ASTM D4329-21

(Practice)Standard Practice for Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of Plastics

Standard Practice for Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of Plastics

SIGNIFICANCE AND USE

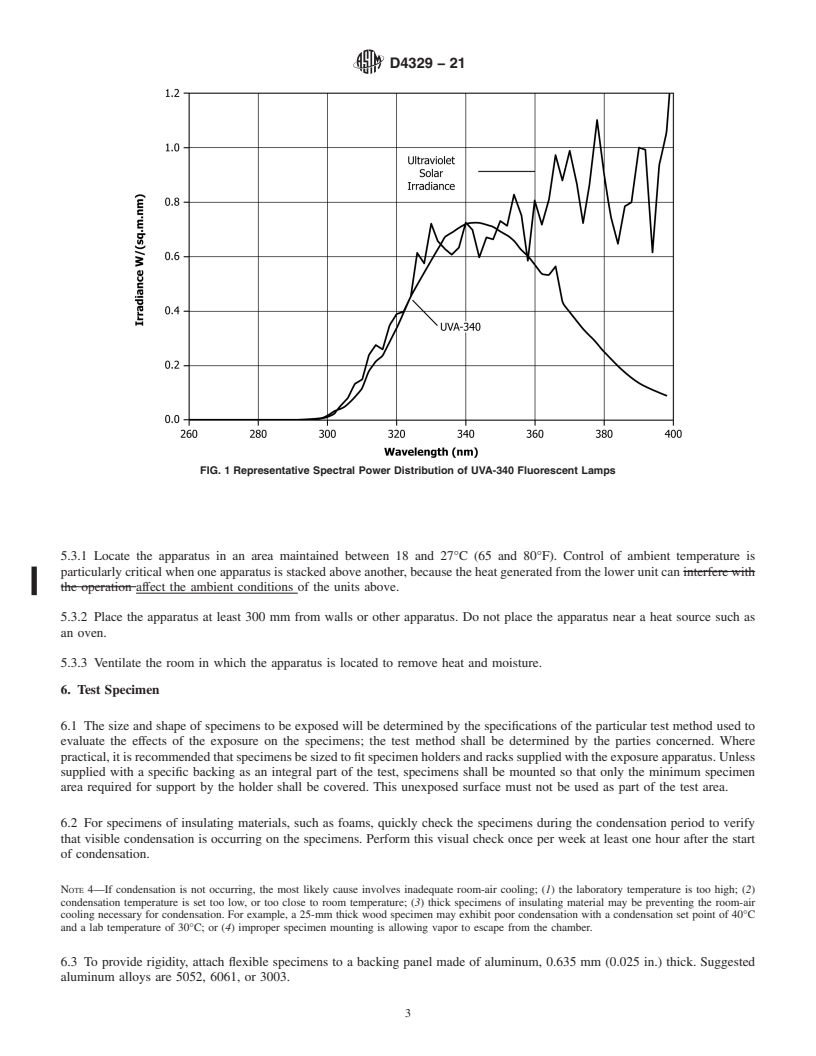

4.1 The ability of a plastic material to resist deterioration caused by exposure to light, heat, and water is a property of significance in many applications. This practice is intended to induce property changes associated with end-use conditions, including the effects of ultraviolet solar irradiance, moisture, and heat. The exposure used in this practice is not intended to simulate the deterioration caused by localized weather phenomena, such as, atmospheric pollution, biological attack, and saltwater exposure. (Warning—Variation in operating conditions within the accepted limits of this practice will not necessarily provide the same results. Therefore, no reference to the use of this practice shall be made unless accompanied by a report prepared in accordance with Section 8 that describes the specific operating conditions used. Refer to Practice G151 for detailed information on the caveats applicable to use of results obtained in accordance with this practice.)

Note 2: Additional information on sources of variability and on strategies for addressing variability in the design, execution, and data analysis of laboratory-accelerated exposure tests is found in Guide G141.

4.2 Reproducibility of test results between laboratories has been shown to be good when the stability of materials is evaluated in terms of performance ranking compared to other materials or to a control.5,6 Therefore, exposure of a similar material of known performance (a control) at the same time as the test materials is strongly recommended. It is recommended that at least three replicates of each material be exposed to allow for statistical evaluation of results.

4.3 Test results will depend upon the care that is taken to operate the equipment in accordance with Practice G154. Significant factors include regulation of line voltage, temperature of the room in which the device operates, temperature control, and condition and age of the lamp.

SCOPE

1.1 This practice covers specific procedures and test conditions that are applicable for using a fluorescent UV lamp and water apparatus exposure of plastics conducted in accordance with Practices G151 and G154. This practice also covers the preparation of test specimens, the test conditions best suited for plastics, and the evaluation of test results.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: This standard and ISO 4892-3 address the same subject matter, but differ in technical contact.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4329 − 21

Standard Practice for

Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of

1

Plastics

This standard is issued under the fixed designation D4329; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* G113 Terminology Relating to Natural andArtificial Weath-

ering Tests of Nonmetallic Materials

1.1 This practice covers specific procedures and test condi-

G141 Guide for Addressing Variability in Exposure Testing

tions that are applicable for using a fluorescent UV lamp and

of Nonmetallic Materials

water apparatus exposure of plastics conducted in accordance

G147 Practice for Conditioning and Handling of Nonmetal-

with Practices G151 and G154. This practice also covers the

lic Materials for Natural and Artificial Weathering Tests

preparationoftestspecimens,thetestconditionsbestsuitedfor

G151 Practice for Exposing Nonmetallic Materials inAccel-

plastics, and the evaluation of test results.

erated Test Devices that Use Laboratory Light Sources

1.2 The values stated in SI units are to be regarded as

G154 Practice for Operating Fluorescent Ultraviolet (UV)

standard. The values given in parentheses are for information

Lamp Apparatus for Exposure of Nonmetallic Materials

only.

G169 Guide for Application of Basic Statistical Methods to

1.3 This standard does not purport to address all of the Weathering Tests

safety concerns, if any, associated with its use. It is the

G177 Tables for Reference Solar Ultraviolet Spectral Distri-

responsibility of the user of this standard to establish appro- butions: Hemispherical on 37° Tilted Surface

3

priate safety, health, and environmental practices and deter-

2.2 ISO Standard:

mine the applicability of regulatory limitations prior to use.

ISO 4892-3 Plastics—Methods of Exposure to Laboratory

Light Sources—Part 3, Fluorescent UV Lamps

NOTE 1—This standard and ISO 4892-3 address the same subject

4

2.3 SAE Standard:

matter, but differ in technical contact.

SAE J2020 Accelerated Exposure of Automotive Exterior

1.4 This international standard was developed in accor-

Materials Using a Fluorescent UV and Condensation

dance with internationally recognized principles on standard-

Apparatus

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3. Terminology

mendations issued by the World Trade Organization Technical

3.1 For definitions of terms relating to plastics used in this

Barriers to Trade (TBT) Committee.

practice, refer to Terminology D883.

2. Referenced Documents

3.2 For definitions of terms relating to precision and bias

2

andassociatedusedinthispractice,refertoTerminologyE456.

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

3.3 For definitions of terms relating to weathering used in

D5870 Practice for Calculating Property Retention Index of

this practice, refer to Terminology G113.

Plastics

E456 Terminology Relating to Quality and Statistics 4. Significance and Use

E691 Practice for Conducting an Interlaboratory Study to

4.1 The ability of a plastic material to resist deterioration

Determine the Precision of a Test Method

caused by exposure to light, heat, and water is a property of

significance in many applications. This practice is intended to

induce property changes associated with end-use conditions,

1

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsand

including the effects of ultraviolet solar irradiance, moisture,

is the direct responsibility of Subcommittee D20.50 on Durability of Plastics.

and heat. The exposure used in this practice is not intended to

Current edition approved July 1, 2021. Published July 2021. Originally approved

in 1984. Last previous edition approved in 2013 as D4329 - 13. DOI: 10.1520/

D4329-21.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

the ASTM website. PA 15096, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4329 − 13 D4329 − 21

Standard Practice for

Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of

1

Plastics

This standard is issued under the fixed designation D4329; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers specific procedures and test conditions that are applicable for using a fluorescent UV lamp and water

apparatus exposure of plastics conducted in accordance with Practices G151 and G154. This practice also covers the preparation

of test specimens, the test conditions best suited for plastics, and the evaluation of test results.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—This practice is technically similar to ISO 4892-3.

NOTE 1—This standard and ISO 4892-3 address the same subject matter, but differ in technical contact.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D5870 Practice for Calculating Property Retention Index of Plastics

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G113 Terminology Relating to Natural and Artificial Weathering Tests of Nonmetallic Materials

G141 Guide for Addressing Variability in Exposure Testing of Nonmetallic Materials

G147 Practice for Conditioning and Handling of Nonmetallic Materials for Natural and Artificial Weathering Tests

G151 Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources

G154 Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials

G169 Guide for Application of Basic Statistical Methods to Weathering Tests

G177 Tables for Reference Solar Ultraviolet Spectral Distributions: Hemispherical on 37° Tilted Surface

1

This practice is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.50 on Durability of Plastics.

Current edition approved July 15, 2013July 1, 2021. Published August 2013July 2021. Originally approved in 1984. Last previous edition approved in 20052013 as

D4329 - 05.D4329 - 13. DOI: 10.1520/D4329-13.10.1520/D4329-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4329 − 21

3

2.2 ISO Standard:

ISO 4892-3 Plastics—Methods of Exposure to Laboratory Light Sources—Part 3, Fluorescent UV Lamps

4

2.3 SAE Standard:

SAE J2020 Accelerated Exposure of Automotive Exterior Materials Using a Fluorescent UV and Condensation Apparatus

3. Terminology

3.1 The definitions in TerminologyFor definitions of terms relating to plastics used in this G113 are applicable topractice, refer

to Terminology D883this practice.

3.2 For definitions of terms relating to precision and bias and associated used in this practice, refer to Terminology E456.

3.3 For definitions of terms relating to weathering used in this practice, refer to Terminology G113.

4. Significance and Use

4.1 The ability of a plastic material to resist deterioration of its electrical, mechanical, and optical properties caused by exposure

to light, heat, and water can be very significant for is a property of significance in many applications.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.