-1A or an equivalent accepted standard. An equivalent standard is one which covers the qualification and certification of ultrasonic nondestructive examination candidates and which is acceptable to the purchaser.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This procedure covers the standard and acceptance standards for straight-beam, pulse-echo, ultrasonic examination of rolled carbon and alloy steel plates. The amplitude linearity of the apparatus to be used shall be checked by positioning the transducer over the depth resolution notch in the IIW or similar block. The inspection shall be performed in an area free of operations that interfere with proper performance of the test. The test shall be performed either by direct contact, immersion, or liquid column coupling. Grid scanning shall be conducted along a continuous perpendicular line on the center. All discontinuities causing complete loss of reflection shall be recorded.

SCOPE

1.1 This specification2 covers the procedure and acceptance standards for straight-beam, pulse-echo, ultrasonic examination of rolled carbon and alloy steel plates, 3/8 in. [10 mm] in thickness and over, for special applications. The method will detect internal discontinuities parallel to the rolled surfaces. Three levels of acceptance standards are provided. Supplementary requirements are provided for alternative procedures.

1.2 Individuals performing examinations in accordance with this specification shall be qualified and certified in accordance with the requirements of the latest edition of ASNT SNT-TC-1A or an equivalent accepted standard. An equivalent standard is one which covers the qualification and certification of ultrasonic nondestructive examination candidates and which is acceptable to the purchaser.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

ABSTRACT

This test method deals with the procedures for the standard practice of performing pulse-echo ultrasonic examination of heat-treated carbon, low-alloy, and martensitic stainless steel castings by the longitudinal-beam technique. Calibration shall be executed by either flat-bottomed hole or back-wall reflection. The instrument to be used for examination shall be the ultrasonic, pulsed, reflection type. Personnel and equipment qualifications, materials preparation, casting and test conditions, data recording methods, and the acceptance standards for both types of testing procedure are all detailed thoroughly.

SCOPE

1.1 This practice2 covers the standards and procedures for the pulse-echo ultrasonic examination of heat-treated carbon, low-alloy, and martensitic stainless steel castings.

1.2 This practice is to be used whenever the inquiry, contract, order, or specification states that castings are to be subjected to ultrasonic examination in accordance with Practice A609/A609M.

1.3 This practice contains two procedures. Procedure A is the original A609/A609M practice and requires calibration using a series of test blocks containing flat-bottomed holes. It also provides supplementary requirements for angle beam testing. Procedure B requires calibration using a back wall reflection from a series of solid calibration blocks.

Note 1: Ultrasonic examination and radiography are not directly comparable. This examination technique is intended to complement Guide E94/E94M in the detection of discontinuities.

1.4 Supplementary requirements of an optional nature are provided for use at the option of the purchaser. The supplementary requirements shall apply only when specified individually by the purchaser in the purchase order or contract.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5.1 Within the text, the SI units are shown in brackets.

1.5.2 This practice is expressed in both inch-pound units and SI units; however, unless the purchase order or contract specifies the applicable M-specification designation (SI units), the inch-pound units shall apply.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard9 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the standard procedure and acceptance for straight-beam, pulse-echo, ultrasonic examination of rolled fully killed carbon and alloy steel plates. The equipment shall be of the pulse-echo straight beam type. Nondestructive examination of the material shall be conducted in an area free of operations that interfere with proper functioning of the equipment. The test shall be done by one of the following methods: direct contact, immersion, or liquid column coupling. Ultrasonic examination shall be made on either major surface of the plate. Grid scanning shall be continuous along perpendicular grid lines or shall be continuous along parallel paths, transverse to the major plate axis, or shall be continuous along parallel paths, parallel to the major plate axis, or smaller centers. Any discontinuity indication causing a total loss of back reflection which cannot be contained within a circle is unacceptable.

SCOPE

1.1 This specification2 covers the procedure and acceptance standards for straight-beam, pulse-echo, ultrasonic examination of rolled fully killed carbon and alloy steel plates, 1/2 in. [12.5 mm] and over in thickness. It was developed to assure delivery of steel plates free of gross internal discontinuities such as pipe, ruptures, or laminations and is to be used whenever the inquiry, contract, order, or specification states that the plates are to be subjected to ultrasonic examination.

1.2 Individuals performing examinations in accordance with this specification shall be qualified and certified in accordance with the requirements of the latest edition of ASNT SNT-TC-1A or an equivalent accepted standard. An equivalent standard is one which covers the qualification and certification of ultrasonic nondestructive examination candidates and which is acceptable to the purchaser.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents, therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

ABSTRACT

This practice covers the acceptance criteria for surface inspection of investment castings through visual examination. The material shall conform to Levels II, III, and IV acceptance criteria for features of surface pits, positive metal, parting line and ejector pin marks, gate height, and surface roughness. The material shall be free of any linear discontinuity.

SCOPE

1.1 This practice covers the acceptance criteria for surface inspection of investment castings by visual examination.

1.2 This practice is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable M-specification designation (SI units), the inch-pound units shall apply.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

- Standard2 pagesEnglish languagesale 15% off

ABSTRACT

This specification deals with the procedures and acceptance standards for straight beam, pulse echo, ultrasonic examination of rolled structural shapes. The section surfaces shall be sufficiently clean and smooth to maintain a back reflection from the opposite side of the flanges, legs and webs. Ultrasonic testing shall be made on the major surface of each flange and one major web surface. Evaluation of indications may require inspection from an opposite surface. Two levels of acceptance standards are included. Level II is intended for normal applications where freedom from gross internal discontinuities is desired, particularly in connection regions. Level I is intended for critical applications such as welded chord members used in tension loading.

SCOPE

1.1 This specification covers the procedure and acceptance standards for straight beam, pulse echo, ultrasonic examination of rolled structural shapes having a minimum section thickness of 1/2 in. [12.5 mm]. It was developed to ensure delivery of steel structural shapes free of gross internal discontinuities such as pipe, ruptures, or laminations and is to be used whenever the inquiry, contract, order, or specification states that the shapes are to be ultrasonically examined. Two levels of acceptance standards are included. Level II is intended for normal applications where freedom from gross internal discontinuities is desired, particularly in connection regions. Level I is intended for critical applications such as welded chord members used in tension loading, where internal discontinuities could be detrimental. Level II is normally applicable unless otherwise specified in contract documents or the purchase order. Supplementary requirements for alternative scanning coverages are provided.

1.2 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This test method deals with the procedures for the standard practice of performing contact, pulse-echo ultrasonic examination of austenitic steel forgings by the straight and angle beam techniques. This practice does not cover the ultrasonic examination of nonmagnetic retaining ring forgings. The instrument used for this test method shall be the electronic pulsed reflection type. Prior to examination, specimens shall be heat treated and machined to a rectangular, parallel, or concentric surface configuration, and its surface shall be free of extraneous material such as loose scale, paint, and dirt. Calibration of the apparatus shall be done by either the single-block method or distance-amplitude curve method. Choice of method to be employed shall be determined by the test metal distance involved. Quality levels for acceptance, established by the type and amount of indication present, are detailed thoroughly.

SCOPE

1.1 This practice2 covers straight and angle beam contact, pulse-echo ultrasonic examination of austenitic steel forgings produced in accordance with Practice A388/A388M and Specifications A965/A965M and A1049/A1049M.

1.2 Ultrasonic examination of nonmagnetic retaining ring forgings should be made to Practice A531/A531M rather than this practice.

1.3 Supplementary requirements of an optional nature are provided for use at the option of the purchaser. The supplementary requirements shall apply only when specified individually by the purchaser in the purchase order or contract.

1.4 This practice is expressed in inch-pound and SI units; however, unless the purchase order or contract specifies the applicable “M” specification designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the practice, the SI units are shown in brackets. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

- Standard6 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.