ASTM G169-01

(Guide)Standard Guide for Application of Basic Statistical Methods to Weathering Tests

Standard Guide for Application of Basic Statistical Methods to Weathering Tests

SIGNIFICANCE AND USE

The correct use of statistics as part of a weathering program can greatly increase the usefulness of results. A basic understanding of statistics is required for the study of weathering performance data. Proper experimental design and statistical analysis strongly enhances decision-making ability. In weathering, there are many uncertainties brought about by exposure variability, method precision and bias, measurement error, and material variability. Statistical analysis is used to help decide which products are better, which test methods are most appropriate to gauge end use performance, and how reliable the results are.

Results from weathering exposures can show differences between products or between repeated testing. These results may show differences which are not statistically significant. The correct use of statistics on weathering data can increase the probability that valid conclusions are derived.

SCOPE

1.1 This guide covers elementary statistical methods for the analysis of data common to weathering experiments. The methods are for decision making, in which the experiments are designed to test a hypothesis on a single response variable. The methods work for either natural or laboratory weathering.

1.2 Only basic statistical methods are presented. There are many additional methods which may or may not be applicable to weathering tests that are not covered in this guide.

1.3 This guide is not intended to be a manual on statistics, and therefore some general knowledge of basic and intermediate statistics is necessary. The text books referenced at the end of this guide are useful for basic training.

1.4 This guide does not provide a rigorous treatment of the material. It is intended to be a reference tool for the application of practical statistical methods to real-world problems that arise in the field of durability and weathering. The focus is on the interpretation of results. Many books have been written on introductory statistical concepts and statistical formulas and tables. The reader is referred to these for more detailed information. Examples of the various methods are included. The examples show typical weathering data for illustrative purposes, and are not intended to be representative of specific materials or exposures.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G169–01

Standard Guide for

Application of Basic Statistical Methods to Weathering

Tests

This standard is issued under the fixed designation G 169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and General Statistical Terms

ISO 3534/3 Vocabulary and Symbols – Part 3: Design of

1.1 This guide covers elementary statistical methods for the

Experiments

analysis of data common to weathering experiments. The

methods are for decision making, in which the experiments are

3. Terminology

designedtotestahypothesisonasingleresponsevariable.The

3.1 Definitions—See Terminology G 113 for terms relating

methods work for either natural or laboratory weathering.

to weathering, Terminology E 41 for terms relating to condi-

1.2 Only basic statistical methods are presented. There are

tioning and handling, ISO 3534/1 for terminology relating to

many additional methods which may or may not be applicable

statistics, and ISO 3534/3 for terms relating to design of

to weathering tests that are not covered in this guide.

experiments.

1.3 This guide is not intended to be a manual on statistics,

3.2 Definitions of Terms Specific to This Standard:

and therefore some general knowledge of basic and interme-

3.2.1 arithmetic mean; average—the sum of values divided

diate statistics is necessary. The text books referenced at the

by the number of values. ISO 3534/1

end of this guide are useful for basic training.

3.2.2 blocking variable—a variable that is not under the

1.4 This guide does not provide a rigorous treatment of the

control of the experimenter, (for example, temperature and

material. It is intended to be a reference tool for the application

precipitation in exterior exposure), and is dealt with by

of practical statistical methods to real-world problems that

exposing all samples to the same effects

arise in the field of durability and weathering. The focus is on

3.2.2.1 Discussion—Theterm“block”originatedinagricul-

the interpretation of results. Many books have been written on

tural experiments in which a field was divided into sections or

introductory statistical concepts and statistical formulas and

blocks having common conditions such as wind, proximity to

tables. The reader is referred to these for more detailed

underground water, or thickness of the cultivatable layer.

information. Examples of the various methods are included.

ISO 3534/3

The examples show typical weathering data for illustrative

3.2.3 correlation—in weathering, the relative agreement of

purposes, and are not intended to be representative of specific

resultsfromonetestmethodtoanother,orofonetestspecimen

materials or exposures.

to another.

2. Referenced Documents 3.2.4 median—the midpoint of ranked sample values. In

samples with an odd number of data, this is simply the middle

2.1 ASTM Standards:

2 value, otherwise it is the arithmetic average of the two middle

D 1898 Practice for Sampling of Plastics

values.

E 41 Terminology Relating to Conditioning

3.2.5 nonparametric method—a statistical method that does

G 113 Terminology Relating to Natural and Artificial

not require a known or assumed sample distribution in order to

Weathering Tests of Nonmetallic Materials

support or reject a hypothesis.

G 141 GuideforAddressingVariabilityinExposureTesting

3.2.6 normalization—a mathematical transformation made

on Nonmetallic Materials

to data to create a common baseline.

2.2 ISO Documents:

3.2.7 predictor variable (independent variable)—avariable

ISO 3534/1 Vocabulary and Symbols – Part 1: Probability

contributing to change in a response variable, and essentially

under the control of the experimenter. ISO 3534/3

This guide is under the jurisdiction of ASTM Committee G03 on Weathering

3.2.8 probability distribution (of a random variable)—a

and Durability and is the direct responsibility of Subcommittee G03.93 on Relating

functiongivingtheprobabilitythatarandomvariabletakesany

to Statistics.

Current edition approved Jan. 10, 2001. Published May 2001.

Discontinued 1998; see 1997 Annual Book of ASTM Standards, Vol 08.01. 4

Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 14.04.

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G169–01

given value or belongs to a given set of values. ISO 3534/1 5.1.3 The probability that a random variable X is greater

3.2.9 random variable—a variable that may take any of the than the critical value for a given distribution is written P

values of a specified set of values and with which is associated (X>cv). This probability is often called the “p-value.” In this

a probability distribution. notation, the null hypothesis can be rejected if

3.2.9.1 Discussion—A random variable that may take only P(X>cv) < a

isolated values is said to be “discrete.” A random variable

5.2 Experimental Design—The next step in setting up a

which may take any value within a finite or infinite interval is

weathering test is to design the weathering experiment. The

said to be “continuous.” ISO 3534/1

experimental design will depend on the type and number of

3.2.10 replicates—test specimens with nominally identical

predictor variables, and the expected variability in the sample

composition, form, and structure.

population, exposure conditions, and measurements. The ex-

3.2.11 response variable (dependent variable)— a random

perimental design will determine the amount of replication,

variable whose value depends on other variables (factors).

specimen positioning, and appropriate statistical methods for

Response variables within the context of this guide are usually

analyzing the data.

property measurements (for example, tensile strength, gloss,

5.2.1 Response Variable—The methods covered in this

color, and so forth). ISO 3534/3

guide work for a single response variable. In weathering and

durability testing, the response variable will usually be a

4. Significance and Use

quantitative property measurement such as gloss, color, tensile

4.1 The correct use of statistics as part of a weathering

strength, modulus, and others. Sometimes, qualitative data

program can greatly increase the usefulness of results.Abasic

such as a visual rating make up the response variable, in which

understanding of statistics is required for the study of weath-

case nonparametric statistical methods may be more appropri-

ering performance data. Proper experimental design and sta-

ate.

tistical analysis strongly enhances decision-making ability. In

5.2.1.1 If the response variable is “time to failure,” or a

weathering, there are many uncertainties brought about by

counting process such as “the number of failures over a time

exposure variability, method precision and bias, measurement

interval,” then reliability-based methods should be used.

error, and material variability. Statistical analysis is used to

5.2.1.2 Here are the key considerations regarding the re-

help decide which products are better, which test methods are

sponse variable:

most appropriate to gauge end use performance, and how

((1) What is the response variable?

reliable the results are.

4.2 Results from weathering exposures can show differ- ((2) Will the data represent quantitative or qualitative

measurements?

ences between products or between repeated testing. These

results may show differences which are not statistically signifi- Qualitative data may be best analyzed with a nonparamet-

ric method.

cant. The correct use of statistics on weathering data can

increase the probability that valid conclusions are derived.

((3) What is the expected variability in the measure-

ment?

5. Test Program Development

When there is a high amount of measurement variability,

5.1 Hypothesis Formulation:

then more replication of test specimens is needed.

5.1.1 Allofthestatisticalmethodsinthisguidearedesigned

((4) What is the expected variability in the sample

to test hypotheses. In order to apply the statistics, it is

population?

necessary to formulate a hypothesis. Generally, the testing is

More variability means more replication.

designed to compare things, with the customary comparison

((5) Is the comparison relative (ranked) or a direct

being:

comparison of sample statistics (for example, means)?

Ranked data is best handled with nonparametric methods.

Do the predictor variables significantly affect the

5.2.1.3 It is important to recognize that variability in expo-

response variable?

sure conditions will induce variability in the response variable.

Taking this comparison into consideration, it is possible to

Variability in both outdoor and laboratory exposures has been

formulate a default hypothesis that the predictor variables do

well-documented (for example, see Guide G 141). Excessive

not have a significant effect on the response variable. This

variability in exposure conditions will necessitate more repli-

default hypothesis is usually called H , or the Null Hypothesis.

o

cation. See 5.2.2 for additional information.

5.1.2 The objective of the experimental design and statisti-

5.2.2 Predictor Variables—The objective of most of the

cal analysis is to test this hypothesis within a desired level of

methods in this guide is to determine whether or not the

significance, usually an alpha level (a). The alpha level is the

predictor variables had a significant effect on the response

probabilitybelowwhichwerejectthenullhypothesis.Itcanbe

variable. The variables will be a mixture of the things that are

thought of as the probability of rejecting the null hypothesis

controllable (predictor variables – the items of interest), things

when it is really true (that is, the chance of making such an

that are uncontrolled (blocking variables), or even worse,

error). Thus, a very small alpha level reduces the chance in

things that are not anticipated.

making this kind of an error in judgment. Typical alpha levels

are5 %(0.05)and1 %(0.01).The x-axisvalueonaplotofthe 5.2.2.1 The most common variables in weather and durabil-

distribution corresponding to the chosen alpha level is gener- ity testing are the applied environmental stresses.These can be

ally called the critical value (cv). controlled, for example, temperature, irradiance, humidity

G169–01

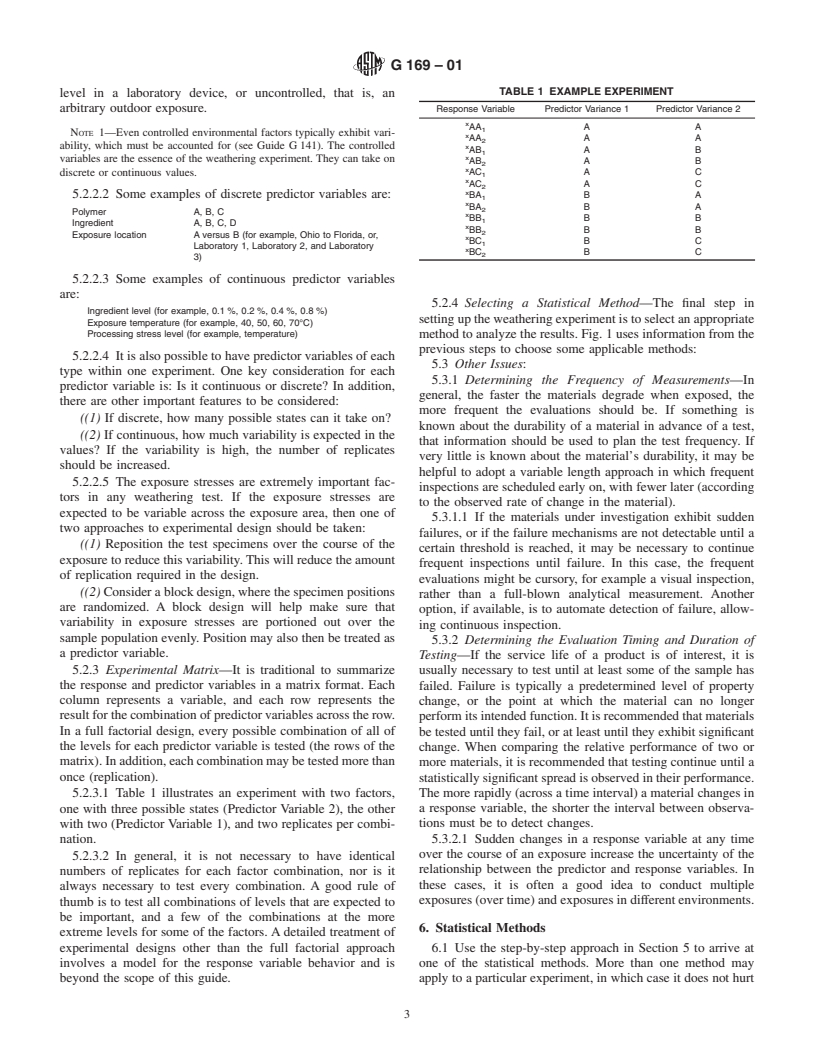

TABLE 1 EXAMPLE EXPERIMENT

level in a laboratory device, or uncontrolled, that is, an

arbitrary outdoor exposure. Response Variable Predictor Variance 1 Predictor Variance 2

x

AA AA

NOTE 1—Even controlled environmental factors typically exhibit vari-

x

AA AA

ability, which must be accounted for (see Guide G 141). The controlled x

AB AB

x

variables are the essence of the weathering experiment. They can take on

AB AB

x

discrete or continuous values. AC AC

x

AC AC

x

5.2.2.2 Some examples of discrete predictor variables are: BA BA

x

BA BA

Polymer A, B, C

x

BB BB

Ingredient A, B, C, D

x

BB BB

Exposure location A versus B (for example, Ohio to Florida, or,

x

BC BC

Laboratory 1, Laboratory 2, and Laboratory

x

BC BC

3)

5.2.2.3 Some examples of continuous predictor variables

are:

5.2.4 Selecting a Statistical Method—The final step in

Ingredient level (for example, 0.1 %, 0.2 %, 0.4 %, 0.8 %)

settinguptheweatheringexperimentistoselectanappropriate

Exposure temperature (for example, 40, 50, 60, 70°C)

Processing stress level (for example, temperature)

method to analyze the results. Fig. 1 uses information from the

previous steps to choose some applicable methods:

5.2.2.4 It is also possible to have predictor variables of each

5.3 Other Issues:

type within one experiment. One key consideration for each

5.3.1 Determining the Frequency of Measurements—In

predictor variable is: Is it continuous or discrete? In addition,

general, the faster the materials degrade when exposed, the

there are other important features to be considered:

more frequent the evaluations should be. If something is

((1) If discrete, how many possible states can it take on?

known about the durability of a material in advance of a test,

((2) If continuous, how much variability is expected in the

that information should be used to plan the test frequency. If

values? If the variability is high, the number of replicates

very little is known about the material’s durability, it may be

should be increased.

helpful to adopt a variable length approach in which frequent

5.2.2.5 The exposure stresses are extremely important fac-

inspections are scheduled early on, with fewer later (according

tors in any weathering test. If the exposure stresses are

to the observed rate of change in the material).

expected to be variable across the exposure area, then one of

5.3.1.1 If the materials under investigation exhibit sudden

two approaches to experimental design should be taken:

failures, or if the failure mechanisms are not detectable until a

((1) Reposition the test specimens over the course of the

certain threshold is reached, it may be necessary to continue

exposure to reduce this variability.This will reduce the amount

frequent inspections until failure. In this case, the frequent

of replication required in the design.

evaluations might be cursory, for example a visual inspection,

((2) Consider a block design, where the specimen positions

rather than a full-blown analytical measurement. Another

are randomized. A block design will help make sure that

option, if available, is to automate detection of failure, allow-

variability in exposure stresses are portioned out over the

ing continuous inspection.

sample population evenly. Position may also then be treated as

5.3.2 Determining the Evaluation Timing and Duration of

a predictor variable.

Testing—If the service life of a product is of interest, it is

5.2.3 Experimental Matrix—It is traditional to summarize usually necessary to test until at least some of the sample has

the response and predictor variables in a matrix format. Each

failed. Failure is typically a predetermined level of property

column represents a variable, and each row represents the change, or the point at which the material can no longer

resultforthecombinationofpredictorvariablesacrosstherow.

performitsintendedfunction.Itisrecommendedthatmaterials

In a full factorial design, every possible combination of all of be tested until they fail, or at least until they exhibit significant

the levels for each predictor variable is tested (the rows of the

change. When comparing the relative performance of two or

matrix).Inaddition,eachcombinationmaybetestedm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.